Application of three-dimensional ordered macroporous carbon nitride supported palladium catalyst in catalytic hydrogenation of styrene unsaturated copolymers

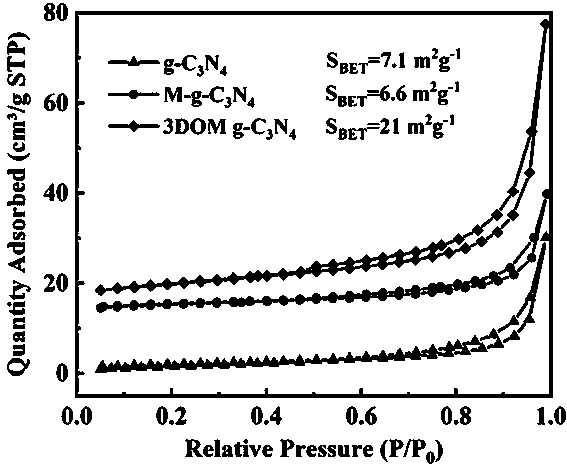

A three-dimensional ordered, porous carbon nitride technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of not easy to agglomerate, high specific surface area, and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

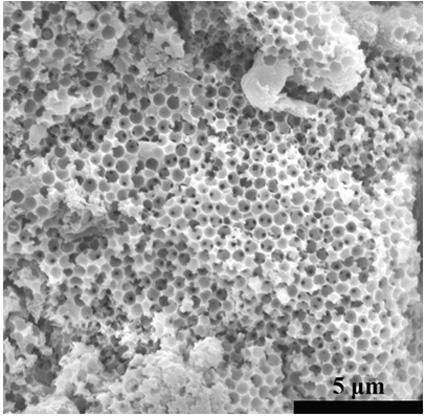

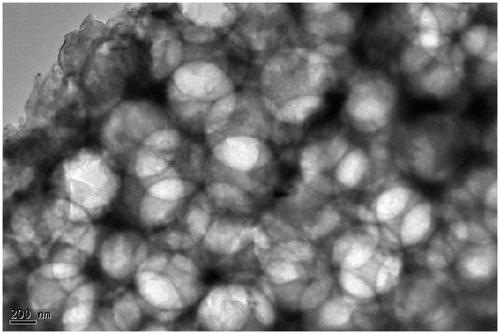

[0039] Disperse 10 mL tetraethyl orthosilicate (TEOS) in 50 mL ethanol to obtain solution A; mix 50 mL ethanol, 20 mL deionized water and 10 mL 25-28wt% ammonia solution and stir evenly, and control the stirring speed was 1100 rpm to obtain solution B; quickly added solution A to solution B in a water bath at 40 °C, kept stirring at 1100 rpm for 1 min, then reduced the rotation speed to 600 rpm, and continued the reaction for 2.5 h to obtain uniformly dispersed core SiO 2 Mixed solution of solids; add the mixed solution containing 1 mL TEOS, 5 mL ethanol and 0.2 g PVP dropwise to the above solution under vigorous stirring, continue to stir the reaction at 40 °C for 2 h, and then stand overnight at room temperature , the white solid obtained after centrifugation was washed with deionized water and ethanol, dried in a vacuum oven at 60 °C for 12 h, then transferred to a crucible, and calcined in a muffle furnace at 700 °C for 6 h to obtain a three-dimensional ordered mesoporous ...

Embodiment 2

[0044] The catalyst synthesis steps are the same as in Example 1. Dissolve 2 g of SBS in 80 g of cyclohexane and add 1 g of catalyst Pd / 3DOM g-C 3 N 4 , Catalytic hydrogenation reaction is carried out in the autoclave. The reaction conditions are: temperature 140 °C, hydrogen pressure 3.0 MPa, reaction time 6.0 h. After the reaction, centrifuge, add ethanol coagulation to the glue solution to obtain the product SEBS, and the degree of hydrogenation is listed in Table 1.

Embodiment 3

[0046] The catalyst synthesis steps are the same as in Example 1. Dissolve 3 g of SBS in 80 g of cyclohexane and add 1 g of catalyst Pd / 3DOM g-C 3 N 4 , Catalytic hydrogenation reaction is carried out in the autoclave. The reaction conditions are: temperature 140 °C, hydrogen pressure 3.0 MPa, reaction time 6.0 h. After the reaction, centrifuge, add ethanol coagulation to the glue solution to obtain the product SEBS, and the degree of hydrogenation is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com