Water-based environmental-friendly sandpaper and production method thereof

A production method and environmentally friendly technology, applied in abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems that abrasives cannot fully function, reduce the service life of sandpaper, and end the service life of sandpaper, so as to improve waterproof ability and improve grinding. Good efficiency and waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

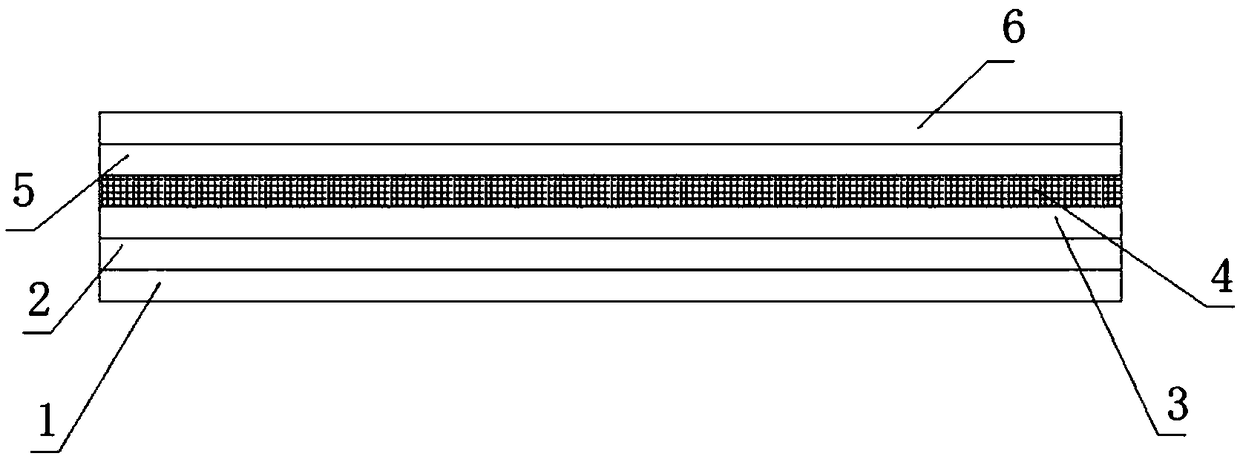

[0031] like figure 1 As shown, a water-based environmentally friendly green sandpaper includes a base paper layer 1, a waterproof treatment layer 2, a primer layer 3, an abrasive layer 4, a rubber layer 5, and an anti-blocking treatment layer 6 arranged in sequence from bottom to top.

[0032] The production method of the water-based environmentally friendly green sandpaper comprises a base paper treatment process, a primer coating process, an electrostatic sand planting process, a glue coating process, and a coating process, which are carried out in sequence;

[0033] The base paper treatment process includes: selecting foreign imported high-quality paper base as the base paper layer 1, soaking the paper base in the waterproof treatment solution, squeezing the paper base evenly with two rubber rollers immediately after the paper base is soaked from the waterproof treatment solution, and then The soaked paper base is sent to the drying tunnel connected to the industrial combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com