Smokeless coal gasification micro grease gun igniting pulverized coal burner

A pulverized coal burner and micro-oil gun technology, which is applied in the direction of burners, burners burning powder fuel, combustion chambers, etc., can solve the problem of stable combustion and large fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

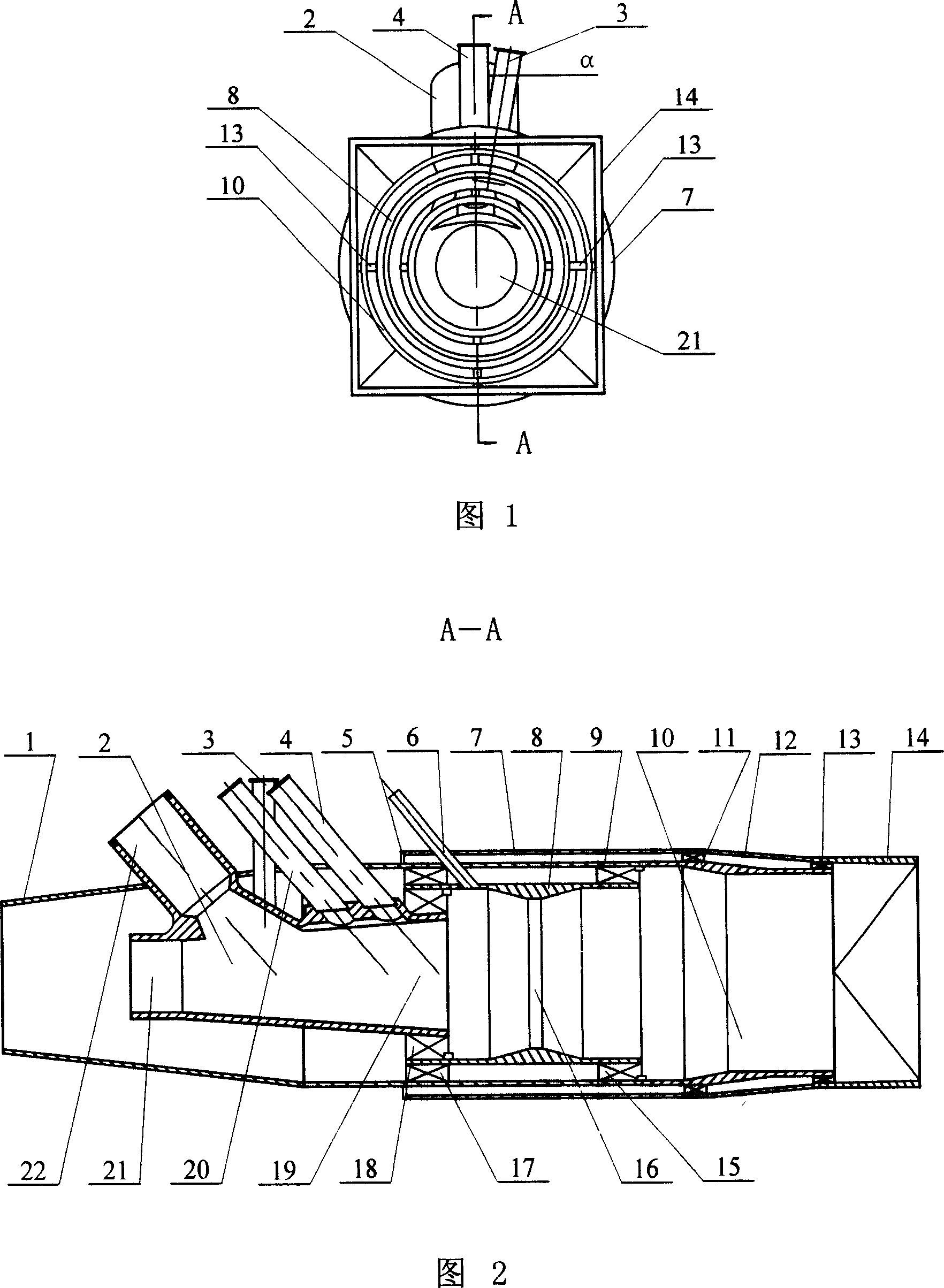

[0005] Specific embodiment one: (referring to Fig. 1 and Fig. 2) this embodiment consists of reducing pipe 1, primary pulverized coal combustion chamber 2, fire detection probe 3, first auxiliary gasification small oil gun fixed sleeve 4, perimeter cooling Air duct 7, secondary combustion chamber straight section 8, burner outer pipe 9, secondary combustion chamber contraction section 10, first rib 11, perimeter cooling air contraction section 12, second rib 13, secondary combustion chamber Outlet section 14, the 3rd rib plate 15, the 4th rib plate 17, the 5th rib plate 18 and the oxygenation pipe 6 are made up, between the outer wall of the straight section 8 of the secondary combustion chamber and the inner wall of the burner outer pipeline 9 respectively fixed with The third rib plate 15 and the fourth rib plate 17, the inner wall of the straight section 8 of the secondary combustion chamber is provided with an annular neck 16, the outlet end of the reducer pipe 1 is fixedly...

specific Embodiment approach 2

[0006] Specific embodiment two: (see Fig. 1) The difference between this embodiment and specific embodiment one is that the second auxiliary gasification small oil gun fixed sleeve 20 is added, and the second auxiliary gasification small oil gun fixed sleeve 20 It is arranged in parallel with the first auxiliary gasification small oil gun fixing sleeve 4 and fixed on the primary combustion chamber 2 . The increased second auxiliary gasification small oil gun fixing sleeve 20 can increase the position of an auxiliary gasification small oil gun to accelerate pulverized coal combustion. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Embodiment 3: The cross-section of the outlet section 14 of the secondary combustion chamber in this embodiment is circular or square. The cross-section is a circular or square secondary combustion chamber outlet section 14, which can be adapted to the specific structure of the boiler. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com