Reinforcement and concentration type cyclone pulverized coal burner

A pulverized coal burner, concentrated type technology, which is applied to burners, burners burning pulverized fuels, combustion types, etc., can solve the problems of the swirl burner's ability to reduce emissions, disadvantage, and weaken the staging combustion effect of rich and lean fuels. , to achieve the effect of inhibiting the formation of NOx and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

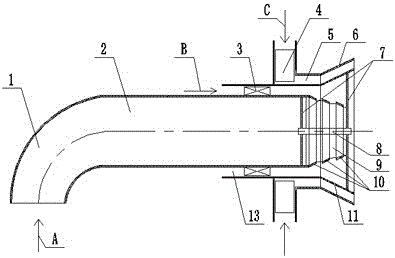

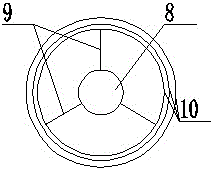

[0024] Such as figure 1 As shown, the present invention includes a primary air channel 2, an inner secondary air channel 13, and an outer secondary air channel 5 arranged coaxially from the inside to the outside, and an inner secondary air cyclone is arranged in the inner secondary air channel 13 3. An external secondary air cyclone 4 is provided in the external secondary air passage 5, the internal secondary air cyclone 3 and the external secondary air cyclone 4, one of which is a tangential cyclone, and the other One is an axial swirler; a primary air nozzle is provided at the outlet end of the primary air passage 2, an inner secondary air nozzle 11 is provided at the outlet end of the inner secondary air passage 13, and an inner secondary air nozzle 11 is provided at the outlet end of the outer secondary air passage 5. An outer secondary air nozzle 6 is provided, and the inner secondary air nozzle 11 and the outer secondary air nozzle 6 are conically flared, and the inner d...

specific Embodiment 2

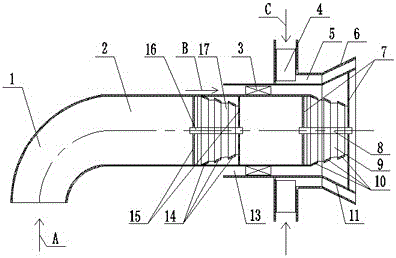

[0026] Such as image 3 As shown, in the primary air channel 2 of the swirl pulverized coal burner described in the specific embodiment 1, a conical pulverized coal concentrator is coaxially arranged, and the conical pulverized coal concentrator includes a second central axis 16, the The two ends of the second central axis 16 are respectively fixed on the inner wall of the primary air passage 2 through a plurality of fixing steel bars 15, and a plurality of second support plates 17 are evenly arranged around the circumferential direction of the second central axis 16, and along the second central axis 16 The axial direction is the length direction of the second support plate 17, the radial direction along the second central axis 16 is the height direction of the second support plate 17, the outer edge of the second support plate 17 is to the second central axis 16 The distance is the height of the second support plate 17, the distance from the outer edge of the second support ...

specific Embodiment 3

[0027] Such as Figure 4 As shown, in the primary air channel 2 of the swirl pulverized coal burner described in the specific embodiment 2, a concentrated pulverized coal airflow separation pipe 18 is coaxially arranged, and the concentrated pulverized coal airflow separation pipe 18 is located in the conical pulverized coal concentrator Between the primary air nozzle, the inner diameter of the dense pulverized coal air separation pipe 18 is equal to the minimum inner diameter of one or more stages of conical rings 14; further, one end of the dense pulverized coal air separation pipe 18 can also be connected to Shaped pulverized coal concentrator is connected, the other end of thick coal pulverized air flow separation pipe 18 is provided with interval between the primary air spout. The setting of the dense pulverized coal air flow separation pipe 18 can make the pulverized coal air flow passing through the conical pulverized coal concentrator continue to run forward to the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com