Fuel cell system

A fuel cell system, fuel cell technology, applied in the direction of fuel cell, fuel cell application, fuel cell integration, etc., can solve the problem of large size of fuel cell system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

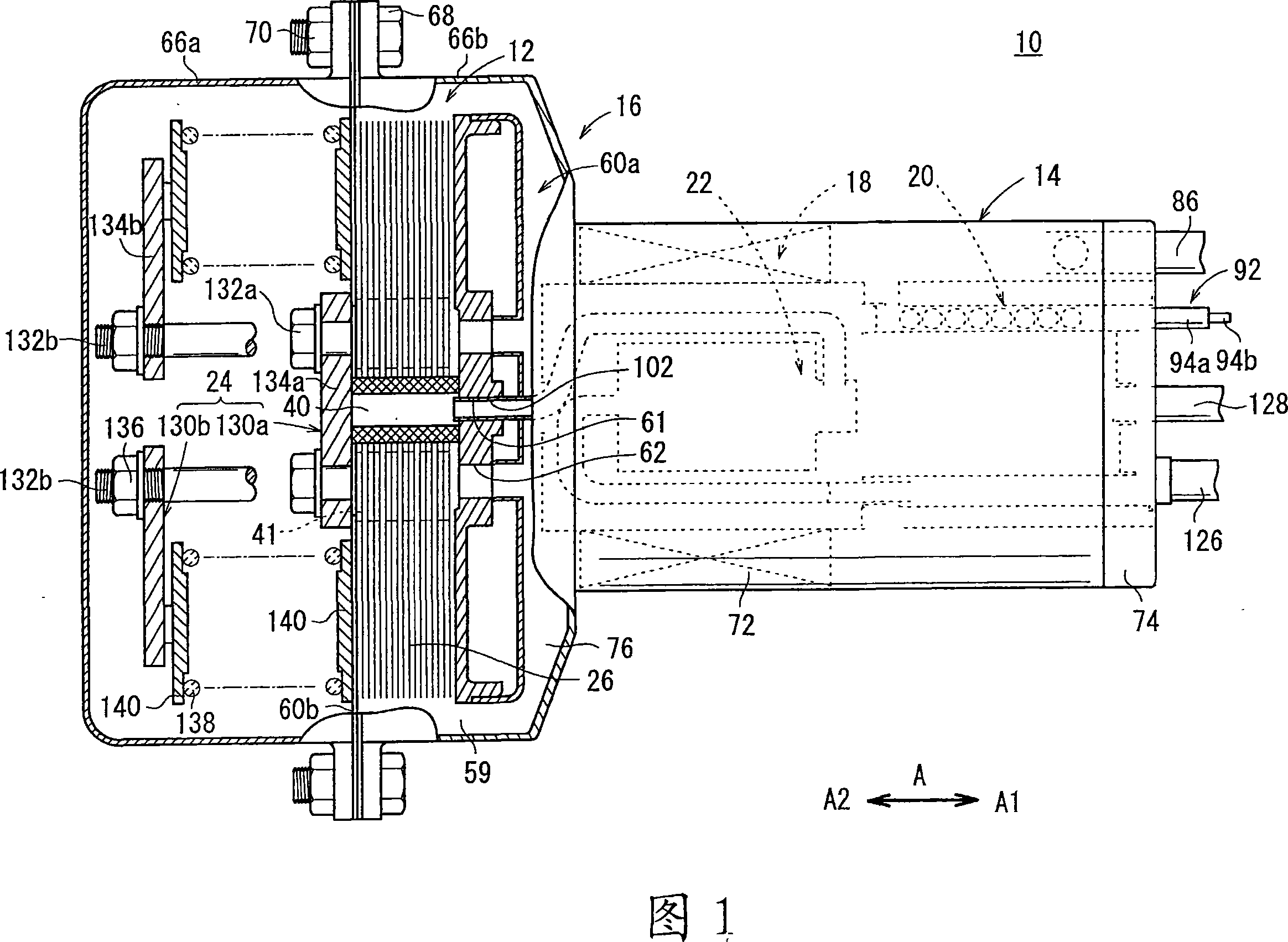

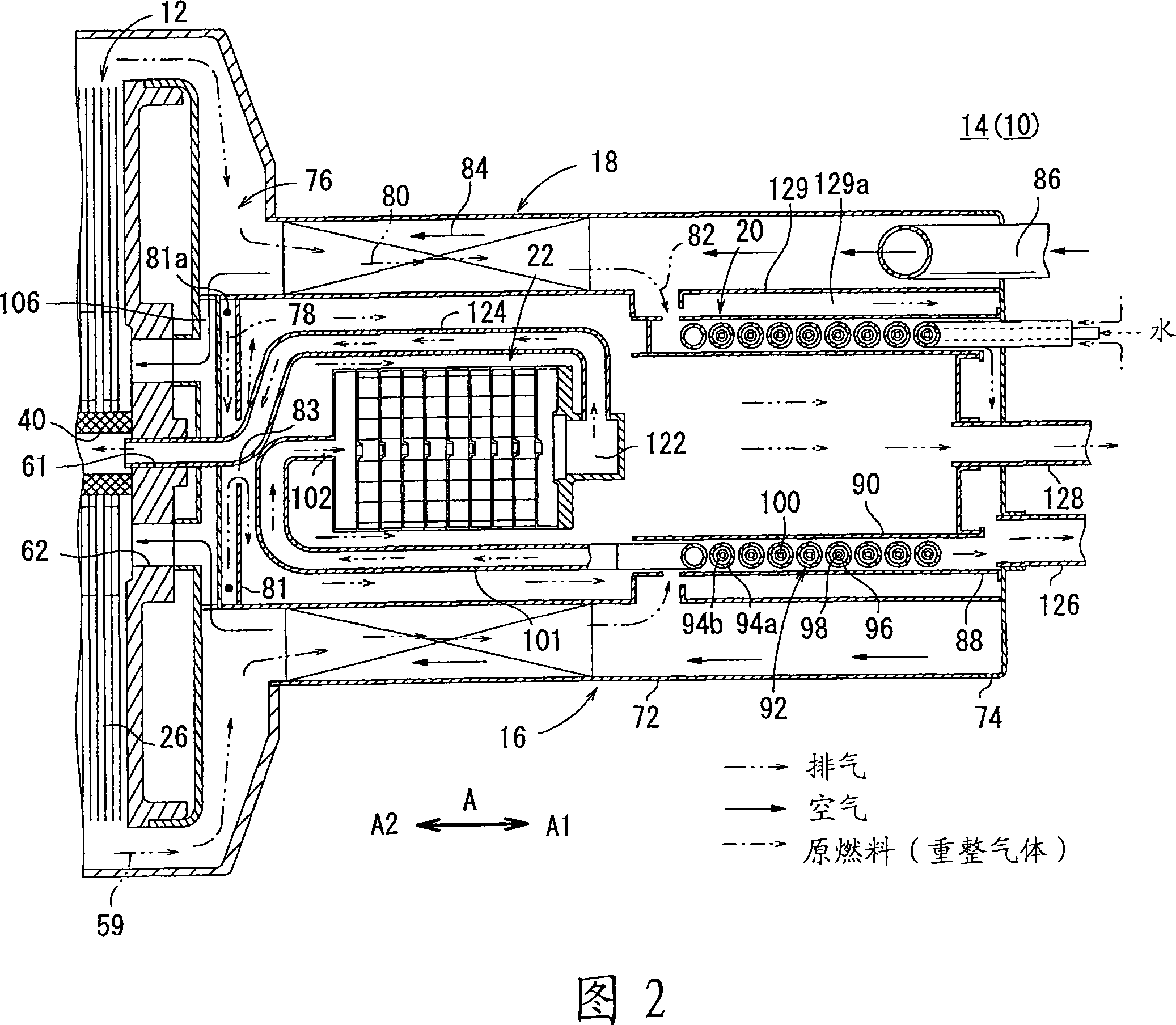

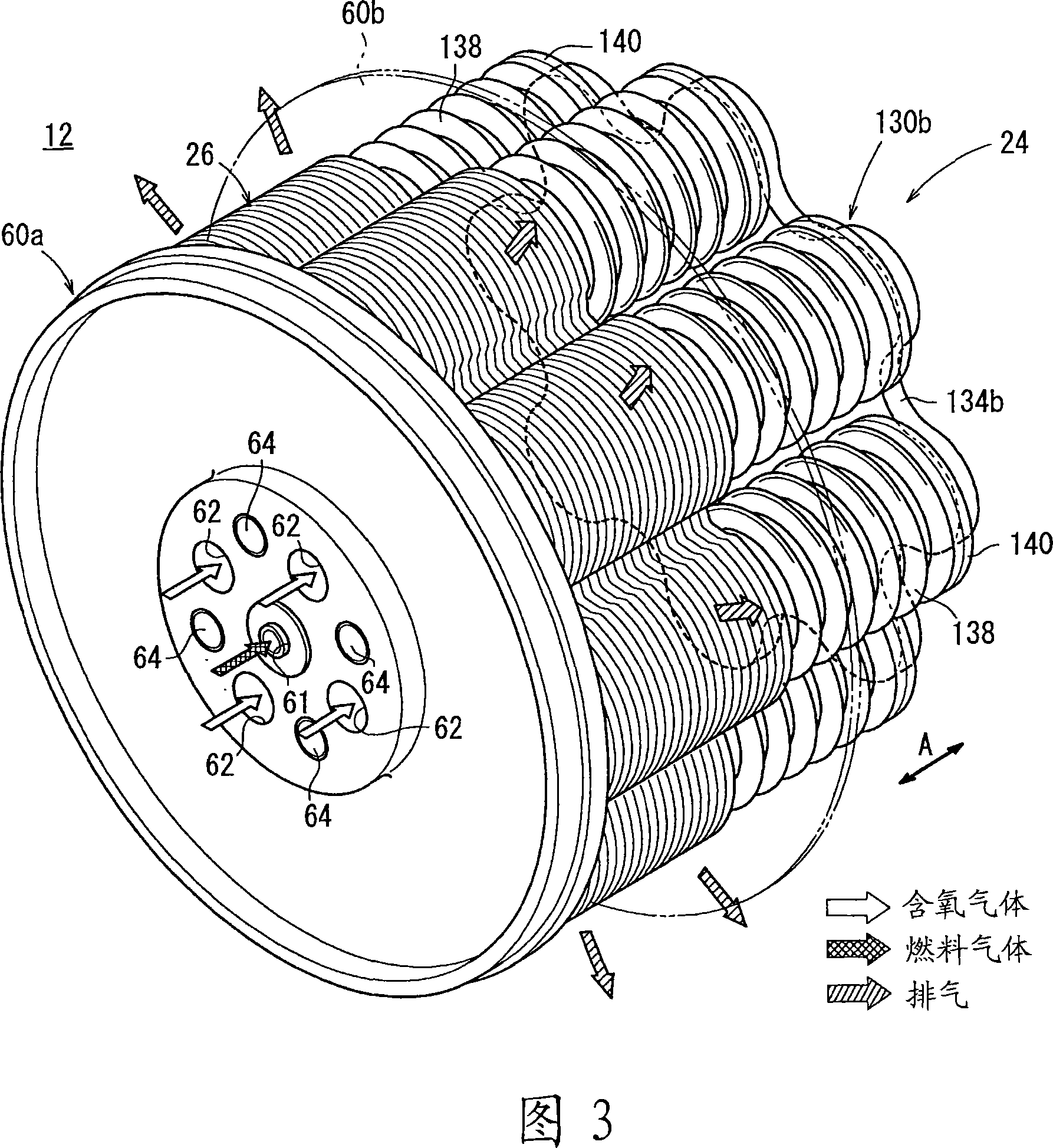

[0027] The fuel cell system 10 is used in a variety of applications, including stationary and mobile applications. For example, the fuel cell system 10 is mounted on a vehicle. As shown in FIG. 1 , the fuel cell system 10 includes a fuel cell stack 12 , a fluid unit 14 disposed on one side of the fuel cell stack 12 , and a case 16 that accommodates the fuel cell stack 12 and the fluid unit 14 .

[0028] As shown in FIGS. 1 and 2 , the fluid unit 14 includes a heat exchanger 18 for heating the oxygen-containing gas before it is supplied to the fuel cell stack 12 , for evaporating water to produce a primarily hydrocarbon-containing raw fuel (e.g. , city gas) and steam mixed fuel evaporator 20 and reformer 22 for reforming the mixed fuel to produce reformed gas.

[0029] Reformer 22 is used to use high carbon (C 2+ ) hydrocarbons (such as ethane (C 2 h 6 ), propane (C 3 h 6 ) and butane (C 4 h 10 )) by steam reforming to produce mainly methane (CH 4 ) primary reformer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com