Luminous sandstone imitating decorating material and manufacturing method thereof

The technology of a decorative material and production method is applied in the field of luminous imitation sandstone decorative material and its production field, which can solve the problems such as difficult coloring and achieve the effects of good hardness, high strength and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

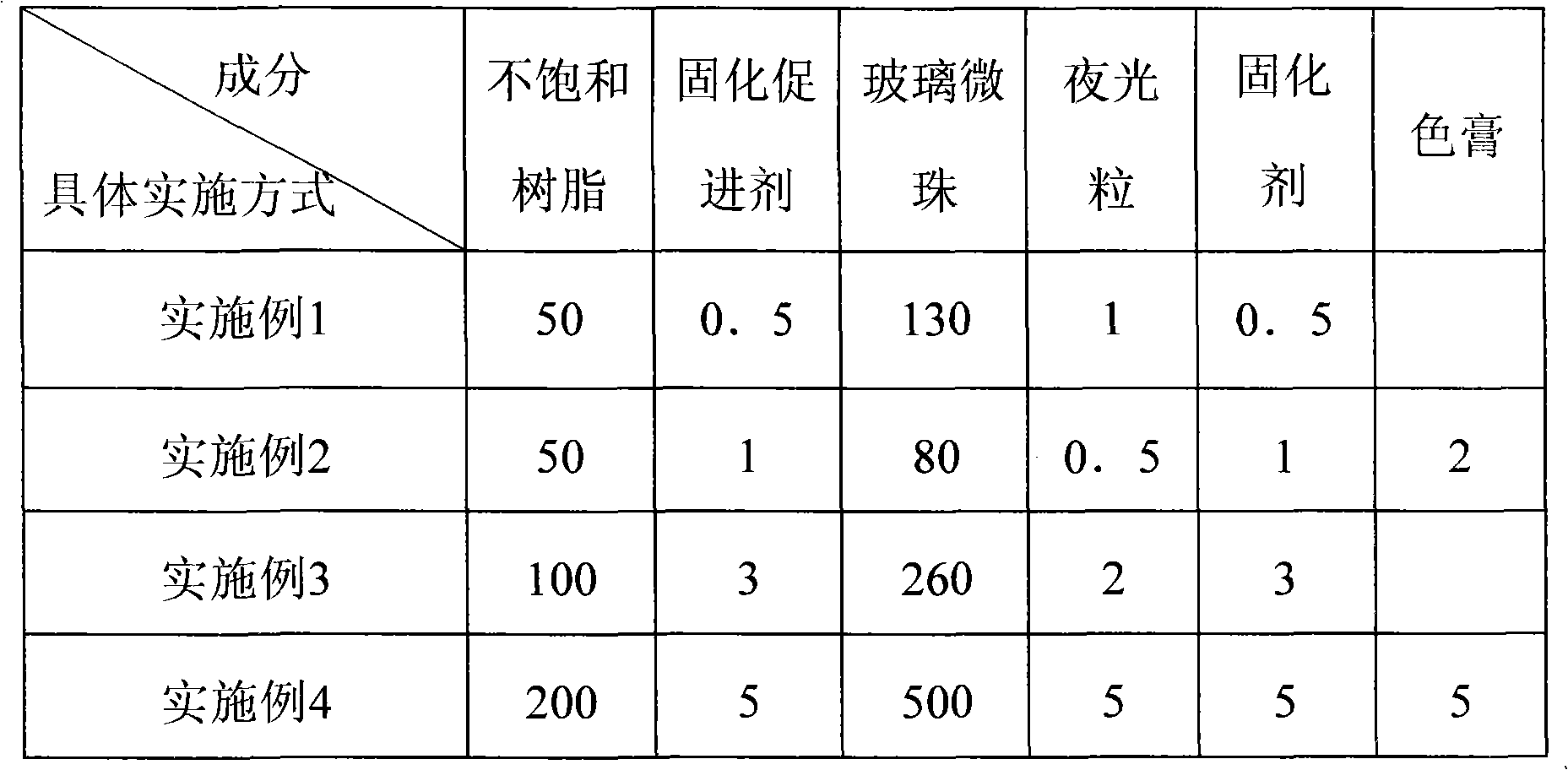

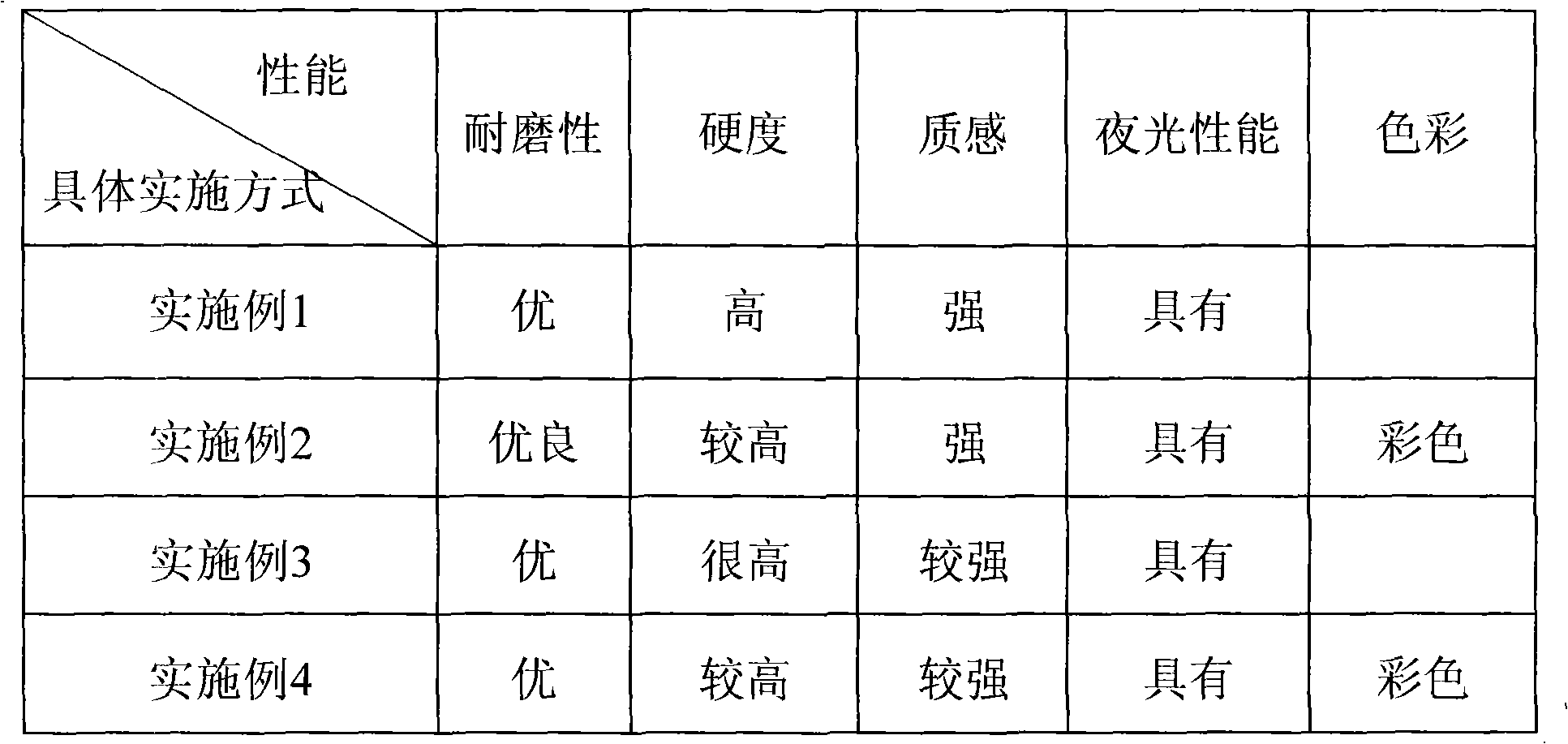

Embodiment 1

[0026] Prepare the raw materials according to the weight parts of Example 1 in Table 1; put the unsaturated resin and curing accelerator into the container and stir for 5 to 10 minutes in the above-mentioned prepared ingredients, and then place it at room temperature for 15 minutes after stirring evenly Then add glass microspheres and luminous particles and stir again for 5 to 10 minutes; add the above-mentioned components that have been stirred evenly again, add a curing agent, pour them into a mold, place them at room temperature to cure and shape, and after curing and shape, polish them into luminous sandstone-like decorative materials.

Embodiment 2

[0028] Prepare the raw materials according to the weight parts of Example 2 in Table 1; first stir the unsaturated resin, curing accelerator, and color paste in the above-mentioned ingredients for 5 to 10 minutes, and then add glass microbes after 15 minutes at room temperature. Stir the beads and luminous particles again for 5 to 10 minutes; add the above-mentioned components that have been stirred evenly again, add a curing agent, pour them into a mold, place them at room temperature for curing and molding, and after curing and molding, polish them into a colored luminous imitation sandstone decorative material.

Embodiment 3

[0030] Raw materials were prepared according to the weight parts of Example 3 in Table 1; other technological processes were the same as in Example 1, and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com