Antislip impact-resistant prefabricated surface material for PVC (polyvinyl chloride) plastic tracks and preparation method thereof

A technology for plastic track and surface layer materials, applied in the field of prefabricated surface layer materials, can solve the problems of poor resilience, poor anti-skid performance, low anti-skid and wear resistance, and achieve excellent overall comprehensive performance and improved interface. Adhesive strength, the effect of increasing the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

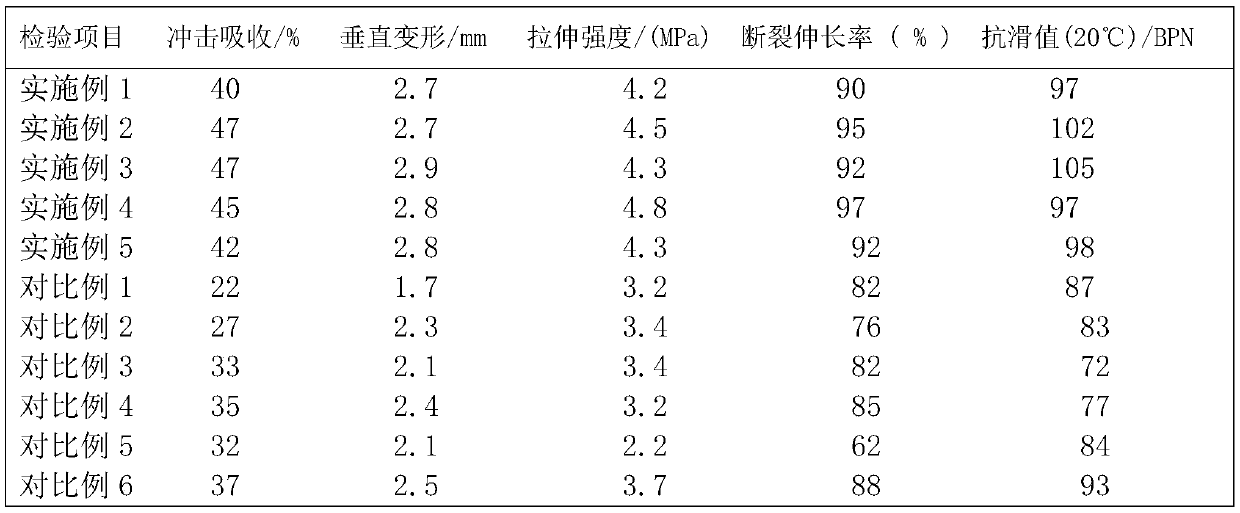

Examples

Embodiment 1

[0032] According to parts by weight, the raw materials of the modified paper-plastic compounding ingredients include the following components: 10 parts of fly ash, 50 parts of light nano-calcium carbonate, 25 parts of paper-plastic composite grinding powder, silane coupling agent (KH-570 ) 2.5 parts. Add fly ash and calcium carbonate into the high-speed mixer and stir evenly, raise the stirring temperature to 75°C to form a uniform mixture, then add paper-plastic composite grinding powder and silane coupling agent, and continue stirring when the temperature rises to 110°C, control the stirring time to 10 minutes, discharge the material, transfer to cold mixing, and discharge the material when the cold mixing temperature is controlled at 45°C, to obtain the modified paper-plastic compound compound.

[0033] A prefabricated surface layer material for a PVC plastic runway, comprising the following components in parts by weight: 100 parts of PVC resin (SJ-5), 2.7 parts of calcium-...

Embodiment 2

[0037] According to parts by weight, the raw materials of modified paper-plastic compounding ingredients include the following components: 15 parts of fly ash, 60 parts of light nano-calcium carbonate, 20 parts of paper-plastic composite grinding powder, aluminate coupling agent (NXH -821) 3 copies. During preparation, fly ash and light nano-calcium carbonate are added into the high-speed mixer for uniform stirring, and the stirring temperature is raised to 80°C to form a uniform mixture, and then the paper-plastic composite grinding powder and silane coupling agent are added to continue Stir when the temperature rises to 115°C, the time is 12 minutes, and the material is transferred to cold mixing. When the temperature of the cold mixing is controlled at 45°C, the material is discharged, and the modified paper-plastic compound compound is obtained.

[0038] A prefabricated surface material for a skid-resistant and impact-resistant PVC plastic runway, comprising the following ...

Embodiment 3

[0041] Raw material components of the modified paper-plastic composite compound: 20 parts of fly ash, 70 parts of ultra-fine ground calcium carbonate; 15 parts of paper-plastic composite grinding powder, and 3.5 parts of silane coupling agent (KH-570). During preparation, fly ash and light nano-calcium carbonate are added into the high-speed mixer for uniform stirring, and the stirring temperature is raised to 85°C to form a uniform mixture, then add paper-plastic composite grinding powder and silane coupling agent, and continue Stir when the temperature rises to 125°C, the time is 12 minutes, and the material is transferred to cold mixing. When the temperature of the cold mixing is controlled at 45°C, the material is discharged, and the modified paper-plastic compound compound is obtained.

[0042] A prefabricated surface material for a skid-resistant and impact-resistant PVC plastic runway, comprising the following components in parts by weight: 100 parts of PVC resin (SJ-5),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com