Catalytic hydrogenation catalyst and preparation method and application thereof

A catalyst and compound technology, applied in the field of catalytic hydrogenation catalyst and its preparation, can solve the problems of high cost of noble metal catalyst, inconvenient transportation and storage, difficult process control, etc., and achieve good stability, recyclability, easy operation, High-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

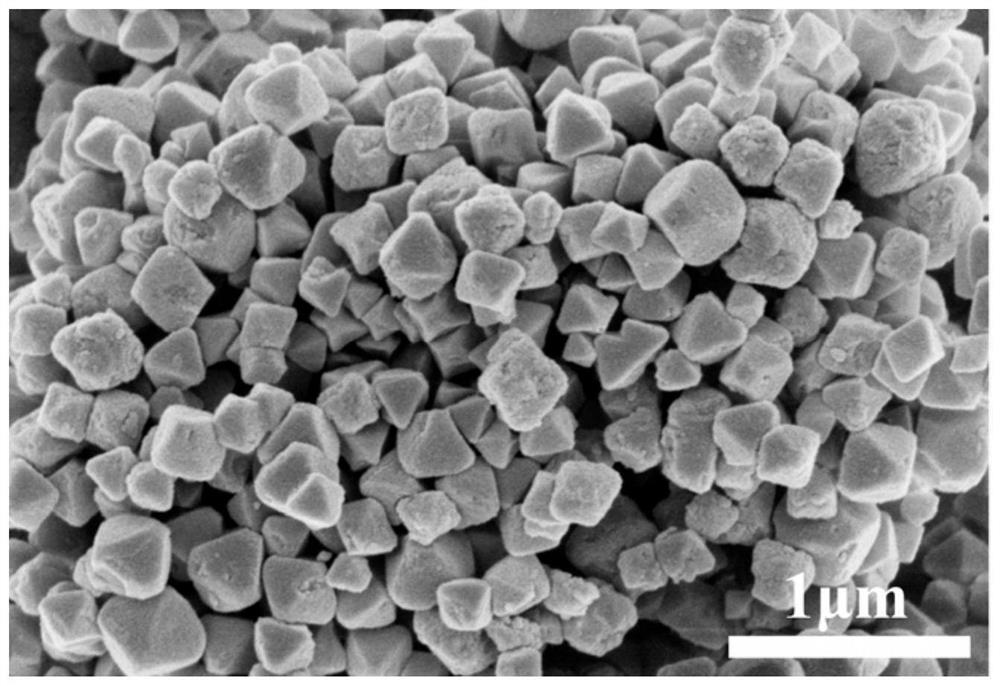

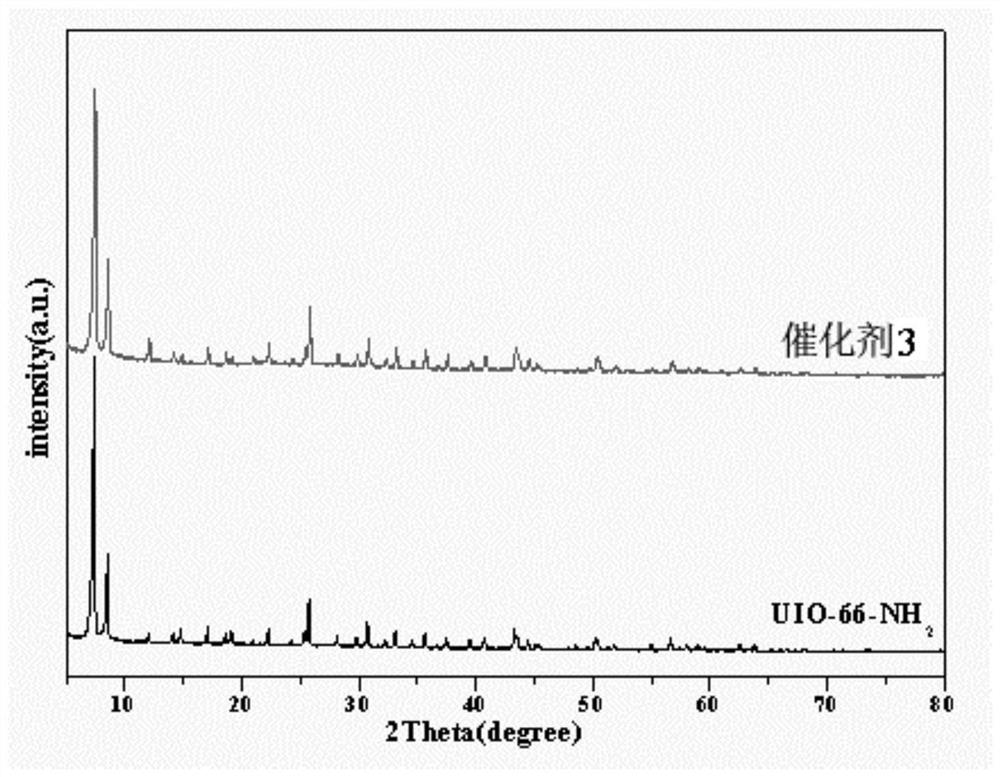

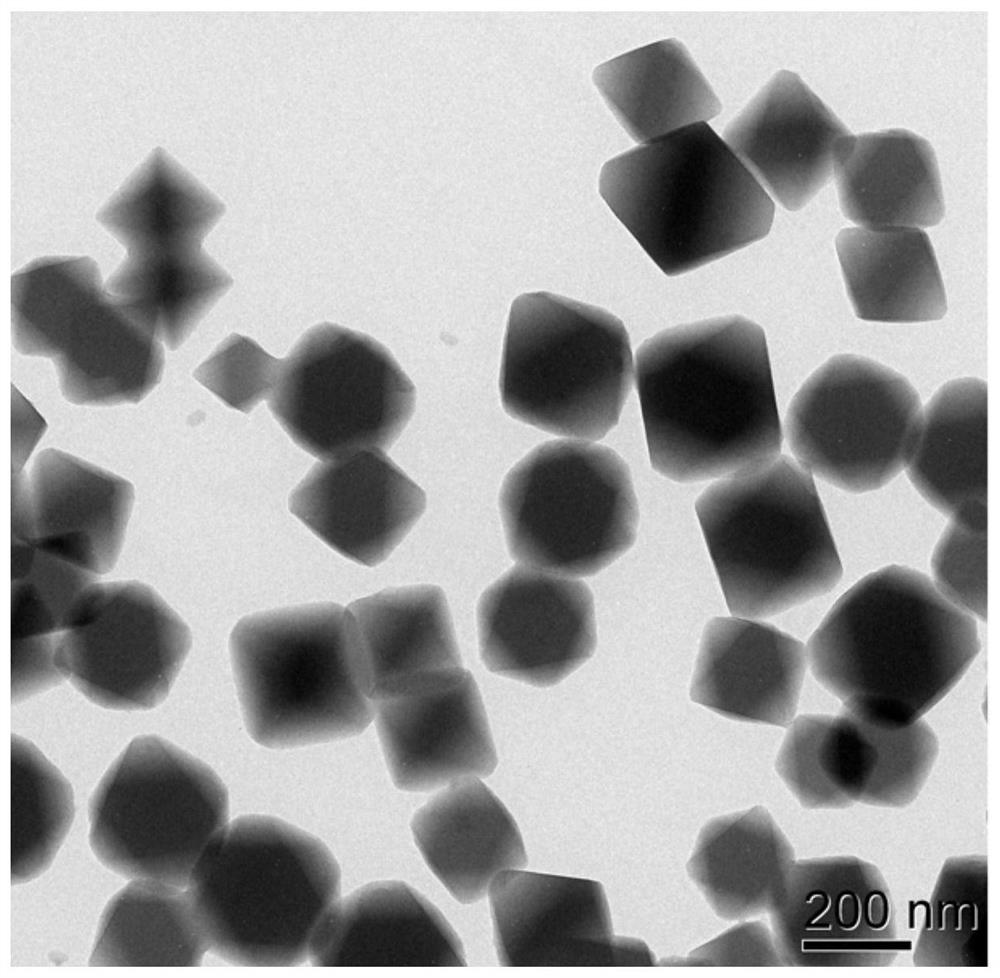

[0051] A catalyst for catalytic hydrogenation comprising metal organic framework compound UIO-66-NH 2 And doped in the metal organic framework compound UIO-66-NH 2 cobalt and copper on.

[0052] The preparation method of above-mentioned catalyst, comprises the following steps:

[0053] Dissolve 0.373g of zirconium chloride and 0.435g of 2-aminoterephthalic acid in 20ml of N,N-dimethylformamide respectively, and dissolve 0.1523g of cobalt chloride hexahydrate and 0.1637g of copper chloride dihydrate in 10ml In N,N-dimethylformamide, stirred at 500rpm for 30 minutes to obtain a mixed solution of zirconium chloride solution, 2-aminoterephthalic acid solution, cobalt chloride hexahydrate and cupric chloride dihydrate, and then Add the 2-aminoterephthalic acid solution dropwise into the zirconium chloride solution at a rate of 4mL / min, mix and stir evenly, then drop the mixed solution of cobalt chloride hexahydrate and copper chloride dihydrate at a rate of 4mL / min Add the above...

Embodiment 2

[0057] A catalyst for catalytic hydrogenation comprising metal organic framework compound UIO-66-NH 2 And doped in the metal organic framework compound UIO-66-NH 2 cobalt and copper on.

[0058] The preparation method of above-mentioned catalyst, comprises the following steps:

[0059] Dissolve 0.373g zirconium chloride and 0.29g 2-aminoterephthalic acid in 20ml N,N-dimethylformamide respectively, dissolve 0.114g cobalt chloride hexahydrate and 0.191g copper chloride dihydrate in 10ml In N,N-dimethylformamide, stirred at 600rpm for 40 minutes to obtain a mixed solution of zirconium chloride solution, 2-aminoterephthalic acid solution, cobalt chloride hexahydrate and cupric chloride dihydrate, and then Add the 2-aminoterephthalic acid solution dropwise into the zirconium chloride solution at a rate of 3mL / min, mix and stir evenly, then drop the mixed solution of cobalt chloride hexahydrate and copper chloride dihydrate at a rate of 3mL / min Add the above solution, mix and sti...

Embodiment 3

[0063] A catalyst for catalytic hydrogenation comprising metal organic framework compound UIO-66-NH 2 And doped in the metal organic framework compound UIO-66-NH 2 cobalt and copper on.

[0064] The preparation method of above-mentioned catalyst, comprises the following steps:

[0065] Dissolve 0.373g of zirconium chloride and 0.29g of 2-aminoterephthalic acid in 20ml of N,N-dimethylformamide respectively, and dissolve 0.076g of cobalt chloride hexahydrate and 0.218g of copper chloride dihydrate in 10ml In N,N-dimethylformamide, stirred at 400rpm for 30 minutes to obtain a mixed solution of zirconium chloride solution, 2-aminoterephthalic acid solution, cobalt chloride hexahydrate and cupric chloride dihydrate, and then Add the 2-aminoterephthalic acid solution dropwise into the zirconium chloride solution at a rate of 4mL / min, mix and stir evenly, then drop the mixed solution of cobalt chloride hexahydrate and copper chloride dihydrate at a rate of 4mL / min Add the above so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com