Anthracite composite fuel, composite coal and preparation method for composite coal

A composite fuel and composite briquette technology, applied in the field of fuel, can solve the problems of reducing the calorific value of coal combustion and large amount of black smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

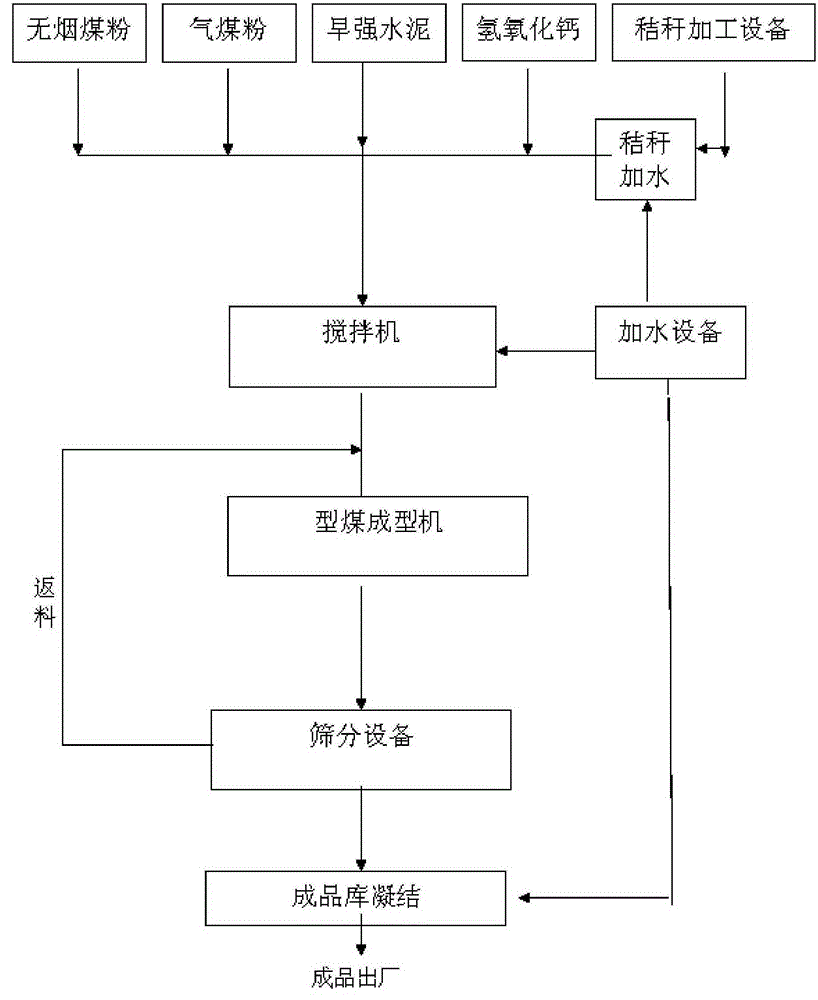

Image

Examples

preparation example Construction

[0034] In the present invention, the preparation method of the anthracite composite fuel preferably comprises the following steps:

[0035] Anthracite coal powder, gas coal powder, plant fiber, binder, desulfurizer and water are mixed to obtain anthracite composite fuel.

[0036] In the present invention, the consumption, source and type of the anthracite powder, gas coal powder, plant fiber, binding agent, desulfurizer and water are the same as those of the anthracite coal powder, gas coal powder, plant fiber, binding agent described in the above technical scheme , desulfurizer and water are the same in amount, source and type, and will not be repeated here.

[0037] In the present invention, there is no special limitation on the method of mixing the anthracite composite fuel, and a mixing technical solution well known to those skilled in the art can be used.

[0038] The invention provides a composite briquette made of the anthracite composite fuel described in the above te...

Embodiment 1

[0062] The corn stalks are sequentially flattened, cut open and cut to obtain fiber filaments;

[0063] The fiber silk is fully soaked in water to obtain corn stalk fiber silk; the length of the corn stalk fiber silk is 10-20 mm, and the diameter is 0.5-1 mm; the water content of the corn stalk fiber silk is 15 wt %;

[0064] Mix 53 parts by weight of anthracite powder, 32 parts by weight of gas coal powder, 2.5 parts by weight of the above-mentioned corn stalk fiber silk, 6 parts by weight of cement, 1.5 parts by weight of calcium hydroxide and 5 parts by weight of water, and stir to obtain a mixture;

[0065] Press the mixture with a molding machine to obtain briquettes, the pressing temperature is 20°C, and the pressing pressure is 300MPa;

[0066] The briquettes are sprayed with mist-like water, and the amount of water sprayed should be kept moist inside and outside the briquettes, and then condensed at 20° C. for 48 hours to obtain composite briquettes.

[0067] The mold...

Embodiment 2

[0074] The corn stalks are sequentially flattened, cut open and cut to obtain fiber filaments;

[0075] The fiber silk is fully soaked in water to obtain corn stalk fiber silk; the length of the corn stalk fiber silk is 10-20 mm, and the diameter is 0.5-1 mm; the water content of the corn stalk fiber silk is 15 wt %;

[0076] Mix 58 parts by weight of anthracite powder, 28.5 parts by weight of gas coal powder, 3.5 parts by weight of the above-mentioned corn stalk fiber, 4.5 parts by weight of cement, 2 parts by weight of calcium hydroxide and 3.5 parts by weight of water, and stir to obtain a mixture;

[0077] Press the mixture with a molding machine to obtain briquettes, the pressing temperature is 20°C, and the pressing pressure is 300MPa;

[0078] The briquettes are sprayed with mist-like water, and the amount of water sprayed should be kept moist inside and outside the briquettes, and then condensed at 20° C. for 48 hours to obtain composite briquettes.

[0079] The moldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center height | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com