Light-curing colored paint

A light-curing, light-curing resin technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve problems such as the inability to completely overcome color paint, and the difficulty of rapid curing of thick paint bottom layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

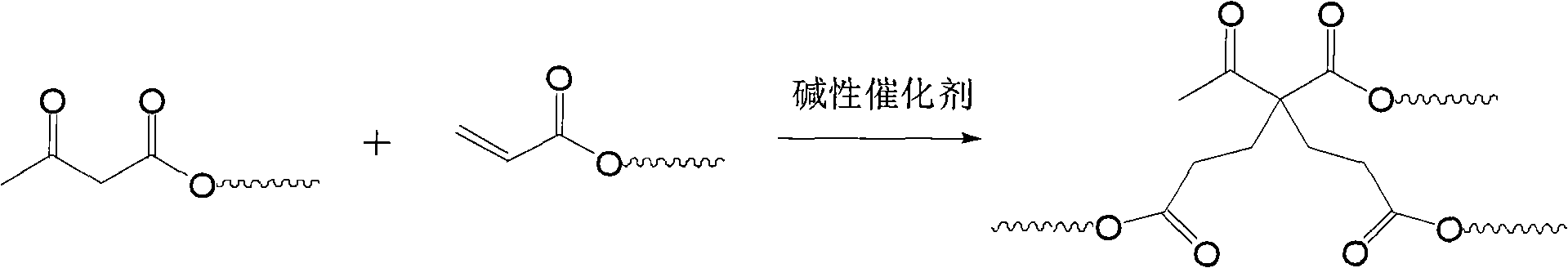

Method used

Image

Examples

Embodiment 1

[0055] Prepare the black photocurable paint by the above-mentioned method by preparing the following materials in corresponding proportions.

[0056] Carbot black pigment MogulE 5 parts

[0057] Pigment dispersant 0.5 parts

[0058] 11.5 parts of isooctyl acrylate

[0059] Trimethylolpropane triacrylate 18 parts

[0060] Epoxy acrylate (light curing resin) 42 parts

[0061] Acetoacetoxy ethyl methacrylate 12 parts

[0062] Irgacure 184 4 servings

[0063] Darocur TPO 1.5 parts

[0064] 0.5 parts of isopropylthioxanthone

[0065] Photoamine generator PBG-1(R 1 is ethyl, R 2 for H, X - for Ph 3 BuB - ) 2 copies

[0066] Amine proliferator APG-1 (Y=H, R 6 = H) 3 copies

[0067] After curing, the adhesion of the paint film is 5B.

Embodiment 2

[0075] The following materials are prepared in corresponding proportions to make red photocurable coatings by the aforementioned method.

[0076] Irgalite Rubine L4BE 6 parts

[0077] Pigment dispersant 0.5 parts

[0078] 12.5 parts of isooctyl acrylate

[0079] 1,6-hexanediol diacrylate 18 parts

[0080] Hexafunctional polyurethane acrylate 40 parts

[0081] Neopentyl glycol diacetoacetate 12 parts

[0082] Darcur 1173 4 servings

[0083] Darocur TPO 1.5 parts

[0084] 0.5 parts of isopropylthioxanthone

[0085] Photoamine generator PBG-2(R 3 for benzyl) 2 parts

[0086] Amine proliferator APG-1 (Y=Br, R 6 for methyl) 3 parts

[0087] After curing, the adhesion of the paint film is 5B.

Embodiment 3

[0095] Prepare the black photocurable paint by the above-mentioned method by preparing the following materials in corresponding proportions.

[0096] Carbot black pigment MogulE 5 parts

[0097] Pigment dispersant 1.5 parts

[0098] 12.5 parts of isobornyl acrylate

[0099] Ethoxylated trimethylolpropane triacrylate (EOTMPTA) 18 parts

[0100]Trifunctional polyurethane acrylate 40 parts

[0101] Acrylate Copolymer Polyol Acetoacetate

[0102] (Number average molecular weight 18200, average functionality of acetoacetate group) 12 parts

[0103] Irgacure 369 1 serving

[0104] Irgacure 184 3 servings

[0105] Darocur TPO 1.5 parts

[0106] 0.5 parts of isopropylthioxanthone

[0107] Photoamine generator PBG-3(R 4 is the residue derived from 1,6-hexanediol diacrylate, ie -CH 2 CH 2 COO(CH 2 ) 6 OCOCH 2 CH 2 -) 2 copies

[0108] Amine proliferator APG-1 (Y=CN, R 6 for phenyl) 3 parts

[0109] After curing, the adhesion of the paint film is 5B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com