Epoxy-acrylate composite emulsion and preparation method therefor

A technology of acrylate and composite emulsion, applied in coating and other directions, can solve the problems of waterborne epoxy resin stability and corrosion resistance being difficult to take into account at the same time, short storage period, low epoxy resin content, etc. Chemical application, easy operation, solving the effect of stability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

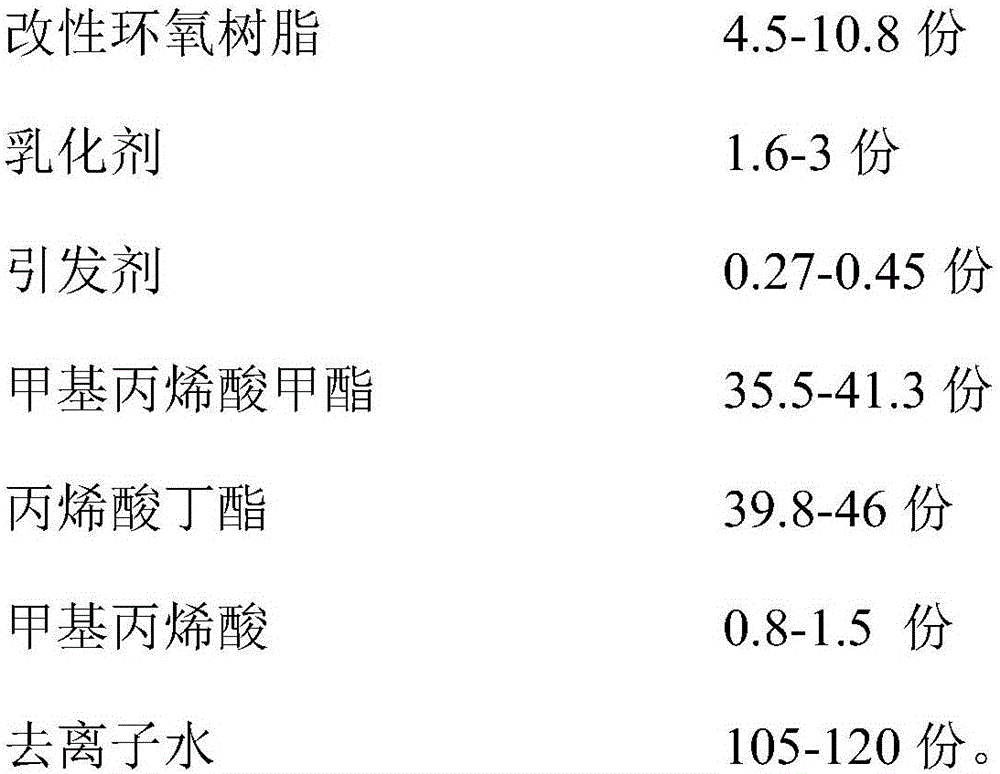

Method used

Image

Examples

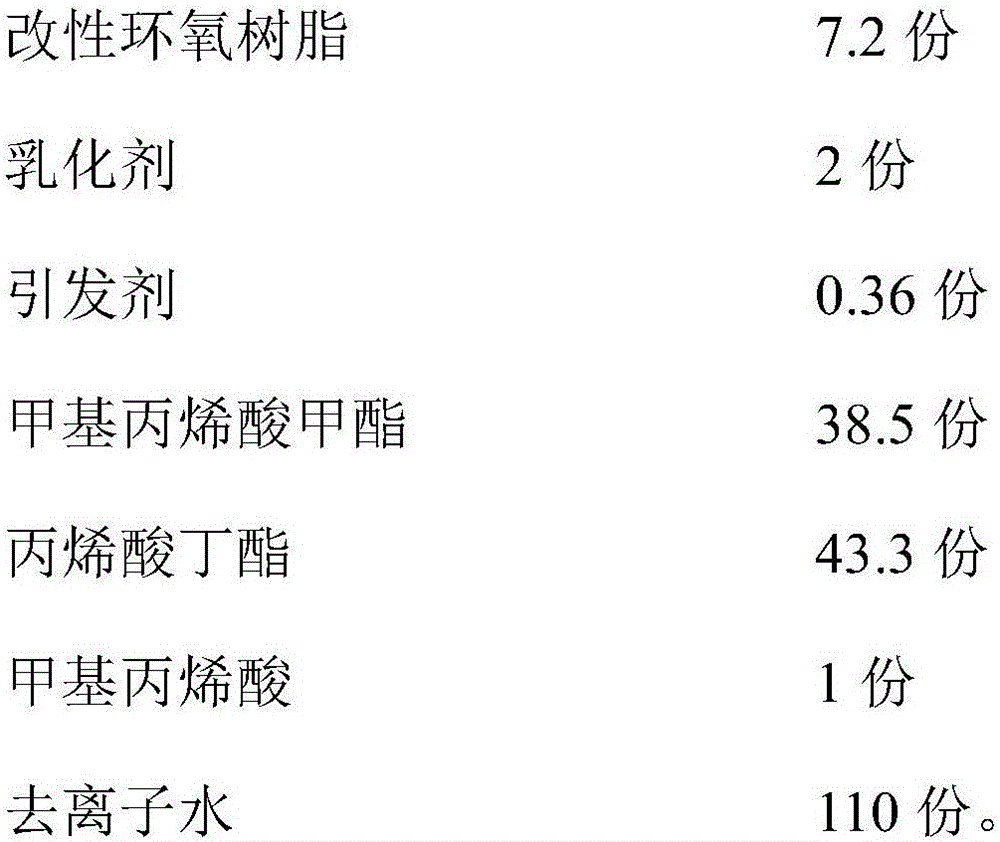

Embodiment 1

[0064] A kind of preparation method of epoxy-acrylate composite emulsion is characterized in that, the steps that comprise are as follows:

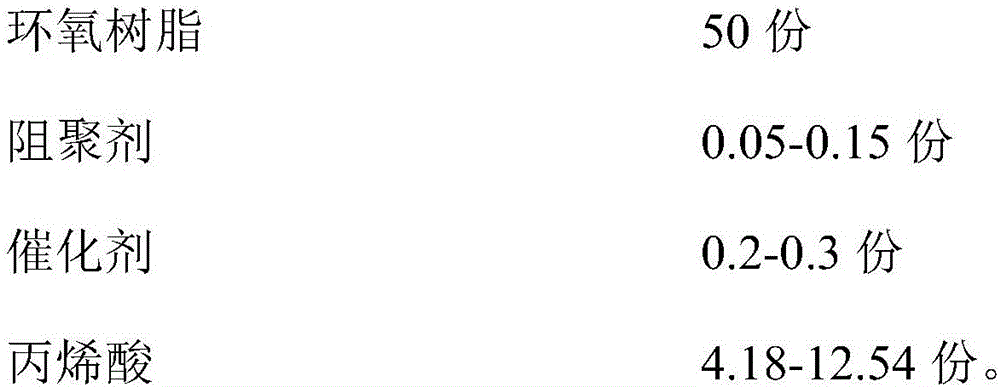

[0065] A. Preparation of modified epoxy resin:

[0066] A1. In a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, add 50g epoxy resin and 0.1g hydroquinone, stir evenly, and obtain the still material;

[0067] A2. take by weighing 0.25g catalyst and 8.36g of acrylic acid, dissolve catalyst into acrylic acid, obtain the acrylic acid monomer that is dissolved with catalyst;

[0068] A3. When the temperature of the kettle material in step A1 rises to 75°C, evenly add the acrylic acid monomer in step A2 dropwise, the control time is within 30min, and the temperature is kept at 75°C for 30min, then the temperature is raised to 80°C, and the reaction is kept for 4h until the acid value is less than 0.03mg / g, obtain modified epoxy resin;

[0069] B. Emulsion polymerization:

[0070] B1. Weigh 7.2g of modified ...

Embodiment 2

[0080] A kind of preparation method of epoxy-acrylate composite emulsion is characterized in that, the steps that comprise are as follows:

[0081] A. Preparation of modified epoxy resin:

[0082] A1. In a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, add 50g epoxy resin and 0.1g hydroquinone, stir evenly, and obtain the still material;

[0083] A2. take by weighing 0.25g catalyst and 8.36g of acrylic acid, dissolve catalyst into acrylic acid, obtain the acrylic acid monomer that is dissolved with catalyst;

[0084] A3. When the temperature of the kettle material in step A1 rises to 75°C, evenly add the acrylic acid monomer in step A2 dropwise, the control time is within 30min, and the temperature is kept at 75°C for 30min, then the temperature is raised to 80°C, and the reaction is kept for 4h until the acid value is less than 0.03mg / g, obtain modified epoxy resin;

[0085] B. Emulsion polymerization:

[0086] B1. Weigh 6.75g of modified...

Embodiment 3

[0095] A kind of preparation method of epoxy-acrylate composite emulsion is characterized in that, the steps that comprise are as follows:

[0096] A. Preparation of modified epoxy resin:

[0097] A1. In a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, add 50g epoxy resin and 0.1g hydroquinone, stir evenly, and obtain the still material;

[0098] A2. Weigh 0.25g of catalyst and 8.36g of acrylic acid, dissolve the catalyst into acrylic acid, n(E-44):n(AA)=1:1.5-1:0.5, and obtain the acrylic acid monomer dissolved with catalyst;

[0099] A3. When the temperature of the kettle material in step A1 rises to 75°C, evenly add the acrylic acid monomer in step A2 dropwise, the control time is within 30min, and the temperature is kept at 75°C for 30min, then the temperature is raised to 80°C, and the reaction is kept for 4h until the acid value is less than 0.03mg / g, obtain modified epoxy resin;

[0100] B. Emulsion polymerization:

[0101] B1. Weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com