Method of applying atomic layer deposition coatings onto porous non-ceramic substrates

A non-ceramic, substrate-based technology for flow-through atomic layer deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0044] Objects and advantages of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention.

[0045] Method for measuring the surface energy of a sample

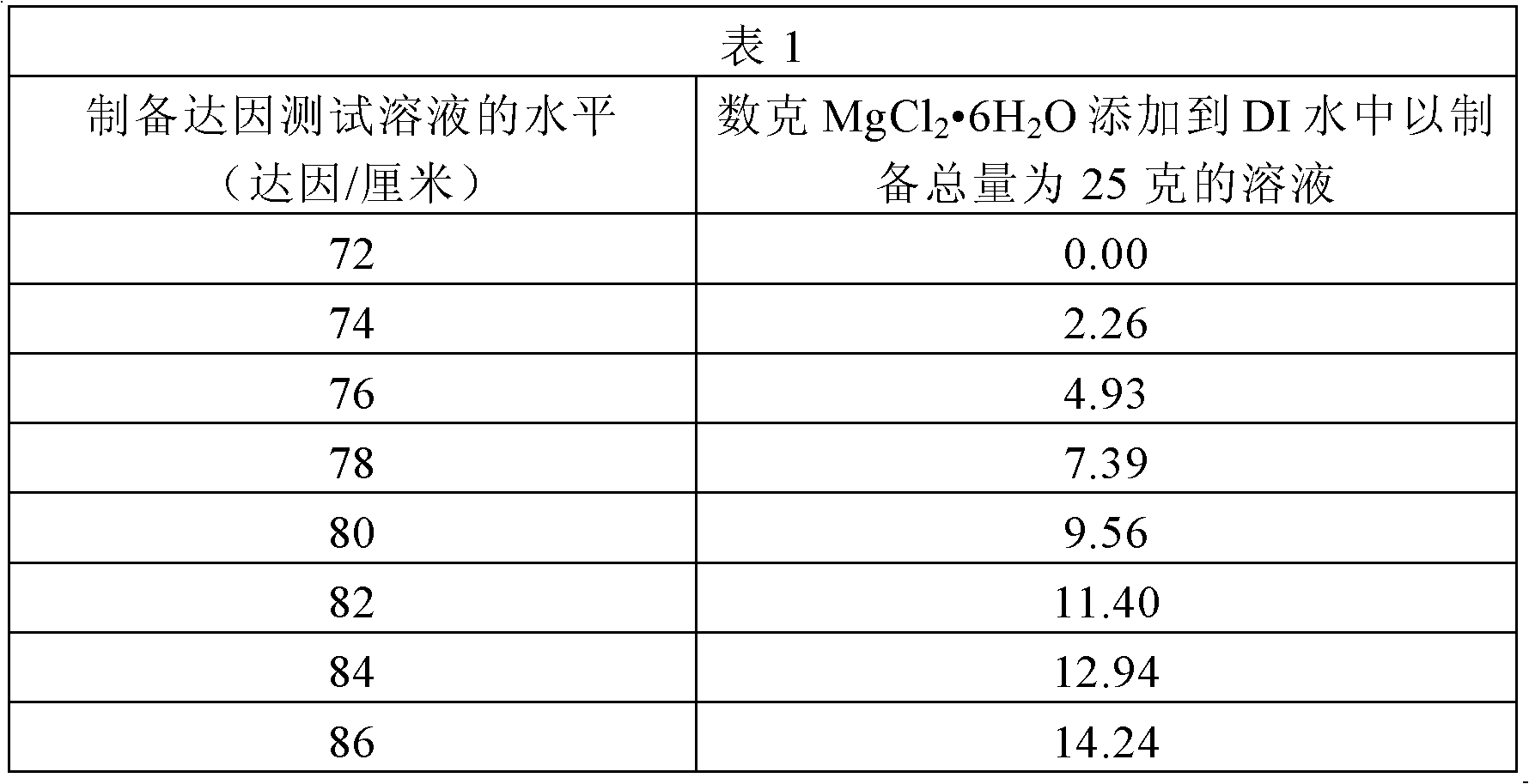

[0046] Various samples of ALD-coated porous non-ceramic substrates are described below in conjunction with the Examples. When the surface energy of a sample is discussed, its readings are obtained in the following manner: Various levels of dyne test solutions are obtained. Solutions according to ASTM standard D-2578 were purchased from Jemmco, LLC (Mequon, WI) at levels ranging from 30 to 70 dynes / cm. through the MgCl shown in Table 1 2 ·6H 2 The amount of O was mixed with sufficient deionized water to make a solution ranging in level from 72 to 86 dynes / cm to make a total of 25 grams of solution.

[0047]

[0048] Using these dyne test so...

example 1

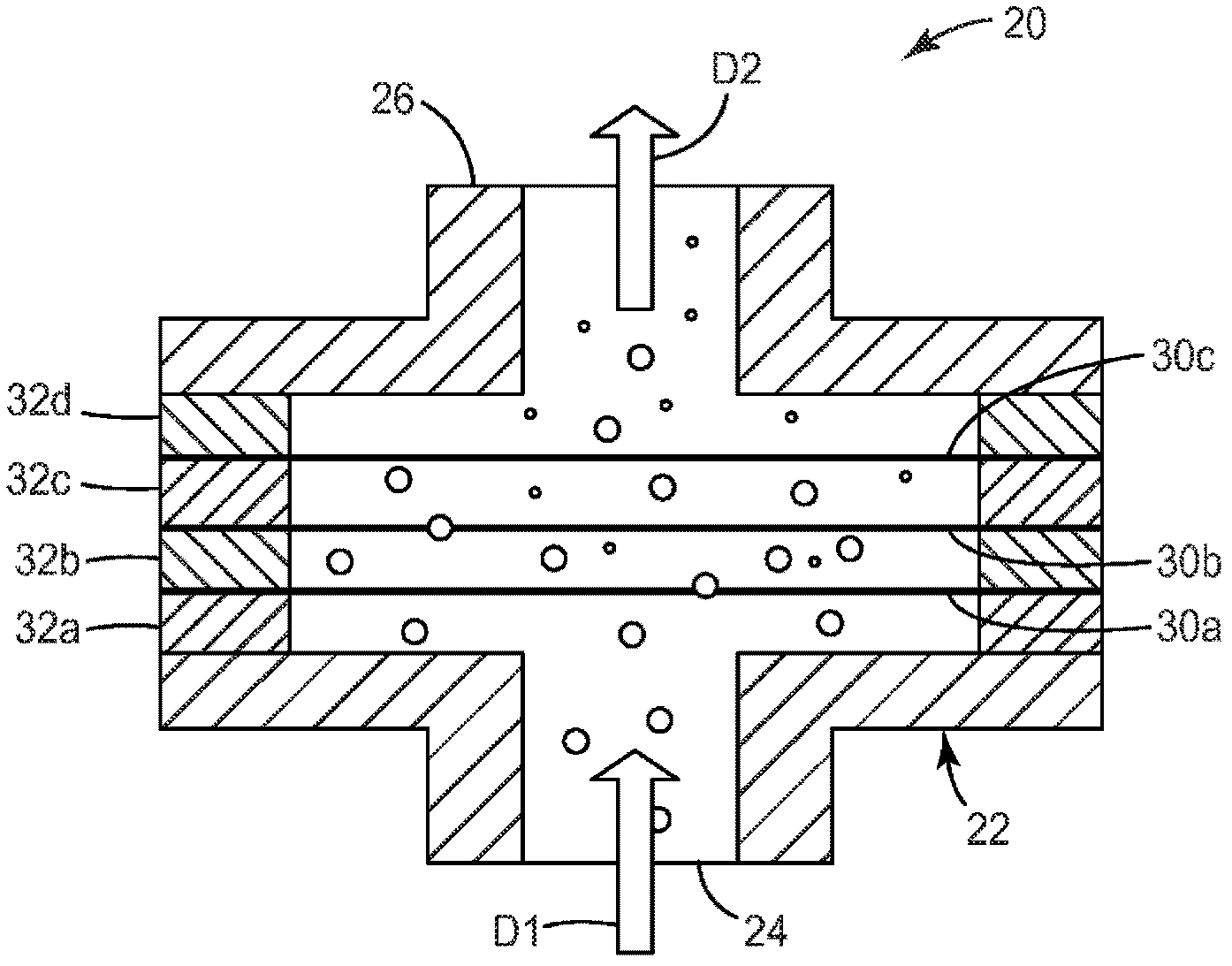

[0068] Each double-sided flange of the reactor was used to support a disc cut from the porous polypropylene film of Substrate A above. The disc was attached by attaching the disc to a copper washer with double sided tape and placing the copper washer into the normal sealing position between the 6 inch (15.24 cm) diameter ConFlat Double side flanges. Each of the three samples of the sheet was placed inside the reactor. As the reactors are sealed together and secured to form the reactor body, the ConFlat double sided flange seals pass through the membrane and form a hermetic seal with conventional copper gasket sealing mechanisms. The sealed reactor will also help to hold the membrane in place and seal the edges of the membrane to prevent any reactive gases from bypassing the membrane.

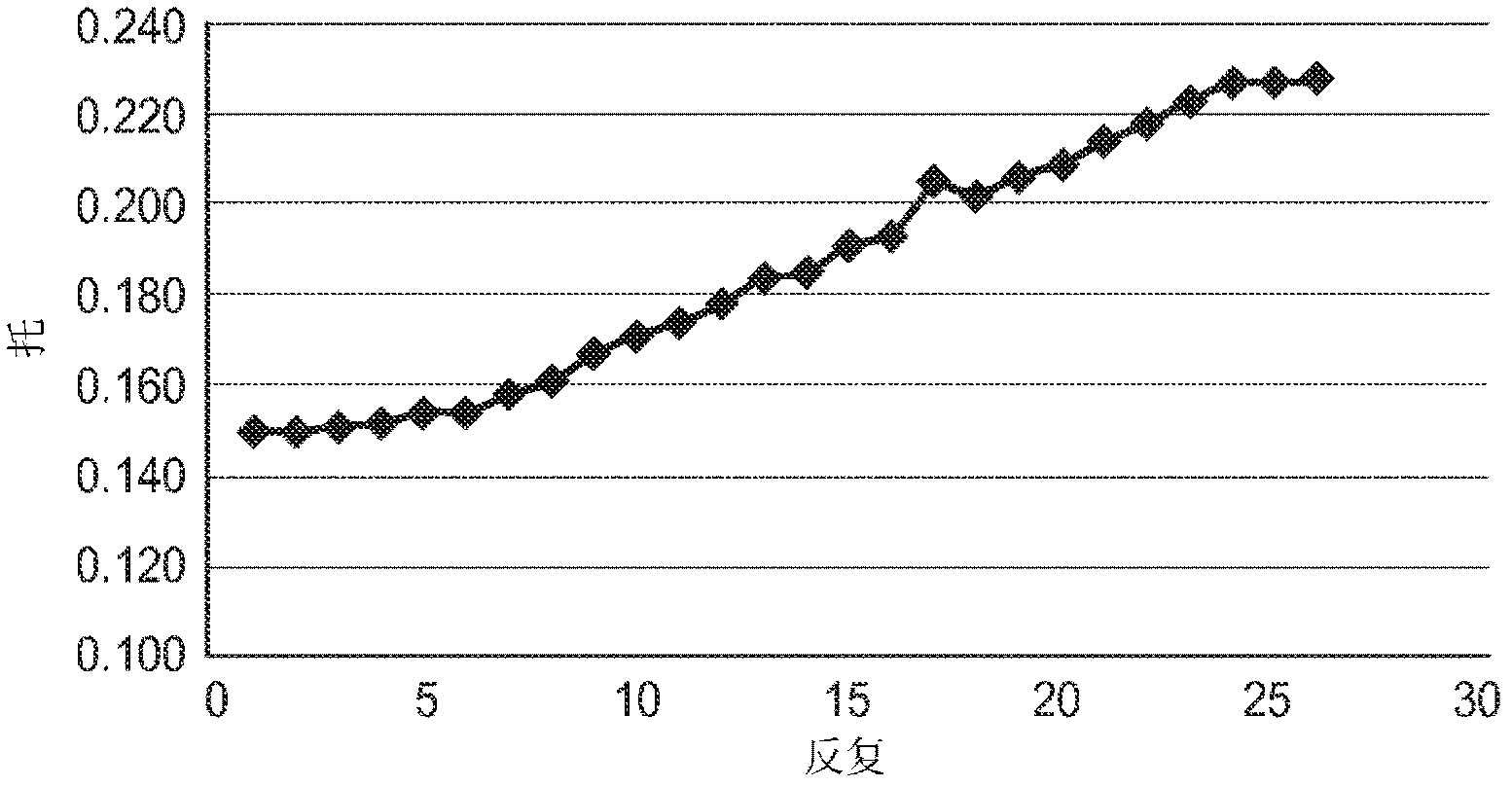

[0069] The reactor with the membrane in place is then attached to the vacuum and gas handling system as described above. The first reactive gas supply tank was filled with 97% trimethylaluminu...

example 2

[0074] The experiment was generally carried out according to the procedure of Example 1, except that the substrate used was substrate B instead of substrate A; the reactor, first and second inlet lines, and purge lines were heated to 60 °C by a heater, and repeated is 20 instead of 35. After 20 iterations had been performed, the reactor was opened and the surface energy of each of the three wafers of Sample B was evaluated. Each disc has a surface energy in excess of 86 dynes / cm, indicating a high degree of hydrophilicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com