Vacuum perfuming method and equipment for cut tobacco

A shredded tobacco and vacuum technology, applied in tobacco, tobacco preparation, application, etc., to achieve the effects of reducing pollution, improving uniformity, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

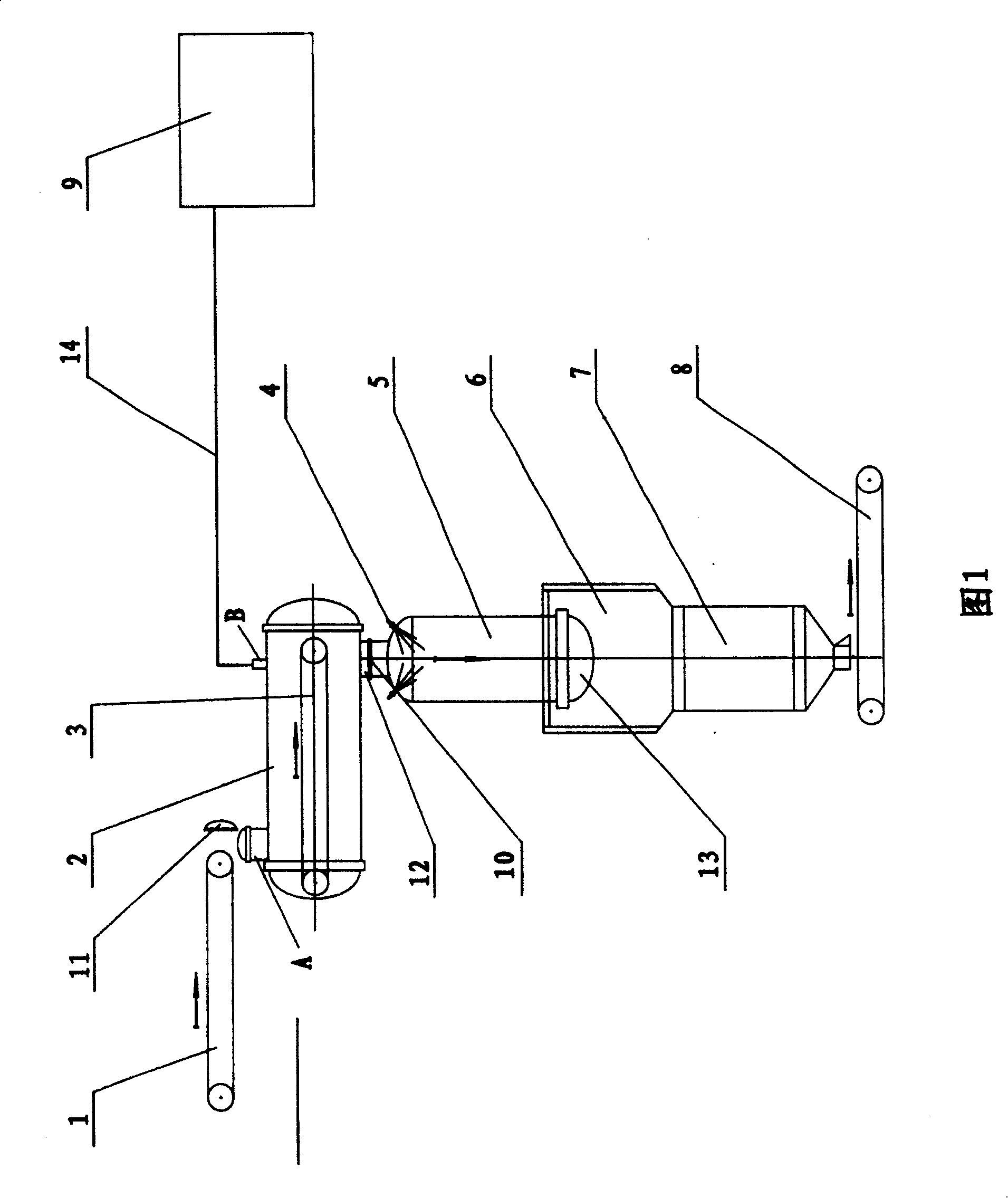

[0016] The vacuum flavoring method for shredded tobacco of the present invention is to use the principle of negative pressure to separate out the air and part of the moisture in the shredded tobacco cells in the shredded tobacco flavoring equipment, and then increase the aroma content of the shredded tobacco by spraying atomized spice liquid, and pass the air in the shredded tobacco Negative pressure draws the atomized spice liquid on the surface of the shredded tobacco into the cells, so that the inside and outside of the shredded tobacco is uniformly infiltrated with the flavor liquid. The specific process steps are as follows: step 1, firstly, the mixed shredded tobacco from the silk-making line, that is, the shredded tobacco to be flavored, is sent into the first negative pressure container through the double-speed conveyor belt conveyor 1 through the opened feeding port A on the first negative pressure container. Pressure container 2, and evenly distributed on the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com