Irradiation cross-linked polyolefin cable material and preparation method thereof

A technology for cross-linking polyolefin and cable material, applied in the field of cable material manufacturing, can solve problems such as safety accidents and material performance differences, save maintenance costs, long service life, reduce extrusion torque, as well as host current and melting point. body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

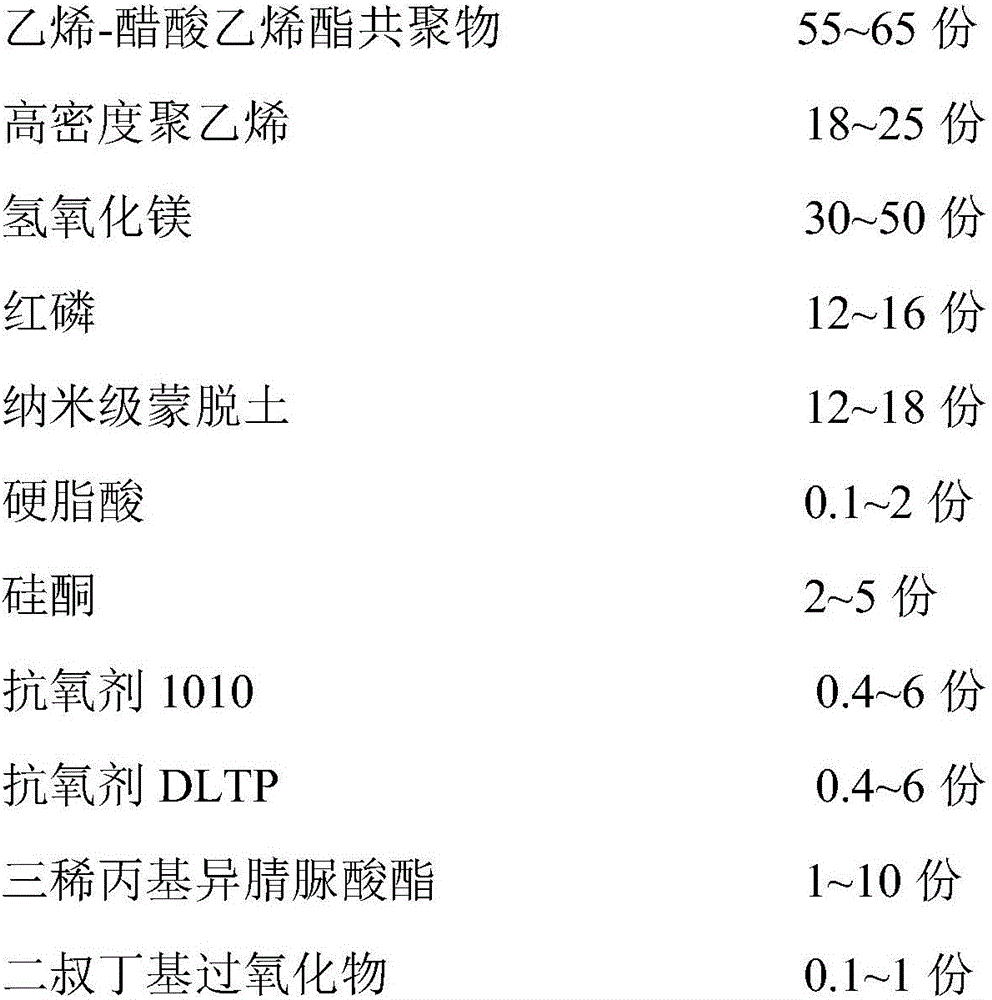

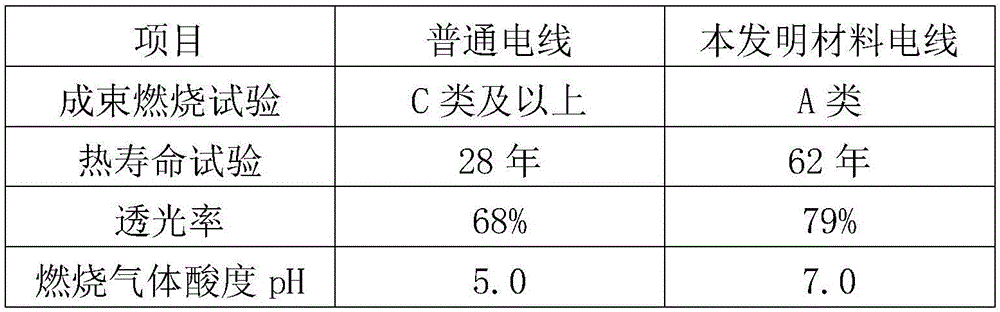

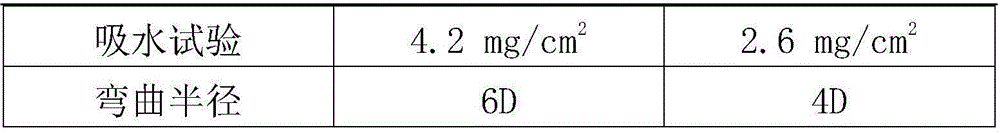

[0029] The irradiation cross-linked polyolefin cable material of the present invention comprises the following components in parts by weight: 55 parts of ethylene-vinyl acetate copolymer; 18 parts of high-density polyethylene; 30 parts of magnesium hydroxide; 12 parts of red phosphorus; 12 parts of grade montmorillonite; 0.1 part of stearic acid; 2 parts of silicone; 0.4 part of antioxidant 1010; 0.4 part of antioxidant DLTP; 1 part of triallyl isocyanurate; 0.1 parts.

[0030] The preparation method of radiation crosslinked polyolefin cable material of the present invention, comprises the steps:

[0031] Step 1: Use a screening machine to filter red phosphorus and nano-level montmorillonite to remove large particles and impurities in the powder; place magnesium hydroxide and stearic acid in a desiccator for 24 hours to remove or reduce the moisture; Add the ethylene-vinyl acetate copolymer to the dryer, and dry it at a constant temperature of 70°C for 4 hours.

[0032] Step...

Embodiment 2

[0039] The radiation cross-linked polyolefin cable material of the present invention comprises the following components in parts by weight: 65 parts of ethylene-vinyl acetate copolymer; 25 parts of high-density polyethylene; 50 parts of magnesium hydroxide; 16 parts of red phosphorus; 18 parts of grade montmorillonite; 2 parts of stearic acid; 5 parts of silicone; 6 parts of antioxidant 1010; 6 parts of antioxidant DLTP; 10 parts of triallyl isocyanurate; 1 serving.

[0040] The preparation method of radiation crosslinked polyolefin cable material of the present invention, comprises the steps:

[0041] Step 1: Use a screening machine to filter red phosphorus and nano-level montmorillonite to remove large particles and impurities in the powder; place magnesium hydroxide and stearic acid in a desiccator for 24 hours to remove or reduce the moisture; Add the ethylene-vinyl acetate copolymer to the dryer, and dry it at a constant temperature of 80°C for 4 hours.

[0042] Step 2:...

Embodiment 3

[0049] The radiation cross-linked polyolefin cable material of the present invention comprises the following components in parts by weight: 60 parts of ethylene-vinyl acetate copolymer; 22 parts of high-density polyethylene; 40 parts of magnesium hydroxide; 15 parts of red phosphorus; 16 parts of grade montmorillonite; 1 part of stearic acid; 3 parts of silicone; 4 parts of antioxidant 1010; 4 parts of antioxidant DLTP; 6 parts of triallyl isocyanurate; 0.5 parts.

[0050] The preparation method of radiation crosslinked polyolefin cable material of the present invention, comprises the steps:

[0051] Step 1: Use a screening machine to filter red phosphorus and nano-level montmorillonite to remove large particles and impurities in the powder; place magnesium hydroxide and stearic acid in a desiccator for 24 hours to remove or reduce the moisture; Add the ethylene-vinyl acetate copolymer to the dryer, and dry it at a constant temperature of 75°C for 4 hours.

[0052] Step 2: P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com