Recovery system and method for desulfurizing agent in desulfurized gas of catalytic-cracking regeneration waste gas

A catalytic cracking and exhaust gas desulfurization technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as high probability of gas condensation, blockage of pipelines and equipment, pollution, etc., to achieve less environmental pollution and reduce emissions Loss, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

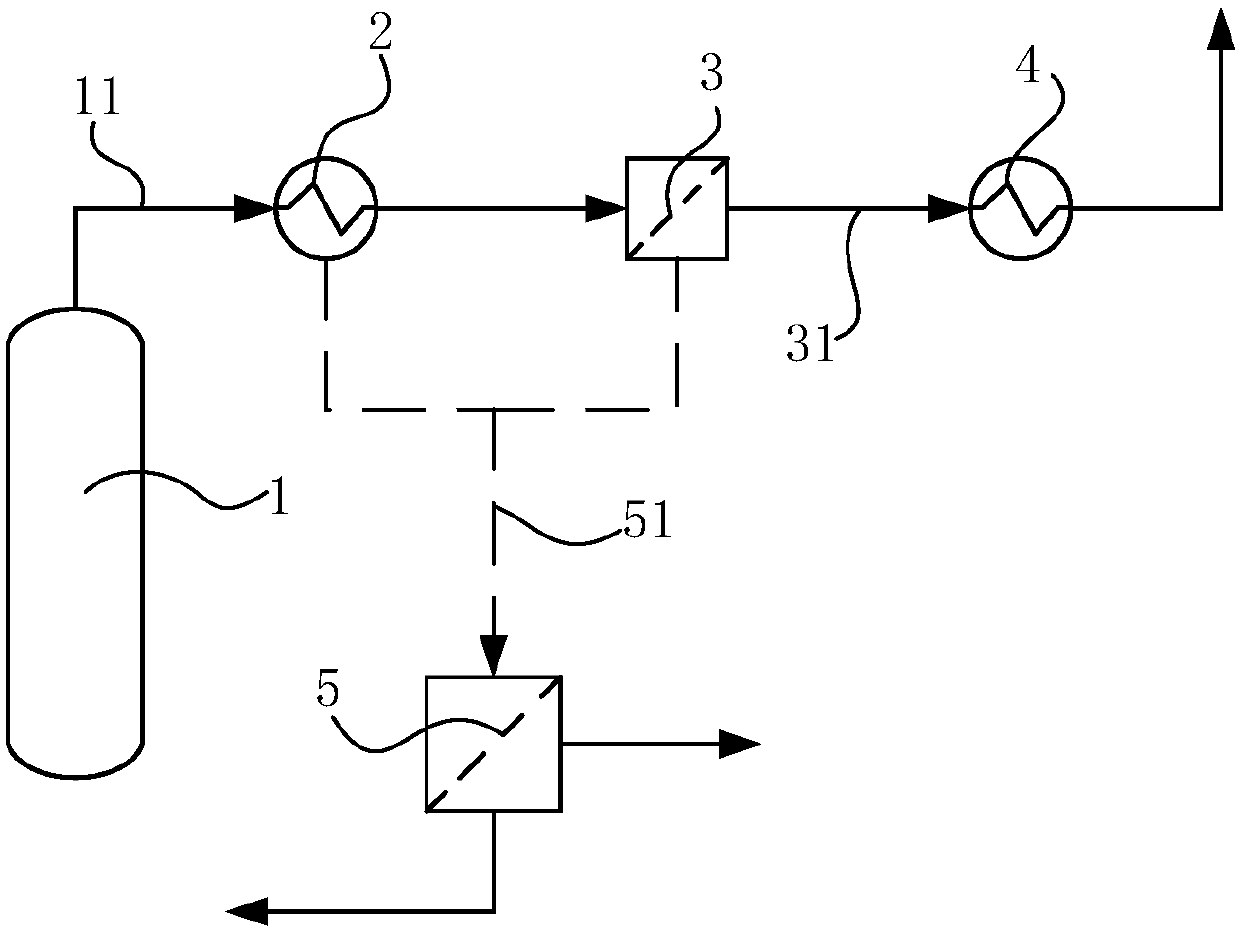

Embodiment 1

[0055] 30000m 3 / h Catalytic cracking regenerated exhaust gas, after desulfurization through the desulfurization tower by sodium alkali method, the obtained desulfurized gas has a temperature of 50-55°C, and is cooled by 3°C through a condensing heat exchanger to obtain a cooled gas with a temperature of 47-52°C. The cooling gas passes through a screen-type mechanical separation purifier to separate the liquid droplets and solid particles in the cooling gas to obtain purified gas; the slurry separated from the cooling gas and the condensed water generated by the condensing heat exchanger form a slurry together, The filtered filtrate containing desulfurization agent is returned to the desulfurization tower for further use. The purified gas finally enters the heating heat exchanger for heating, and is discharged after the temperature rises by 5°C. The condensing heat exchanger is a plate-fin heat exchanger made of titanium alloy, and the windward side of the plate-fin heat exch...

Embodiment 2

[0057] 50000m 3 / h Catalytic cracking regenerated exhaust gas, after desulfurization through the desulfurization tower by calcium method, the obtained desulfurized gas temperature is 50-55°C, cooled by 20°C through the condensing heat exchanger to obtain the cooling gas with a temperature of 30-35°C. The cooling gas passes through a screen-type mechanical separation purifier to separate the liquid droplets and solid particles in the cooling gas to obtain purified gas; the slurry separated from the cooling gas and the condensed water generated by the condensing heat exchanger form a slurry together, The filtered filtrate containing desulfurization agent is returned to the desulfurization tower for further use. The purified gas finally enters the heating heat exchanger for heating, and is discharged after the temperature rises to 40°C. The condensing heat exchanger is a plate-fin heat exchanger made of duplex stainless steel, and there are ceramic sheets on the windward side of...

Embodiment 3

[0059] 50000m 3 / h Catalytic cracking regenerated exhaust gas, after desulfurization treatment through the desulfurization tower by ammonia method, the obtained desulfurized gas has a temperature of 70-80°C, and is cooled by 40°C through a condensing heat exchanger to obtain a cooled gas with a temperature of 30-40°C. The cooling gas is passed through a grid-type mechanical separation purifier to separate the liquid droplets and solid particles in the cooling gas to obtain purified gas; the slurry separated from the cooling gas and the condensed water generated by the condensing heat exchanger form a slurry together. The filtered filtrate containing desulfurization agent is returned to the desulfurization tower for further use. The purified gas finally enters the heating heat exchanger for heating, and is discharged after the temperature rises to 45°C. The condensing heat exchanger is a plate heat exchanger made of austenitic stainless steel, with enamel sheets on the windwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com