Hydrophilicity improvement method of PP film

A hydrophilic and water-soluble polymer technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as complicated procedures and high costs, and achieve improved hydrophilicity, stability, and homogeneity distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

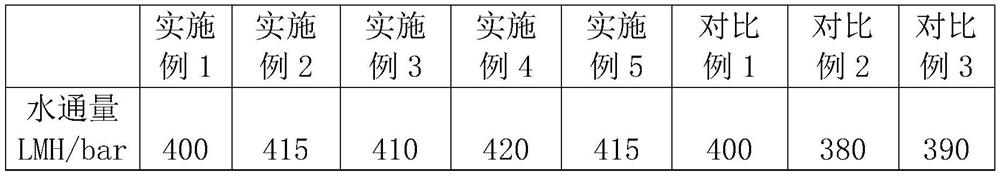

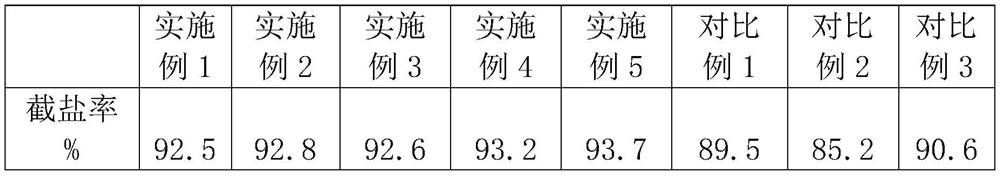

Embodiment 1

[0043] A method for improving the hydrophilicity of a PP film, comprising the following steps:

[0044] Step 1: take the PP film, soak the PP film with 75% ethanol solvent for 30min;

[0045] Step 2: Take deionized water to clean and soak the PP film for 10 minutes, take a 0.5% polyvinyl alcohol solution added with a dispersion medium solvent, and soak the PP film in the polyvinyl alcohol solution for 30 minutes;

[0046] Step 3: Pull out the PP film, and soak the PP film in the crosslinking agent solution for 5 minutes;

[0047] Step 4: The PP film is pulled out and the liquid on the surface is drained to obtain a hydrophilically improved PP film.

Embodiment 2

[0049] A method for improving the hydrophilicity of a PP film, comprising the following steps:

[0050] Step 1: take the PP film, soak the PP film with 75% ethanol solvent for 30min;

[0051] Step 2: take deionized water to clean and soak the PP film for 10 minutes, take a 1% polyvinyl alcohol solution added with a dispersion medium solvent, and soak the PP film in the polyvinyl alcohol solution for 30 minutes;

[0052] Step 3: Pull out the PP film, and soak the PP film in the crosslinking agent solution for 5 minutes;

[0053] Step 4: The PP film is pulled out and the liquid on the surface is drained to obtain a hydrophilically improved PP film.

Embodiment 3

[0055] A method for improving the hydrophilicity of a PP film, comprising the following steps:

[0056] Step 1: take the PP film, soak the PP film with 75% ethanol solvent for 30min;

[0057] Step 2: Take deionized water to clean and soak the PP film for 10 minutes, take a 2% polyvinyl alcohol solution added with a dispersion medium solvent, and soak the PP film in the polyvinyl alcohol solution for 30 minutes;

[0058] Step 3: Pull out the PP film, and soak the PP film in the crosslinking agent solution for 5 minutes;

[0059] Step 4: The PP film is pulled out and the liquid on the surface is drained to obtain a hydrophilically improved PP film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com