Super tough and high heat resistant polylactic acid/elastomer blend material or product and preparation method thereof

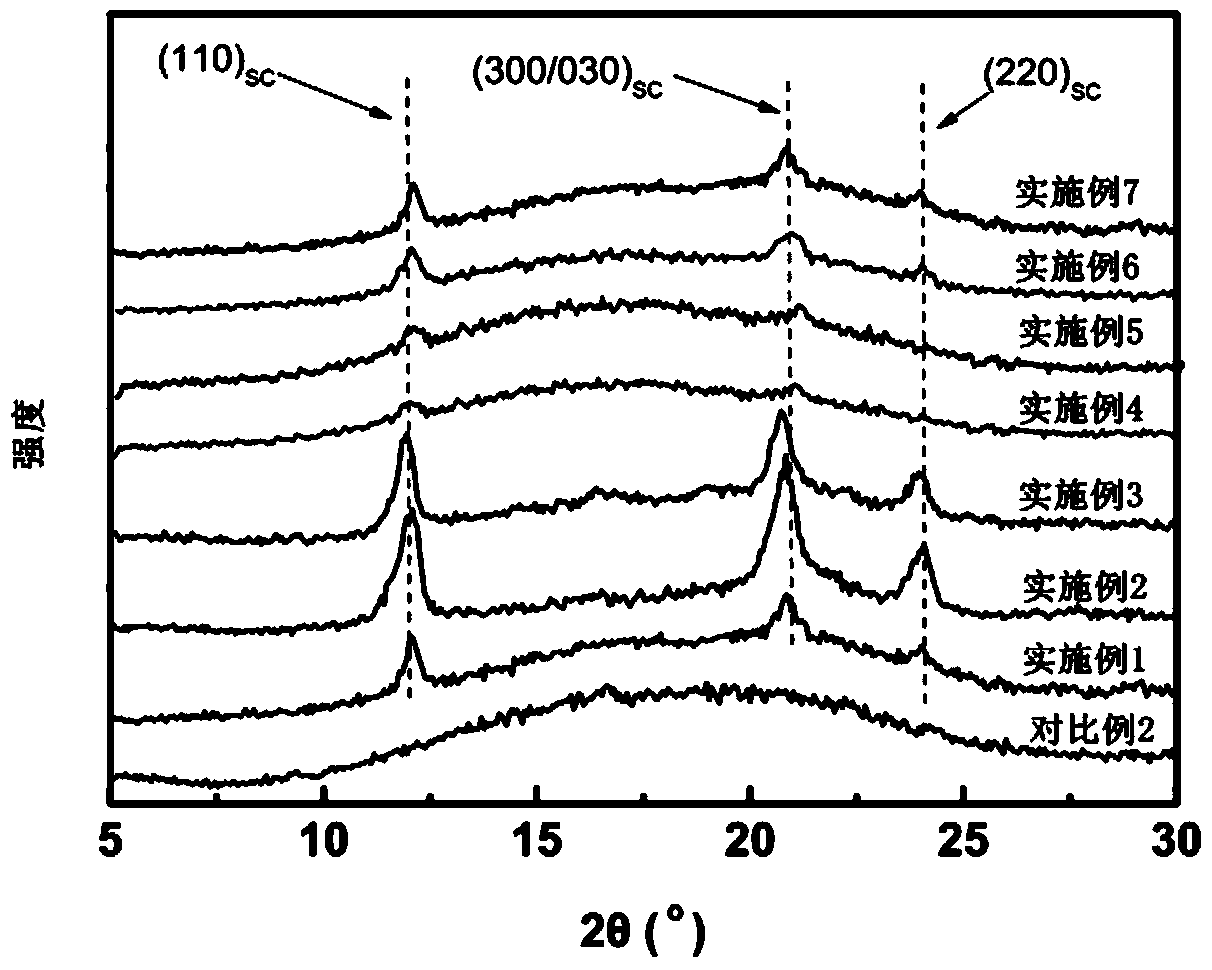

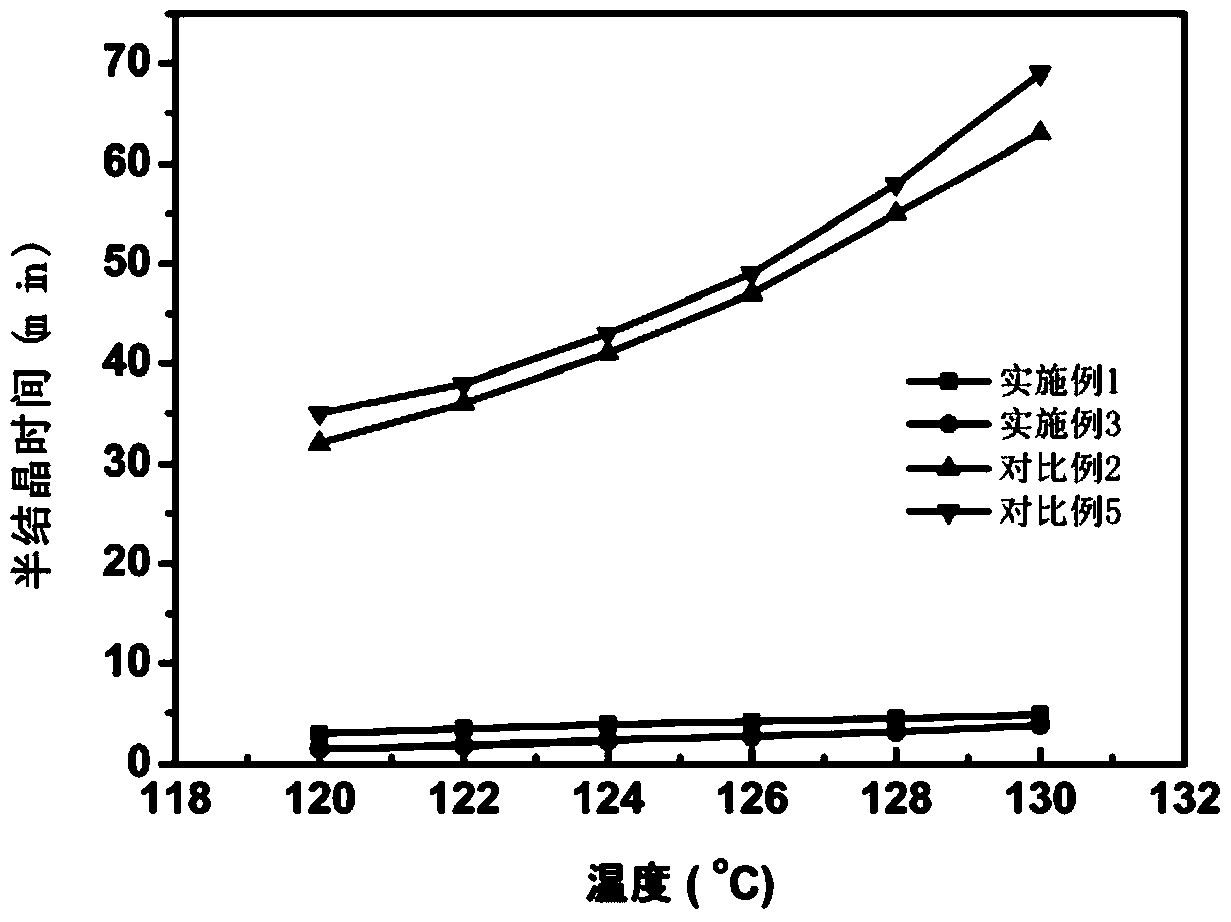

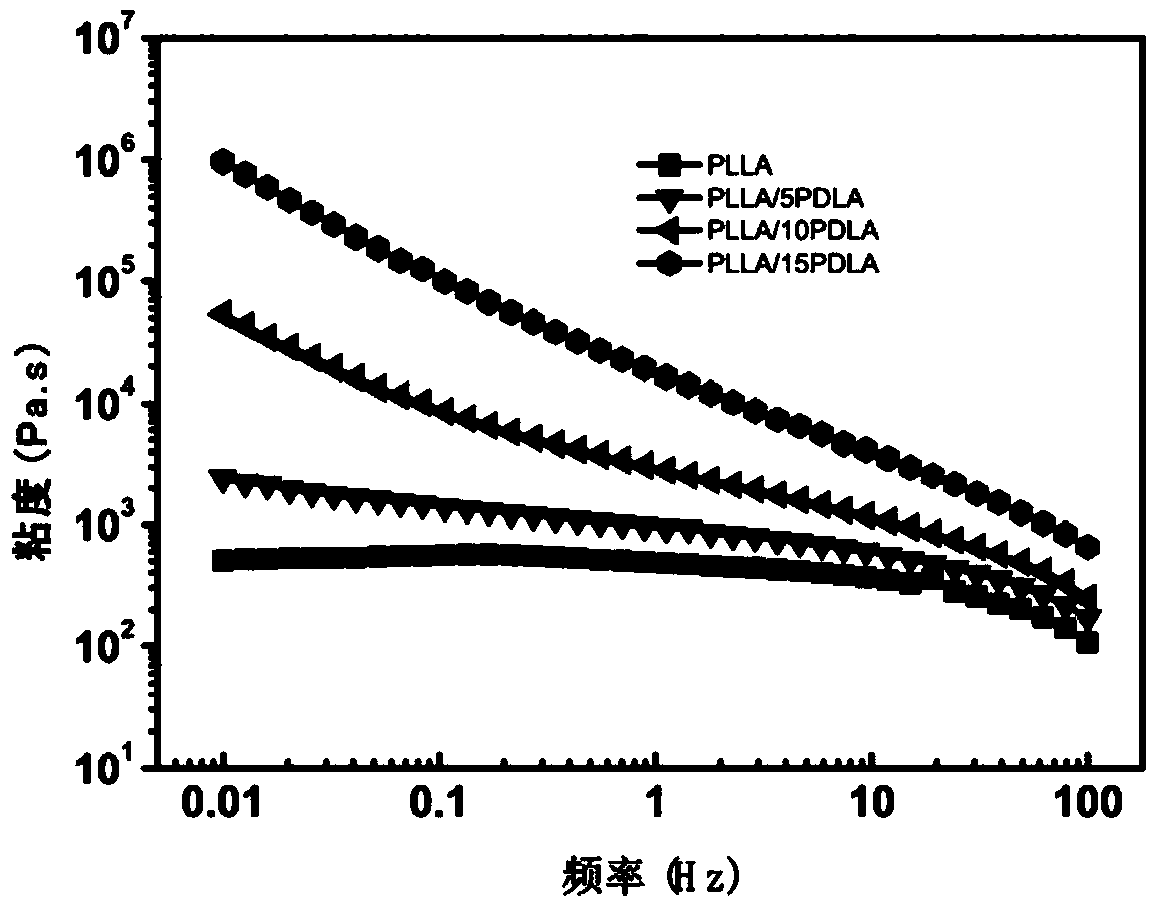

A technology of elastomer and polylactic acid, which is applied in the field of polymer materials and its preparation, can solve problems such as the inability to effectively improve the crystallization rate, poor heat resistance of polylactic acid, and lower operating temperature, so as to increase crystallinity, accelerate matrix crystallization, and improve Effect of Melt Viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First 85 parts of weight average molecular weight of 1.7 × 10 5 g·mol, L-polylactic acid with an optical purity of 98.6% and 15 parts with a molecular weight of 1.2×10 5 g·mol, the third component D-polylactic acid with an optical purity of 99.5% is premixed evenly, and then thermoplastic polyurethane with a weight fraction of 25wt% is added to continue mixing until uniform; Polylactic acid / elastomer blended materials are obtained by granulation after melt mixing, or continue to process the blended materials into products with HAAK MiniJet micro-injection molding machine at 190°C.

Embodiment 2

[0034] First 80 parts of weight average molecular weight of 5.7 × 10 5 g·mol, L-polylactic acid with an optical purity of 99.1% and 20 parts with a molecular weight of 5.2×10 5 g·mol, the third component D-polylactic acid with an optical purity of 99.7% is premixed evenly, and then thermoplastic polyurethane with a weight fraction of 15wt% is added to continue mixing until uniform; Polylactic acid / elastomer blended material is obtained by granulation after melt mixing, or the blended material is processed into products with HAAK MiniJet micro-injection molding machine at 210°C.

Embodiment 3

[0036] First, 75 parts of weight average molecular weight are 5.9×10 4 g·mol, L-polylactic acid with an optical purity of 95% and 25 parts with a molecular weight of 2.5×10 4 g·mol, the third component D-polylactic acid with an optical purity of 97% is premixed uniformly, and then polycaprolactone with a weight fraction of 5wt% is added to continue mixing until uniform; the mixed material is added to the HAAKE internal mixer at Melt and mix at 220°C and then granulate to obtain polylactic acid / elastomer blended material, or continue to process the blended material into products at 220°C with HAAK MiniJet micro injection molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com