Epoxy resin based anti-static coating

An epoxy resin and base anti-corrosion technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of poor mechanical properties and anti-static properties that cannot be further improved, and achieve enhanced anti-oxidation properties, improved mechanical properties, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

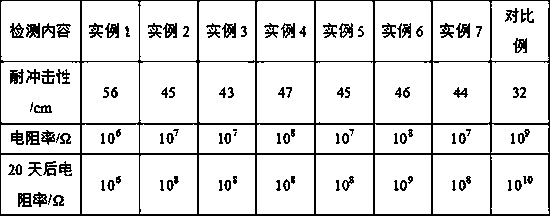

Examples

example 1

[0032]Put the paraffin in a crucible and heat it until it completely melts at 60°C to obtain molten paraffin. Put sodium peroxide and molten paraffin in a beaker at a mass ratio of 1:10, stir and mix with a glass rod for 10 minutes to obtain Mix the slurry, and then place the mixed slurry in a frozen pulverizer to freeze and pulverize to obtain coated sodium peroxide; in parts by weight, 40 parts of a mass fraction of 50% glyoxal solution, 20 parts of a mass fraction of 30 % potassium hydroxide solution, 40 parts of hydroquinone are placed in a four-necked flask, and the four-necked flask is placed in a digital speed measuring constant temperature magnetic stirrer, at a temperature of 78 ° C and a speed of 500 r / min. After stirring and reacting at constant temperature for 4 hours, lower the temperature in the four-necked flask to 62°C, then add ethylene urea 0.3 times the volume of the glyoxal solution into the four-necked flask, and keep the temperature at 62°C and the speed a...

example 2

[0034] Put the paraffin in a crucible and heat it until it completely melts at 60°C to obtain molten paraffin. Put sodium peroxide and molten paraffin in a beaker at a mass ratio of 1:10, stir and mix with a glass rod for 10 minutes to obtain Mix the slurry, and then place the mixed slurry in a frozen pulverizer to freeze and pulverize to obtain coated sodium peroxide; in parts by weight, 40 parts of a mass fraction of 50% glyoxal solution, 20 parts of a mass fraction of 30 % potassium hydroxide solution, 40 parts of hydroquinone are placed in a four-necked flask, and the four-necked flask is placed in a digital speed measuring constant temperature magnetic stirrer, at a temperature of 78 ° C and a speed of 500 r / min. After stirring and reacting at constant temperature for 4 hours, lower the temperature in the four-necked flask to 62°C, then add ethylene urea 0.3 times the volume of the glyoxal solution into the four-necked flask, and keep the temperature at 62°C and the speed ...

example 3

[0036] Put the paraffin in a crucible and heat it until it completely melts at 60°C to obtain molten paraffin. Put sodium peroxide and molten paraffin in a beaker at a mass ratio of 1:10, stir and mix with a glass rod for 10 minutes to obtain Mix the slurry, and then place the mixed slurry in a frozen pulverizer to freeze and pulverize to obtain coated sodium peroxide; in parts by weight, 40 parts of a mass fraction of 50% glyoxal solution, 20 parts of a mass fraction of 30 % potassium hydroxide solution, 40 parts of hydroquinone are placed in a four-necked flask, and the four-necked flask is placed in a digital speed measuring constant temperature magnetic stirrer, at a temperature of 78 ° C and a speed of 500 r / min. After stirring and reacting at constant temperature for 4 hours, lower the temperature in the four-necked flask to 62°C, then add ethylene urea 0.3 times the volume of the glyoxal solution into the four-necked flask, and keep the temperature at 62°C and the speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com