Modified nickel silicon catalyst and application thereof in preparation of gamma-butyrolactone (GBL) by means of catalytic hydrogenation of maleic anhydride

A catalyst and modification technology, which is applied in the field of modified nickel-silicon catalyst and its catalytic hydrogenation of maleic anhydride to prepare γ-butyrolactone, which can solve the problem of accelerating the aggregation and growth of catalyst active centers and the rate of carbon deposition, limiting large-scale In order to improve the activity and selectivity of the target product, promote adsorption and activation, and achieve good stability due to the application and harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

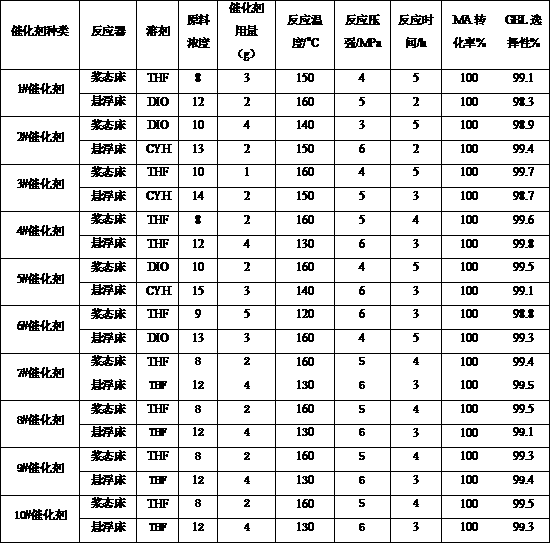

Image

Examples

Embodiment 1

[0028] 1) At room temperature, 15.36 g Ni(NO 3 ) 2 ·6H 2 O and 0.3102g Ce(NO 3 )2 ·6H 2 Dissolve O in 300 ml distilled water, add 25% concentrated ammonia water (wt) dropwise to pH=11~12, stir to form a blue metal-ammonia complex solution;

[0029] 2) Add 17g of alkaline silica sol dropwise to the ammonium complex solution obtained in step 1) while stirring, continue to stir for 6 hours after the dropwise addition, and raise the temperature to 90 °C for uniform precipitation until the pH of the solution is 7. The precipitate was centrifuged, washed with distilled water three times, then dried overnight at 100 °C, and then roasted at 5 °C / min to 500 °C for 4 h to obtain the desired catalyst Ni-Ce-PS, active metal nickel: additive CeO 2 : Carrier SiO 2 The mass ratio is: 1:0.04:2.19.

[0030] 3) Catalyst at 25V%H with a hydrogen flow rate of 40 ml / min 2 -75V%N 2 In a mixed atmosphere, the temperature was raised to 400 °C at 5 °C / min for reduction for 2 h to obtain cataly...

Embodiment 2

[0032] 1) At room temperature, 15.36gNi(NO 3 ) 2 ·6H 2 O and 0.4577g Zn(NO 3 ) 2 ·6H 2 Dissolve O in a mixed solution of 250 ml of water and ethanol, add 25% concentrated ammonia water (wt) dropwise to pH=11~12, and stir to make a metal salt-ammonia complex solution;

[0033] 2) Add 17g of alkaline silica sol dropwise to the ammonium complex solution obtained in step 1) while stirring, continue to stir for 6 hours after the dropwise addition, and raise the temperature to 80 °C for uniform precipitation until the pH of the solution is 7. The precipitate was centrifuged, washed 3 times with distilled water, then dried overnight at 80 °C, and then roasted at 5 °C / min to 550 °C for 5 h to make catalyst Ni-Zn-PS, active metal nickel: additive ZnO: carrier SiO 2 The mass ratio is: 1:0.04:2.19.

[0034] 3) Catalyst at 25V%H with a hydrogen flow rate of 40 ml / min 2 -75V%N 2 In a mixed atmosphere, the temperature was raised to 500 °C at 5 °C / min for 2 h, and the catalyst 2# for...

Embodiment 3

[0036] 1) At room temperature, 15.36g Ni(NO 3 ) 2 ·6H 2 O and 0.1839g (NH 4 ) 6 Mo 7 o 24 4H 2 Dissolve O in 300 ml of water, add 25% concentrated ammonia water (wt) dropwise to pH=11~12, and stir to make a blue metal salt-ammonia complex solution;

[0037] 2) Add 17 g of alkaline silica sol dropwise to the ammonium complex solution obtained in step 1) while stirring, continue stirring for 10 h after the dropwise addition, and raise the temperature to 80 °C for uniform precipitation until the pH of the solution is 7. The precipitate was centrifuged, washed with distilled water three times, then dried overnight at 80 °C, and then calcined at 5 °C / min to 600 °C for 4 h to make the catalyst Ni-Mo-PS, active metal nickel: additive MoO 3 : Carrier SiO 2 The mass ratio is: 1:0.05:2.19.

[0038] 3) Catalyst at 25V%H with a hydrogen flow rate of 40 ml / min 2 -75V%N 2 In a mixed atmosphere, the temperature was raised to 550 °C at 5 °C / min for 2 h to reduce, and catalyst 3# fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com