Aluminum alloy casting method

A technology of aluminum alloy and molten liquid, which is applied in the field of aluminum alloy melting and casting, can solve the problems of hot pressing sintering method, such as difficult demoulding, high price, and low service life of the mold, so as to ensure uniform degassing effect, reduce production cost, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The performance (especially the purity) of the aluminum alloy obtained by the method for producing aluminum alloy in the prior art is relatively poor, and the cost is relatively high.

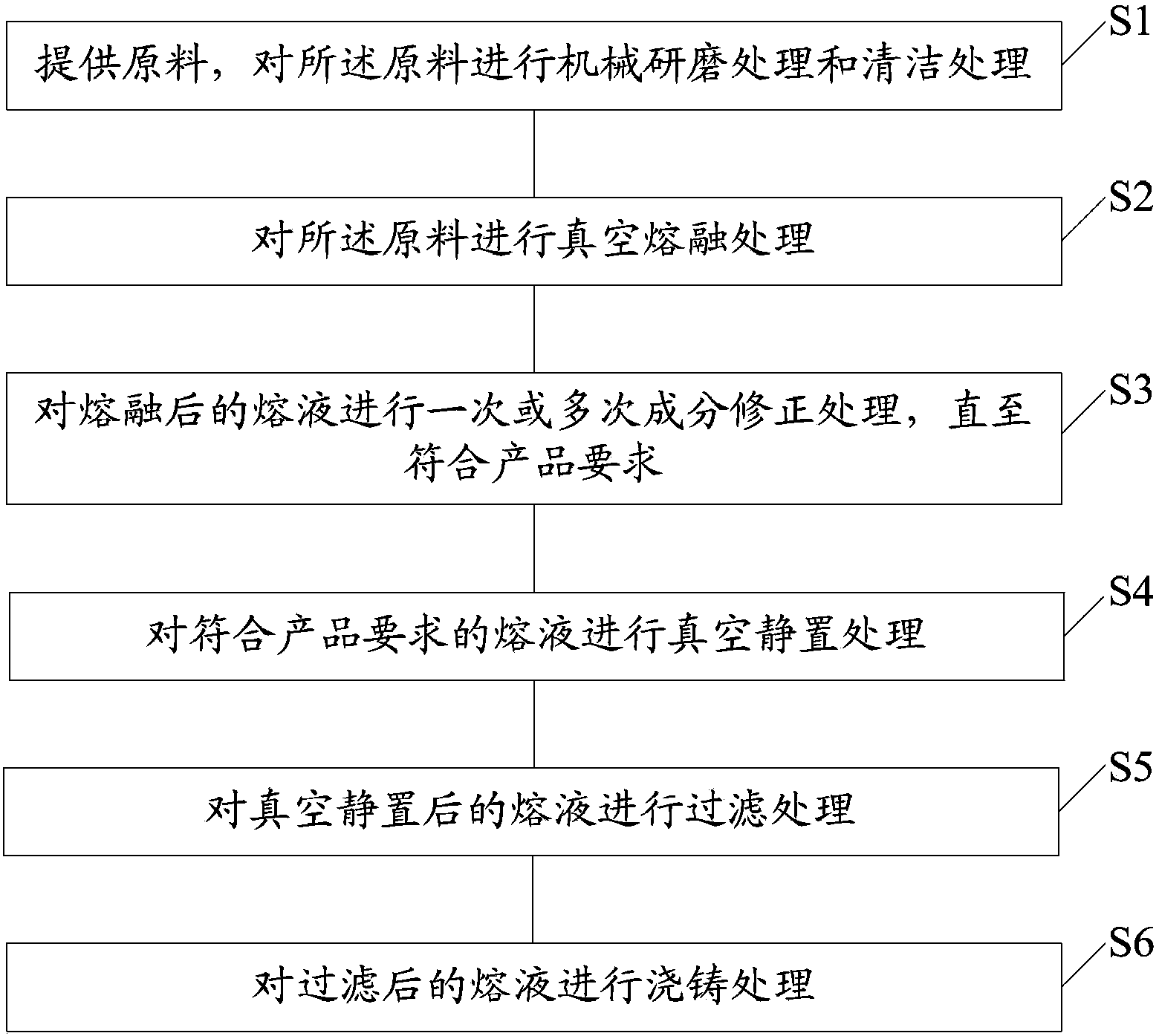

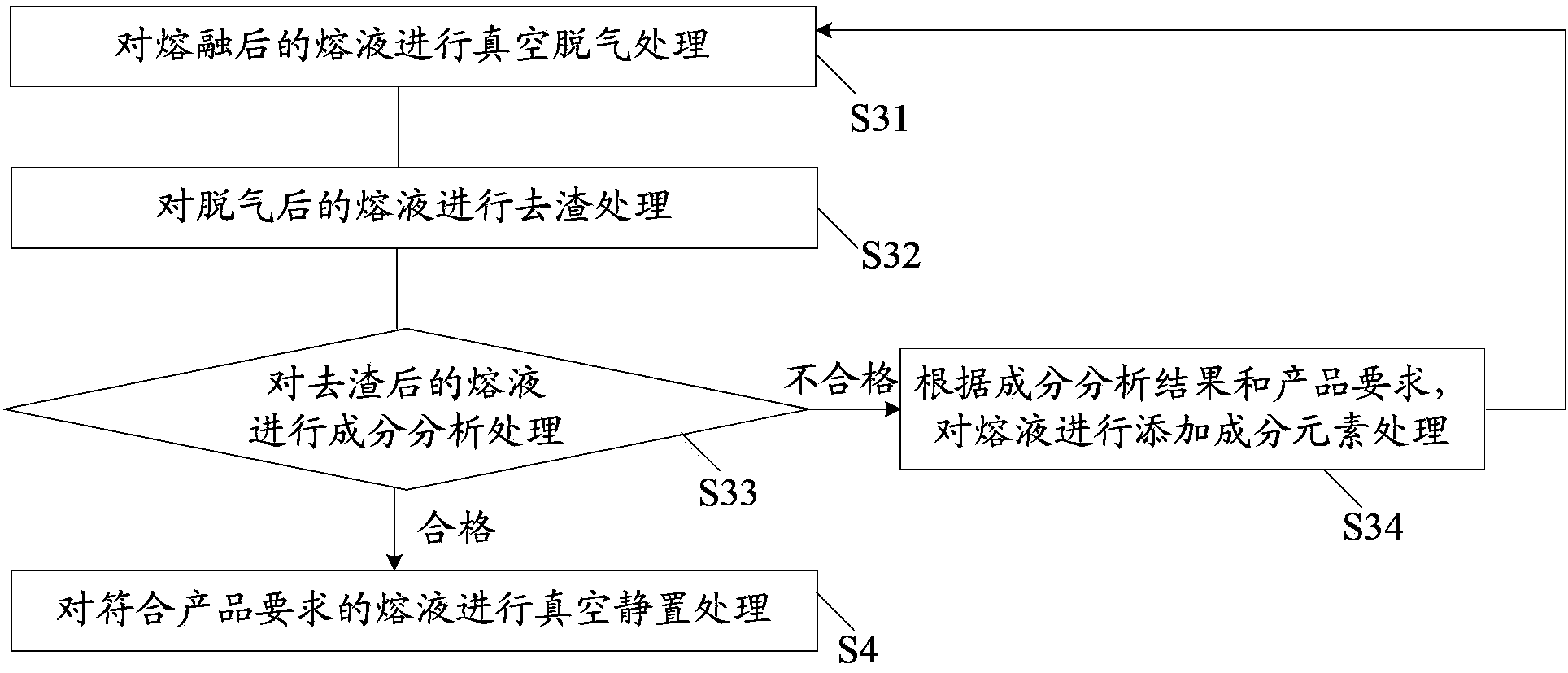

[0036] In view of the above-mentioned defects, the present invention provides a casting method of aluminum alloy. Firstly, the raw materials are subjected to vacuum melting treatment, and then the melted solution is subjected to one or more component correction treatments until the product requirements are met, and then Vacuum static treatment is performed on the melt, and the vacuum static melt is filtered and casted, so that the performance of the aluminum alloy can be improved, the production cost can be reduced, and the production efficiency can be improved.

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com