Device and method for treating carbon black tail gas and application of tail gas

A technology for exhaust gas treatment and carbon black, which is applied in the directions of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of ineffective utilization of heat sources, incomplete combustion of exhaust gas, corrosion of equipment and pipelines, etc., and achieve continuous and stable operation cycle of the device. Longer, higher quality and less corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

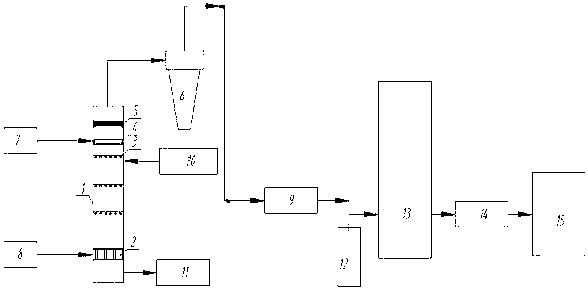

[0025] Such as figure 1 As shown, a carbon black tail gas dehydration device is provided with a carbon black tail gas pressurization fan 8, a dehydration tower 1, a cyclone separator 6, a Roots blower 9, a water seal 12, a gas cabinet 13, and a pressure discharge machine in sequence according to the flow direction of the tail gas. 14 and the coke oven device 15, according to the direction of water flow, a spray water pump 7, a liquid distributor 4, a gas-liquid distributor 3, and a circulating water cooling system 11 are arranged in sequence, and the dehydration tower 1 includes a demister 5, Liquid distributor 4, gas-liquid distributor 3 and gas initial distributor 2; carbon black tail gas pressurization fan 8 is connected with gas initial distributor 2 at the lower part of dehydration tower 1, spray water pump 7 is connected with liquid distributor 4, circulating water The cooling system 11 includes a cooling tower and a cooling pool. The inlet end of the cooling tower is co...

Embodiment 2

[0027] A carbon black tail gas treatment method and application process, comprising the following main steps:

[0028] (1) Turn on the carbon black tail gas pressurization fan 8 and spray water pump 7, the high temperature carbon black tail gas passes through the initial gas distributor 2 and the spray water distributed through the liquid distributor 4 for heat and mass transfer, and the carbon black tail gas after dehydration Enter the cyclone separator 6 through the demister 5, the inlet pressure of the carbon black tail gas of the dehydration tower is 2.5kPa, the outlet pressure of the carbon black tail gas of the dehydration tower is 0.5kPa, the outlet temperature of the spray water pump is 29°C, and the outlet pressure of the spray water pump is 0.3MPa , the outlet water temperature of the dehydration tower is 38°C, and the liquid level of the dehydration tower is 1400mm;

[0029] (2) Start the cyclone separator 6 to remove carbon black dust and water droplets;

[0030] ...

Embodiment 3

[0036] A carbon black dehydration process comprises the following main steps:

[0037] (1) Turn on the carbon black tail gas pressurization fan 8 and the spray water pump 7, and the high-temperature carbon black tail gas passes through the initial gas distributor 2 and the spray water distributed through the liquid inlet distribution device 4 for heat and mass transfer, and the dehydrated carbon black The tail gas enters the cyclone separator 6 through the demister 5, the inlet pressure of the carbon black tail gas of the dehydration tower is 3.5kPa, the outlet pressure of the carbon black tail gas of the dehydration tower is 1.5kPa, the outlet temperature of the spray water pump is 33°C, and the outlet pressure of the spray water pump is 0.4 MPa, the outlet water temperature of the dehydration tower is 42°C, and the liquid level of the dehydration tower is 1600mm;

[0038](2) Start the cyclone separator 6 to remove carbon black dust and water droplets;

[0039] (3) Adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com