Aerosol type UV coating and preparation method thereof

A coating and aerosol technology, used in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of low crosslinking density, high VOC content, and small molecular weight of film-forming resins, and achieve solvent resistance. Good performance, low VOC content, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

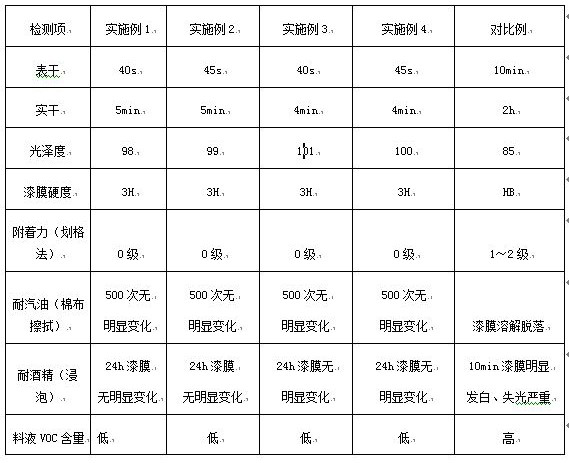

Examples

Embodiment 1

[0046] Attached figure 1 In the proportion by weight, add oligomer resin, polymerization inhibitor, defoamer, 50% reactive diluent, and disperse for 10-15 minutes until uniform;

[0047] S2. Under low-speed stirring, add the filler and color paste in the formula in turn, and then disperse at high speed for 1 hour until there are no obvious particles, and then quickly grind the prepared material liquid through a sand mill, and the detection fineness is <15 μm;

[0048] S3. Add reactive diluent, leveling agent, and photoinitiator in the remaining formulation amount, disperse for 15 minutes until the material liquid is evenly mixed, and the viscosity is tested to be qualified, that is, the paint is prepared.

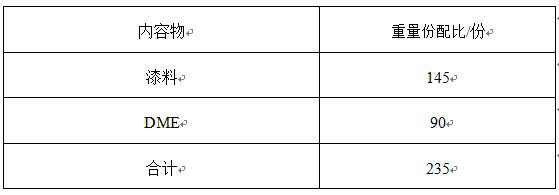

[0049] S4. Put stirring beads into the aerosol can, press the attached figure 2 The prepared paint and propellant are poured into the aerosol can, the valve is placed, sealed, inflated, the head is pressed, and the cap is pressed to obtain the aerosol UV coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com