Method for preparing cyclohexyl crown ether by catalytic hydrogenation of carbon supported ruthenium catalyst

A ruthenium catalyst, catalytic hydrogenation technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of easy combustion of metal catalysts, large amount of precious metal ruthenium Catalysts are difficult to separate and other problems, to achieve the effect of strong operability of the synthesis process, simple preparation method, and reduced process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing cyclohexyl crown ether by catalytic hydrogenation of a carbon-supported ruthenium catalyst. The preparation method uses benzocrown ether as a raw material, and carries out a catalytic hydrogenation reaction under the action of a carbon-supported ruthenium catalyst to generate the corresponding The cyclohexyl crown ether, its concrete steps are as follows:

[0021] 1) With benzo-12 crown 4, benzo-15 crown 5, benzo-18 crown 6, benzo-21 crown 7, dibenzo-12 crown 4, dibenzo-15 crown 5, dibenzo -18 crown 6, dibenzo-21 crown 7, and one of the methyl, ethyl, isopropyl or tert-butyl substituents of the above-mentioned benzo crown ethers are used as raw materials, with n-butanol, n-octyl At least one of alcohol, ethylene glycol, dichloromethane, chloroform, ethylene dichloride, ethylene glycol monomethyl ether, ethylene glycol dimethyl ether and toluene is used as a reaction solvent, and benzo crown ether is added to dissolved in an...

Embodiment 1

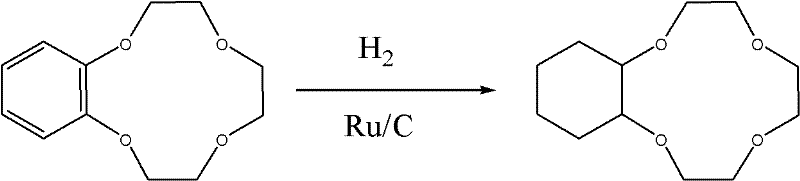

[0026] 1) Preparation of cyclohexyl-12 crown 4

[0027] The reaction equation is as follows:

[0028]

[0029] Using benzo-12 crown 4 as a raw material, n-butanol as a reaction solvent, under the action of a ruthenium catalyst supported by a carbon molecular sieve, the catalytic hydrogenation reaction is carried out under stirring conditions; the loading capacity of the ruthenium catalyst supported by a carbon molecular sieve is 25% , the mass ratio of benzo-12 crown 4 to the catalyst is 1:0.01, the reaction temperature is controlled at 70°C, and the hydrogen pressure is 2MPa. After 24 hours of reaction, the mixture of the reaction product and the catalyst is filtered to remove the catalyst. After the filtrate is concentrated, The obtained product was detected by gas chromatography, wherein the conversion rate of benzo-12 crown 4 reached 94%, and the yield of cyclohexyl-12 crown 4 was 84%.

[0030] 2) The ruthenium catalyst supported by the above-mentioned carbon molecular...

Embodiment 2

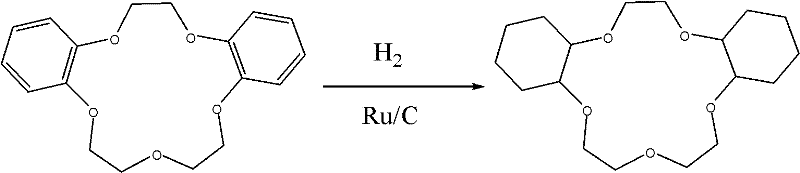

[0033] 1) Preparation of dicyclohexyl-15 crown 5

[0034]The reaction equation is as follows:

[0035]

[0036] Using dibenzo-15 crown 5 as a raw material, n-octanol as a reaction solvent, under the action of a carbon nanotube-supported ruthenium catalyst, the catalytic hydrogenation reaction is carried out under stirring conditions; the loading capacity of the carbon nanotube-supported ruthenium catalyst 10%, the mass ratio of dibenzo-15 crown 5 and catalyst is 1:1, the reaction temperature is controlled at 100° C., and the hydrogen pressure is 10 MPa. After reacting for 2 hours, the reaction product and the catalyst mixture are filtered to remove the catalyst. After the filtrate was concentrated, the obtained product was detected by gas chromatography, wherein the conversion rate of dibenzo-15 crown 5 reached 100%, and the yield of dicyclohexyl-15 crown 5 was 92%.

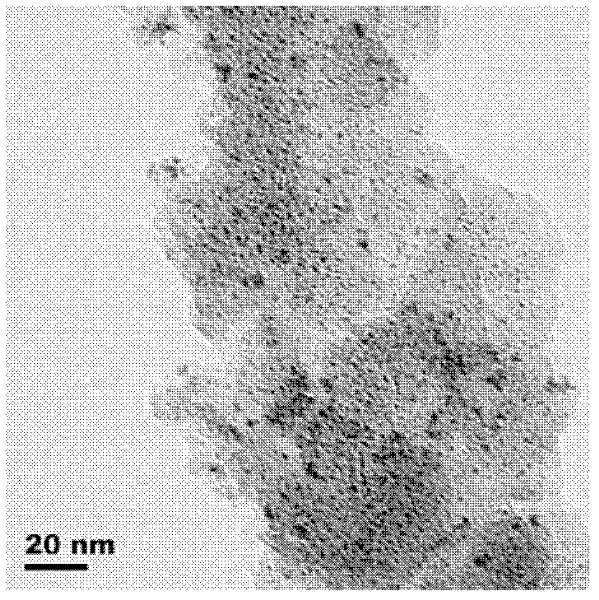

[0037] 2) The ruthenium catalyst supported by the above-mentioned carbon nanotubes is prepared by the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com