Single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the field of polyurethane waterproof coatings, can solve the problems of catalysts affecting the storage effect, and achieve the effects of shortening the construction period, increasing the curing speed, and prolonging the storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also discloses a preparation method of the above-mentioned one-component polyurethane waterproof coating, comprising the following steps:

[0059] Stir and mix the measured polyether polyol, put in the filler and stir until evenly mixed to obtain a mixture, which is ground and filtered;

[0060] Raise the temperature of the ground mixture to 101°C to 110°C, and vacuum dehydrate;

[0061] Keep the vacuum environment, cool the dehydrated mixture, add isocyanate to the mixture, stir and react to obtain the heteromer mixture, then add chain extender to stir and react, the reaction temperature is 80°C to 85°C;

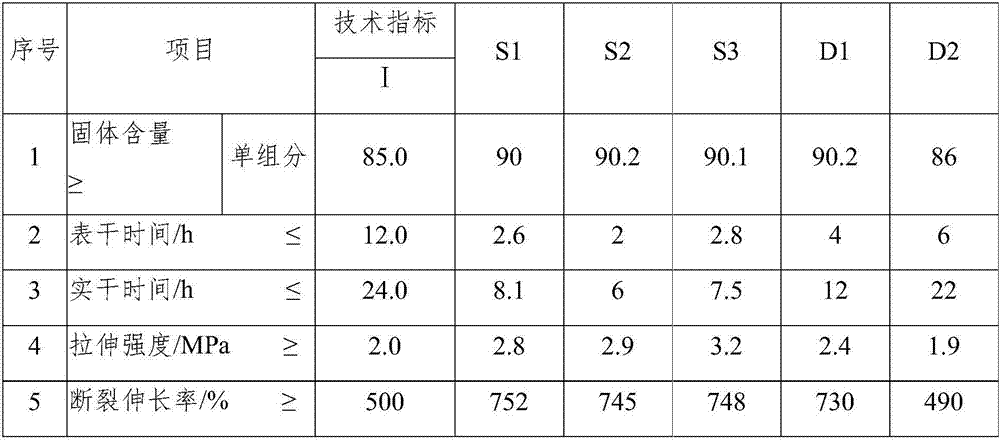

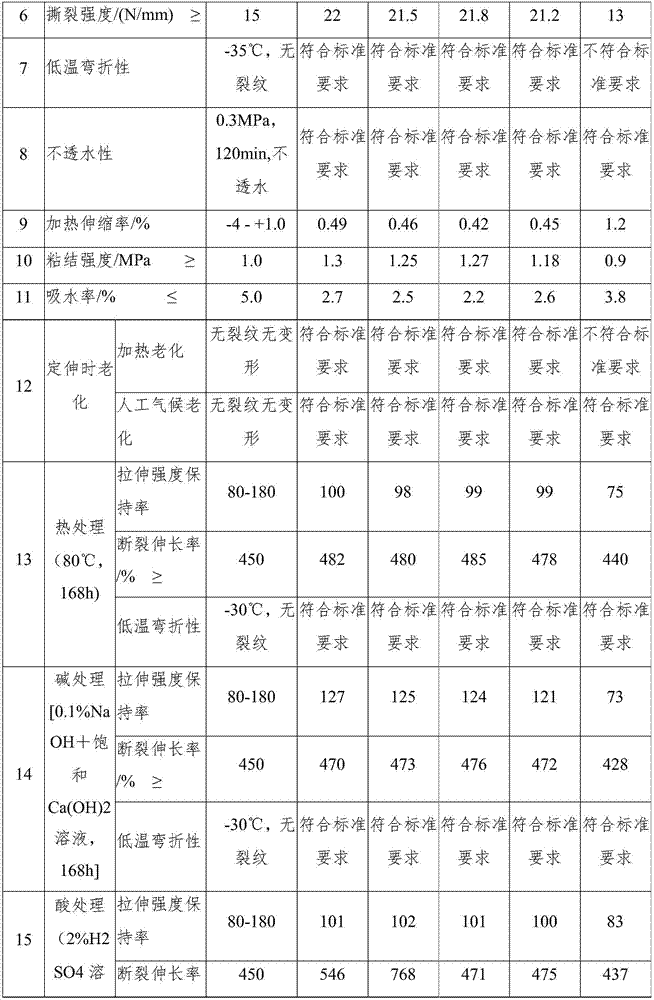

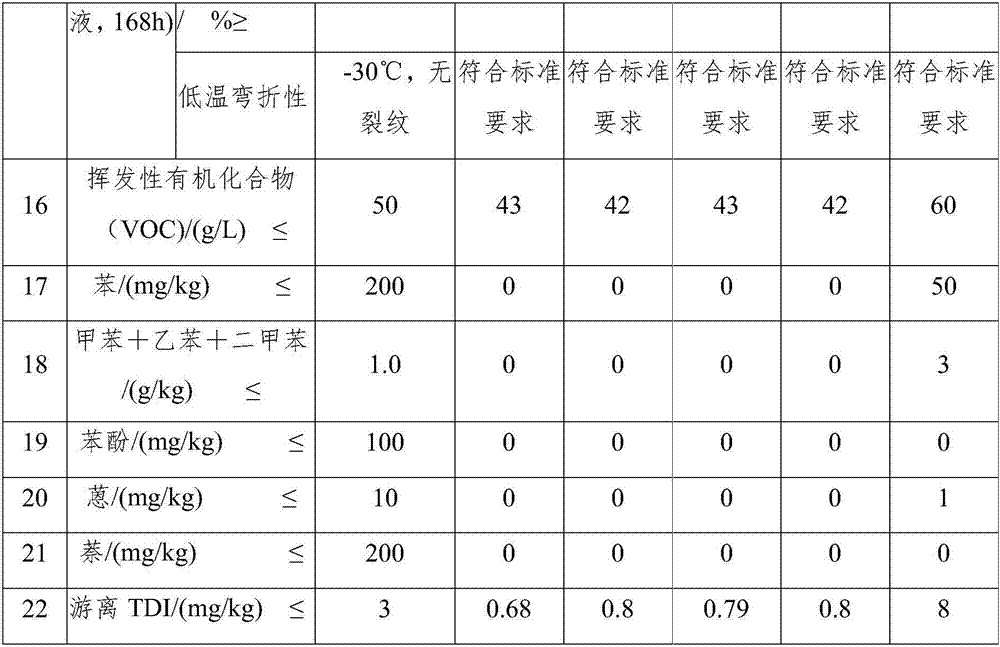

Embodiment 1

[0064] This embodiment is used to illustrate a kind of one-component polyurethane waterproof coating disclosed by the present invention and its preparation method, including the following steps:

[0065] Step 1: Feeding, mixing and grinding

[0066] 22 parts by weight of difunctional 2000 molecular weight polyether polyol, 4 parts by weight of trifunctional polyether polyol of 3000 molecular weight, 4 parts by weight of dibutyl phthalate and 20 parts by weight of chlorinated paraffin are mixed in sequence by vacuum suction In the kettle, stir at 75 rpm for 10 minutes until evenly mixed, then put 0.3 parts by weight of pigment powder, 6 parts by weight of calcined kaolin and 28 parts by weight of calcined talc into the mixing kettle, wherein, calcined kaolin: Bulk specific gravity: 1.05 Gram / cubic centimeter, fineness 1250 mesh, oil absorption 55%. Calcined talcum powder: bulk specific gravity: 1.22 g / cm3, fineness: 1250 mesh, oil absorption: 28%. Stir at 85 rpm for 15 minute...

Embodiment 2

[0084] This embodiment is used to illustrate a kind of one-component polyurethane waterproof coating disclosed by the present invention and its preparation method, including most of the operation steps as in Example 1, and its difference is:

[0085] Step 5: Catalytic reaction and vacuum defoaming

[0086] When the temperature is lowered to 45° C., the stirring speed is adjusted to 85 rpm, and 0.03 parts by weight of catalyst microcapsules are slowly added at normal pressure and stirred for 5 minutes. For ethylene-vinyl acetate copolymer, adjust the stirring to 75 rpm, vacuumize and defoam for 10 minutes, open the vent valve of the reactor, let the internal pressure of the reactor reach normal pressure, and turn off the vacuum pump.

[0087] When in use, heat the one-component polyurethane waterproof coating to 70°C, and after stirring for 5 minutes, mark the coating as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com