Pyrotechnic gas generator for airbag

A technology of gas generator and airbag, which is applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, transportation and packaging, etc. It can solve the problems of filter power loss, gas generator failure, bulkiness, etc., to reduce output slope, Avoid the effects of shock and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

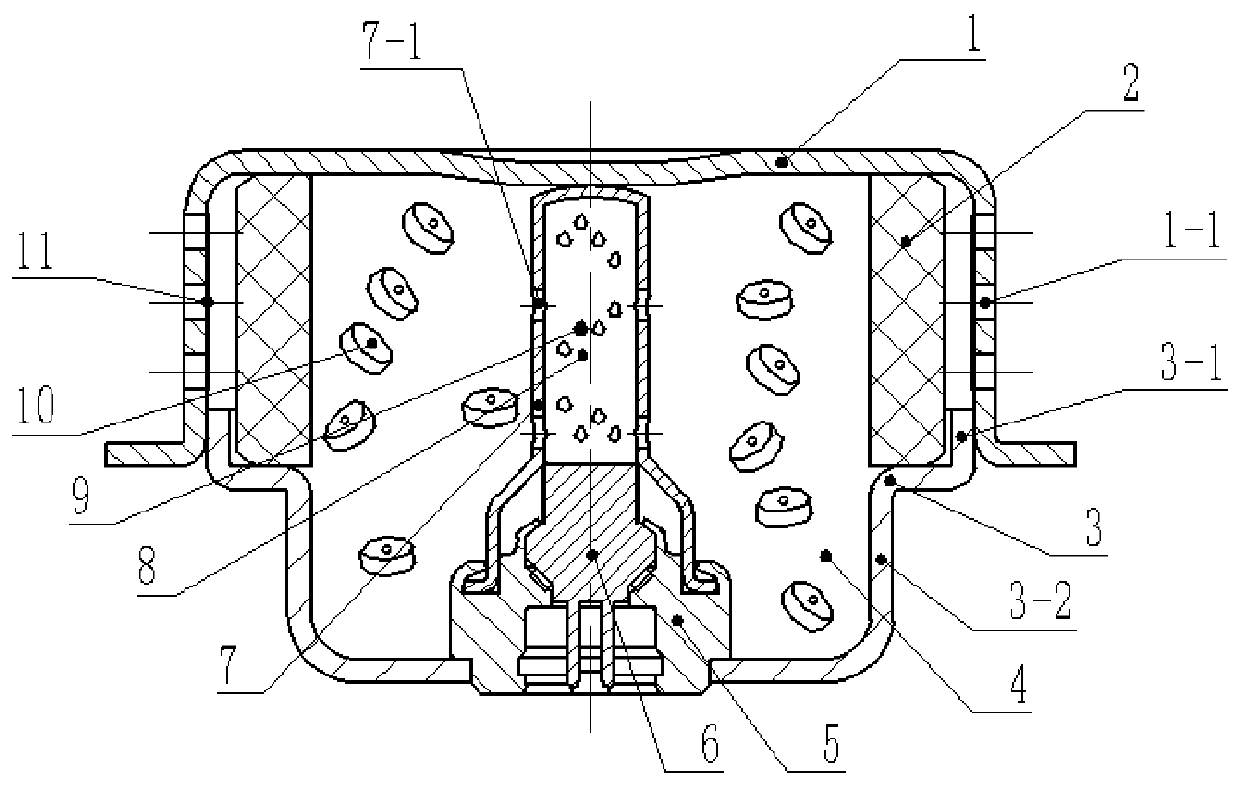

[0035] see figure 1 , image 3 , Figure 4 , the present invention includes an upper shell, a lower shell, an igniter seat, an igniter, an ignition shell, a filter, an igniter, and a gas-generating drug, wherein the igniter seat is embedded in the lower shell, and the igniter seat is connected to The igniter and the ignition shell, the lower shell 3 adopts a double cup design, and is provided with a first cup 3-1 and a second cup 3-2, and the upper shell 1 is connected to the first cup 3-1 At the opening, the filter 2 is built into the first cup, the bottom inner surface of the upper shell 1, the second cup 3-2, the outer surface of the igniter seat 5, the outer surface of the ignition housing 7, the filter 2. The inner surface constitutes a gas-generating drug chamber 4, and the gas-generating drug chamber 4 is built with a gas-generating drug 10, and the ignition shell is built with an ignition powder 9.

[0036] In a preferred embodiment of the present invention, the up...

Embodiment 2

[0046] Figure 7 It is an extended example of the present invention, which is based on Embodiment 1, and there is no gap between the outer surface of the filter 2 and the side wall of the upper casing 1 .

Embodiment 3

[0048] A pyrotechnic gas generator for an airbag, comprising an upper casing, a filter, a lower casing, an igniter seat, an igniter, an ignition casing, a gas-generating agent, and an ignition agent, wherein the igniter seat is embedded in the lower casing In the body, the lower shell is a cup structure with an opening turned outward (for the convenience of expression, the previous label is used in this example, and 3-2 is the main cup structure of the lower shell, which is equivalent to the second cup of the previous embodiment. body, the flanging structure is equivalent to the first cup body 3-1 without side walls), the upper shell is fixedly connected with the outer end surface of the flanging structure; the inner surface of the bottom of the upper shell is connected with the flanging structure Compress the upper and lower end surfaces of the filter; the gas-generating chamber is composed of the bottom inner surface of the upper housing, the side wall of the lower housing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com