Catalyst for catalytic hydrogenation of p-nitrophenol and preparation method thereof

A technology for catalytic hydrogenation of p-nitrophenol, which is applied in the direction of catalyst activation/preparation, preparation of amino hydroxyl compounds, physical/chemical process catalysts, etc. To improve the activity and stability, enhance the interaction force, and improve the dispersion effect

Active Publication Date: 2011-06-15

NANJING UNIV OF TECH

View PDF6 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although researchers at home and abroad have made detailed studies on the preparation method and preparation process of catalytic membranes, two key problems need to be solved for large-scale industrial applications: first, the content of active components in the catalytic membrane per unit volume is small; second, the catalytic activity The binding force between the components and the membrane is weak

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

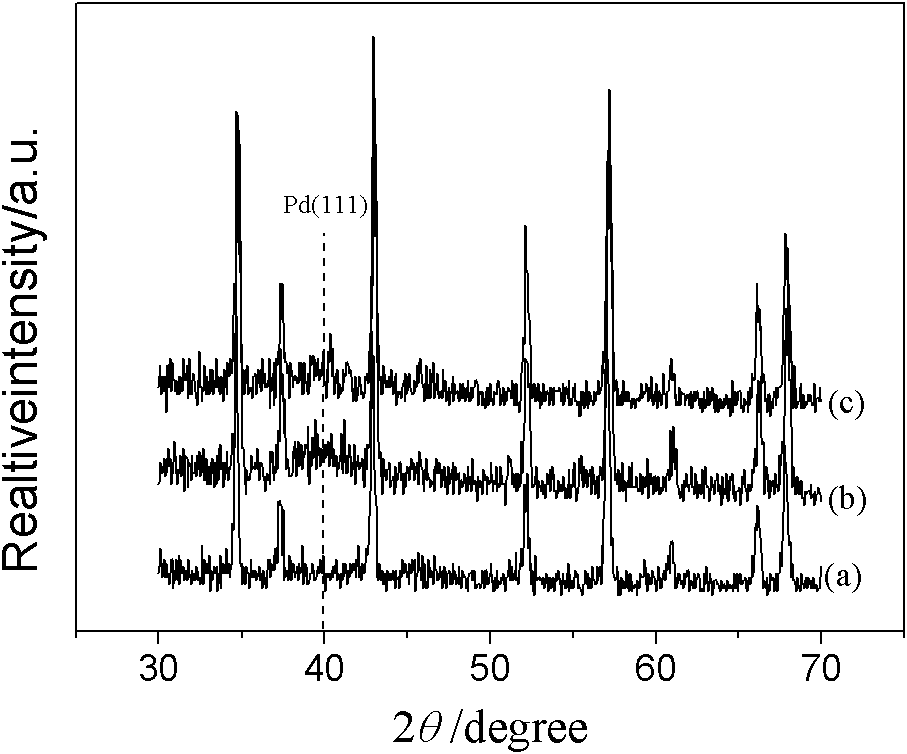

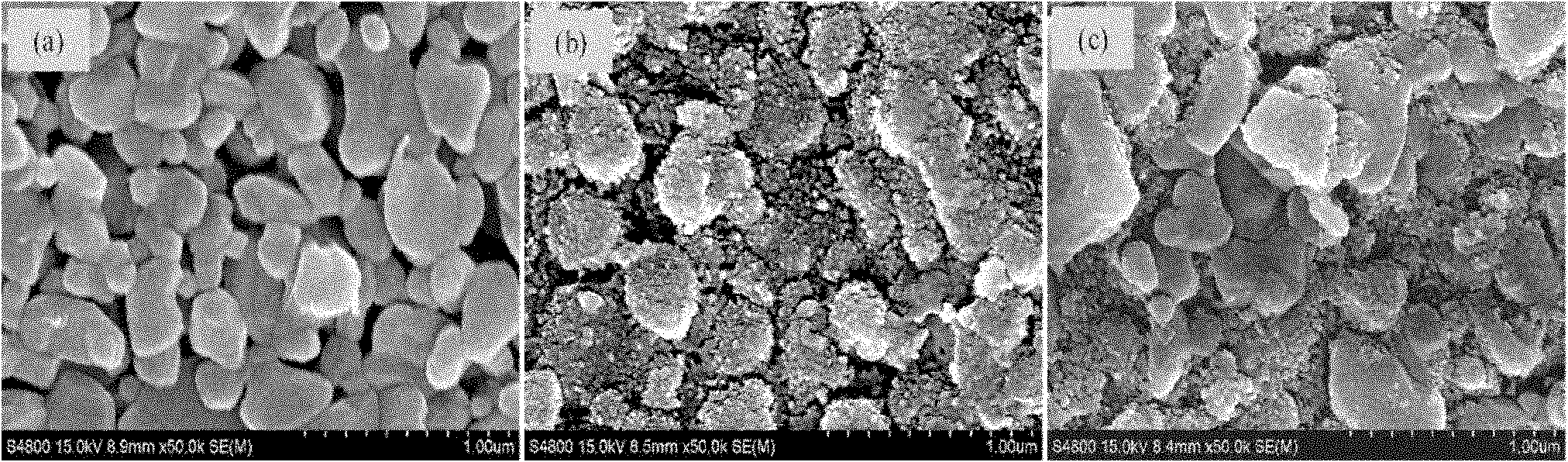

The invention relates to a catalyst for preparing p-aminophenol through catalytic hydrogenation of p-nitrophenol, and a preparation method thereof, and belongs to the technical field of catalysis. The carrier of the catalyst is a ceramic membrane, and the preparation method comprises the following steps of: modifying the membrane surface by using aminosilane; immersing in salt solution of an active ingredient; and performing hydrazine hydrate reduction to prepare a catalytic membrane. The invention has the advantages that: nano-scale catalyst particles are supported on the surface of the ceramic membrane modified by silane, and the activity and stability of the catalyst are improved; moreover, a problem that the catalyst is hardly separated from the product subsequently is avoided. The catalyst is simple in preparation process and high in activity and stability and can be widely applied to preparing the p-aminophenol through catalytic hydrogenation of the p-nitrophenol.

Description

A kind of p-nitrophenol catalytic hydrogenation catalyst and preparation method thereof technical field The invention relates to a supported catalyst and a preparation method thereof, in particular to a catalytic membrane for catalytic hydrogenation of p-nitrophenol and a preparation method thereof, belonging to catalyst preparation technology. Background technique p-Aminophenol is an important intermediate of fine chemicals such as medicines and dyes, and is mainly used in the production of paracetamol, dyes, developers, antioxidants and petroleum additives. At present, the main production methods are nitrobenzene electrolytic reduction method, nitrobenzene catalytic hydrogenation method, p-nitrophenol iron powder reduction method and p-nitrophenol catalytic hydrogenation method. Due to the high technical difficulty, strict production control requirements, and high power consumption, the nitrobenzene electrolytic reduction method has not yet achieved industrialization in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J23/755B01J23/44B01J23/42B01J23/46B01J32/00B01J37/02C07C215/76C07C213/02

Inventor 陈日志姜元国李汉阳邢卫红

Owner NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com