Healthy and environment-friendly dual-component wear-resisting floor paint and preparation method thereof

A wear-resistant floor and two-component technology, which is applied in the field of architectural decorative coatings, can solve problems such as excessive heavy metal content, damage to human immunity, and scratches on the floor paint surface, and achieve excellent health performance, superior environmental performance, and improved attachment. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A healthy and environmentally friendly two-component wear-resistant floor paint, which is prepared by the main paint and isocyanate curing agent in a weight ratio of 1:1; wherein,

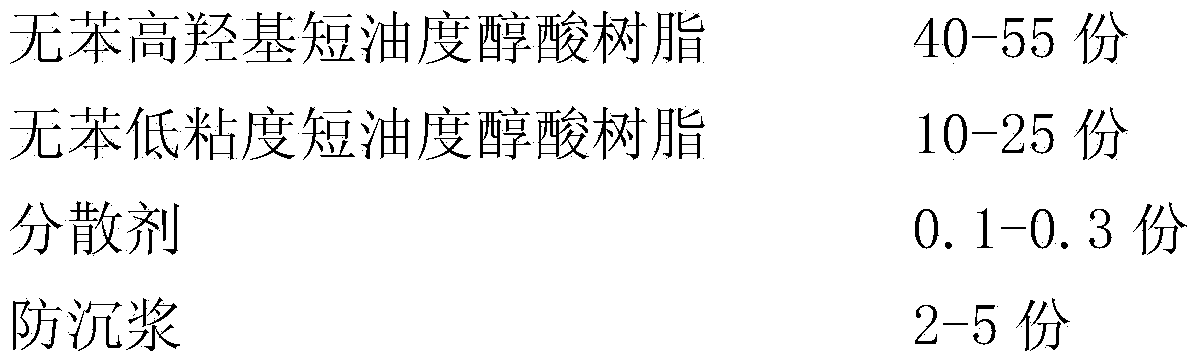

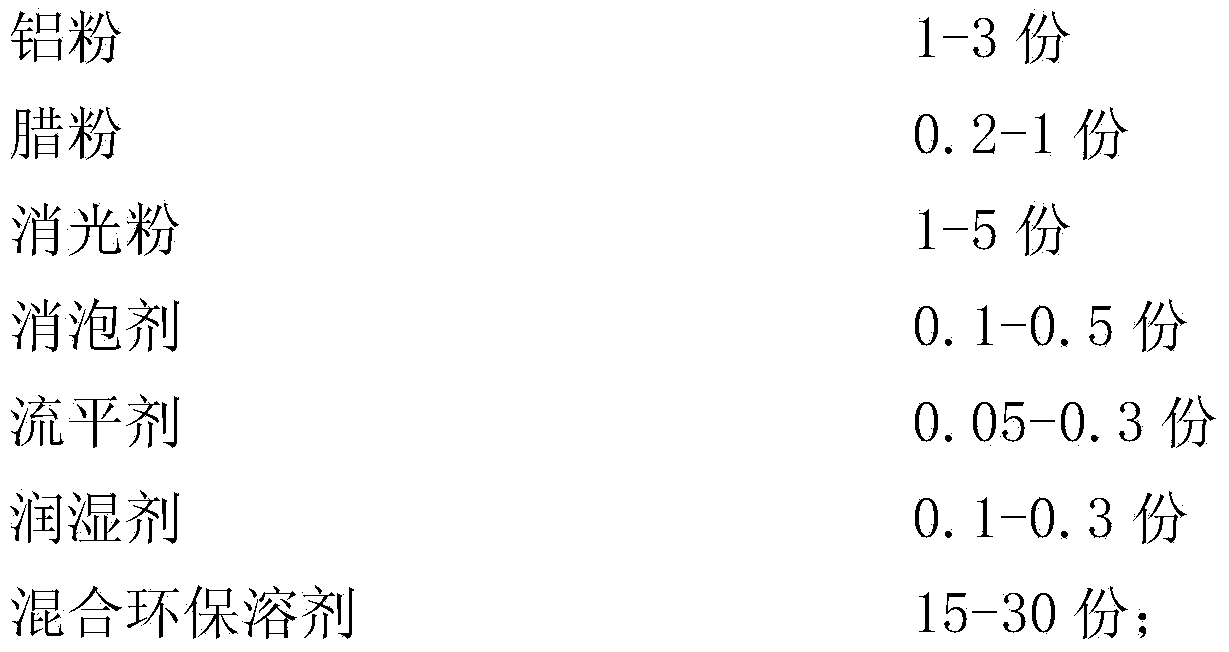

[0040] The main paint is prepared from the following raw materials according to the following weight ratio:

[0041]

[0042] The method for preparing the healthy and environment-friendly two-component wear-resistant floor paint comprises the following steps in sequence:

[0043] Described main paint is prepared according to the following steps carried out in order:

[0044] The preparation method of the main paint of this two-component floor paint comprises the following steps carried out in sequence:

[0045] 1) Pre-prepared mixed environmental solvents:

[0046] 15 parts of dimethyl carbonate, 60 parts of basic aluminum chloride, 10 parts of propylene glycol methyl ether acetate and 15 parts of high boiling point solvent mixed dibasic acid ester are mixed to make a mixed environment-...

Embodiment 2

[0053] A healthy and environmentally friendly two-component wear-resistant floor paint, which is prepared by the main paint and isocyanate curing agent in a weight ratio of 1:0.9; wherein,

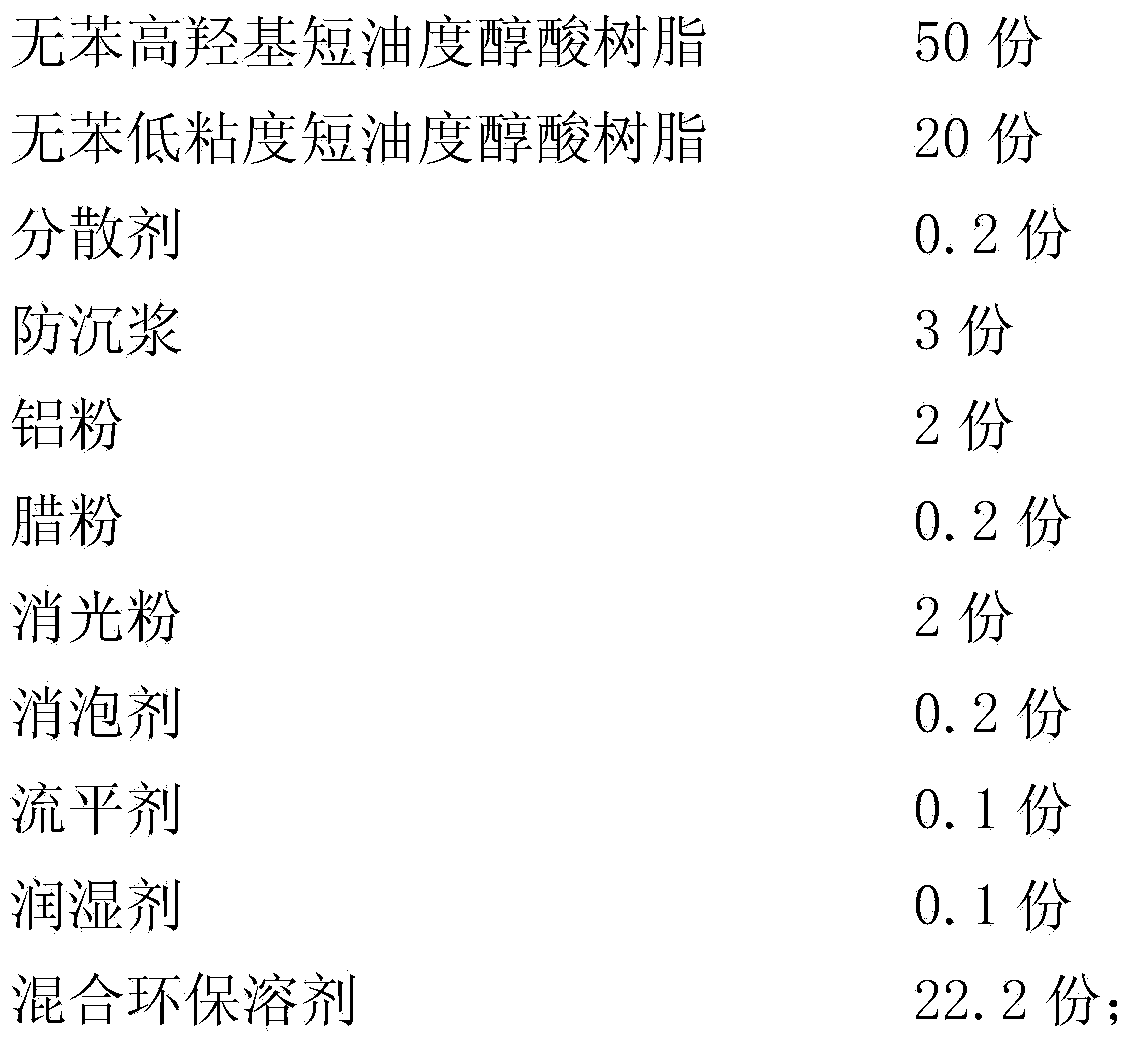

[0054] The main paint is prepared from the following raw materials according to the following weight ratio:

[0055]

[0056] The method for preparing the healthy and environment-friendly two-component wear-resistant floor paint comprises the following steps in sequence:

[0057] Described main paint is prepared according to the following steps carried out in order:

[0058] 1) Pre-prepared mixed environmental solvents:

[0059] 10 parts of dimethyl carbonate, 65 parts of basic aluminum chloride, 15 parts of propylene glycol methyl ether acetate and 10 parts of high boiling point solvent mixed dibasic acid ester are mixed to make a mixed environment-friendly solvent, and then set aside;

[0060] 2) Pre-preparation of anti-settling slurry:

[0061] Mix 28 parts of alkyd resin, 4 parts o...

Embodiment 3

[0066] A healthy and environmentally friendly two-component wear-resistant floor paint, which is prepared by the main paint and isocyanate curing agent in a weight ratio of 1:0.8; wherein,

[0067] The main paint is prepared from the following raw materials according to the following weight ratio:

[0068]

[0069] The method for preparing the healthy and environment-friendly two-component wear-resistant floor paint comprises the following steps in sequence:

[0070] Described main paint is prepared according to the following steps carried out in order:

[0071] 1) Pre-prepared mixed environmental solvents:

[0072] 20 parts of dimethyl carbonate, 55 parts of basic aluminum chloride, 15 parts of propylene glycol methyl ether acetate and 10 parts of high boiling point solvent mixed dibasic acid ester are mixed to make a mixed environment-friendly solvent, and then set aside;

[0073] 2) Pre-preparation of anti-settling slurry:

[0074] Mix 32 parts of alkyd resin, 5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com