Improved device for cool drying

A technology of cold drying and equipment, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of complexity, heavy cooling circuit manufacturing, time-consuming assembly, etc., and achieve multi-energy, simple and energy-saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

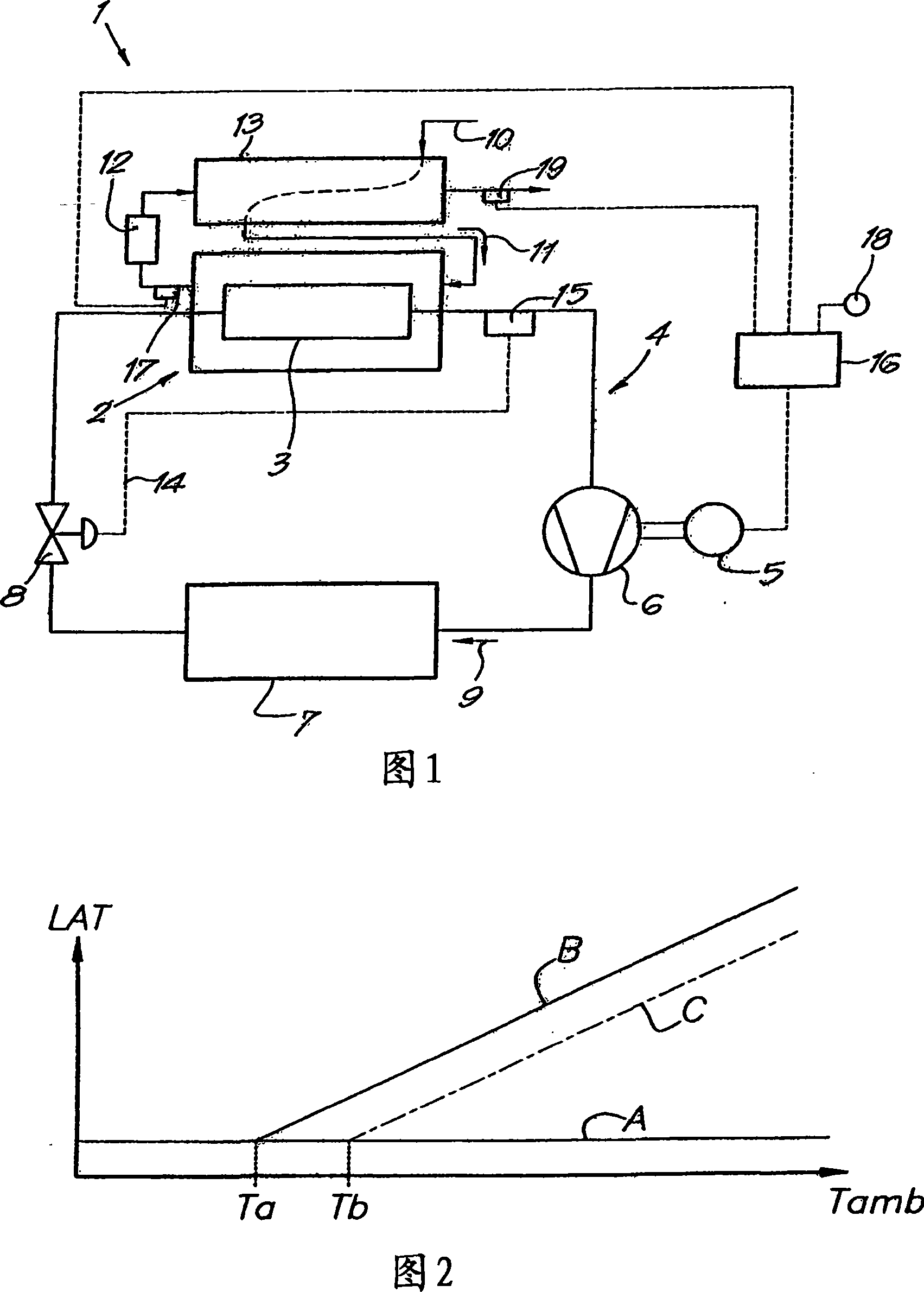

[0028] Figure 1 shows a device 1 for cold drying, which mainly consists of a heat exchanger 2, the first part of which forms an evaporator 3 of a cooling circuit 4, in which a motor driven by an electric motor 5 is also arranged in succession. Compressor 6, condenser 7 and expansion device 8.

[0029] The cooling circuit is filled with a cooling fluid, for example Freon R410a, the flow direction of which is indicated by arrow 9 .

[0030] The second part of the heat exchanger 2 is a part of the tube 10 for the moist air to be dried, the flow direction of which is indicated by the arrow 11 .

[0031] After the heat exchanger 2 , ie at its outlet, a liquid separator 12 is arranged in the tube 10 .

[0032] This pipe 10 may extend partly through a precooler or recuperator 13 before reaching the heat exchanger 2, and then, after the liquid separator 12, again through the recuperator 13, with the aforementioned part parallel or opposite flow.

[0033] The outlet of the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com