Preparation method of silica-supported carbon-nitrogen-coated cobalt-ruthenium catalyst and method for catalytic transfer hydrogenation of unsaturated compound through silica-supported carbon-nitrogen-coated cobalt-ruthenium catalyst

A silicon dioxide and ruthenium catalyst technology, which is applied in the preparation of organic compounds, physical/chemical process catalysts, hydrogenation preparation, etc., can solve the problems of long reaction time, inconvenient storage and transportation, flammability and explosion, etc., and achieves a simple preparation method, Good persistence of activity, not easy to lose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of silicon dioxide supported carbon nitrogen coated cobalt ruthenium catalyst comprises the following steps:

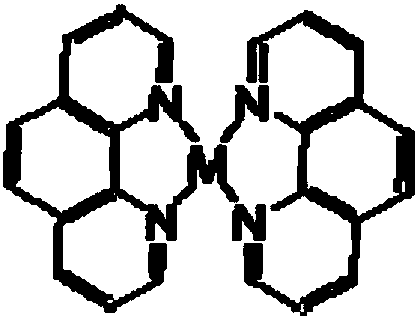

[0031]1) Mix ruthenium salt, cobalt salt, organic ligand, and solvent at a mass ratio of 5.89-35.34:47.5-570:198.2-1189:19.725 and heat for a certain period of time to form A solution; wherein the ruthenium salt is ruthenium chloride, The cobalt salt is cobalt chloride hexahydrate, the organic ligand is o-phenanthroline, and the solvent is absolute ethanol; heating is carried out in a water bath, and the temperature of the water bath heating is 60°C for 1 to 3 hours; preferably, ruthenium salt, cobalt The mass ratio of salt, organic ligand and solvent is 5.89~11.78:95~190:198.2~396.4:19.725; the mass ratio of cobalt to ruthenium is 4:1;

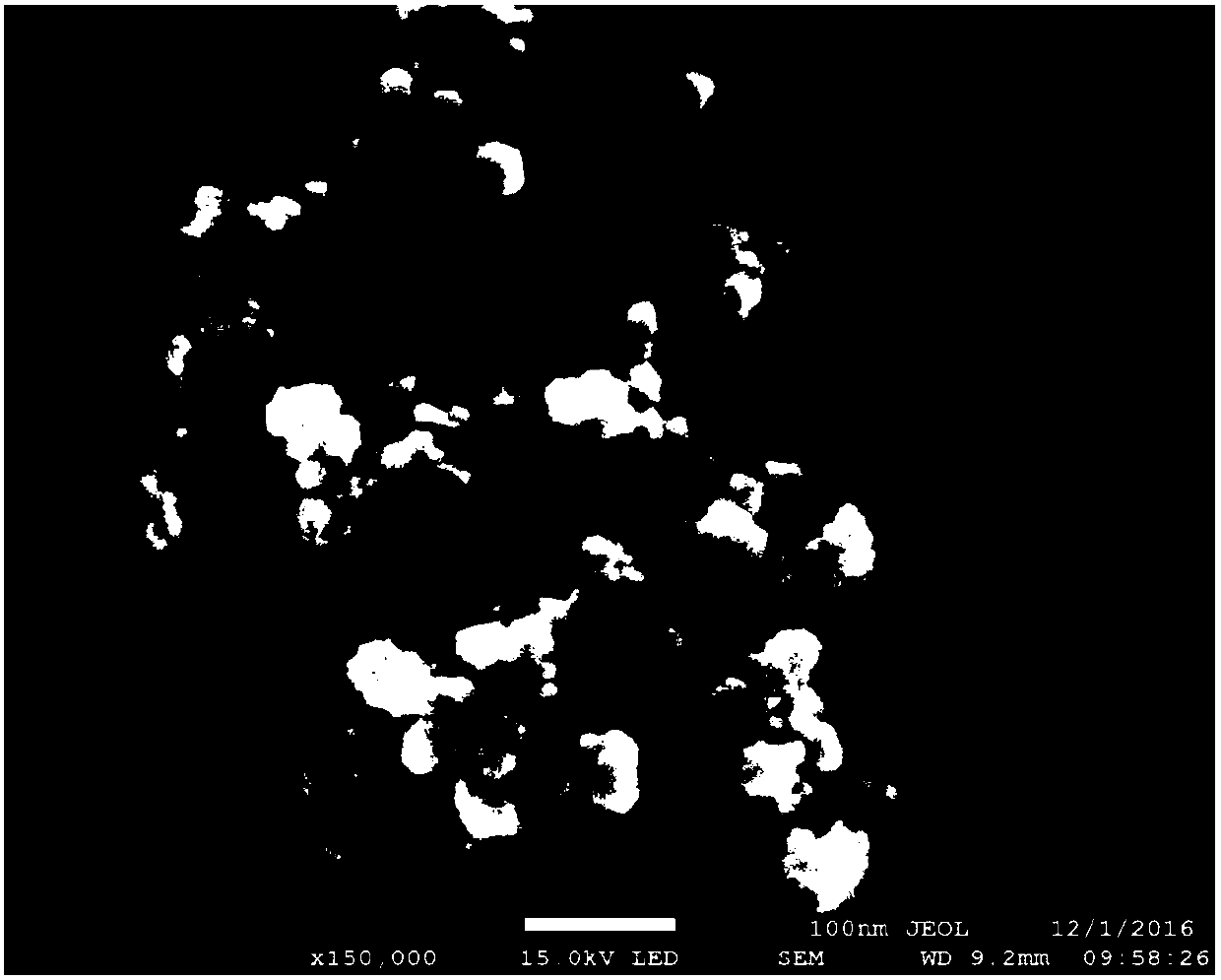

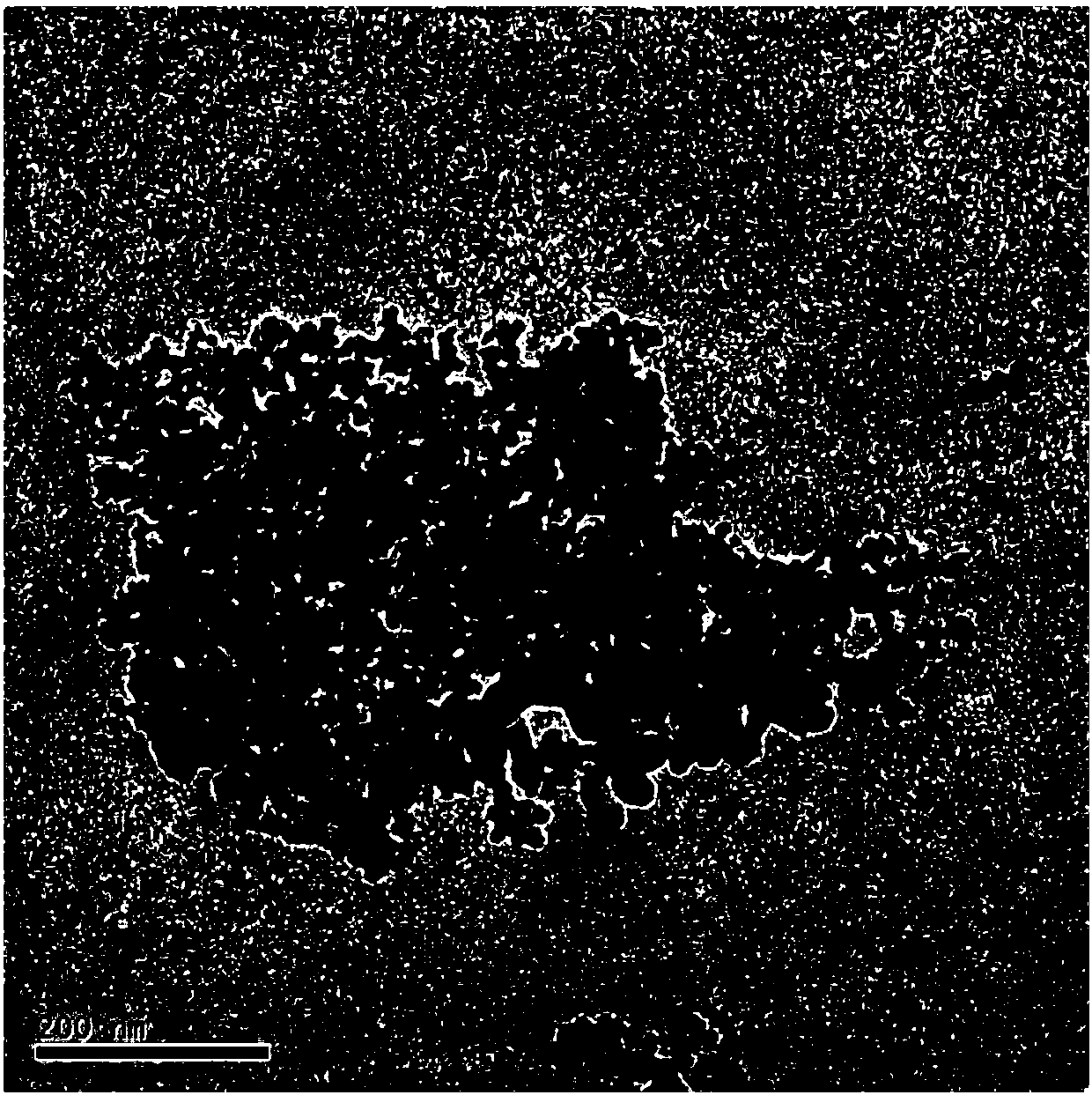

[0032] 2) Add nano silicon dioxide to A solution and mix to form B solution; the mass ratio of nano silicon dioxide to ruthenium salt is 589:5.89~35.34, and the particle diameter of nano silicon dioxide ...

Embodiment 1

[0037] Add 2945mg of ruthenium chloride aqueous solution (mass fraction is 1%) into the round bottom flask and dry the water therein with a rotary evaporator, add 107mg of cobalt chloride hexahydrate, 198.2mg of phenanthroline, and 25mL of absolute ethanol into the dry round flask In the bottom flask, add magnetons, stir in a water bath at 60°C for 1 hour to obtain solution A; add 589 mg of nano-silica to solution A, and mix with ultrasound for 20 minutes, and the power of ultrasound is 100W to obtain solution B; use a rotary evaporator Evaporate the solvent in solution B to dryness, put it in a vacuum oven and keep it for 4 hours, the drying temperature is 60°C, scrape off the solid on the wall of the flask, grind it finely in an agate mortar, transfer it to a crucible, put the crucible in a vacuum tube In a type furnace, the temperature was raised at a rate of 5°C / min, under N 2 Calcined in the atmosphere for 2h, the temperature was kept at 700°C, and a silica-supported carb...

Embodiment 2

[0040] Add 589mg of ruthenium chloride aqueous solution (mass fraction is 1%) into the round bottom flask and dry the water therein with a rotary evaporator, add 95mg of cobalt chloride hexahydrate, 198.2mg of phenanthroline, and 25mL of absolute ethanol into the dry round flask In the bottom flask, add magnetons, stir in a water bath at 60°C for 1 hour to obtain solution A; add 589 mg of nano-silica to solution A, and mix with ultrasound for 20 minutes, and the power of ultrasound is 100W to obtain solution B; use a rotary evaporator Evaporate the solvent in solution B to dryness, put it in a vacuum oven and keep it for 4 hours, the drying temperature is 60°C, scrape off the solid on the wall of the flask, grind it finely in an agate mortar, transfer it to a crucible, put the crucible in a vacuum tube In a type furnace, the temperature was raised at a rate of 5°C / min, under N 2 Calcined in the atmosphere for 2h, the temperature was kept at 700°C, and a silica-supported carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com