Gasification system and technology for efficient heat recovery

A heat recovery and gasification system technology, applied in the gasification process, chemical industry, petroleum industry, etc., can solve the problems of waste pot abrasion, short service life, complex fly ash removal system, etc., and achieve high heat recovery efficiency, The effect of small equipment size and high saturated steam output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

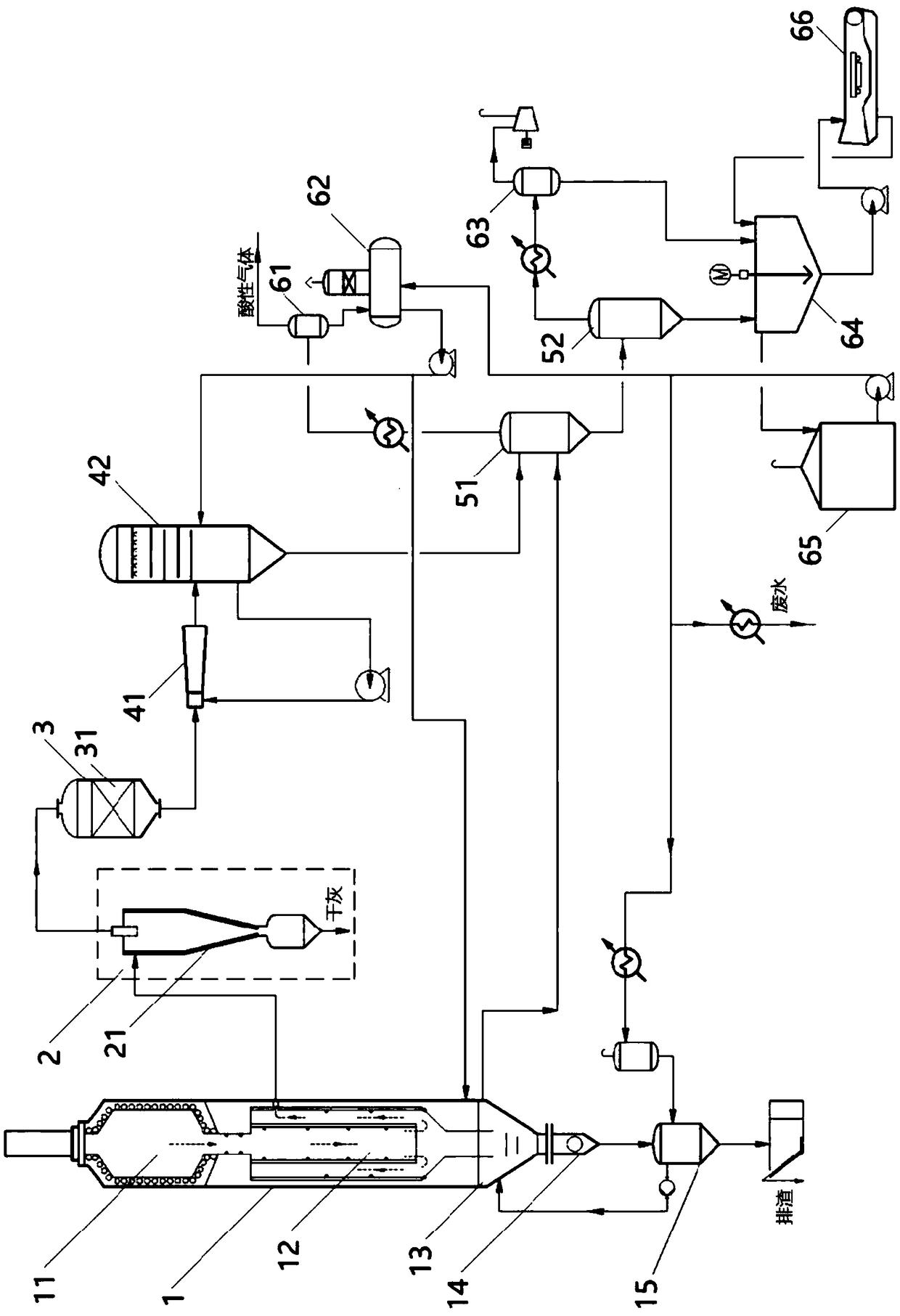

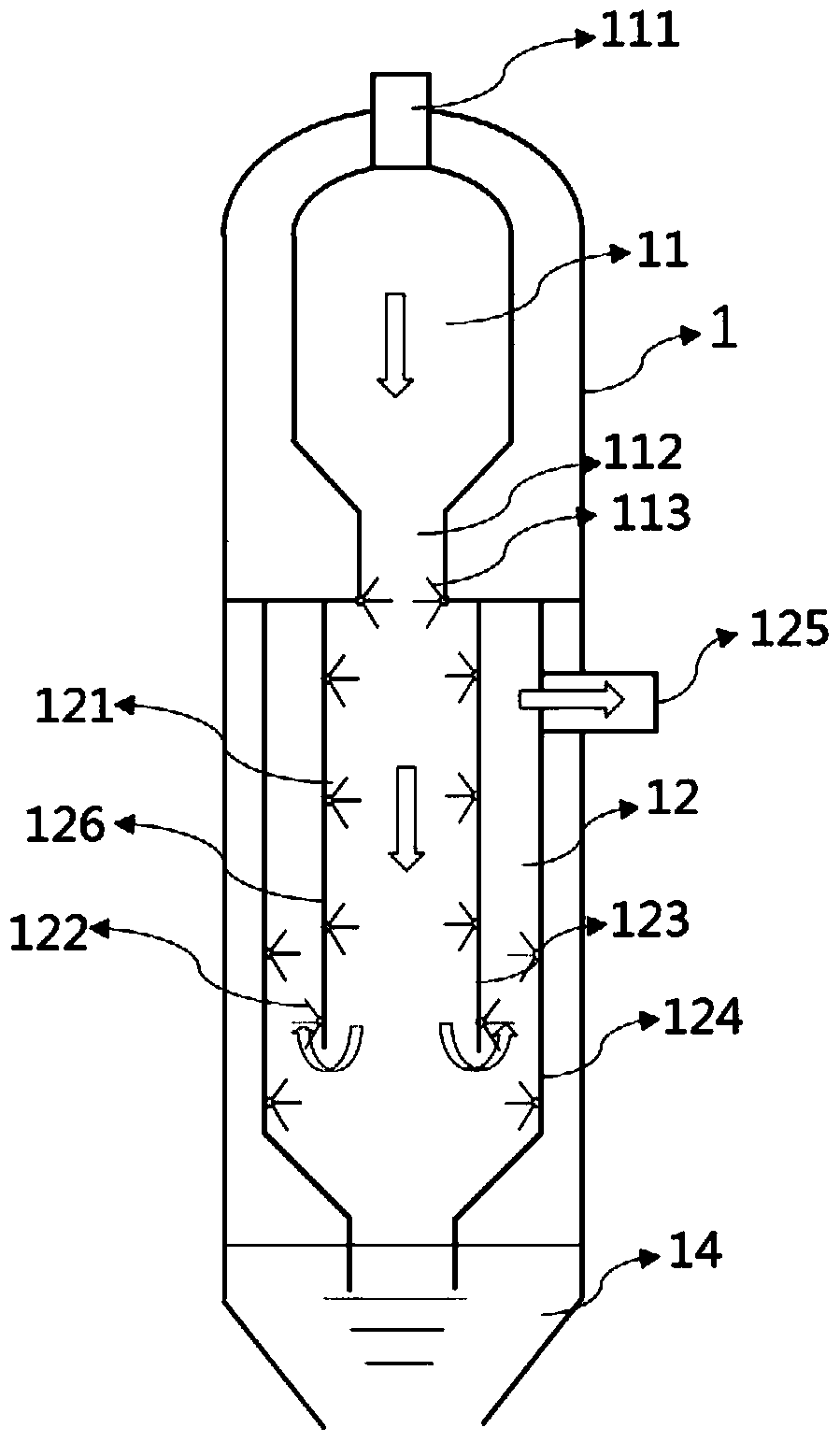

[0043] This embodiment provides a gasification system with high-efficiency heat energy recovery, which can be used to prepare downstream chemical products, such as figure 1 As shown, the gasification system includes: a gasification furnace 1 for preparing syngas and performing radiation heat exchange, and the gasification furnace 1 includes a gasification chamber 11 and a radiation heat exchange chamber 12, described in this embodiment The gasification furnace 1 adopts a structure in which the gasification chamber 11 and the radiation heat exchange chamber 12 are integrated, such as figure 2 shown.

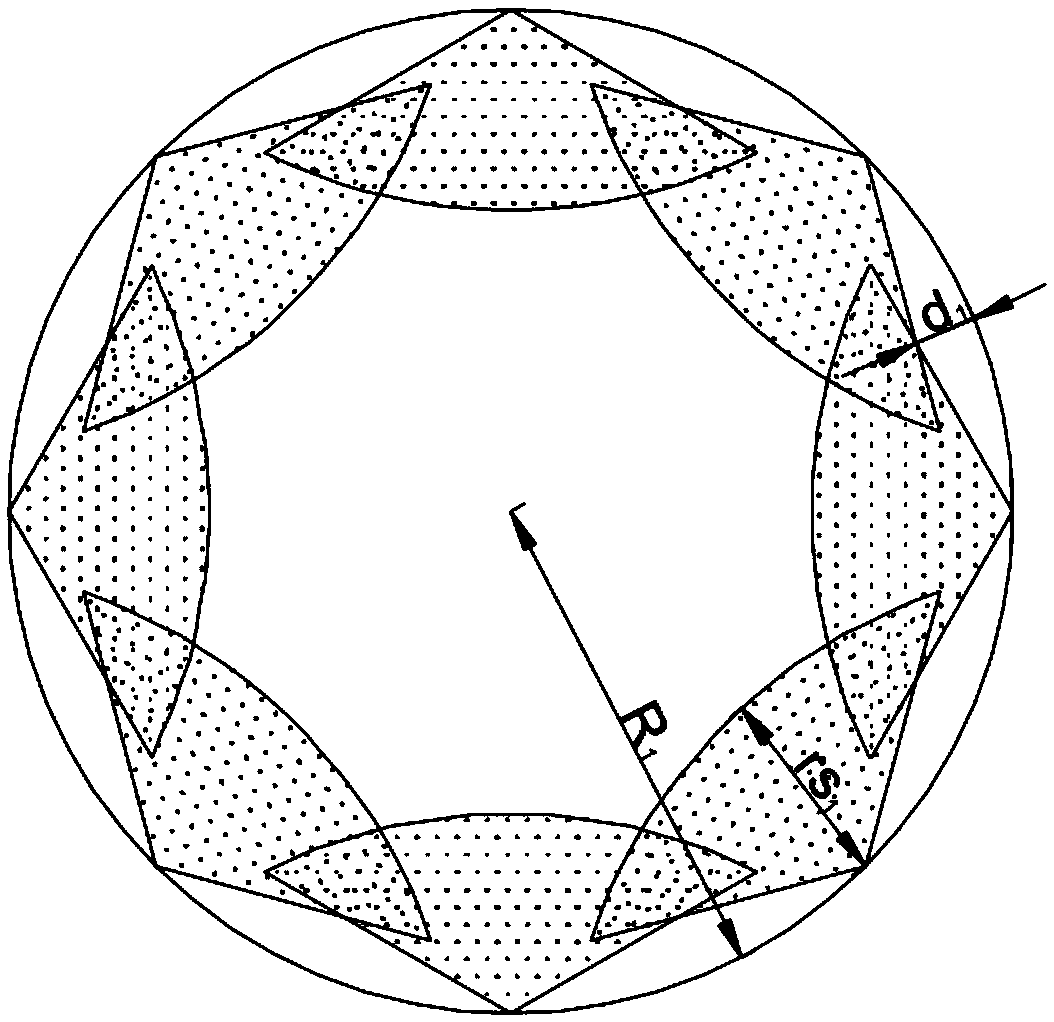

[0044] The radiation heat exchange chamber 12 described in this embodiment is arranged below the gasification chamber 11, and a raw material inlet 111 is arranged on the top of the gasification chamber 11. The radiation heat exchange chamber 12 includes an internal Cylinder 126 and outer cylinder 124; the inner and outer wall surfaces of the inner cylinder 126 and the inner wall...

Embodiment 2

[0064] This embodiment provides a high-efficiency heat energy recovery gasification system, which can be used to prepare downstream fuel gas or IGCC products, such as Figure 5 As shown, the gasification system includes:

[0065] A gasifier 1 for preparing syngas and performing radiative heat exchange, the gasifier 1 described in this embodiment is the same as that in Embodiment 1.

[0066] The gas-solid separation and cooling ash equipment 2 is arranged in communication with the synthesis gas outlet of the gasifier 1; the gas-solid separation and cooling equipment in this embodiment includes a cyclone separator 21, and this embodiment adopts a two-stage cyclone configuration, The particle size of fly ash in syngas can be controlled to be ≤1μm.

[0067] The convective heat exchange device 3 communicates with the gas outlet of the cyclone separator 21, and is used to recover the sensible heat of the synthesis gas and generate power steam; the convective heat exchange device 3 ...

experiment example

[0077] The process system in this application can effectively recover the high-temperature heat energy in the syngas, with (CO+H 2 ) with an output of 100,000Nm 3 / h, the average reaction temperature in the gasification chamber 11 is 1400 DEG C, and the annual operation time is 8000 hours as the basis for estimating the production value in Example 1 and Example 2, the results are shown in the table below:

[0078]

[0079] Note: The price of 10MPag power steam is calculated at 120 yuan / ton, and the price of circulating cooling water is calculated at 0.1 yuan / ton.

[0080] It can be seen from the above table that the ratio of high-temperature sensible heat in the syngas converted to 10.0 MPag grade power steam can reach 50-70%. This process can produce 10.0MPag grade power steam 50-65 tons / h (non-chemical product scheme is 70-80 tons / h), and the annual output value is 48.62-63.02 million yuan (non-chemical product scheme is 67.78-77.38 million yuan) At the same time, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com