Device and method of low temperature separation dehydration of gas field well mouth

A technology of separation and dehydration and low-temperature separator, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., and can solve the problems of unutilized energy, complex process equipment, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

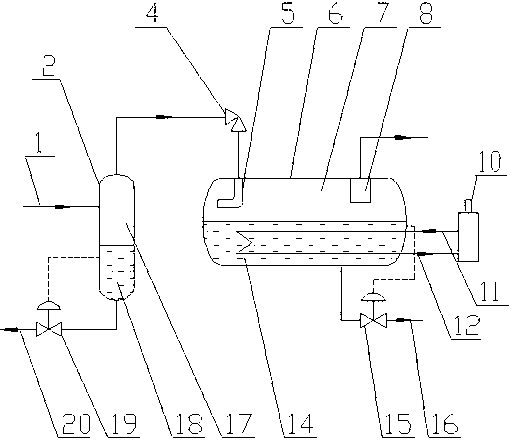

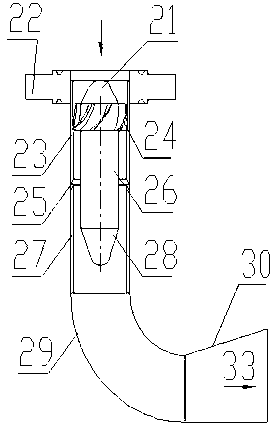

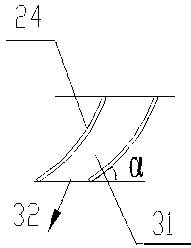

[0022] A gas field wellhead low-temperature separation and dehydration device, such as figure 1 As shown, it includes: free water separator 2, throttle valve 4, primary cyclone separation device 5, low temperature separator 6, gas phase zone of low temperature separator 7, combined separation element 8 at the outlet of low temperature separator, hot water boiler 10. Hot water boiler outlet pipeline 11, hot water boiler return pipeline 12, low temperature separator liquid phase area 14, free water separator gas phase space 17, free water separator liquid phase space 18, etc., among which:

[0023] The free water separator 2 is divided into an upper gas phase space 17 and a bottom liquid phase space 18, wherein the liquid phase space 18 is connected to the free water separator drain line 20, and the free water separator drain valve 19 is arranged on the line 20 The gas phase space 17 is connected with the low-temperature separator 6 through the natural gas pipeline, and on the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com