Patents

Literature

50results about How to "Reduce combustible content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

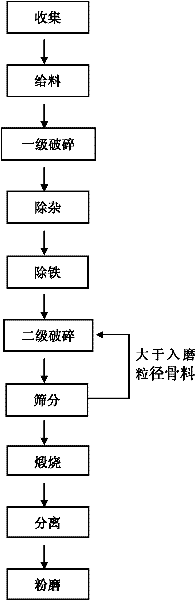

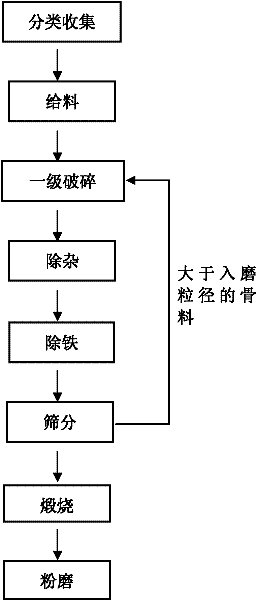

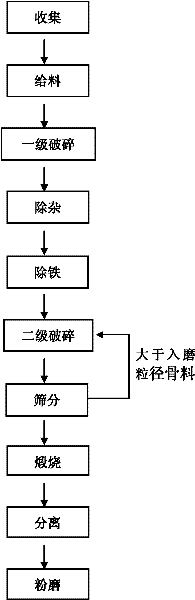

Method for recycling waste clay

InactiveCN102218435AGive full play to the role of materialImprove grindabilityConstruction waste recoverySolid waste disposalLitterIron removal

The invention provides a method for recycling waste clay, which comprises the following steps of: removing impurities from construction waste materials through treatment processes such as crushing, impurity removal, iron removal, sieving and the like, and preparing the materials into a recycled aggregate meeting the requirement of grinding equipment on particle size; burning up combustibles in the recycled aggregate through a calcining process to reduce ignition loss and water content; separating a concrete component from a clay brick component in the recycled aggregate; and grinding the clay brick component to obtain regenerated powder. By the method, waste clay brick resources can be fully utilized by a simple process; moreover, the regenerated clay powder obtained in the production has good performance, wide application range and high added value.

Owner:上海德滨环保科技有限公司

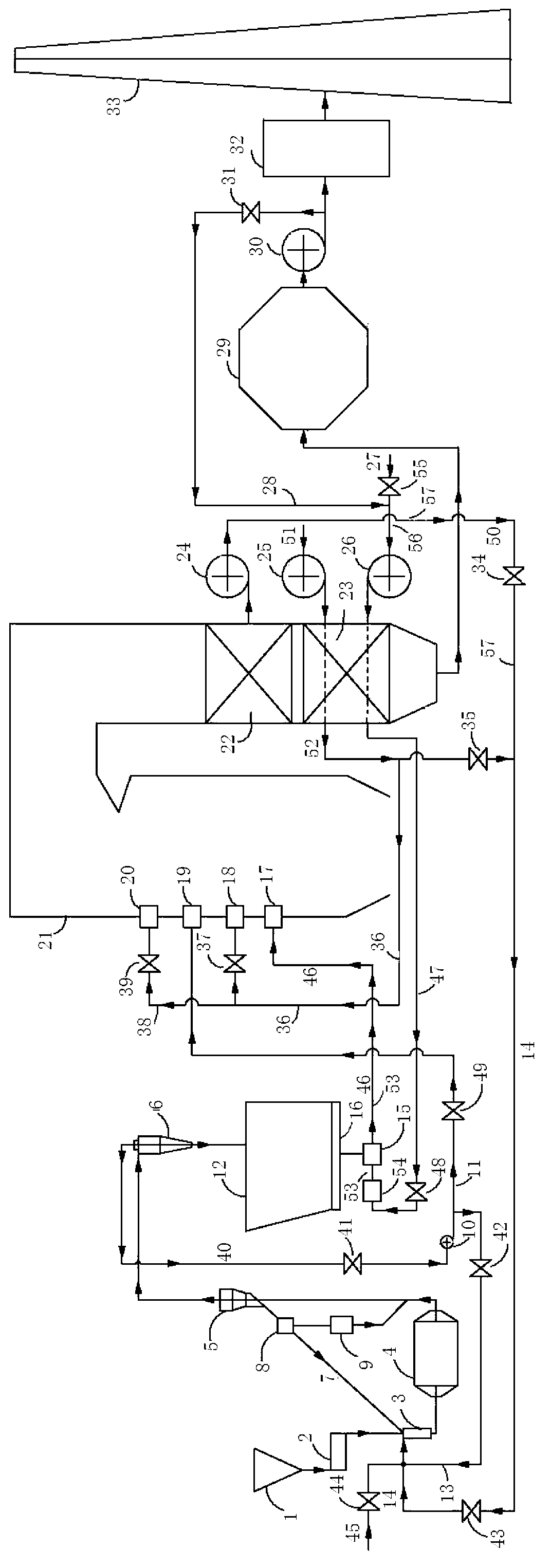

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

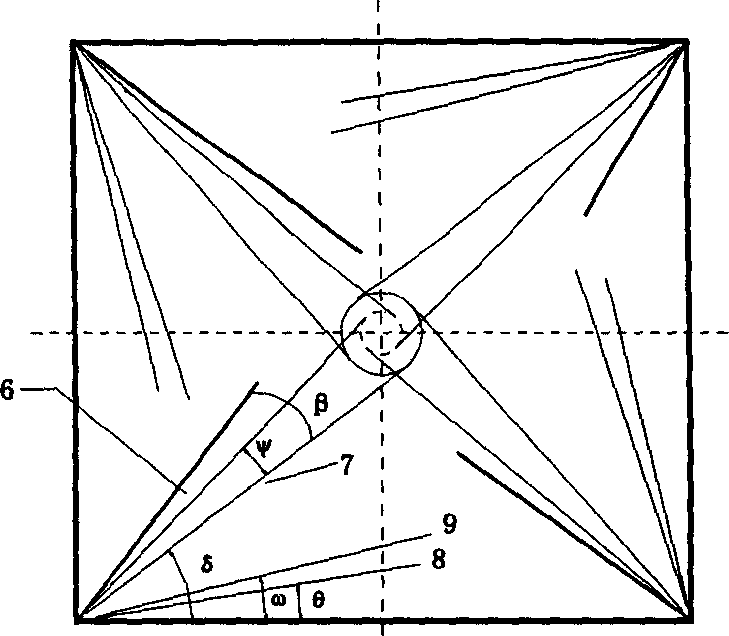

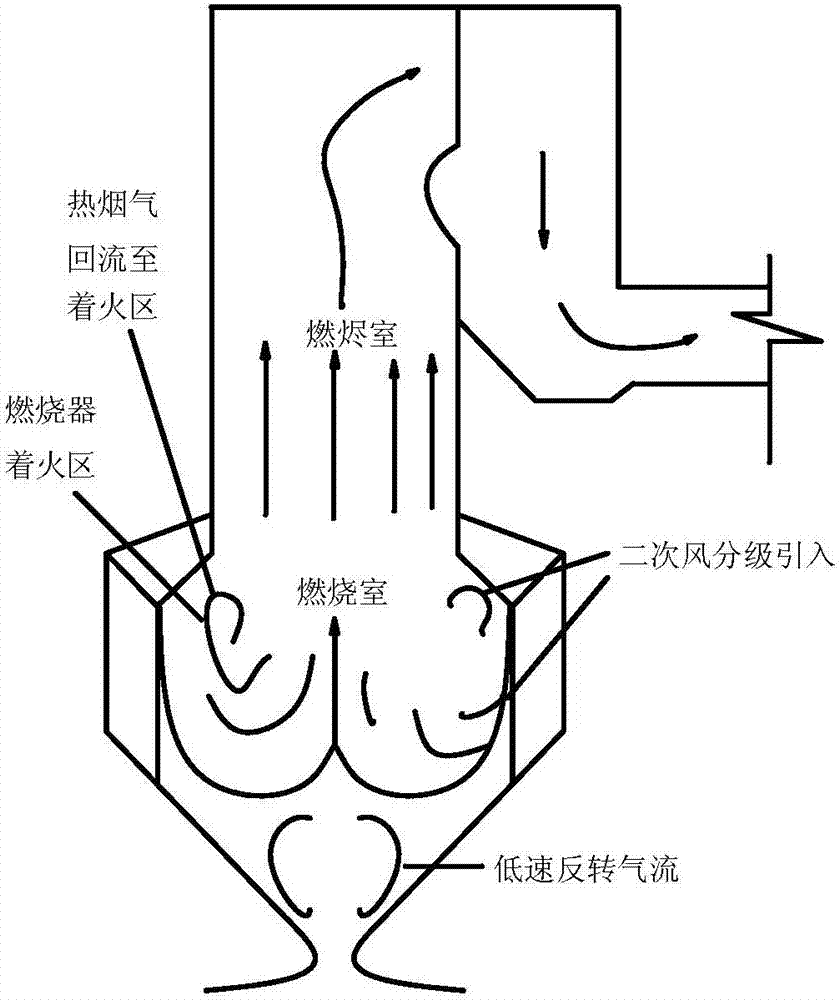

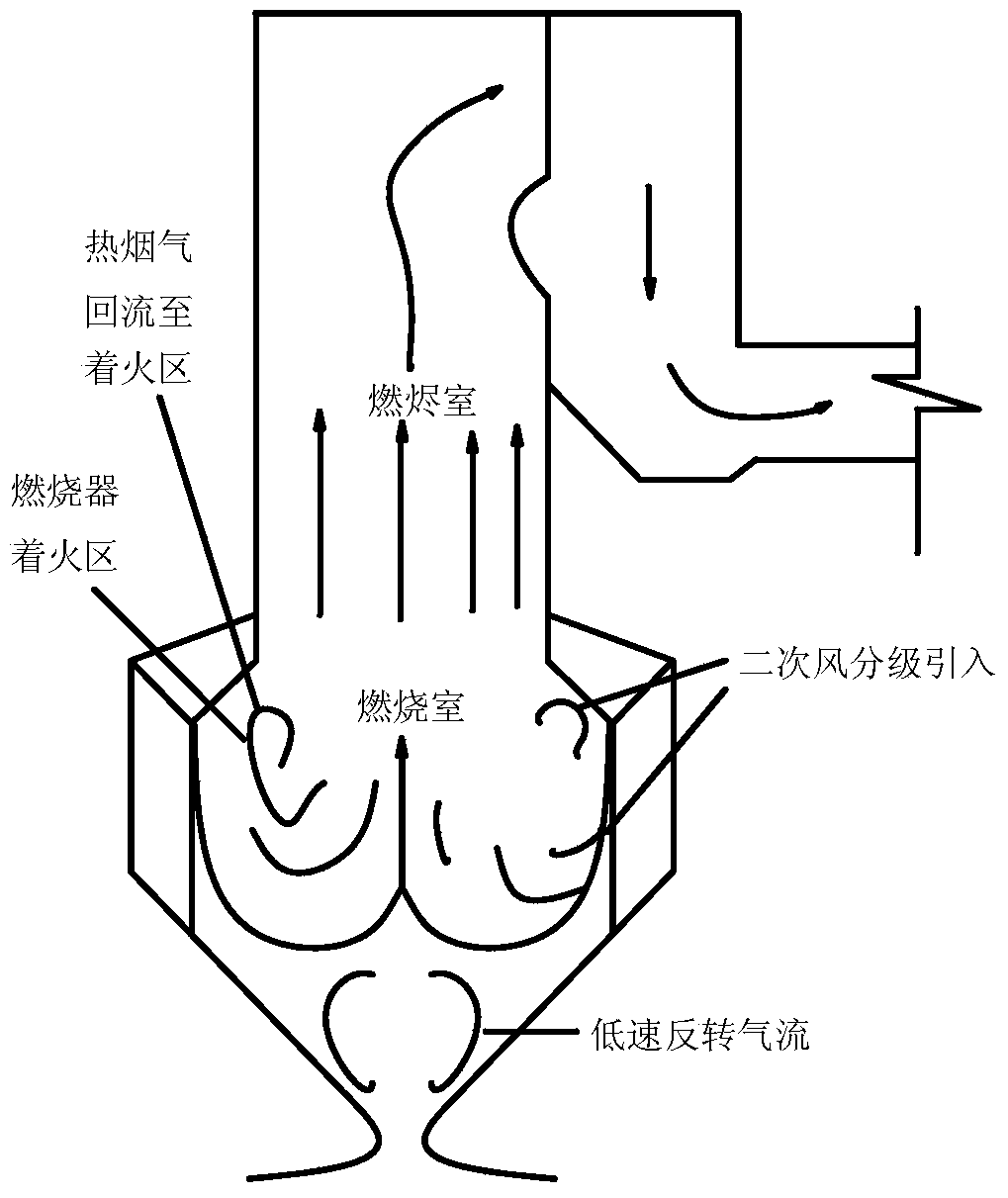

Low-nitric-oxide direct-current pulverized coal combustor adaptive to meager coal boiler

ActiveCN103267279AReduce generationReduce carbon contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

The invention relates to a low-nitric-oxide direct-current pulverized coal combustor adaptive to a meager coal boiler, which can achieve stable and economical combustion, and also reduces nitric oxide emission to the lowest level, so that the low-nitrogen combustion modifying technique of the meager coal boiler is improved. The low-nitric-oxide direct-current pulverized coal combustor adaptive to the meager coal boiler comprises main combustor groups which are arranged on four corners of a hearth of the meager coal boiler in a four-angle tangential circle combustion mode, are matched with a water-cooling wall high-temperature-prevention corrosion system of the hearth, and are identical in structure; each main combustor group comprises pulverized coal combustors arranged at intervals and secondary air spray ports; the upper parts of the main combustor groups are provided with corresponding separation burnout air groups; a layer of precombustion chamber back flow combustor is arranged in each n-layer of pulverized coal combustors; the jet flow rotation direction of the main combustor groups is the anticlockwise direction; the rotation direction of secondary air ports close to the upper parts of the precombustion chamber back flow combustors is the clockwise direction, and the imaginary tangential circle diameter is greater than the imaginary tangential circle diameter of the main combustors; separation burnout air groups include upper groups and lower groups; and the jet flow of the lower groups is in an imaginary tangential circle mode, and the jet flow of the upper groups is in an opposed combustion mode.

Owner:STATE GRID CORP OF CHINA +1

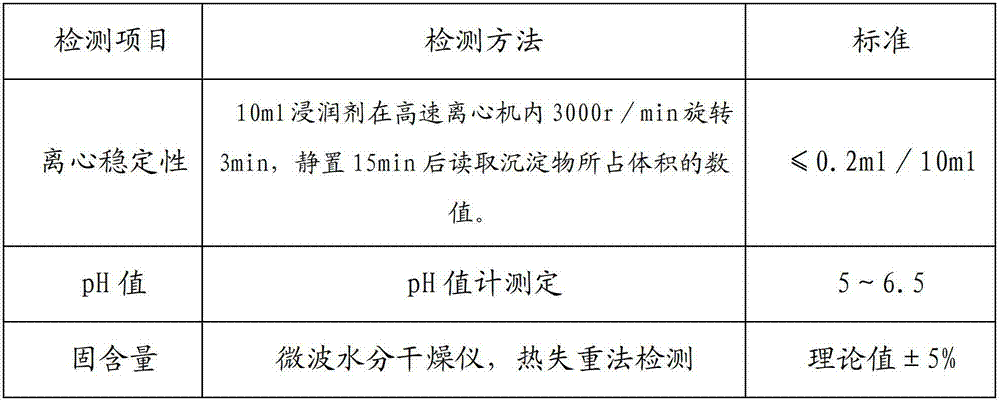

Coal combustion composite nanometer catalyst

A coal combustion composite nanometer catalyst consists of a catalyst, a promoter, a dispersing agent and a penetrating agent, wherein the catalyst accounts for 1-10%, the dispersing agent accounts for 0.1-0.5%, the dispersing agent accounts for 0.1-1%, and the penetrating agent accounts for 90-99%. The adding ratio is 1 to 3000, namely, one ton of the catalysts are used for 3000 tons of coal. When used, the coal combustion composite nanometer catalyst can be diluted by water 5-10 times larger than the coal combustion composite nanometer catalyst according to the dry degree of the coal. The coal combustion composite nanometer catalyst has the advantages of improving sensible heat of the coal, saving the coal and protecting the environment.

Owner:中科朗发新能源科技发展有限公司

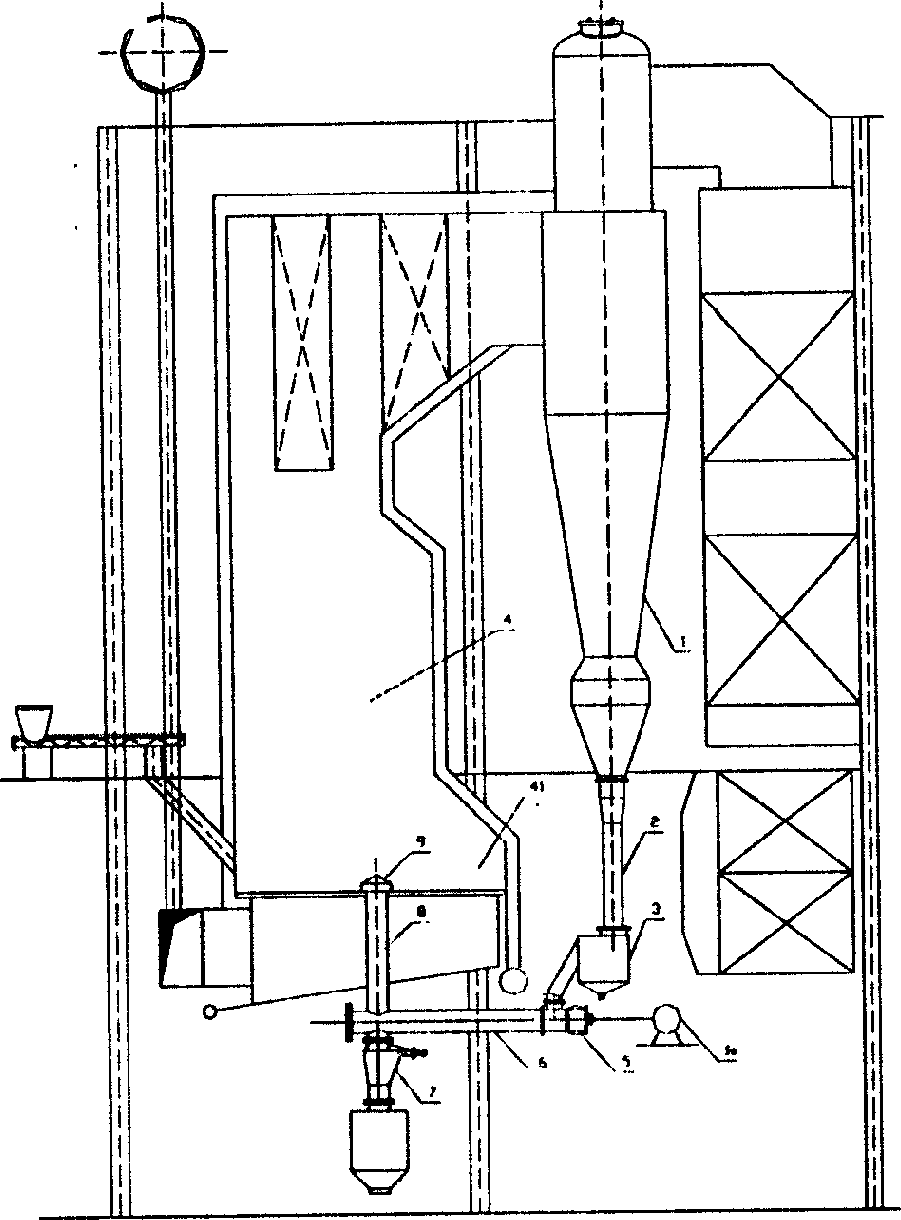

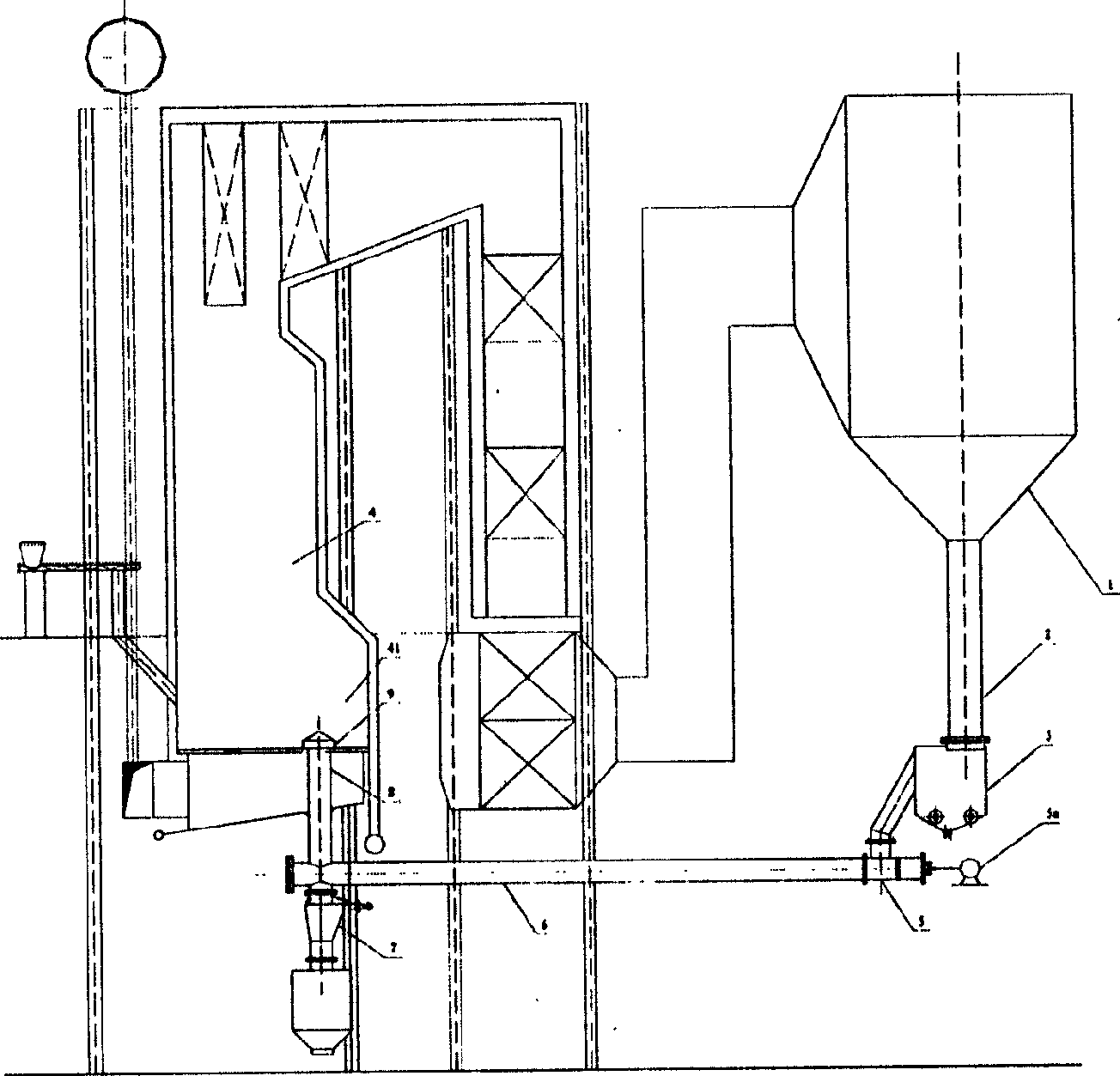

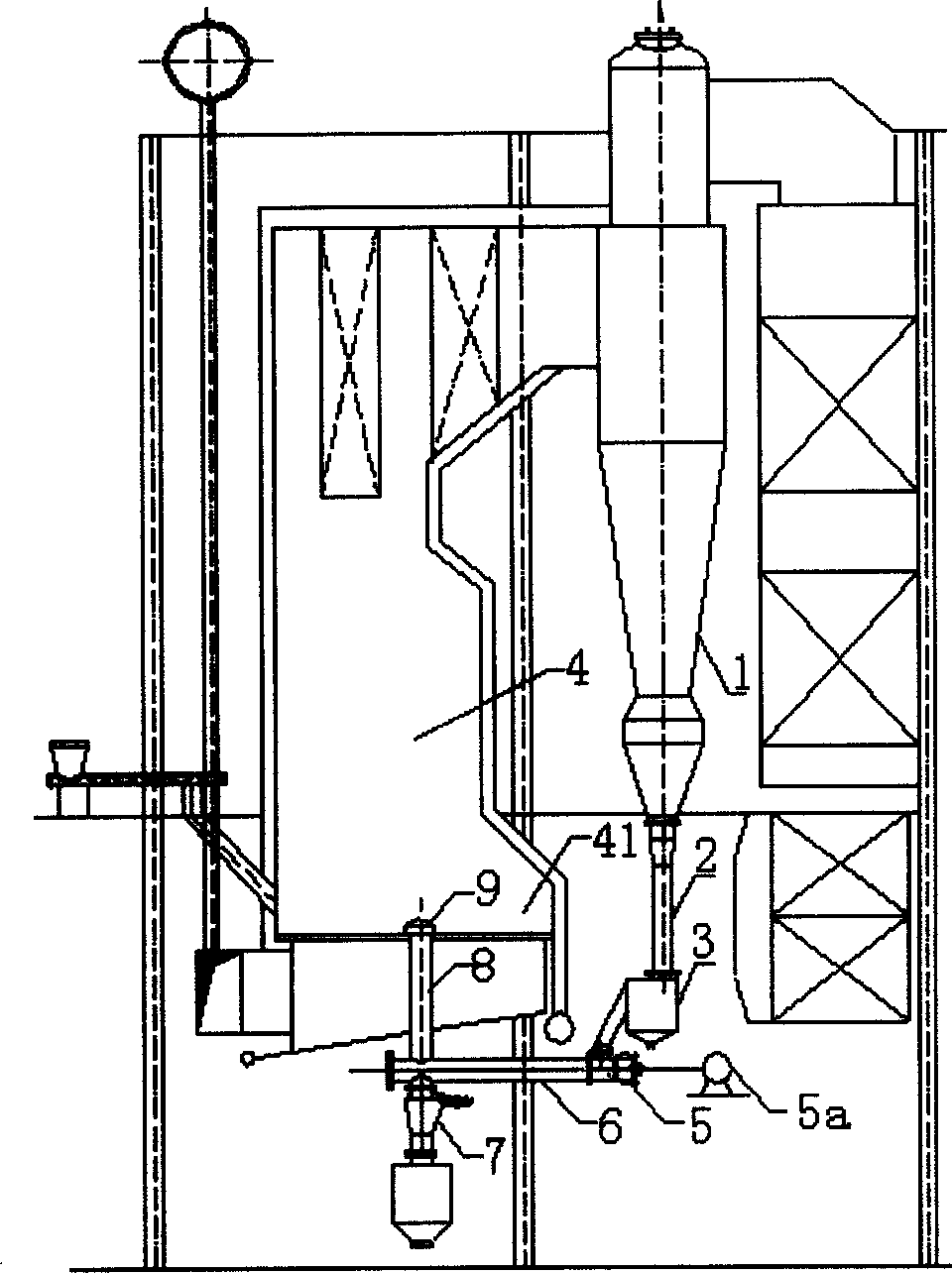

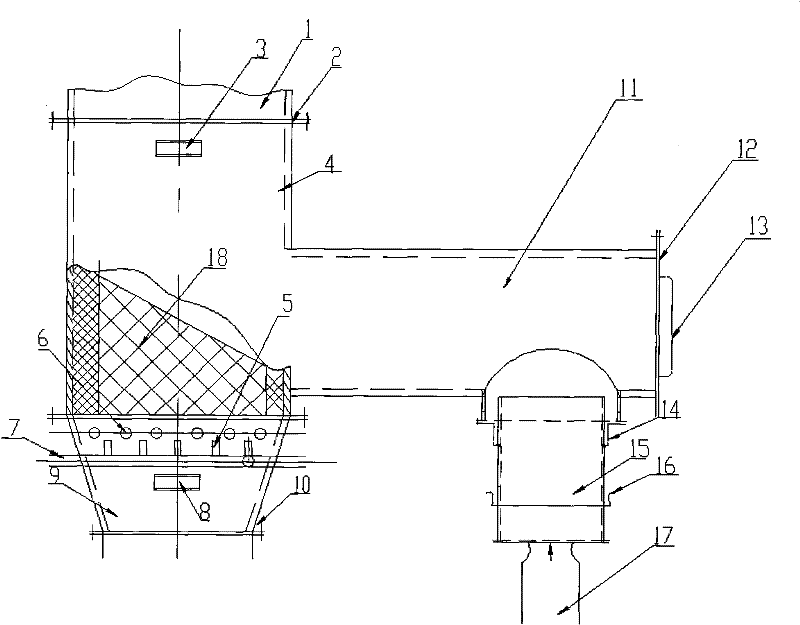

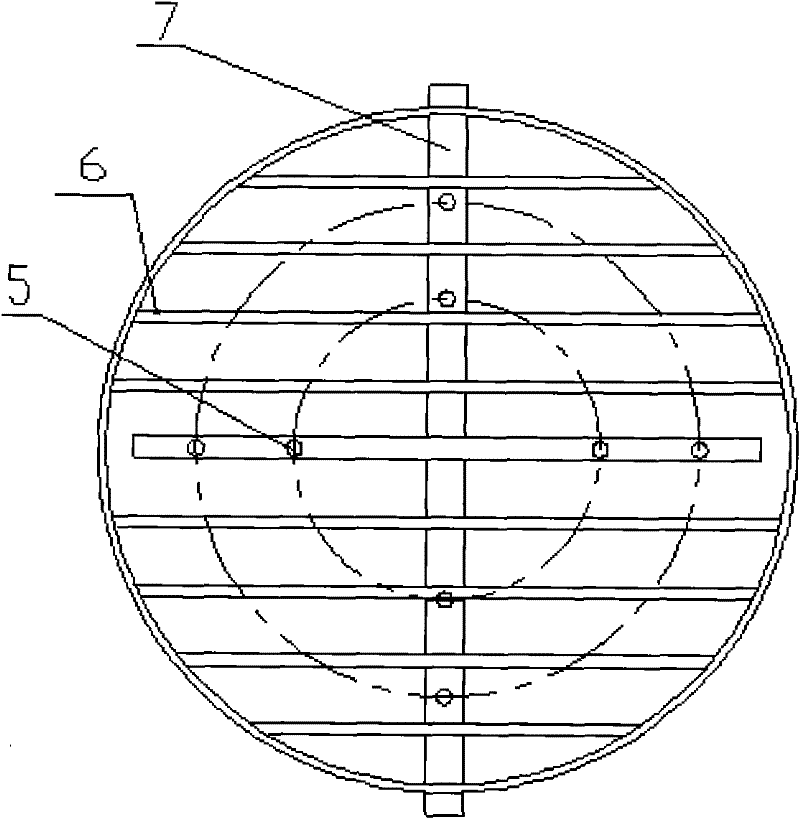

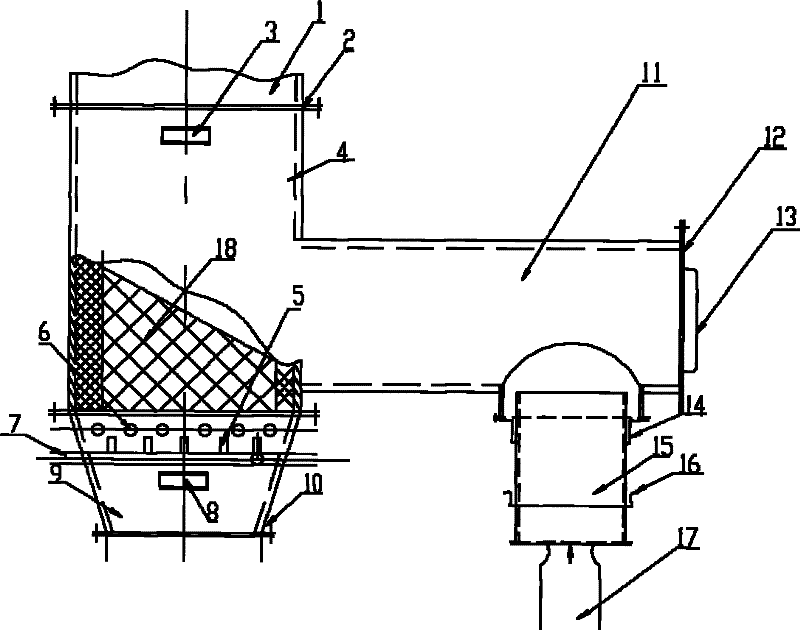

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

ActiveCN1529088AReduce leakageImprove sealing performanceFluidized bed combustionApparatus for fluidised bed combustionInjectorCorrosion

The invention provides a kind of fly ash bottom feeding circular fluidized-bed combustion method and the device, the method is: uses fly ash collector to collect the fly ash with high content in smoke, the fly ash are put into the back material controller through vertical pipe, then and they are carried to the return pipe through transmitting and ejector, and they are returned to the thick phase area of bed through bottom feeding spraying muzzle which is high temperature resisting and corrosion resisting. The device is: it is made up of fly ash collector, back material controller, gas transmitting ejector and the combustion furnace. The top of the combustion furnace connects with the inlet of fly ash collector, the fly ash through the fly ash collector outlet, are carried to the thick phase area of combustion furnace through the bottom feeding sprayer with gas transmitting ejector. The invention can enhance the combustion effect of the fly ash; it can save energy and protect the environment.

Owner:SOUTHEAST UNIV

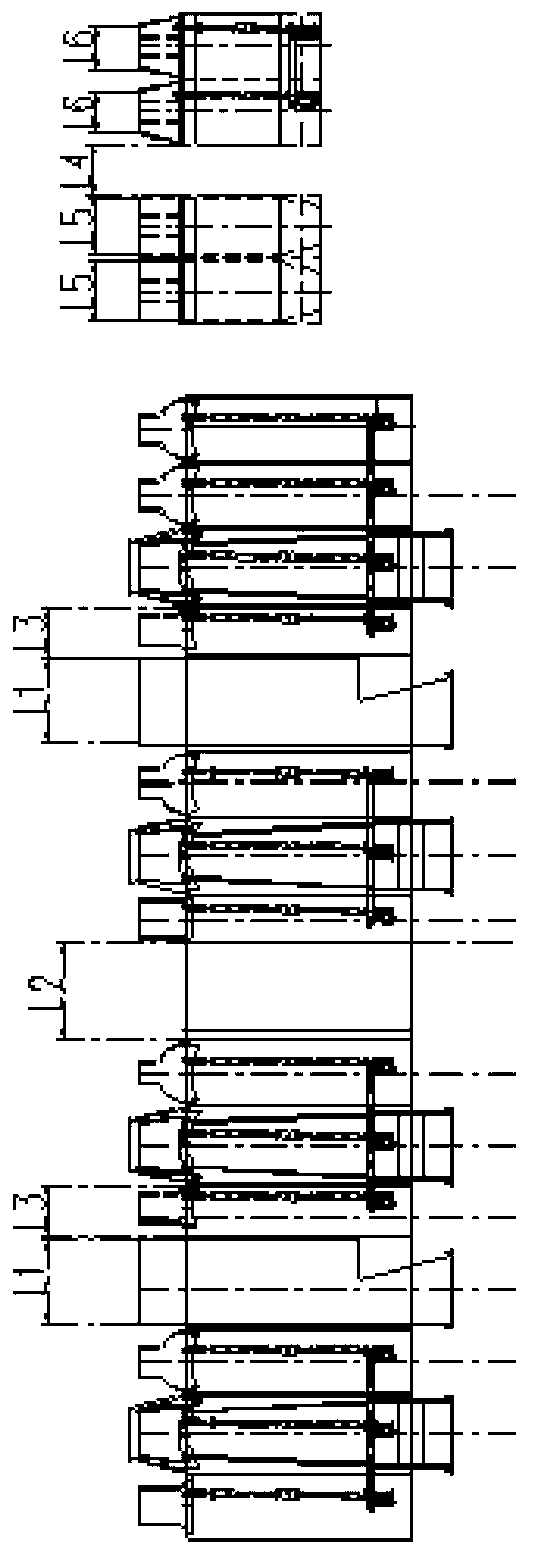

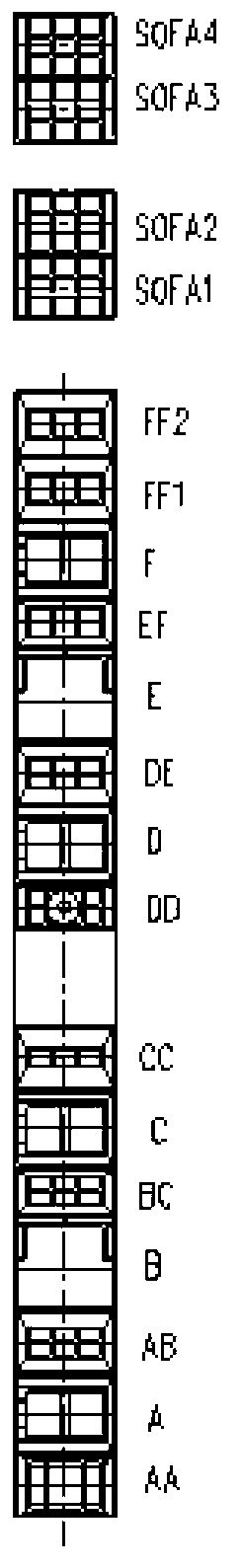

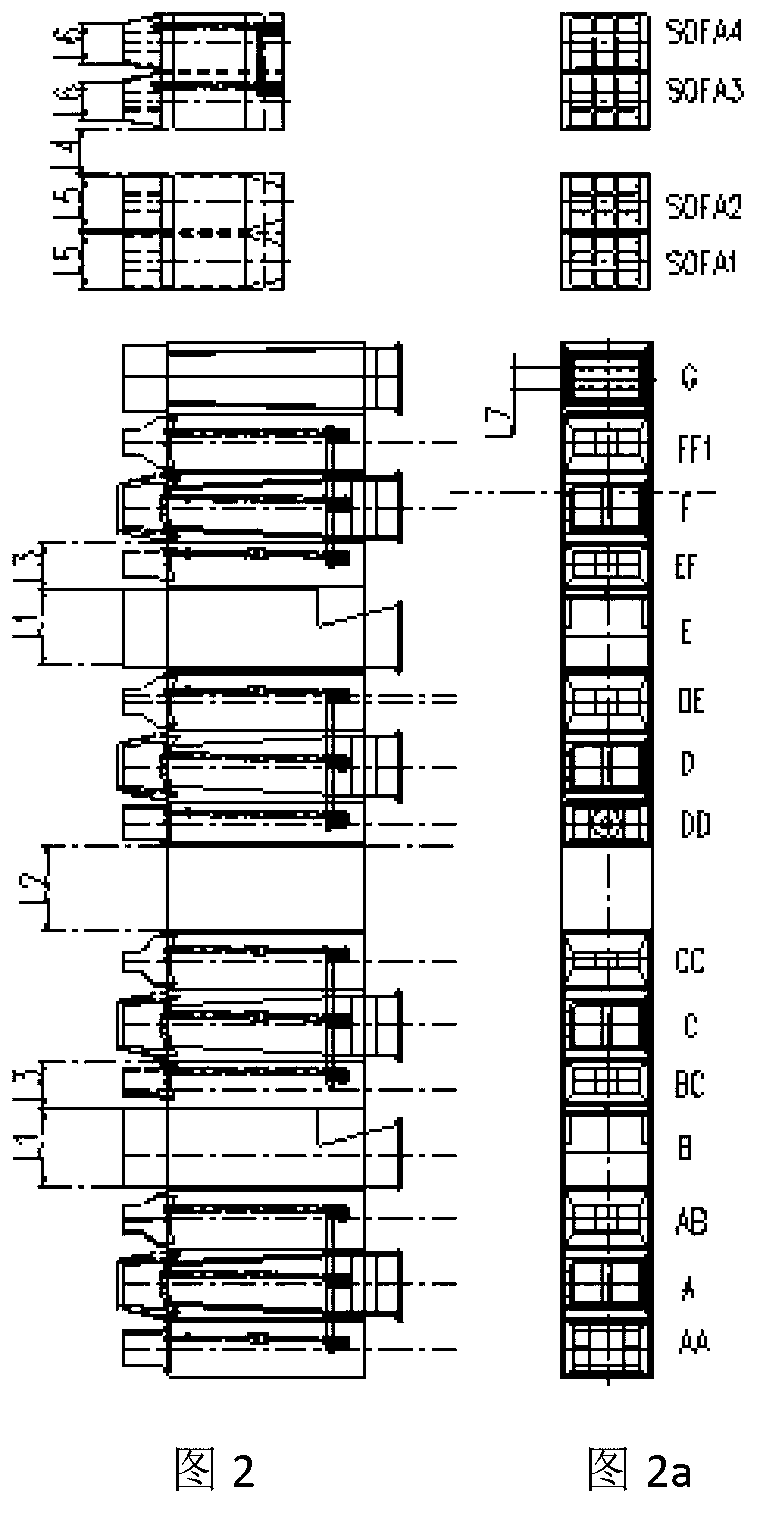

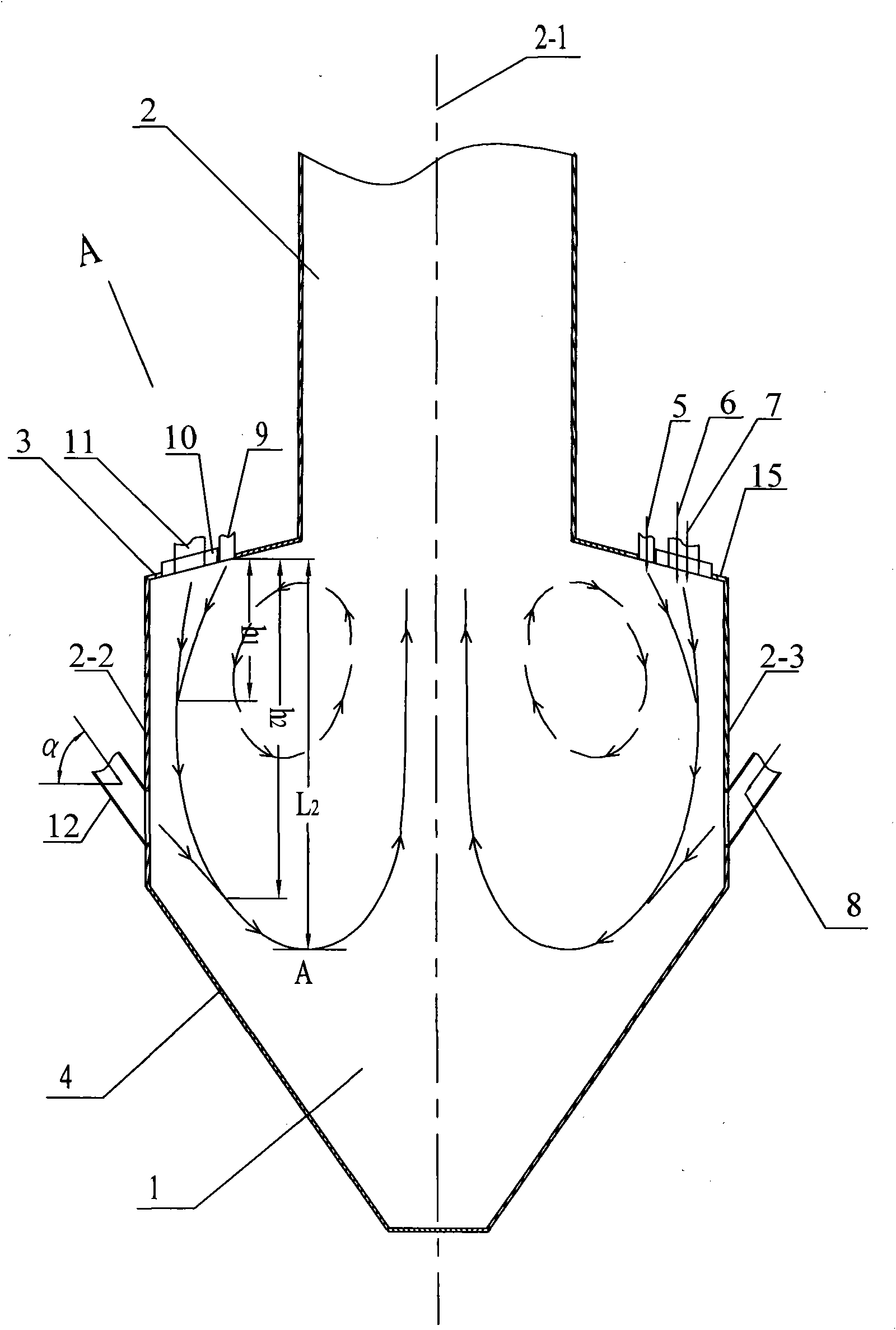

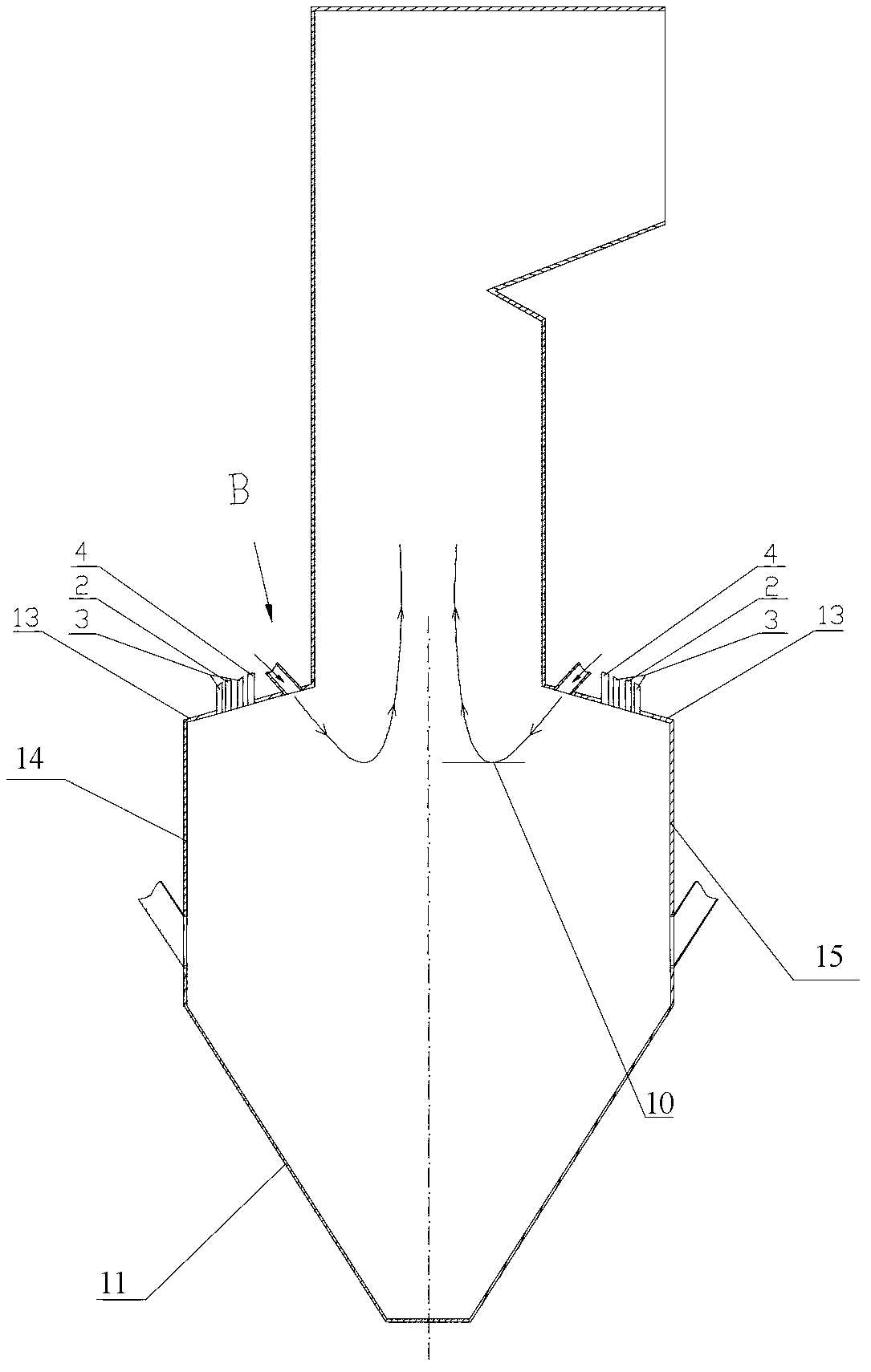

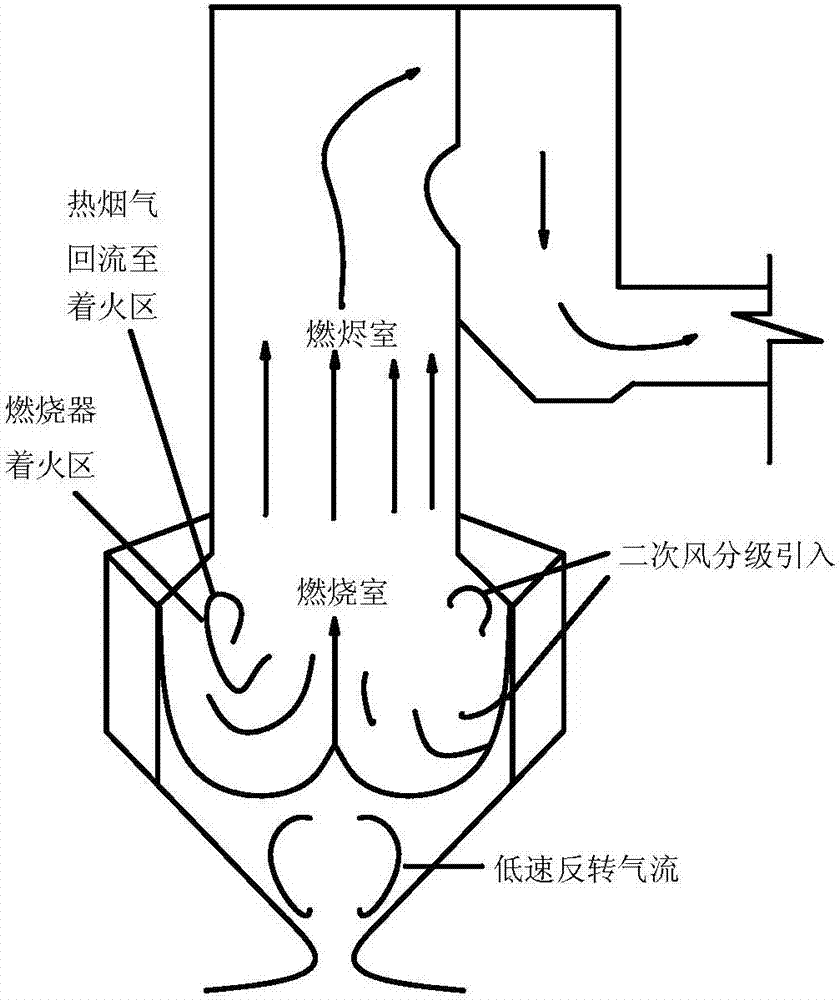

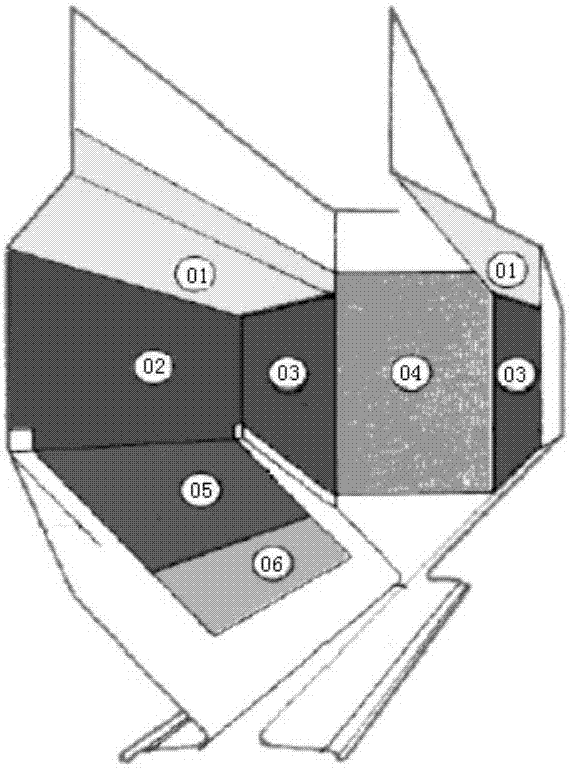

Method for arch single-stage injection fractional combustion and W flame boiler for realizing method

ActiveCN101832548AReduce combustible contentReduce slaggingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionSingle stage

A method for arch single-stage injection fractional combustion and a W flame boiler for realizing the method relate to a fractional combustion method and a W flame boiler. The invention aims at the problems that the W flame boiler has high NOx discharge, high flying ash combustible content, serious lagging on water cool wall front and behind a lower hearth and inferior flame stability. The method of the invention comprises the steps of gradually injecting through arch secondary air with an air speed of 35 to 65 m / s, taking thick coal powder airflow with the air speed of 10 to 20 m / s to inject downwards, and injecting the arch secondary air with the air speed of 35 to 65 m / s into the furnace through an arch secondary air nozzle. The boiler of the invention comprises a thick coal powder airflow nozzle, an arch secondary air nozzle and a thin coal powder airflow nozzle which are arranged on the furnace arch from the center of the furnace to the front and back water cool walls, wherein the thick coal powder airflow nozzle is abutted to the arch secondary air nozzle and an arch lower secondary air nozzle is arranged on the front and back water cool walls on the lower furnace along the width direction of the furnace. The W flame boiler for realizing the method of the invention can decrease the W flame boiler and the flying ash combustible content.

Owner:HARBIN INST OF TECH

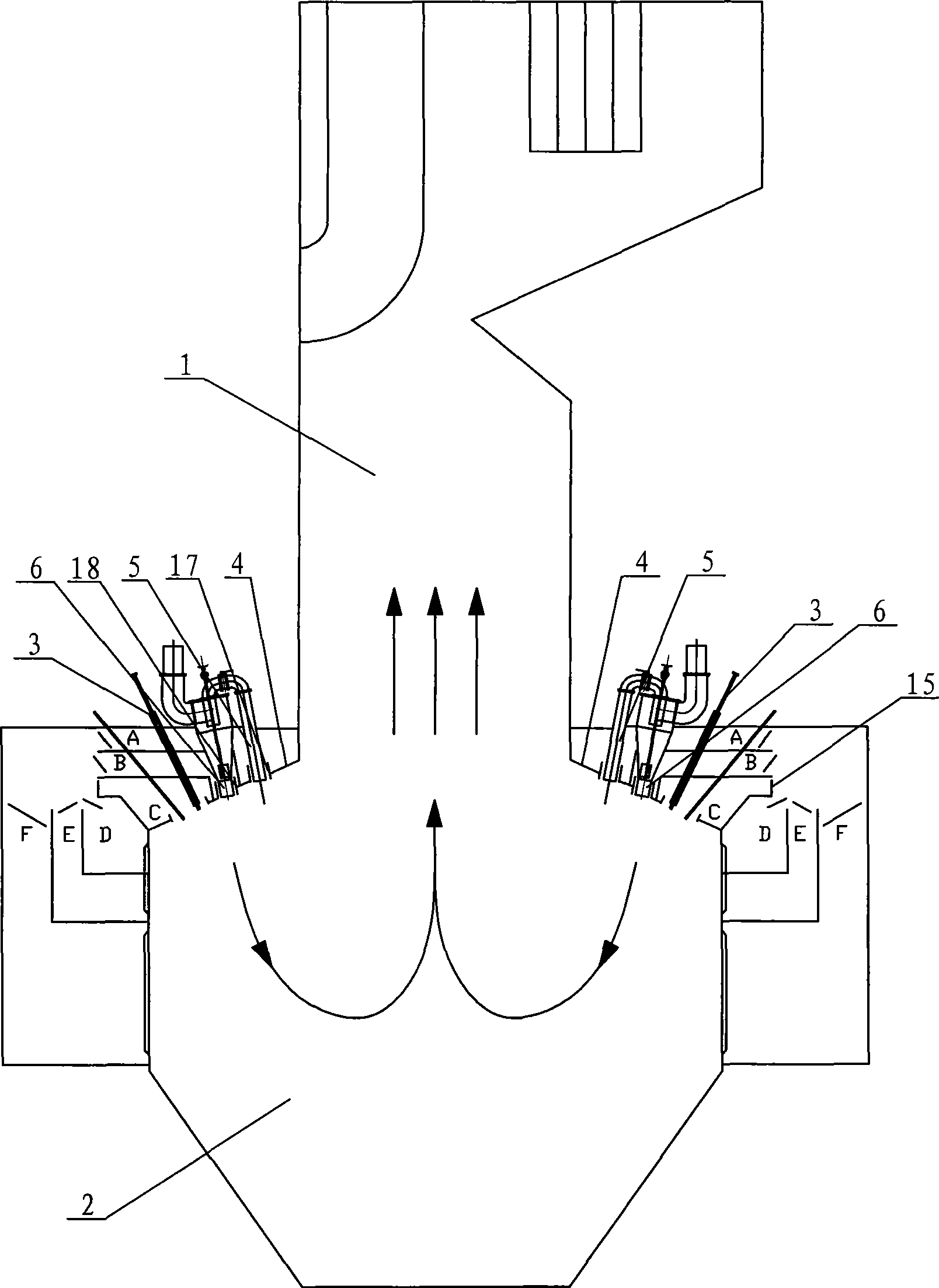

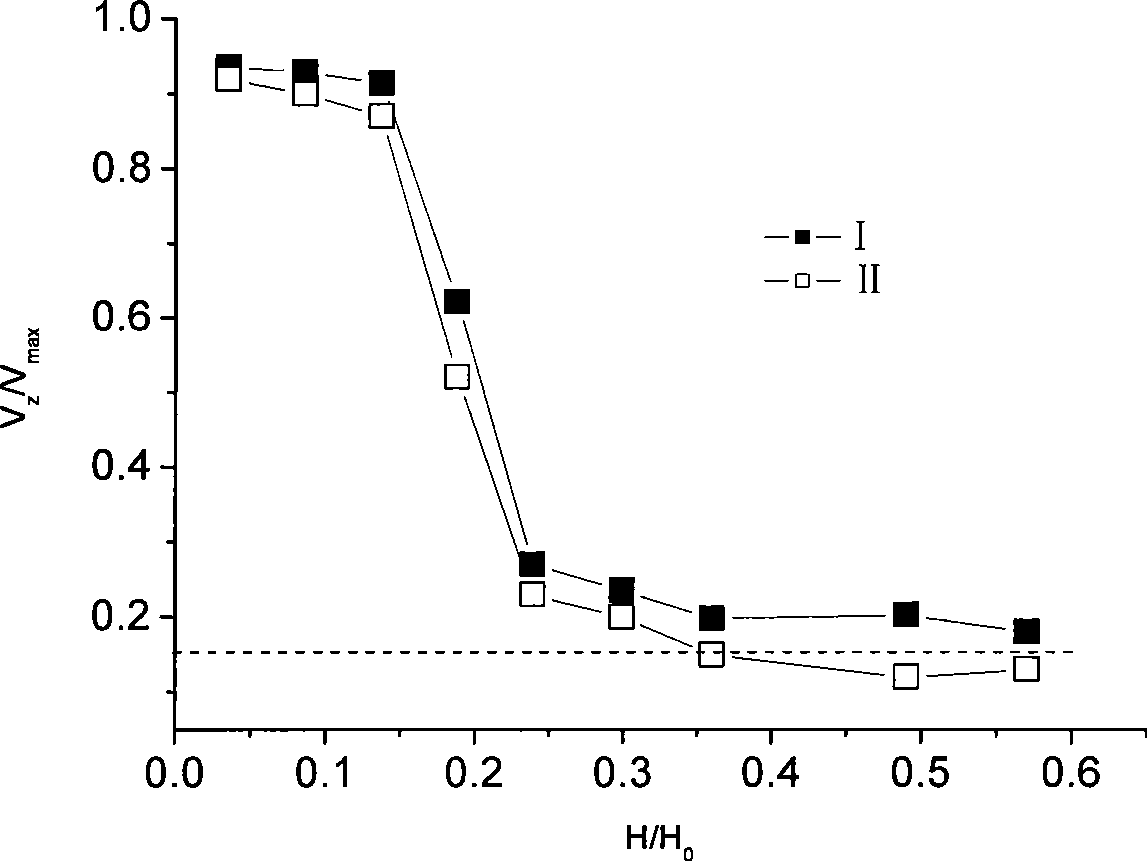

Method for adjusting combustion of W flame furnace by changing quantity of oil secondary air

ActiveCN101545639AChange the combustion situationIncrease the itineraryAir supply regulationCombustion apparatusCombustion chamberMomentum

The invention discloses a method for adjusting combustion of a W flame furnace by changing quantity of oil secondary air, relates to a method for combustion of a W flame furnace, and solves the problem that the fly ash combustible content is over high when the flame combustion technology of the prior W flame furnace designed by Foster Wheeler Company is used. The method is realized by the following steps: when a boiler works normally after an oil gun (3) ignites, opening an air door (9) in a third air layer (C), and continually introducing oil secondary air, wherein the quantity of the introduced oil secondary air is 12 to 40 percent of the quantity of secondary air; and the opening degree of the air door (9) is between 20 and 100 percent. By opening the air door (9) in the third air layer (C) and continually introducing the oil secondary air into a combustion chamber, the combustion condition in the combustion chamber is changed so that a ratio of an upper arch momentum to a lower arch momentum is 6:1-9:1, thereby increasing coal dust stroke and prolonging the detention time of coal dust. The method is favorable for burnout and can effectively reduce the fly ash combustible content.

Owner:HARBIN INST OF TECH

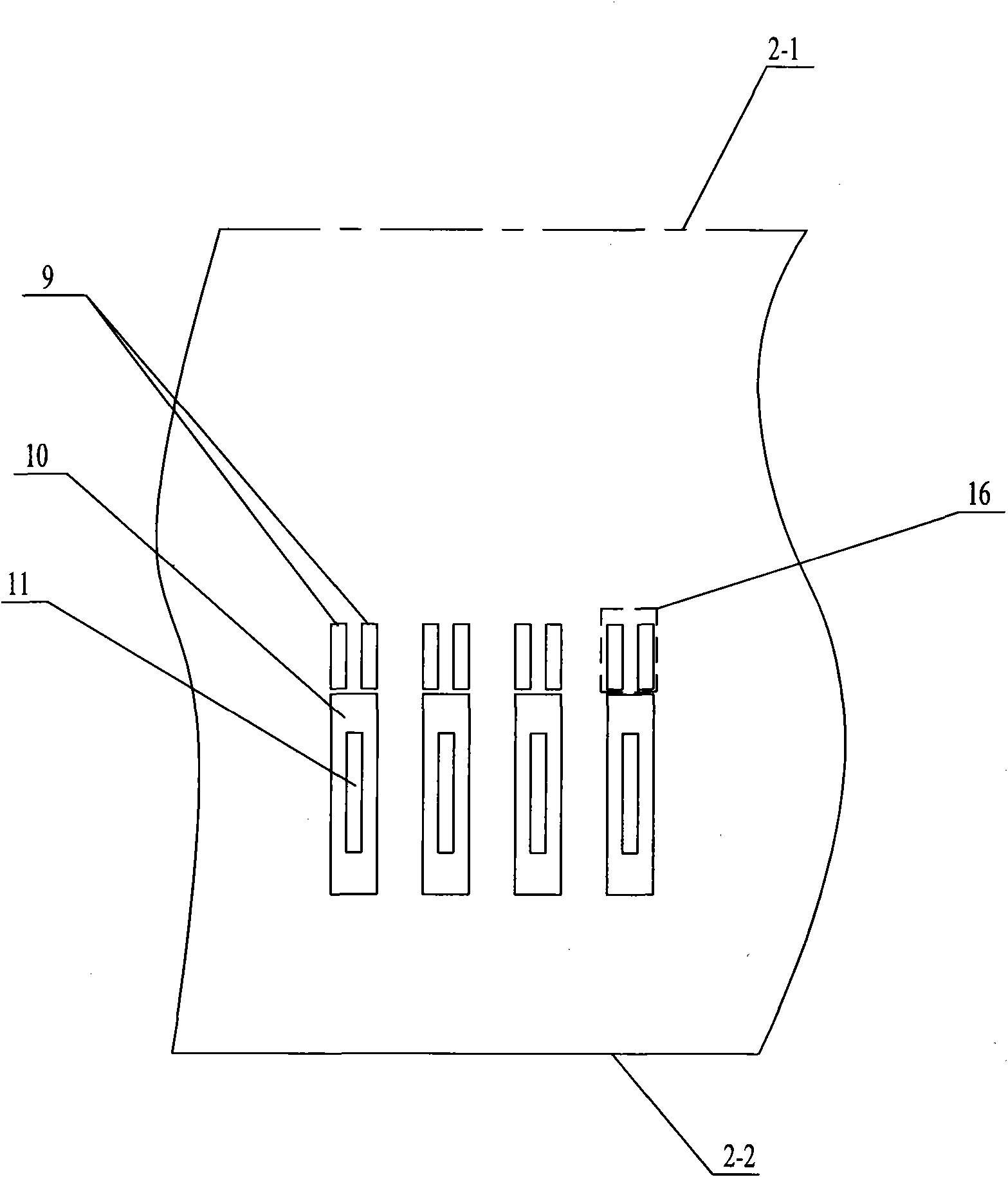

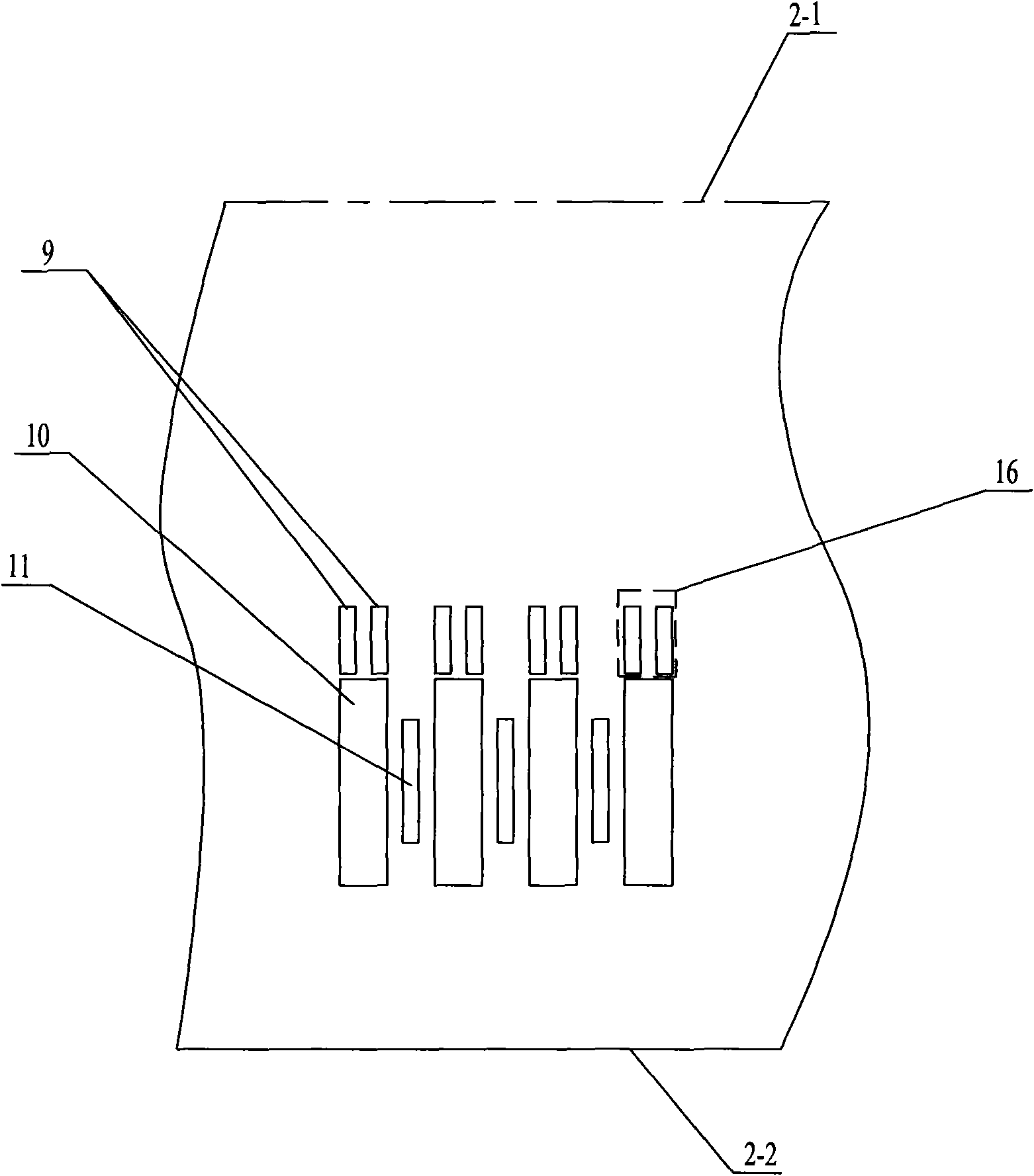

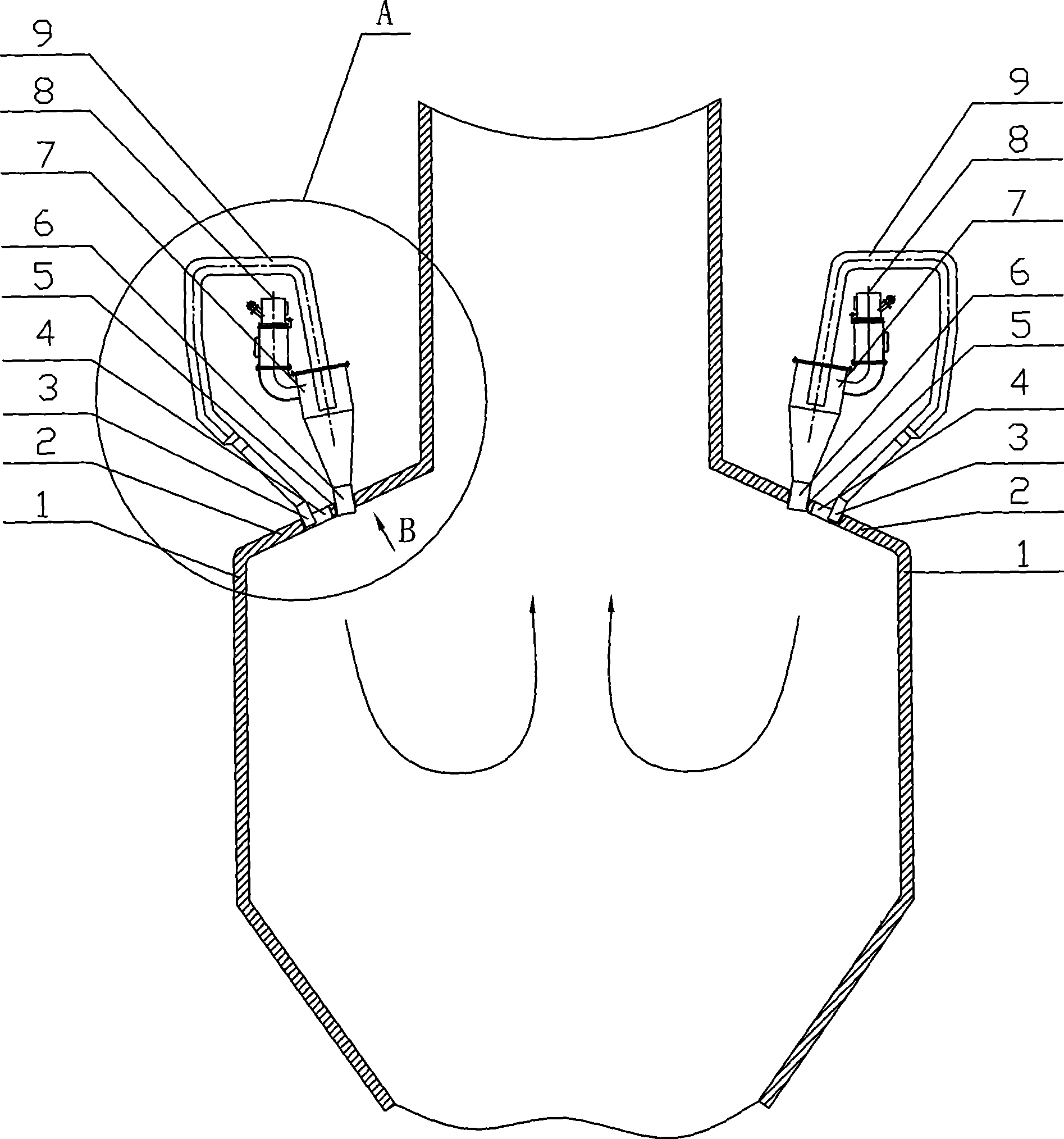

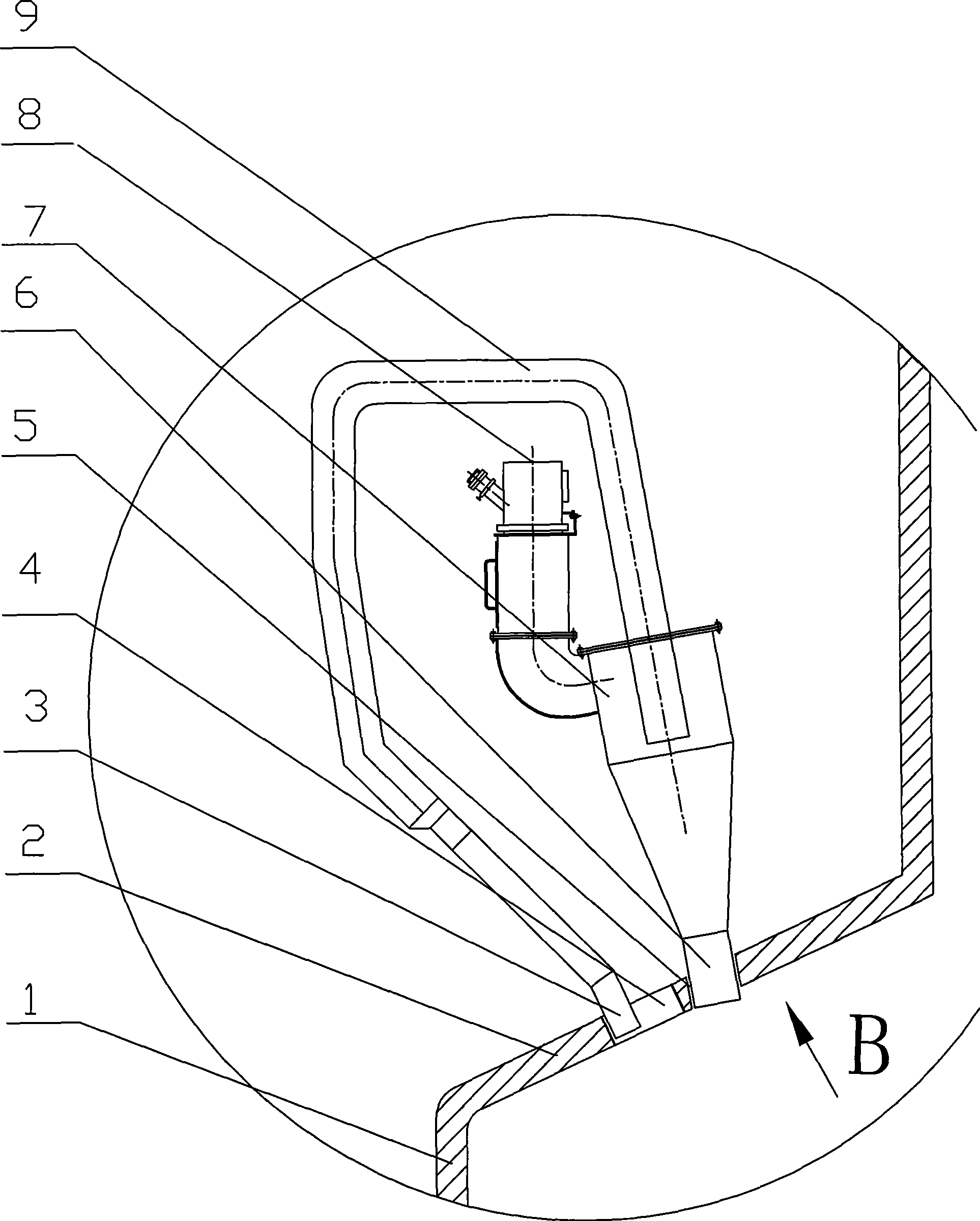

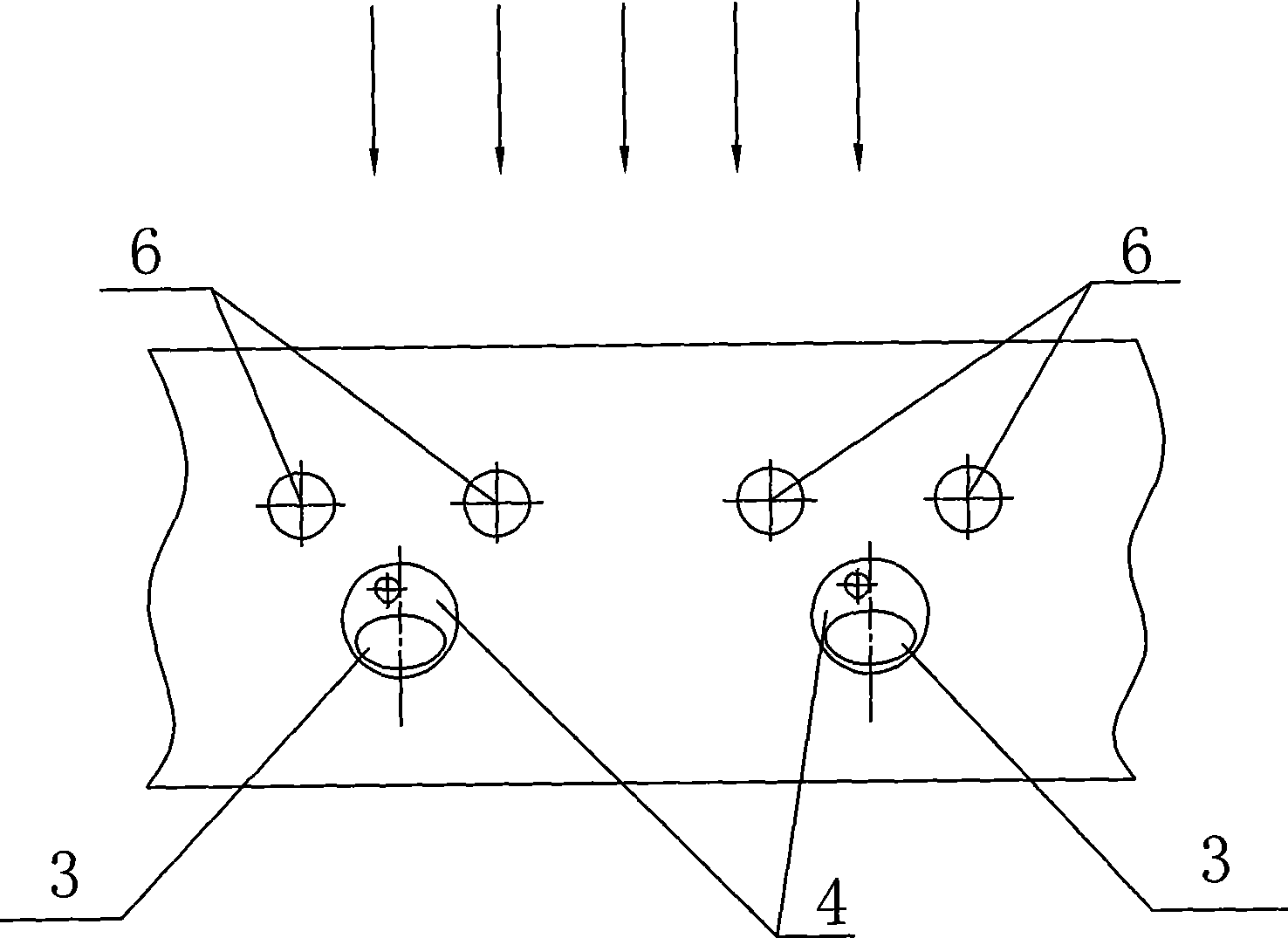

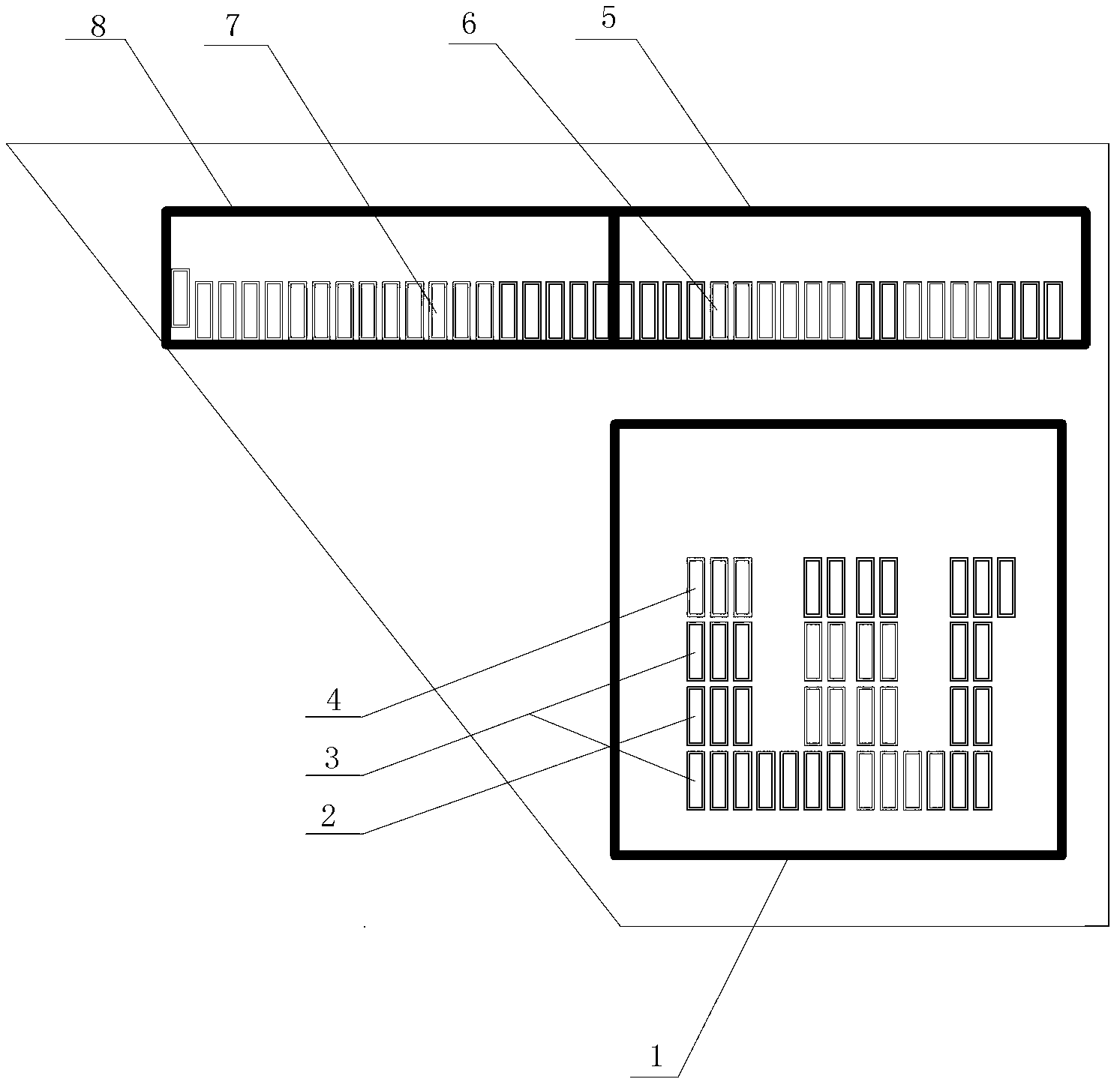

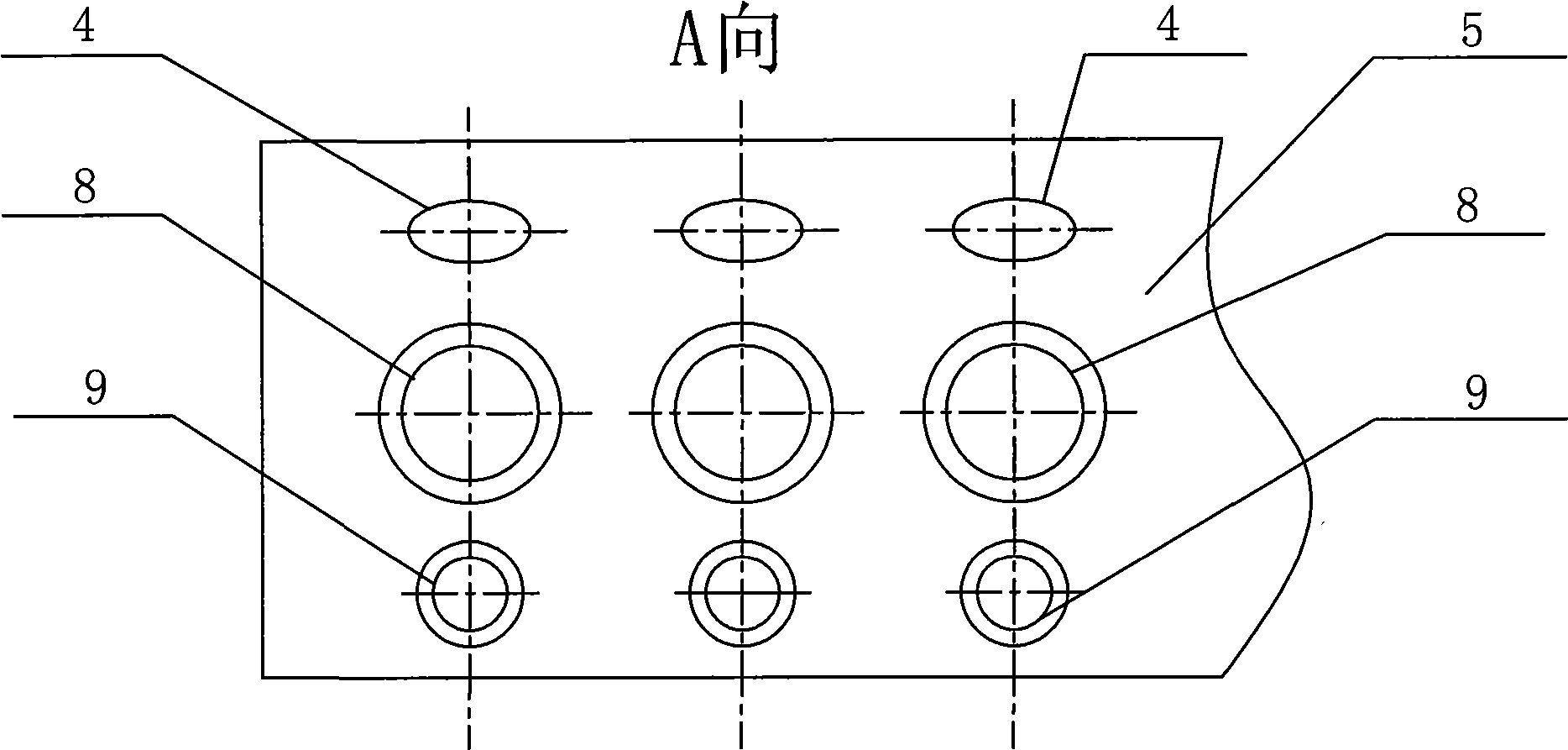

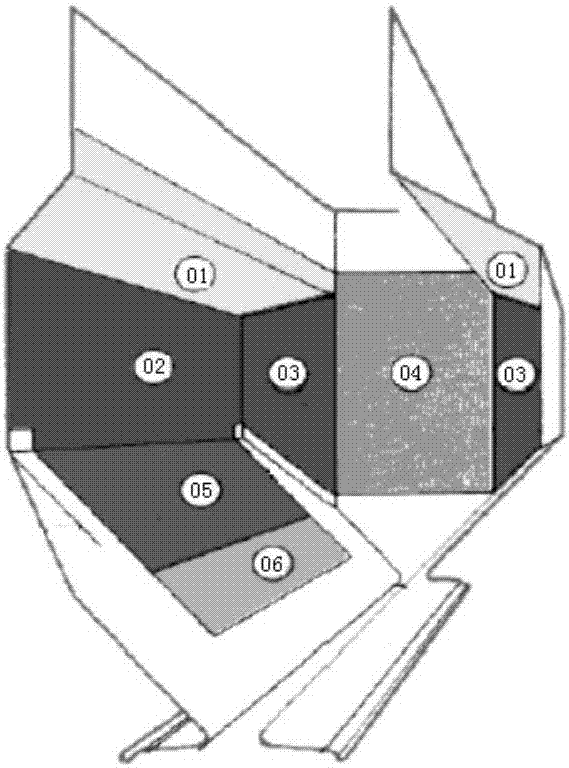

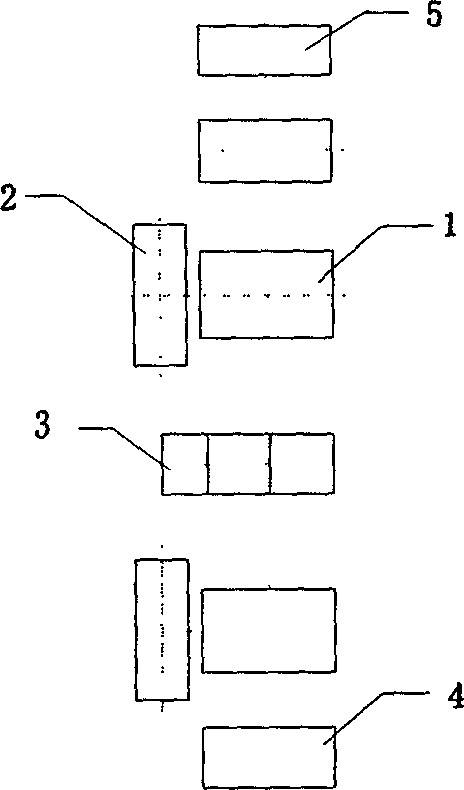

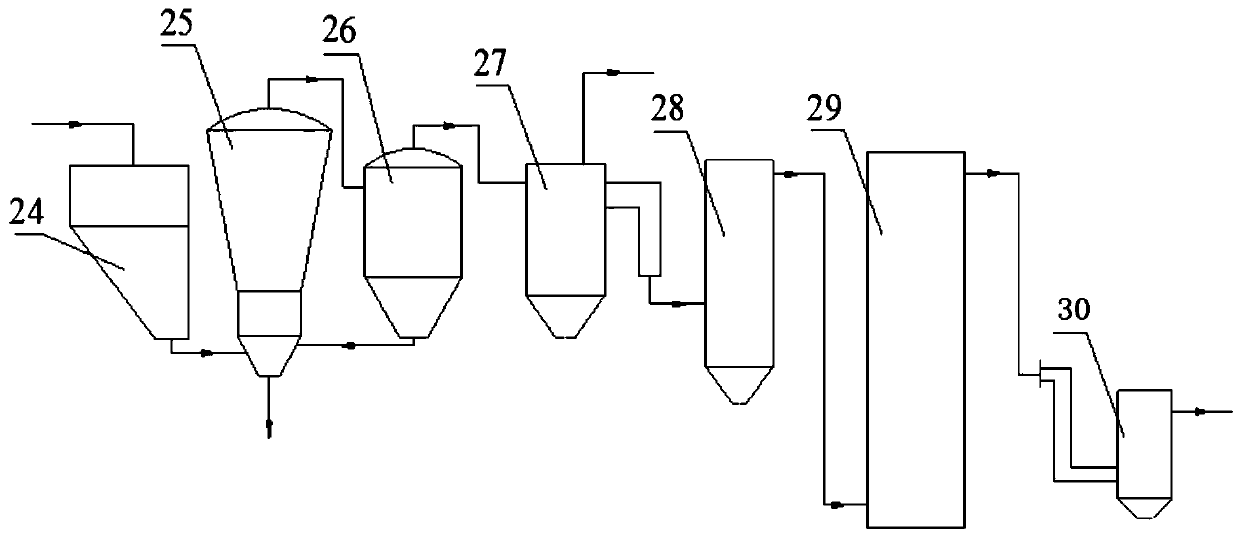

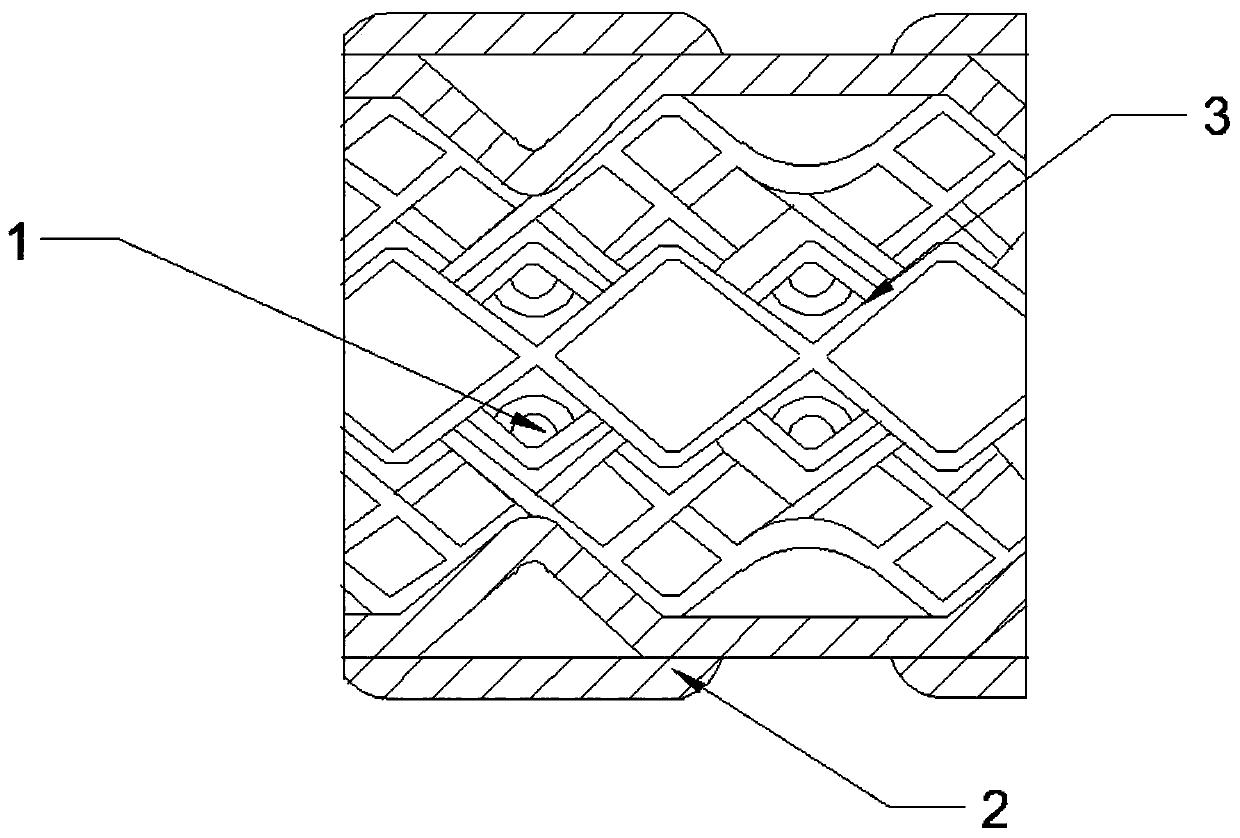

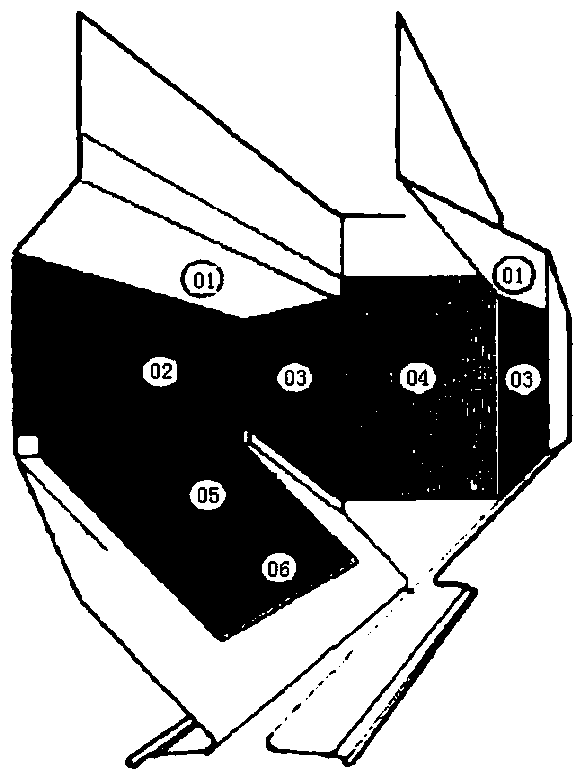

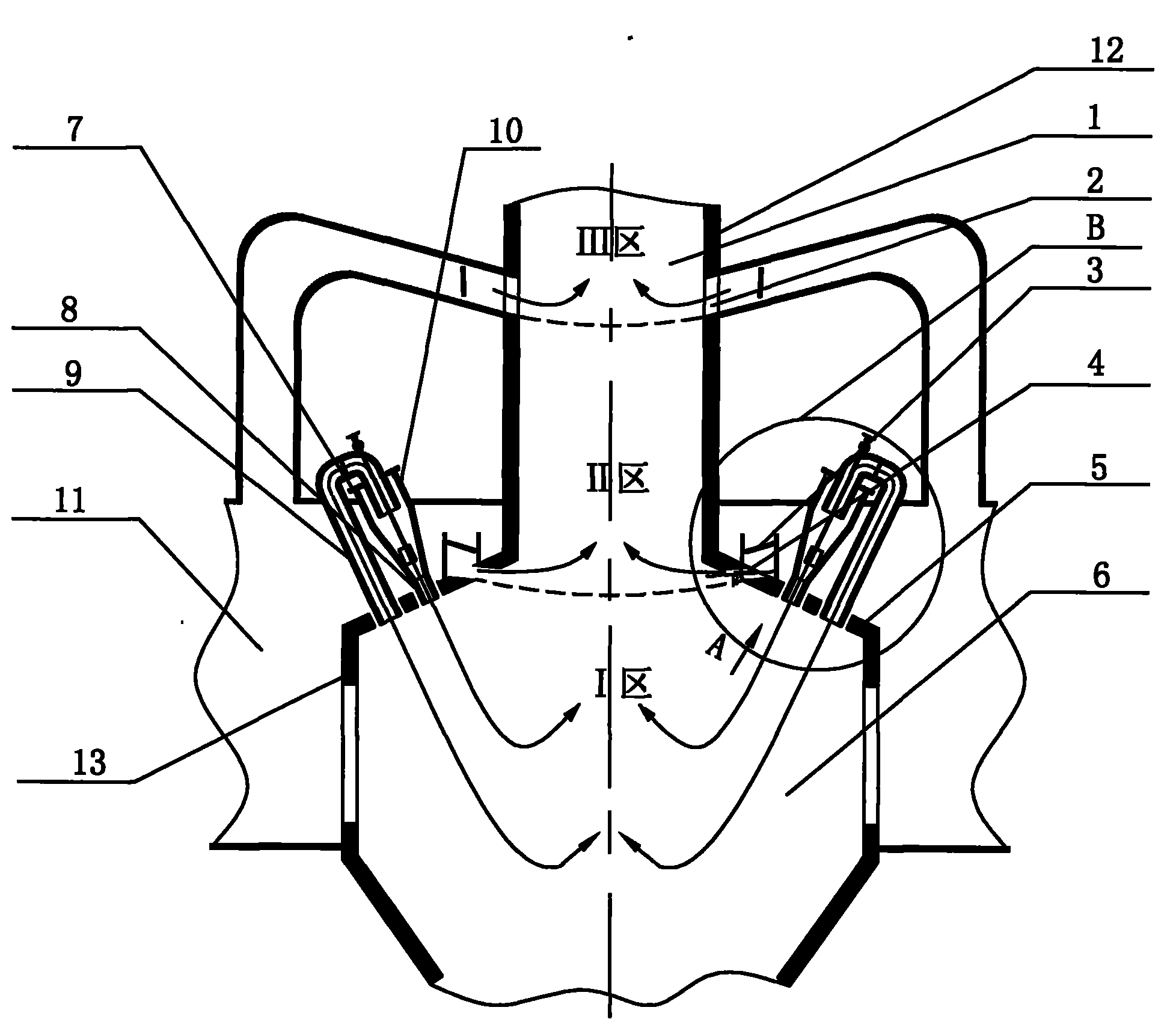

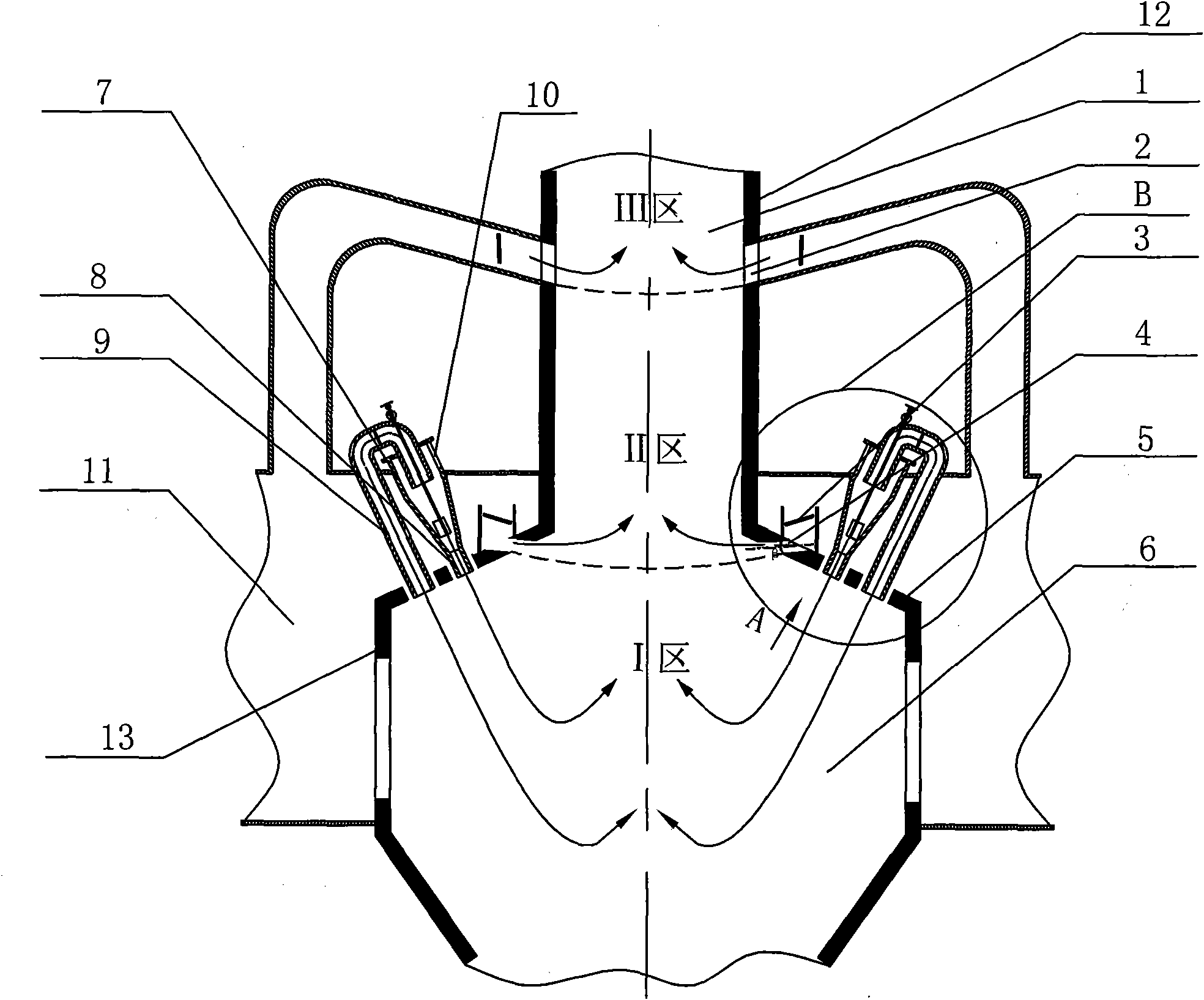

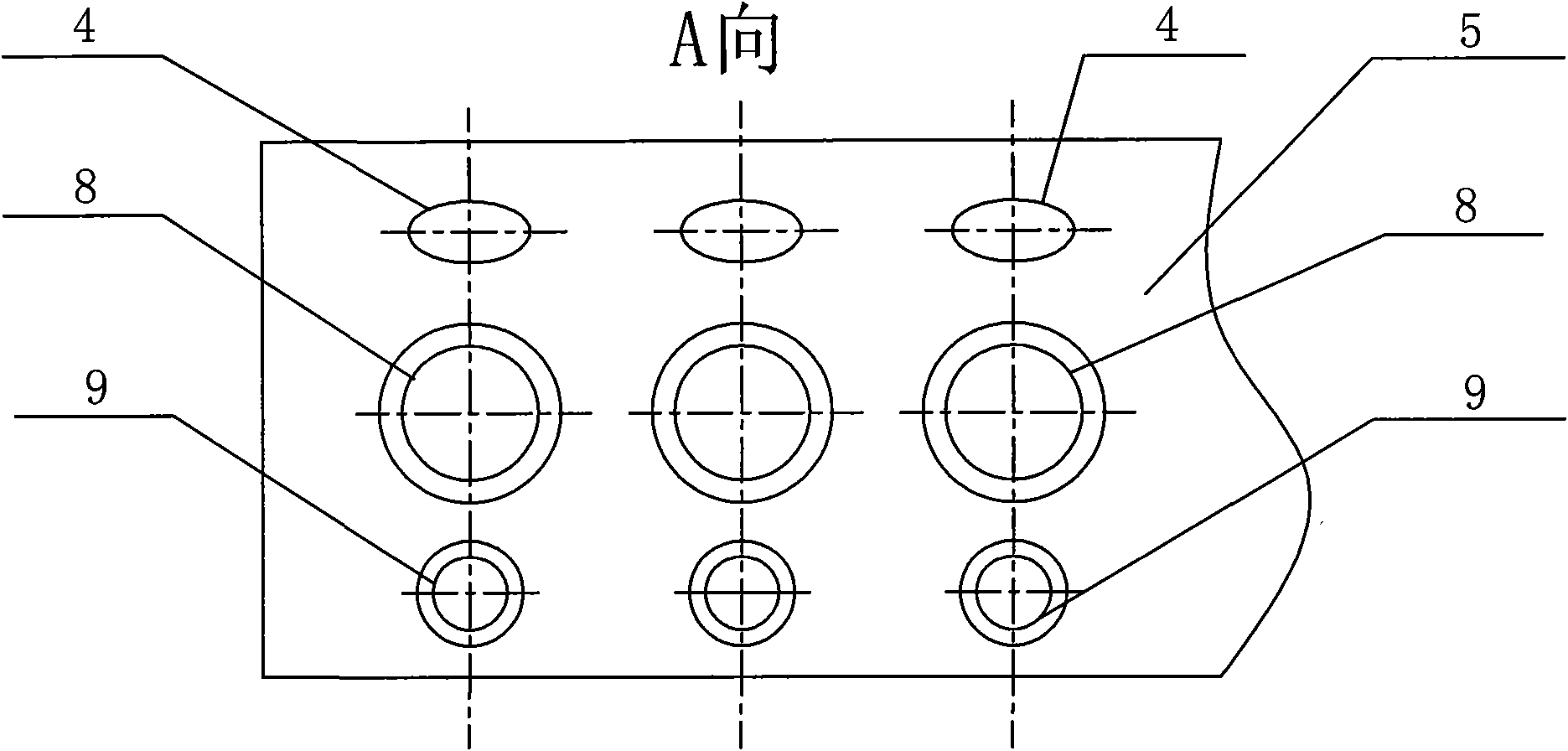

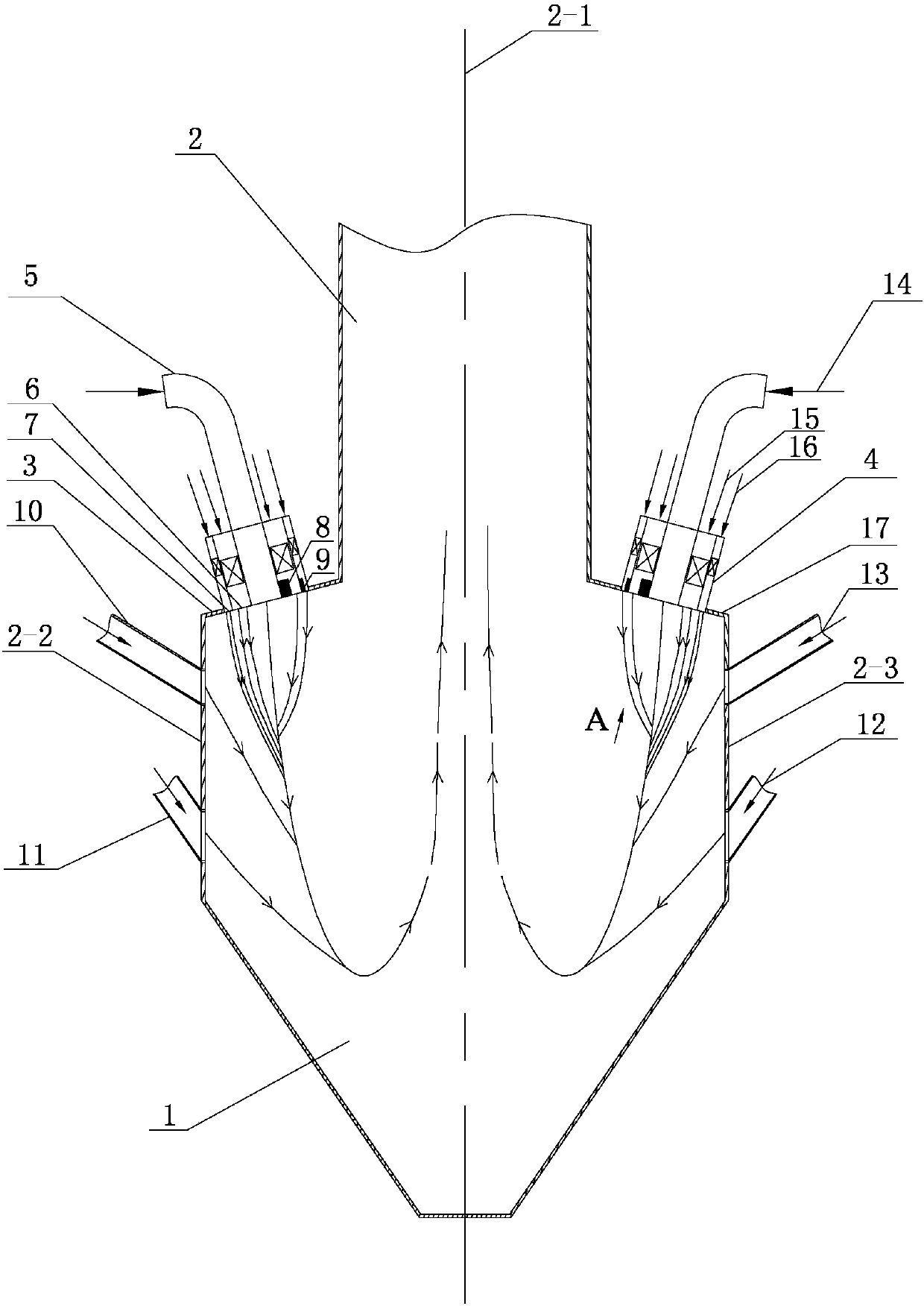

Combustion device with thin and thick breeze airflow stagger arrangement used for W-shaped flame furnace

InactiveCN101476719AEmission reductionReduce combustible contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHearthEngineering

The invention provides a combustion device used for staggeredly arranging rich / lean pulverized coal airflow on a W-shaped flame furnace, and relates to the combustion device. The combustion device solves the problems of unstable combustion and non timely ignition of the prior W-shaped flame furnace. A lean pulverized coal airflow nozzle (3) is inserted into an oil secondary air spout (4) and communicated with a furnace hearth, and the oil secondary air spout (4) is arranged on a furnace arch (2) close to a front wall or a rear wall (1). Rich pulverized coal airflow nozzles (6) are arranged on the furnace arch (2) close to the center of the furnace hearth and communicated with the furnace hearth, and a gap between the rich pulverized coal airflow nozzles (6) and the side wall of the furnace arch (2) is a perimeter air port (5); and the lean pulverized coal airflow nozzle (3) is arranged between the two rich pulverized coal airflow nozzles (6). The invention provides the rich / lean pulverized coal combustion device with high-efficiency and stable combustion and low NOx. The device can make the lean pulverized coal airflow receive radiant heat from a high temperature area in the middle of the furnace hearth well, ignite in time, reduce the fly ash combustible content, and realize low NOx combustion.

Owner:HARBIN INST OF TECH

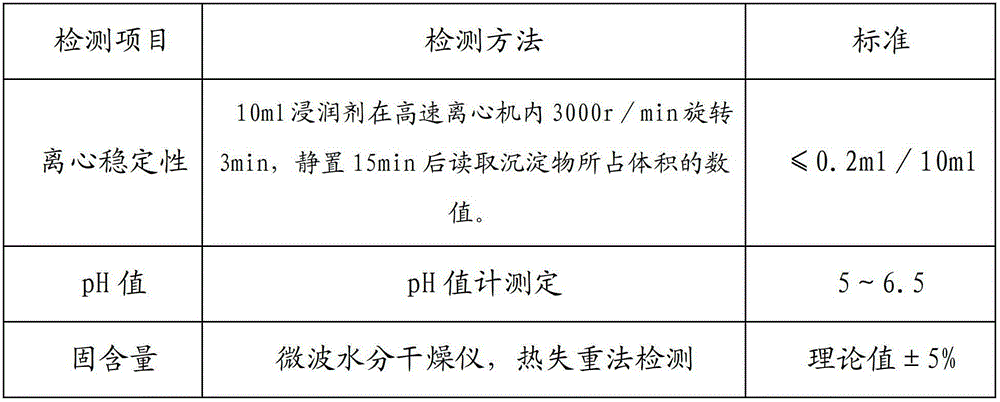

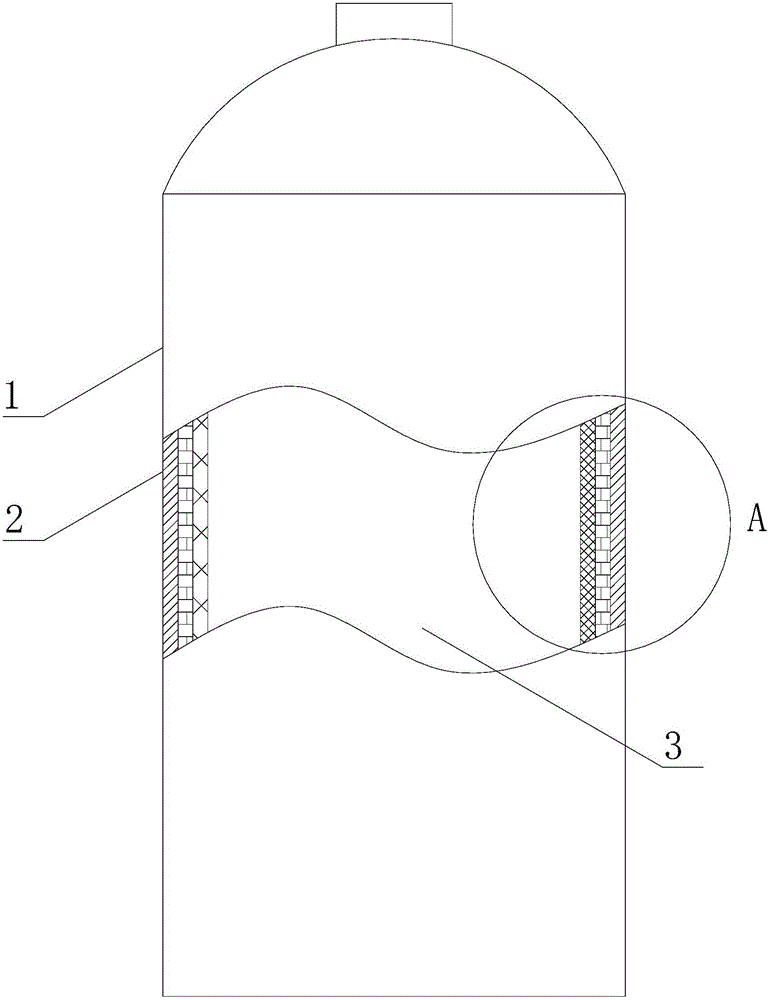

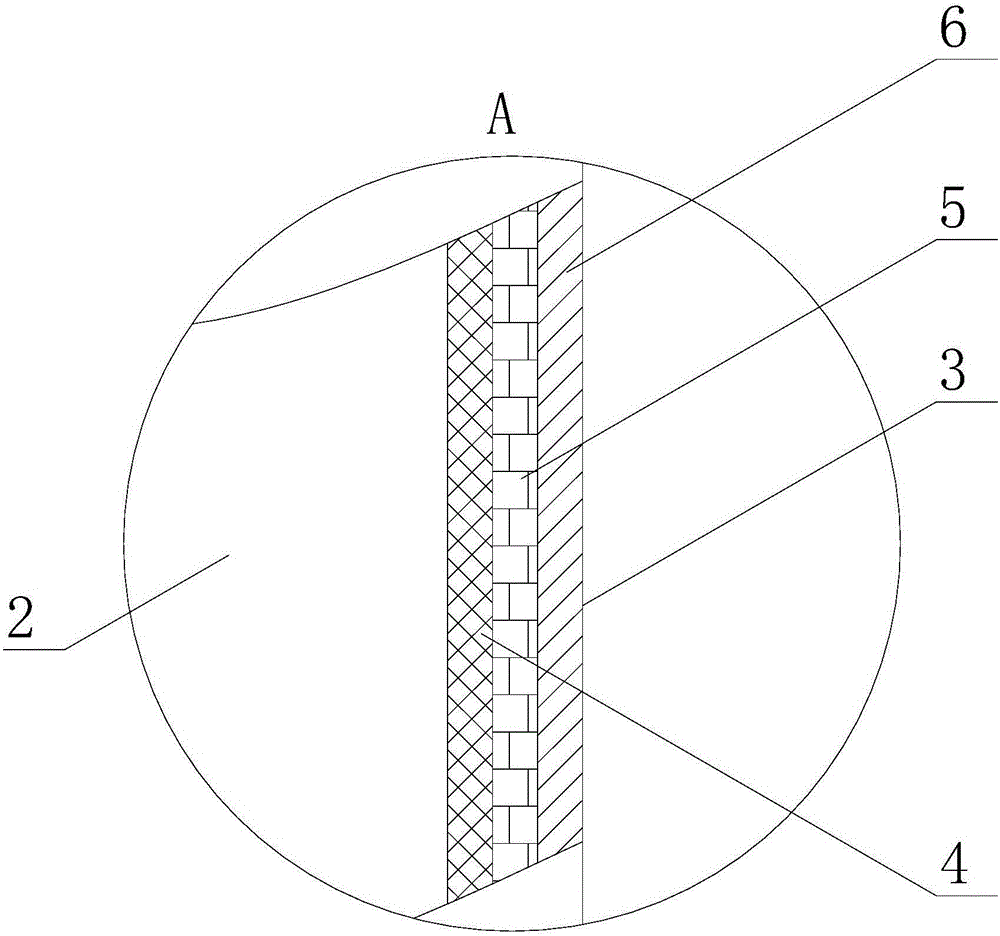

Special impregnating compound for glass fiber swelled yarn and preparation method thereof

The invention relates to a special impregnating compound for glass fiber swelled yarn. The special impregnating compound for glass fiber swelled yarn comprises the following components in proportion relative to the total mass of the impregnating compound: 0.2-0.4% of coupling agent, 0.3-0.6% of lubricating agent A, 0.01-0.1% of lubricating agent B, 0.1-0.3% of lubricating agent C, 1-2% of film-forming agent, 0.09-0.2% of ph value regulating agent, and the balance being deionized water. The impregnating compound provided by the invention adopts ultralow molecular weight epoxy emulsion as the film-forming agent, has the advantages of simpleness in preparation process and low cost. The swelled yarn for the mobile muffler padding, which is prepared from the impregnating compound provided by the invention, has an extremely high swelled rate being above 98%, greatly improves filling efficiency and greatly improves performance of a muffler.

Owner:SHANDONG FIBERGLASS GRP

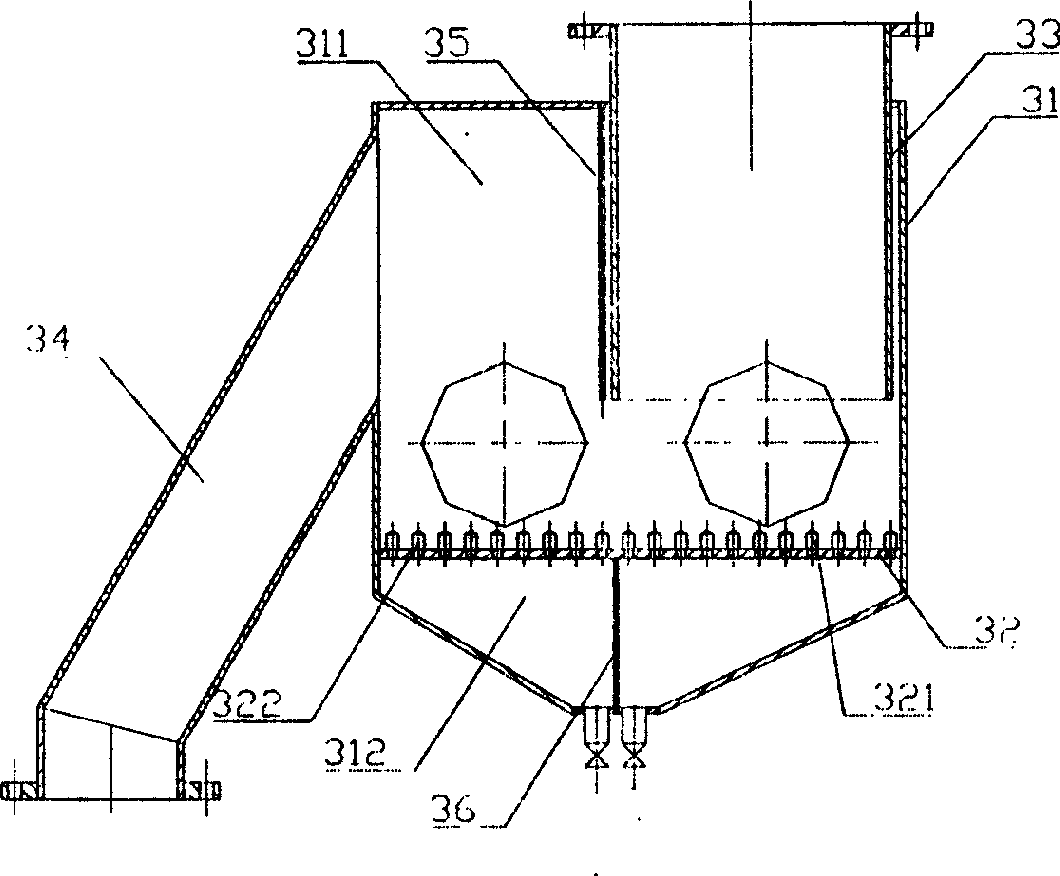

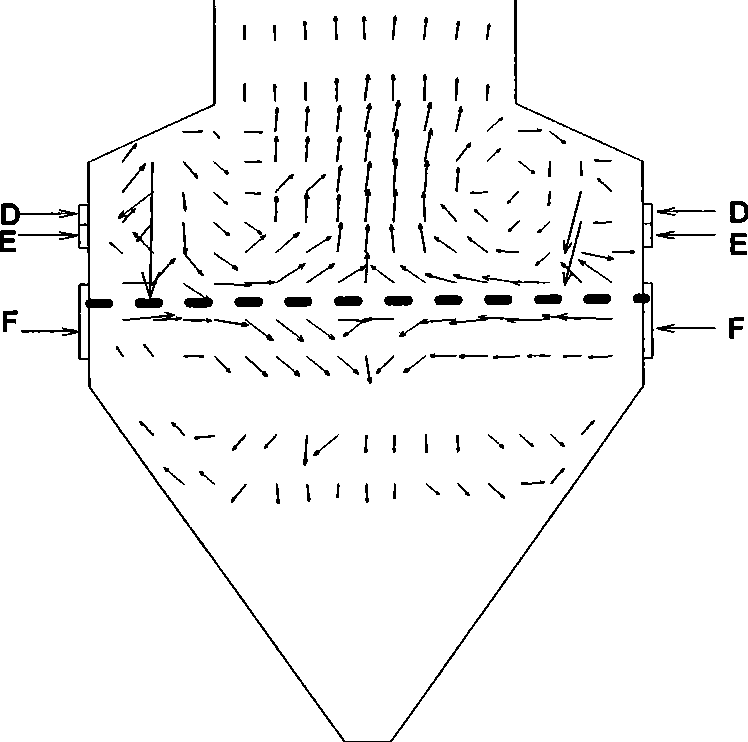

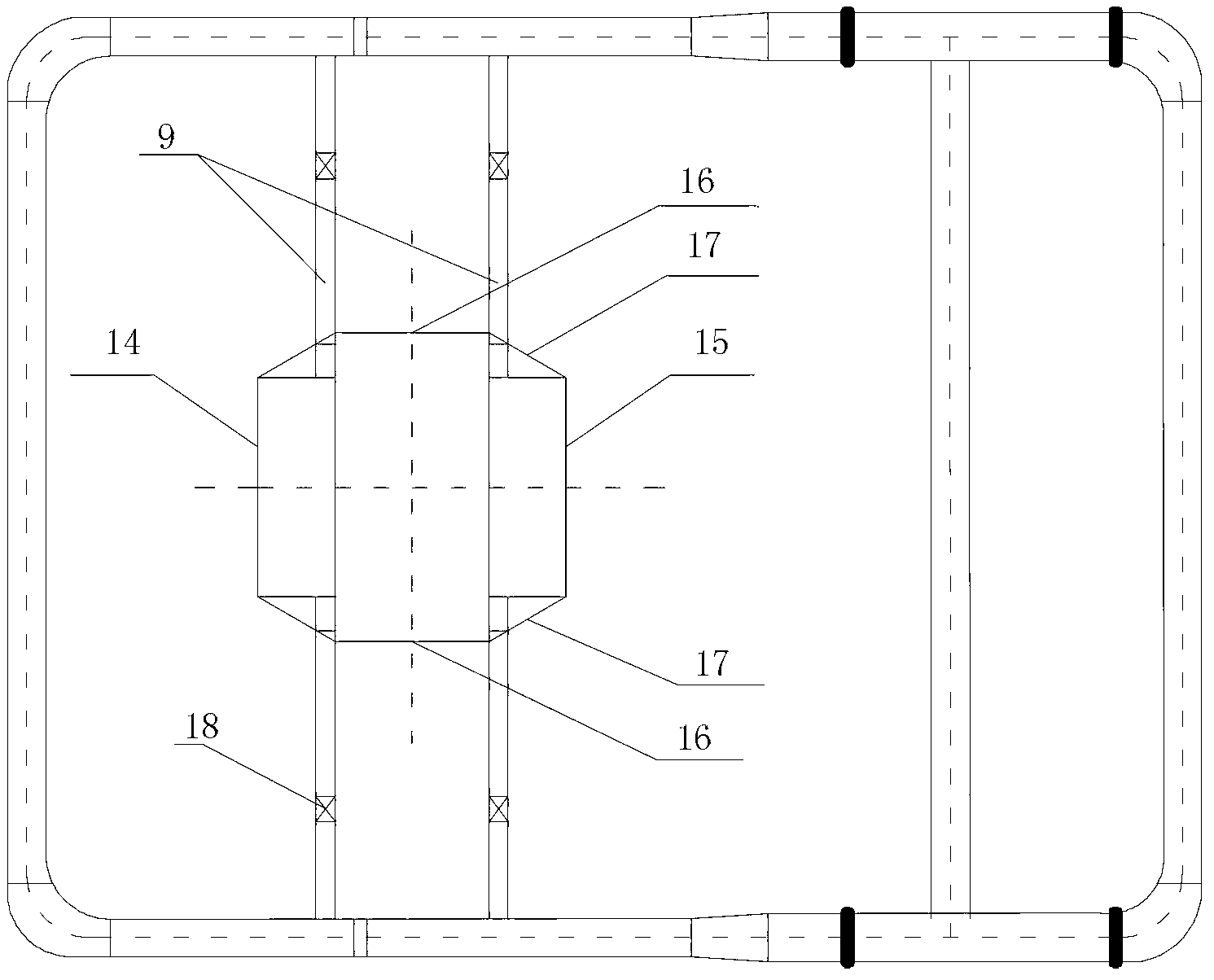

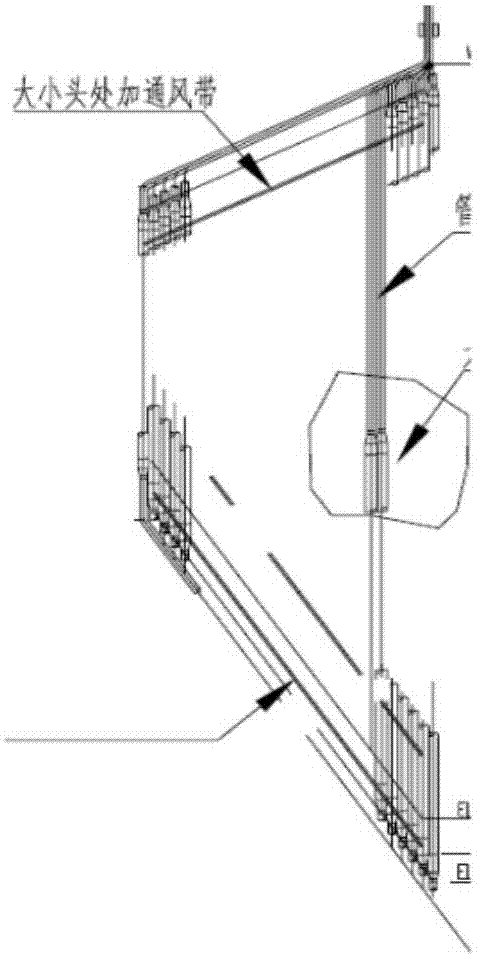

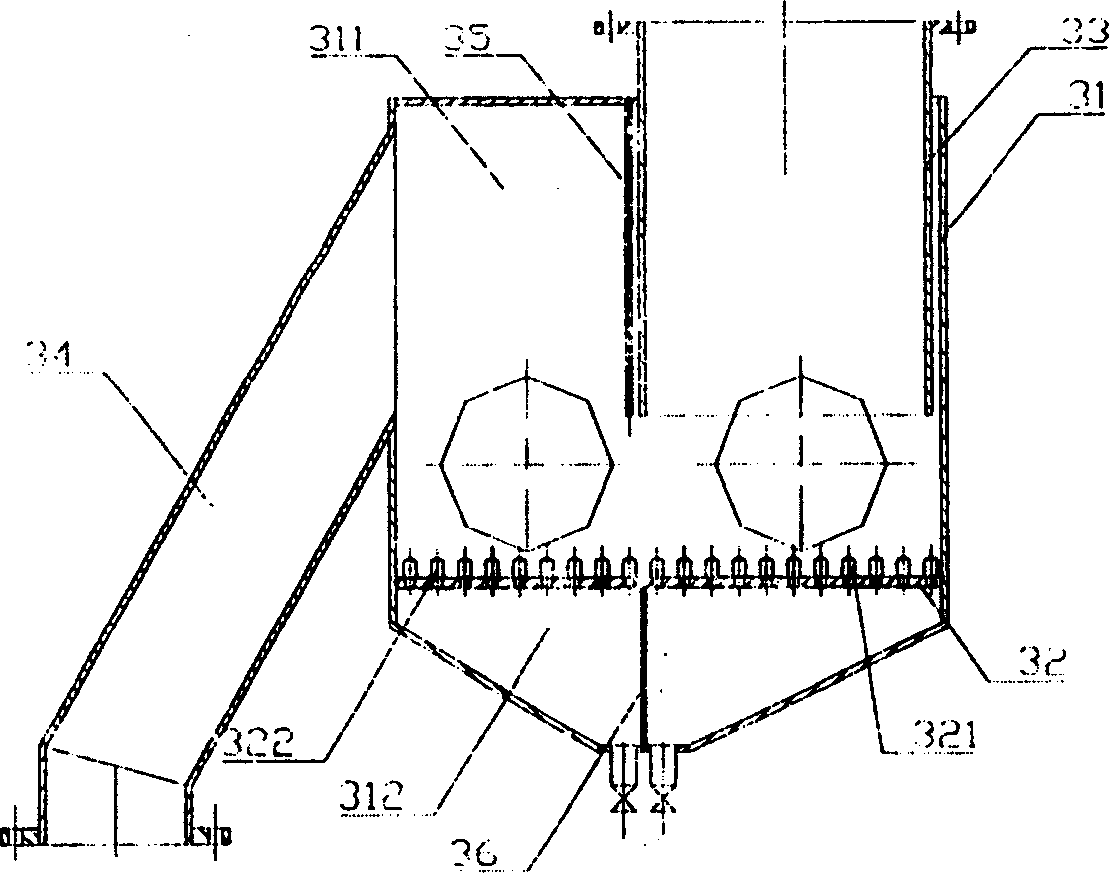

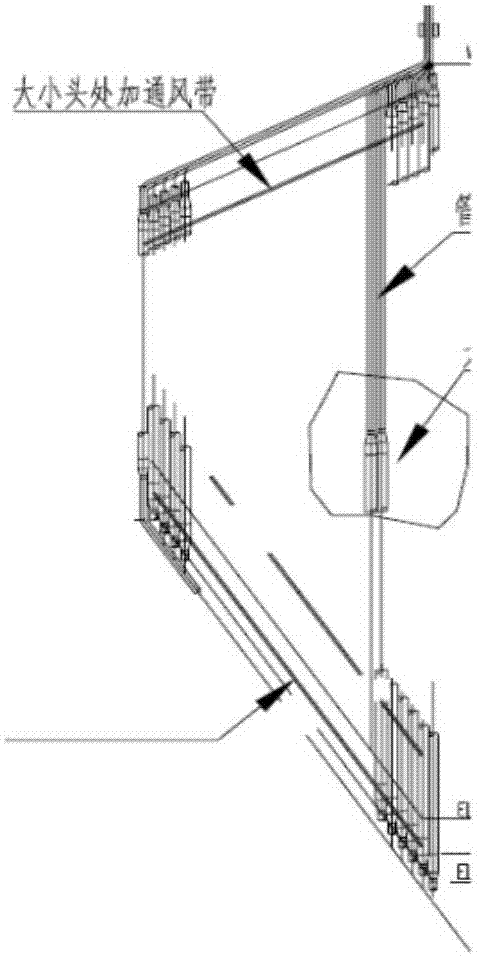

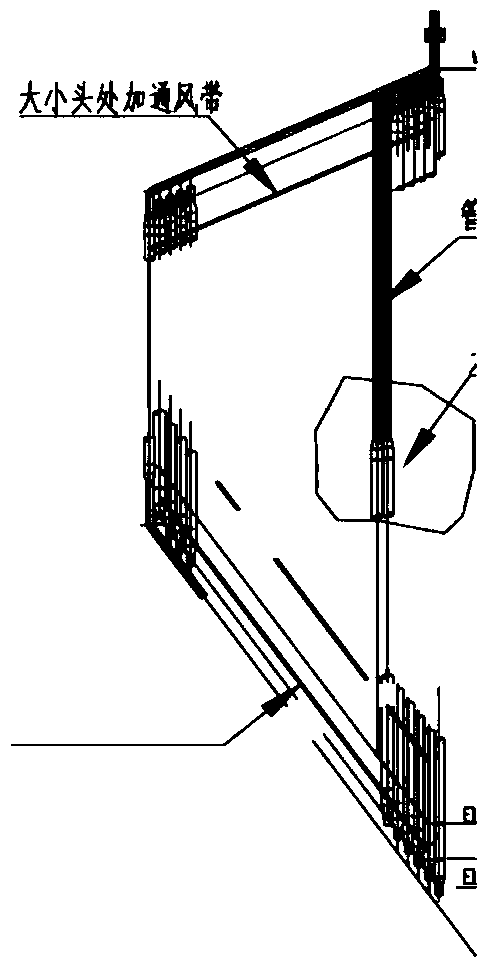

W-shaped flame boiler gap type OFA (over fire air) device arranged above arch wing wall

The invention discloses a W-shaped flame boiler gap type OFA (over fire air) device arranged above an arch wing wall and relates to a boiler OFA device. The device solves the problems of a W-shaped flame boiler that in the case that OFA is increased and the NOX discharge is reduced, the flying ash is caused and the content of combustible matter is high, not all burners at four corners can be put into operation and the wall surfaces of water-cooling walls at beside the a side wall and wing walls are over-temperature, and even the water cooling walls in the region are torn. Each wing wall is provided with a group of gap type wing wall OFA nozzles, each group of gap type wing wall after combustion air nozzles is correspondingly provided with a wing wall OFA box, and each group of gap type arch OFA nozzles is correspondingly provided with an arch OFA box; and an air outlet of a fan is communicated with one end of a secondary air pipe, the other end of the secondary air pipe sequentially passes through a main burner air box, and the side wall of the secondary air pipe is respectively communicated with the arch OFA boxes and wing wall OFA boxes through a plurality of guiding pipes. The W-shaped flame boiler gap type OFA device provided by the invention is used for a W-shaped flame boiler.

Owner:HARBIN INST OF TECH

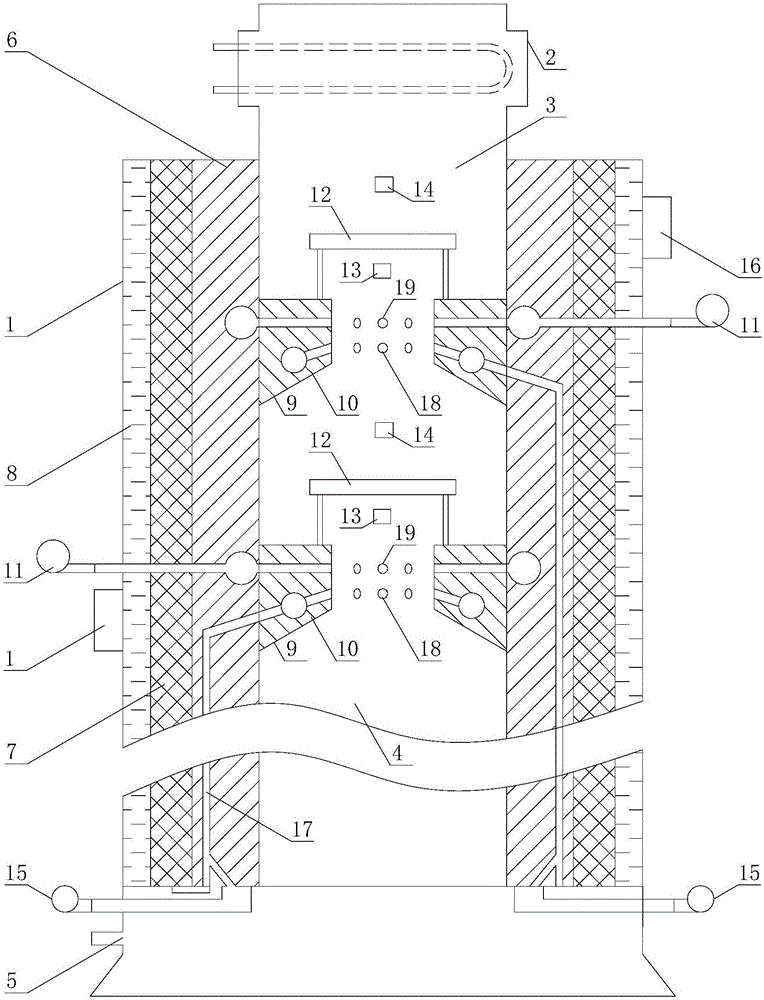

W-shaped flame boiler with two-stage over-fire wind

InactiveCN101476739AGuaranteed burnout rateGood for burnoutNon-combustible gases/liquids supplyCombustorSingle stage

The invention discloses a W-shaped flame boiler with two stages of burn-out wind, which relates to the W-shaped flame boiler and aims at the problems that the W-shaped flame boiler of the prior single-stage burn-out wind device has high content of fly ash inflammable matters and low burn-off rate of coal dust. The W-shaped flame boiler comprises a superior OFA nozzle (2) and an inferior OFA nozzle (4) which is arranged on a furnace arch (5) close to an hearth throat inlet, is communicated with a lower hearth (6), is arranged on the outer side of a burner (8), and is communicated with a secondary wind box (11). The W-shaped flame boiler not only can replenish air for the unburned coal dust in time to benefit the burnout of the coal dust and greatly reduce the content of the fly ash inflammable matters, but also can better achieve the fractional combustion of the coal dust and greatly reduce the emission of NOx.

Owner:HARBIN INST OF TECH

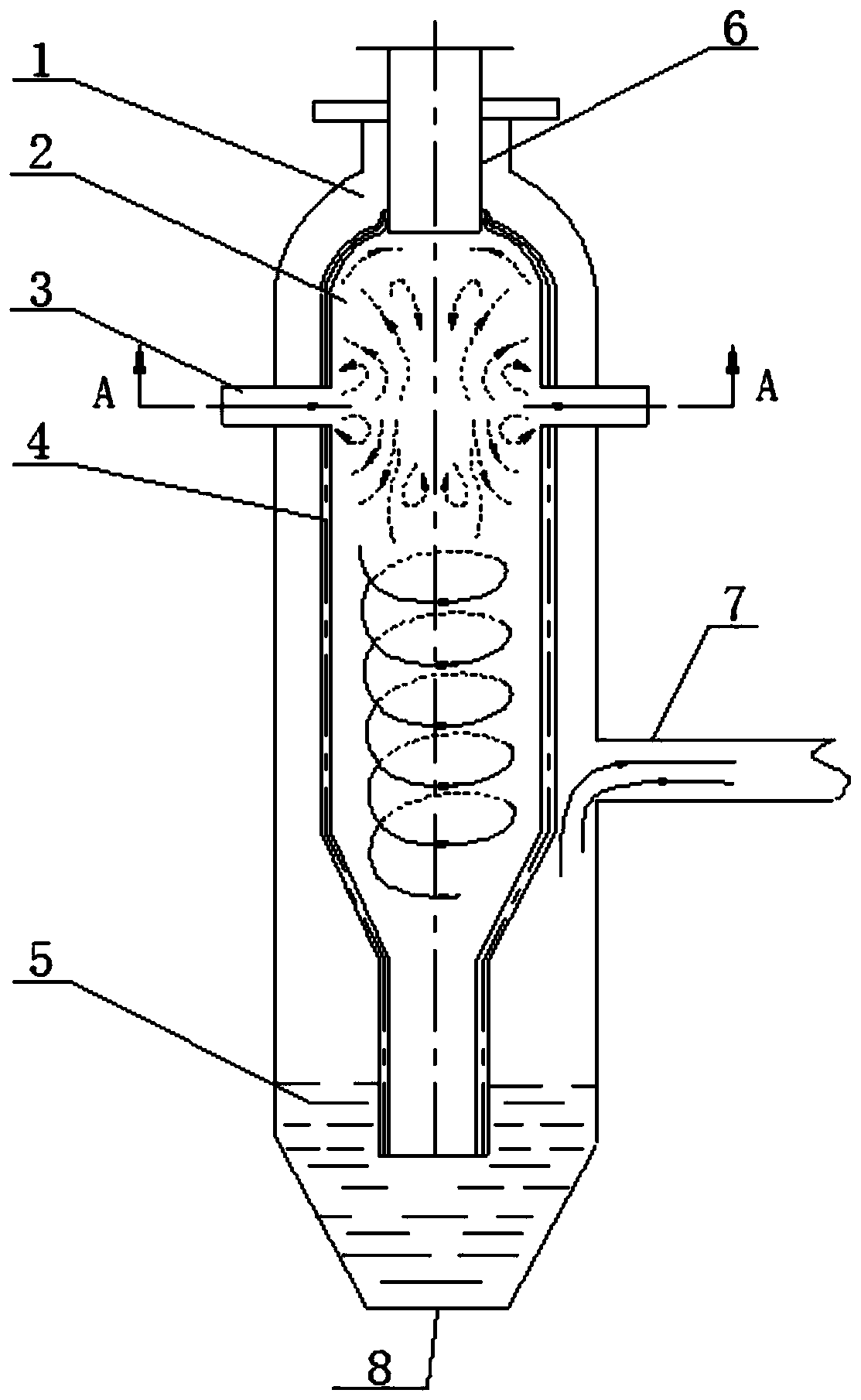

Dry powder gasification furnace

InactiveCN102676228AIncrease transfer rateImprove conversion rateGranular/pulverulent flues gasificationDecompositionWater vapor

The invention discloses a dry powder gasification furnace which comprises a furnace body, a top nozzle and a side nozzle, wherein the furnace body is internally provided with a vaporizing chamber; the top nozzle is arranged at the top of the furnace body, and is used for injecting pulverized coal, oxygen, steam and fuel gas into the vaporizing chamber from the top of the vaporizing chamber; the top nozzle is internally provided with an ignition rod; and the side nozzle is arranged at the side of the furnace body, and is used for injecting pulverized coal, oxygen and steam into the vaporizing chamber from the side of the vaporizing chamber. According to the dry powder gasification furnace, the carbon conversion rate is higher than 99%, and the decomposition rate of water vapor is higher than 80%; therefore, the dry powder gasification furnace has remarkable gasification efficiency and can be widely applied to the field of the existing coal gasification technology.

Owner:BEIJING YINGDE QINGDA TECH

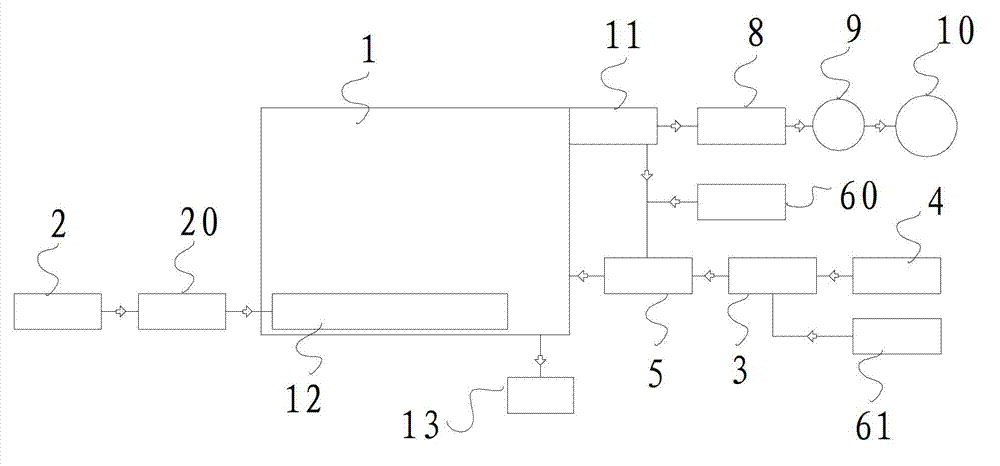

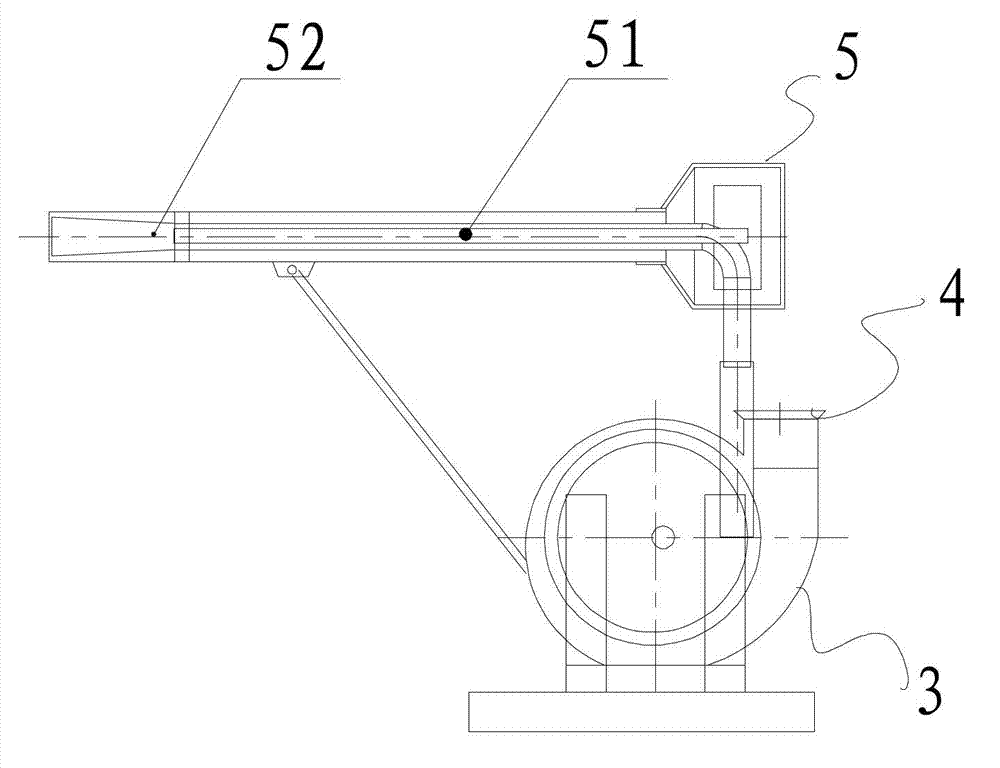

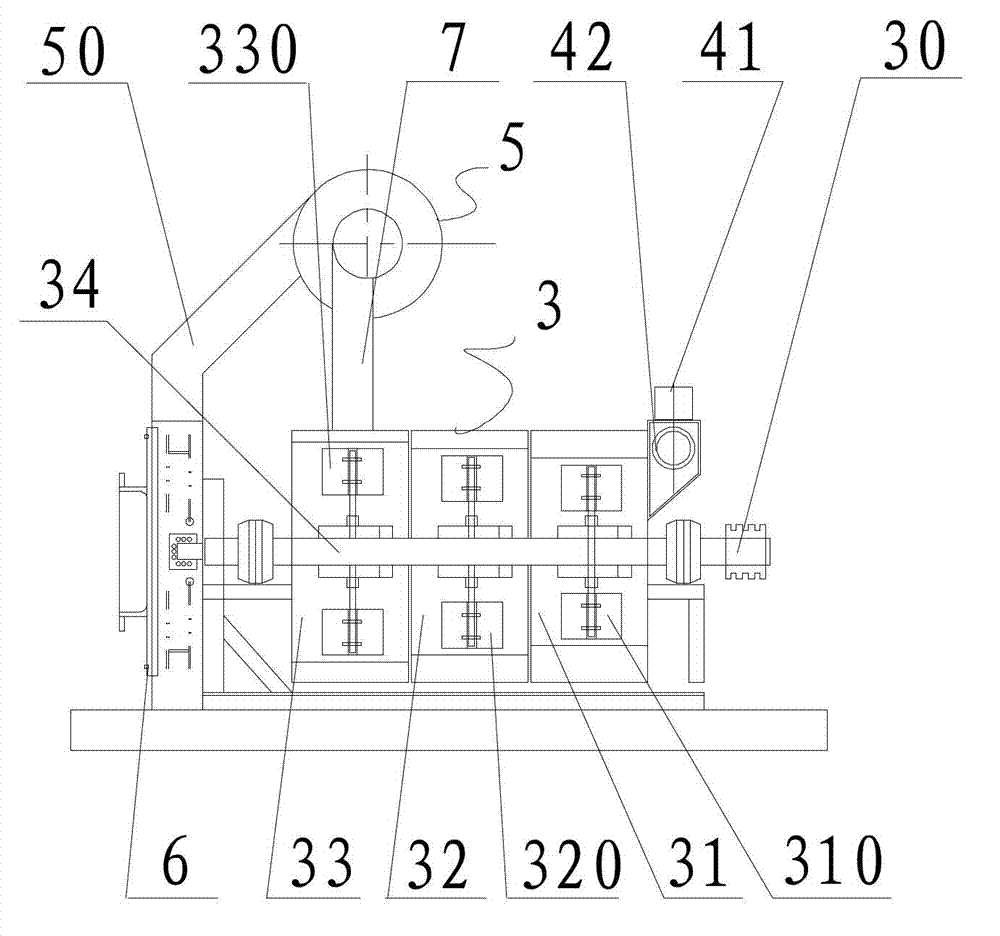

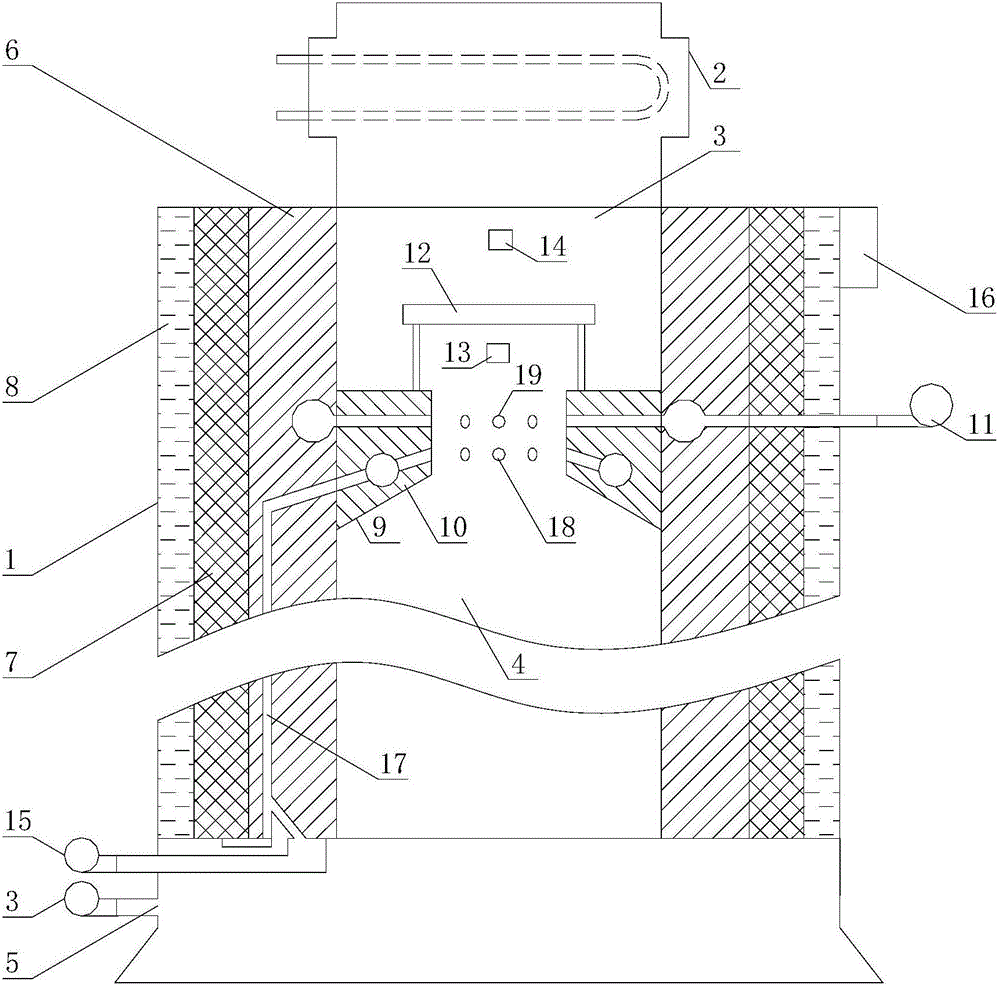

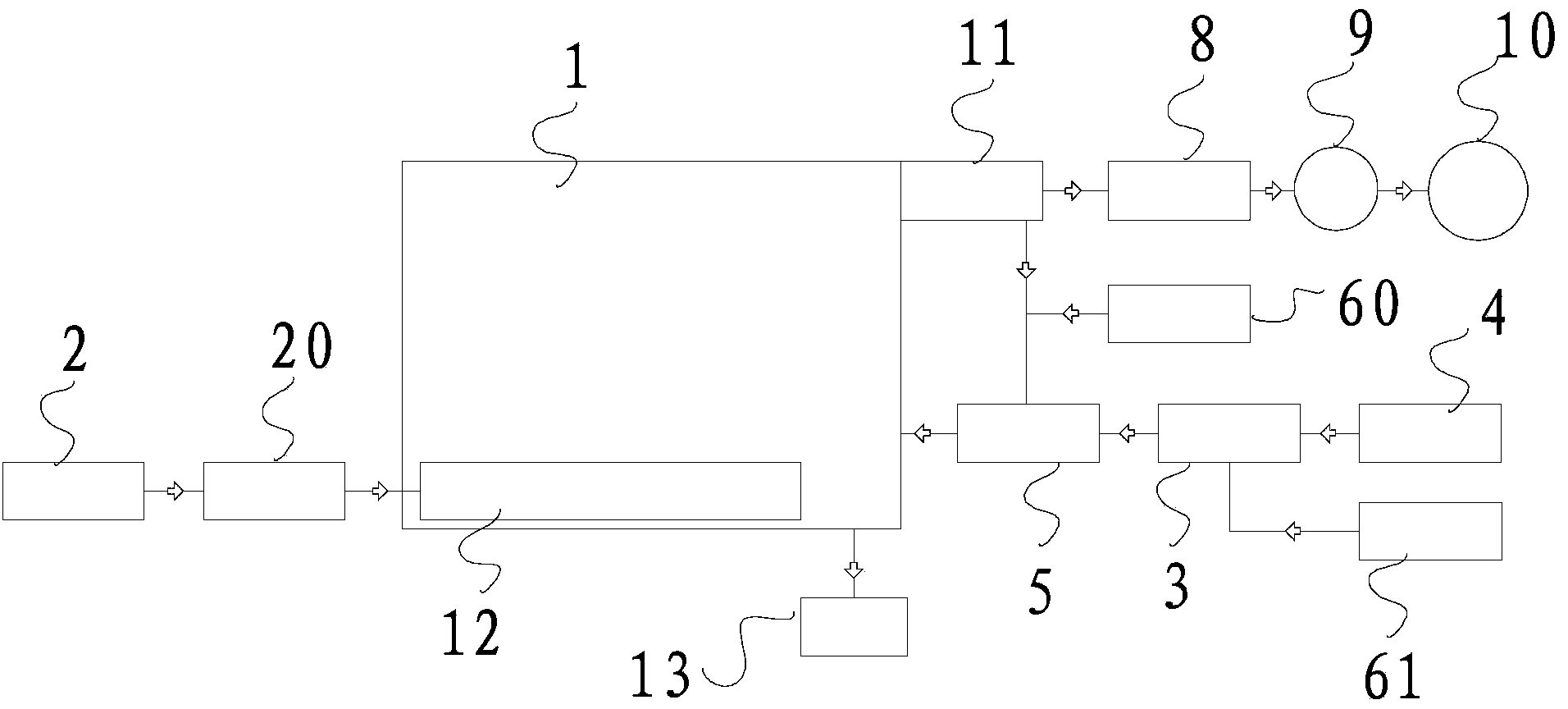

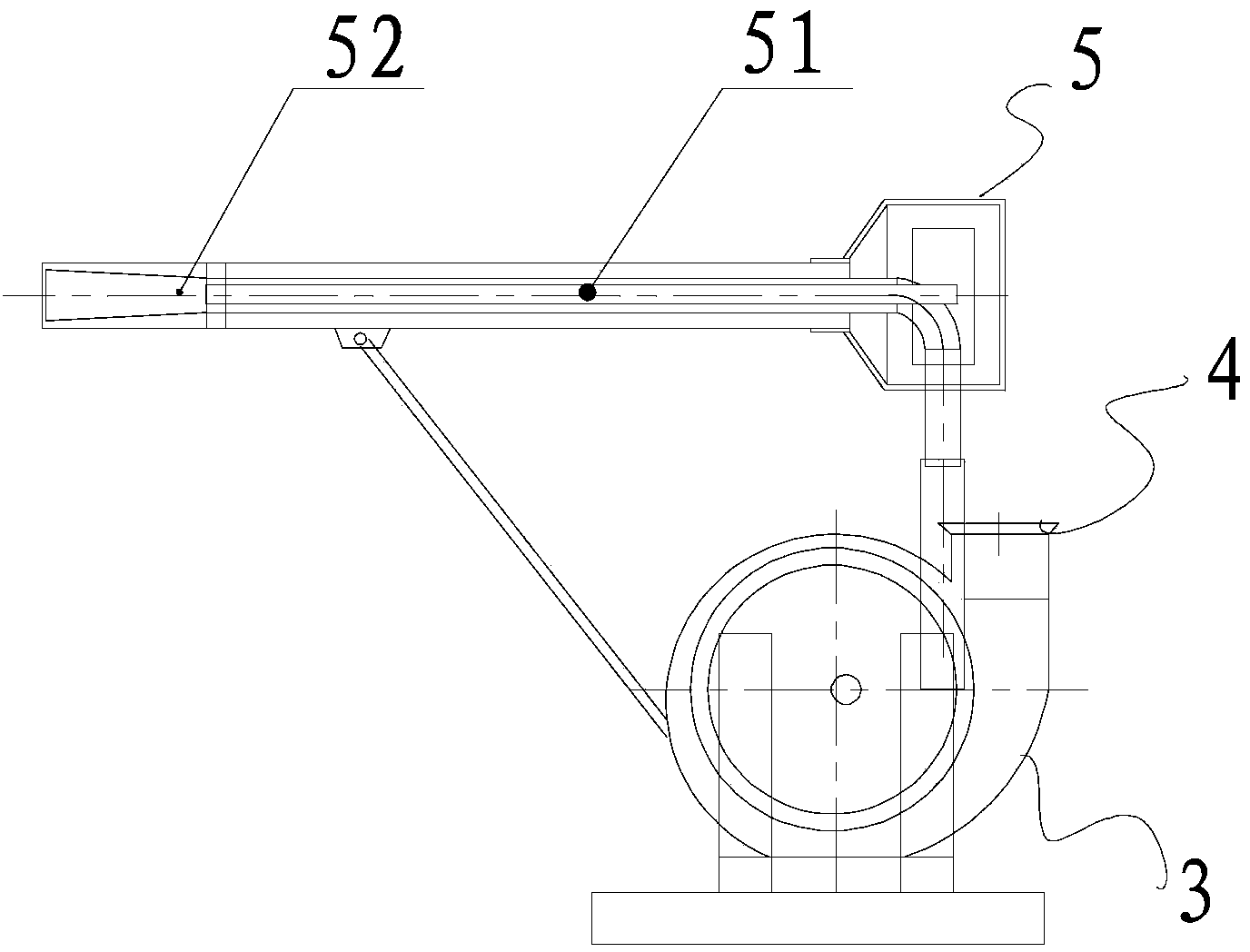

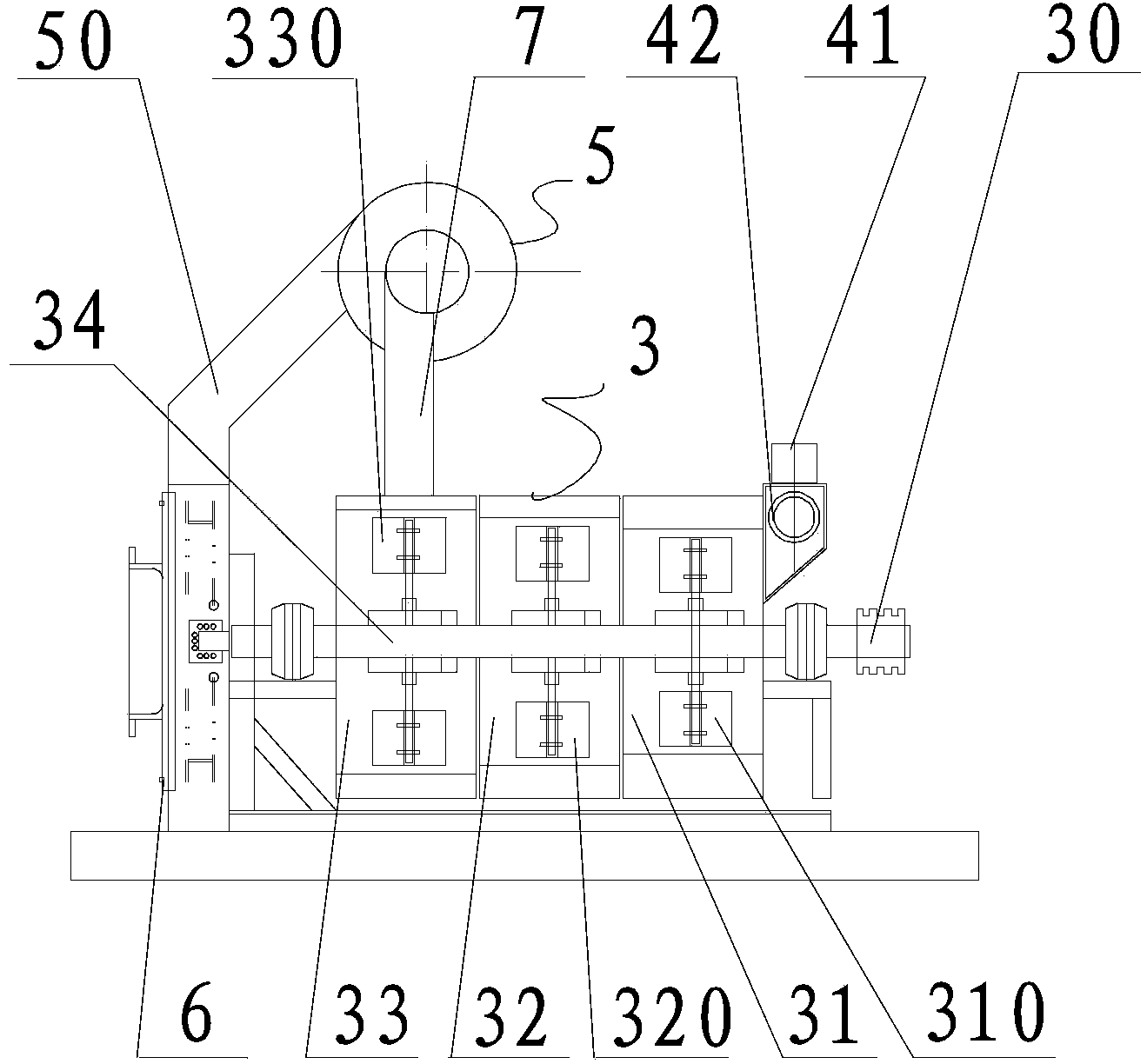

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089AHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

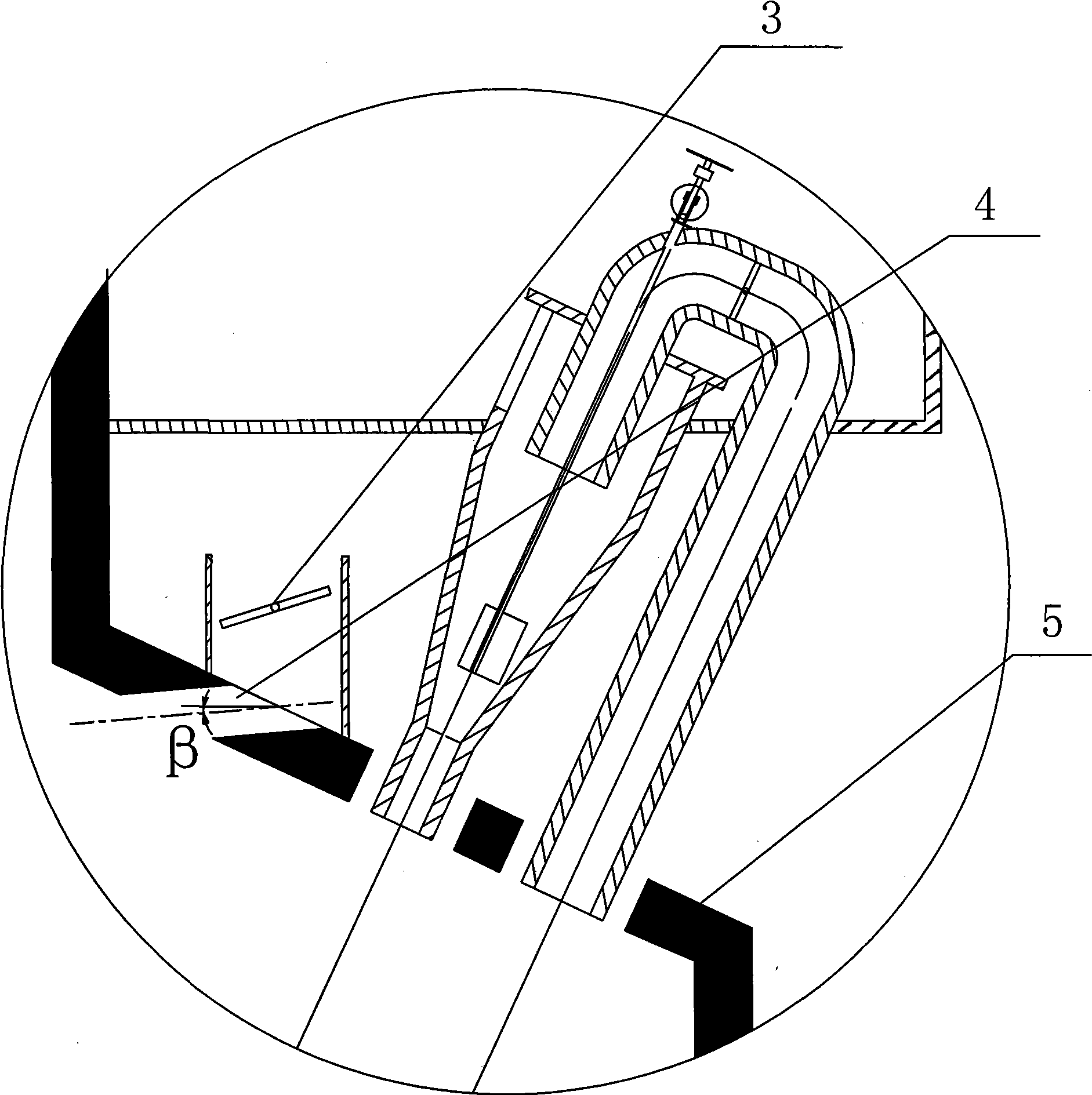

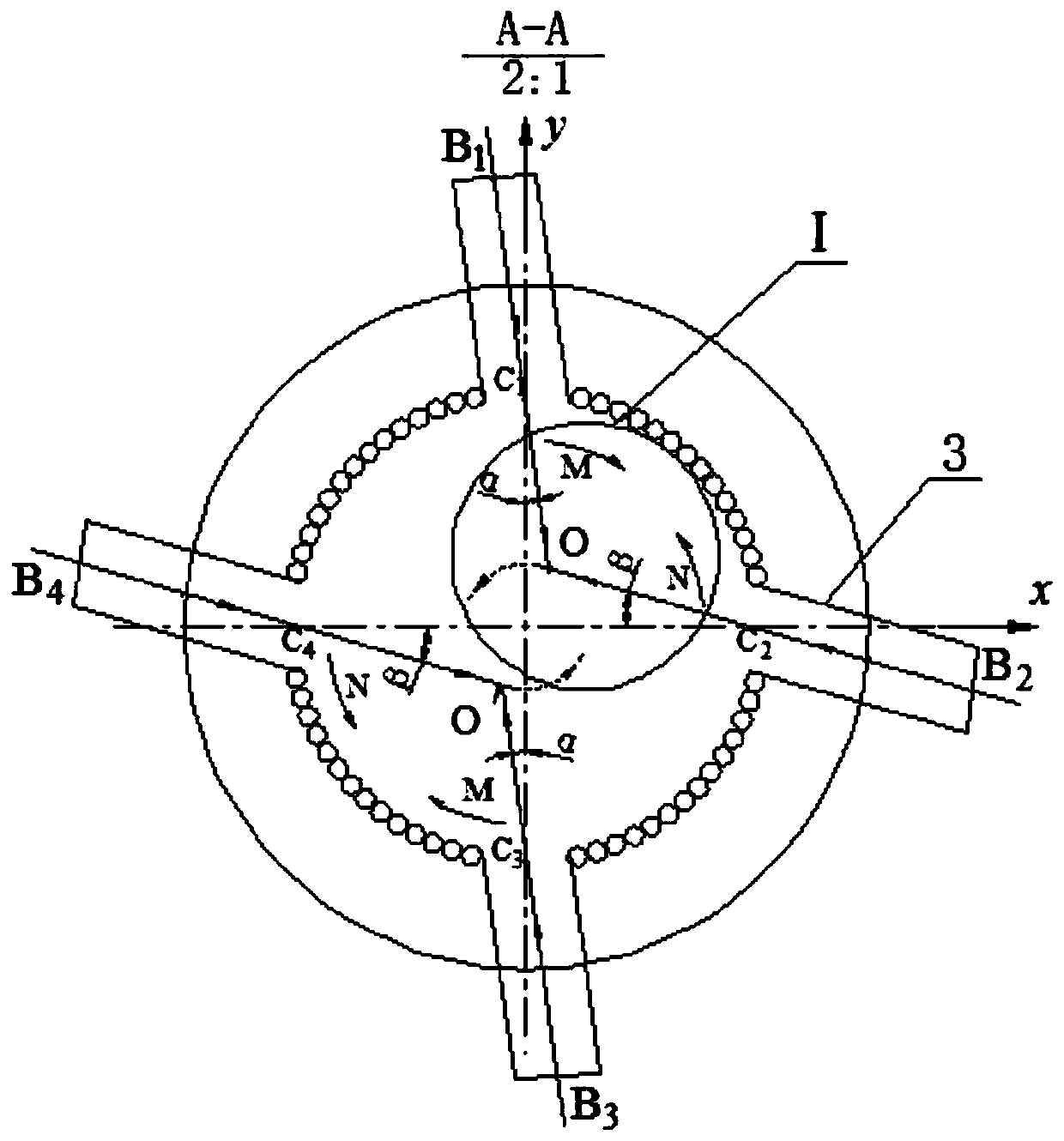

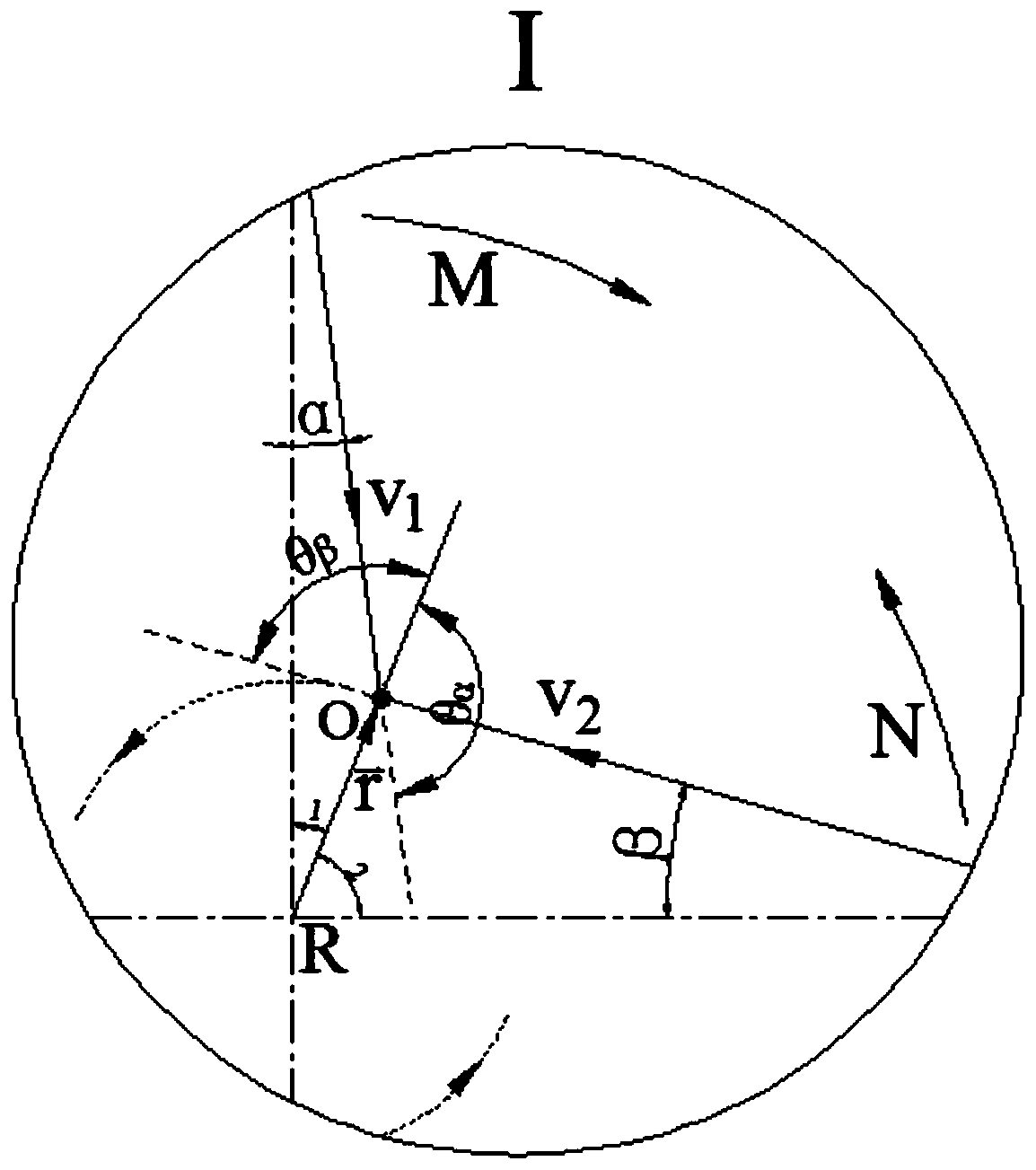

Entrained flow gasifier device with four forward and reverse rotating burners and gasification method

ActiveCN110452737AWell mixedImprove carbon conversionGasification processes detailsGranular/pulverulent flues gasificationSlagEngineering

The invention relates to an entrained flow gasifier device and a gasification method utilizing the device, particularly to an entrained flow gasifier device with four forward and reverse rotating burners and a gasification method, and aims to solve the problems of gasifier water-cooled wall burning loss, low carbon conversion rate and the like caused by unreasonable burner arrangement mode of existing multi-burner entrained flow gasifiers. The entrained flow gasifier device with four forward and reverse rotating burners includes a gasifier body, burners, a water-cooled wall, an igniter burner,a slag tank and a synthesis gas channel. The four burners, i.e. burner B1, burner B2, burner B3 and burner B4 are located on a same horizontal plane, and are evenly distributed along the circumference of the gasifier body in order, the intersection points of center lines and the water-cooled wall surface are C1, C2, C3, and C4 respectively, the center lines of B1 and B2 intersect at point O, andthe center lines of B3 and B4 intersect at point O'; the included angle alpha of C1O and C1C3, and the included angle beta of C2O and C2C4 satisfy that: alpha is greater than 0 and smaller than beta and beta is less than 45 degrees, or beta is greater than 0 and smaller than alpha and alpha is less than 45 degrees. The entrained flow gasifier device provided by the invention is used for the entrained flow gasification field.

Owner:HARBIN INST OF TECH

W-shaped flame boiler grading combustion method

InactiveCN107355802AIncrease burnoutReduce generationSolid fuel pretreatmentStaged combustionFlue gasSlag

The invention relates to a W-shaped flame boiler grading combustion method. Free-burning coal reacts with oxygen to form first grade combustion; the free-burning coal is formed by bituminous coal or a mixture between the bituminous coal and meager coal; and high-temperature flue gas atmosphere formed in the first stage ignites anthracite wrapped up with the high-temperature flue gas and second grade combustion is formed. A method for determining an optimal mixture ratio of a mixture ratio of the bituminous coal and the anthracite and a mixture ratio of the bituminous coal, the meager coal and the anthracite comprises steps of pre-deciding a boiler combustion strategy according to coal quality elements and an industrial analysis result, and comparing and analyzing boiler work conditions when different combustion strategies are employed to achieve an optimal boiler grading combustion coal type ratio, and an coal mill coal powder injection way. A combustion coal and the anthracite mixture ratio is determined during the boiler grading combustion process, so second combustion burn-off rate can be effectively improved; and secondary flying ash and large slag carbon content can be reduced.

Owner:中国大唐集团科学技术研究总院有限公司

Electronic fabric impregnating compound

The invention discloses an electronic fabric impregnating compound. The electronic fabric impregnating compound comprises 1-3wt% of a vinyl silane coupling agent, 5-8wt% of an epoxy silane coupling agent, 2-5wt% of water-soluble polyester, 5-8wt% of polyurethane, 3-5wt% of epoxy resin, 2-3wt% of machine oil, 1-2wt% of Vaseline, 4-8wt% of a paraffin emulsion, 1-2wt% of a special additive, and the balance of water. The use amounts of the machine oil and paraffin in the impregnating compound are reduced, and the epoxy silane coupling agent and other substances are added, so electronic fabrics using the impregnating compound have the characteristics of good textile property, and reduced content of combustibles.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

Composite type multifunctional straight-flow combustor

InactiveCN1227477CEmission reductionReduce combustible contentPulverulent fuel combustion burnersLow loadSlag

The invention discloses a compound multifunctional DC burner, containing in turn performance adjusting wind spout III, secondary wind spout, coal powder horizontal shade primary wind spout, performance adjusting wind spout II, coal powder horizontal shade primary wind spout, and secondary wind spout, there is a performance adjusting wind spout I on the against-fire side of the primary wind spout, the axes of the primary wind spout and performance adjusting wind spout III drift off that of the secondary wind spout and lean to the facing-fire side, and the performance adjusting wind spout II folds toward water-cooled wall from parts of the runners of the secondary wind spout. It has advantages of wide coal applied range, preventing water-cooled wall from clogging (coking), high-temperature corrosion resistance, low load stable combustion, low-nitrogen oxide discharge, self-adjusting performance, etc.

Owner:甘肃省电力试验研究所 +1

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

InactiveCN1257361CExtended stayIncrease burn shareFluidized bed combustionApparatus for fluidised bed combustionCombustionFluidized bed

Owner:SOUTHEAST UNIV

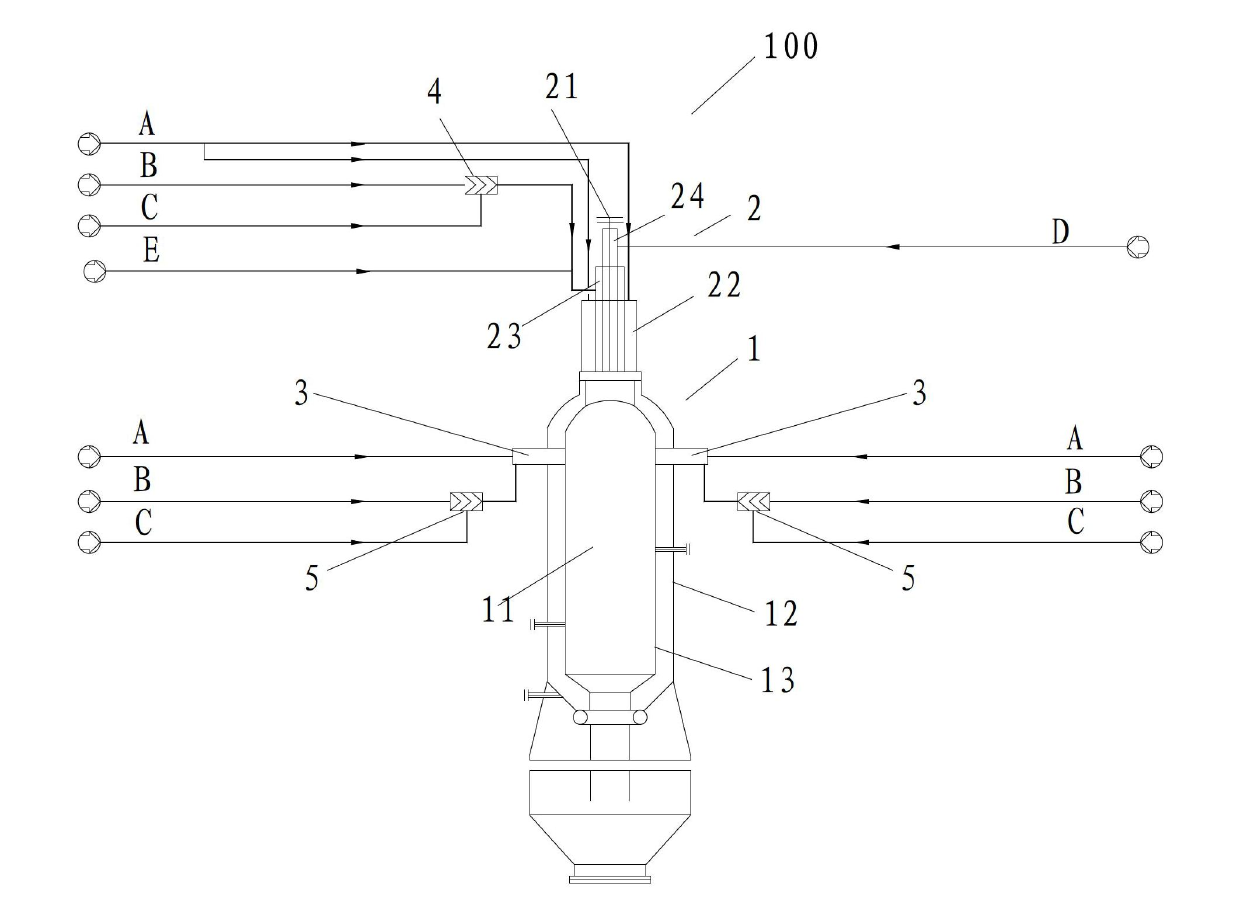

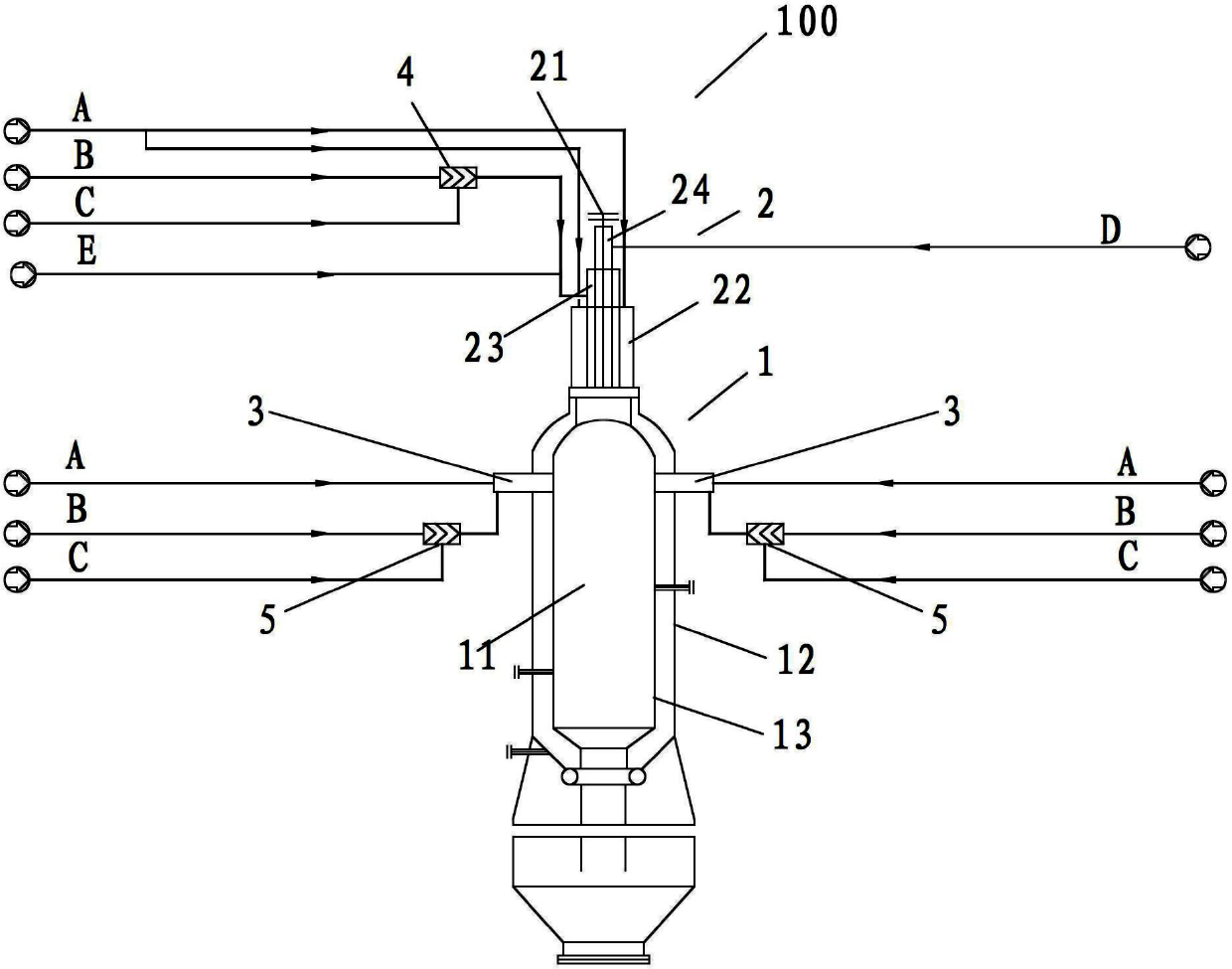

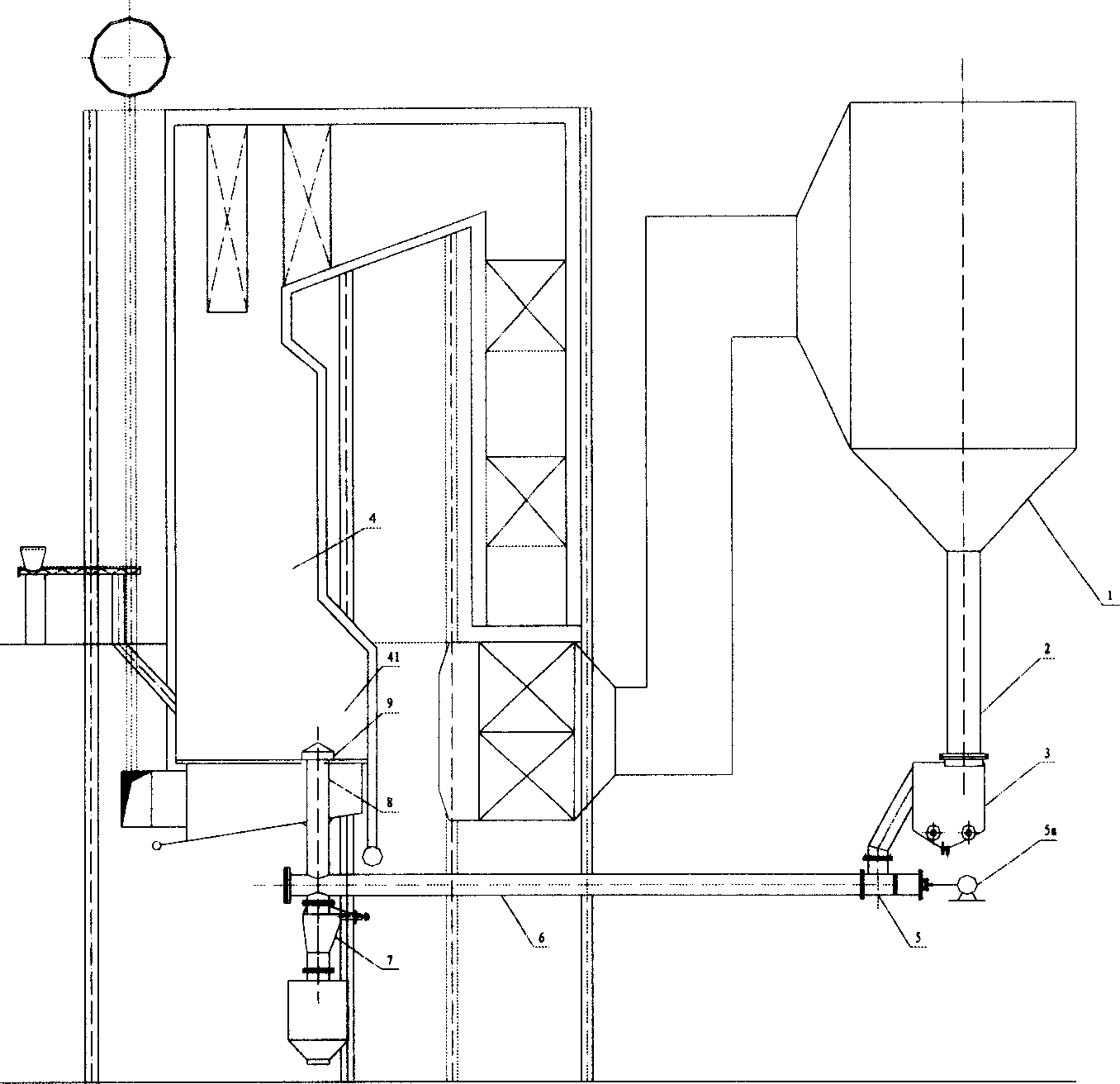

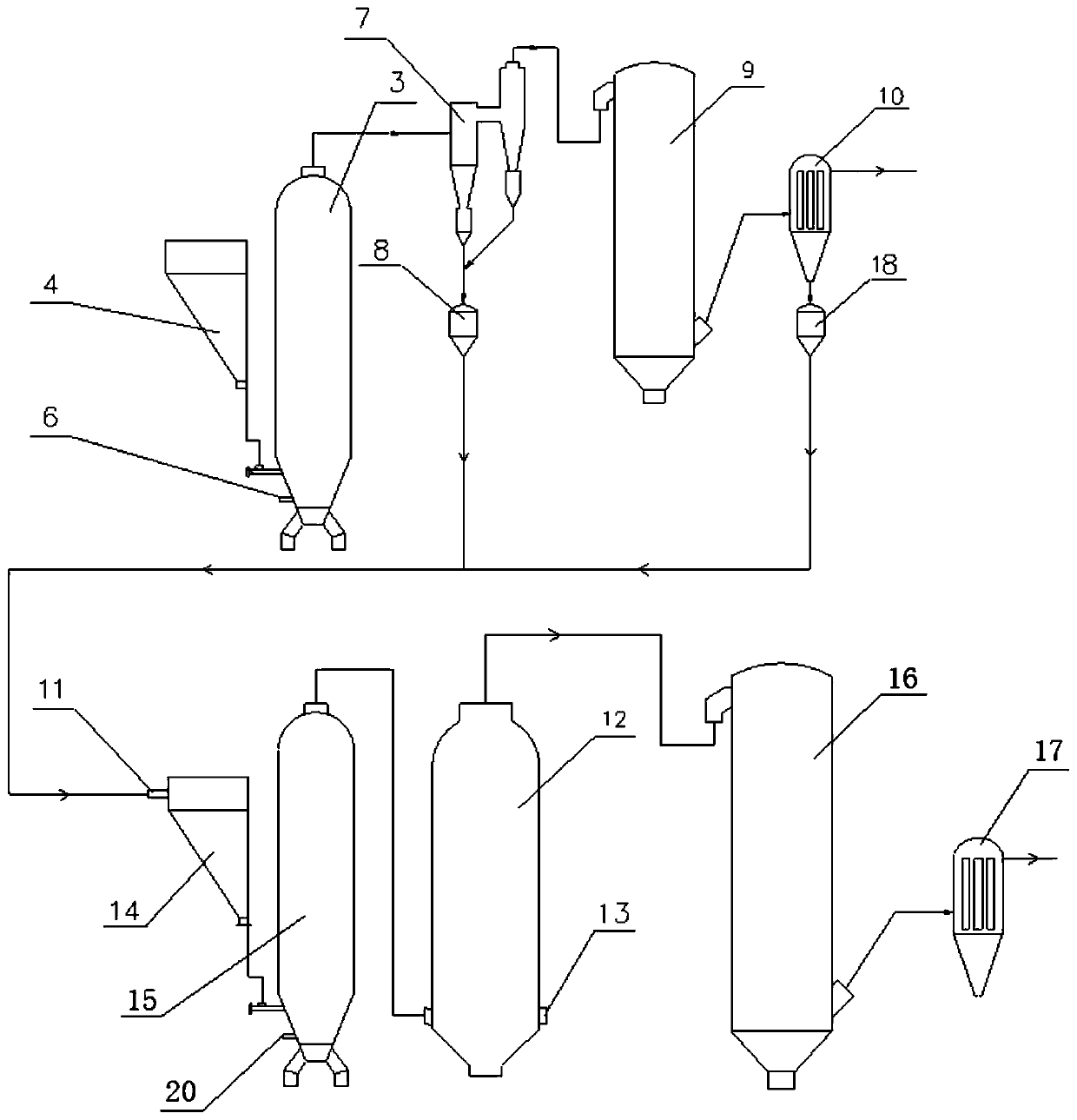

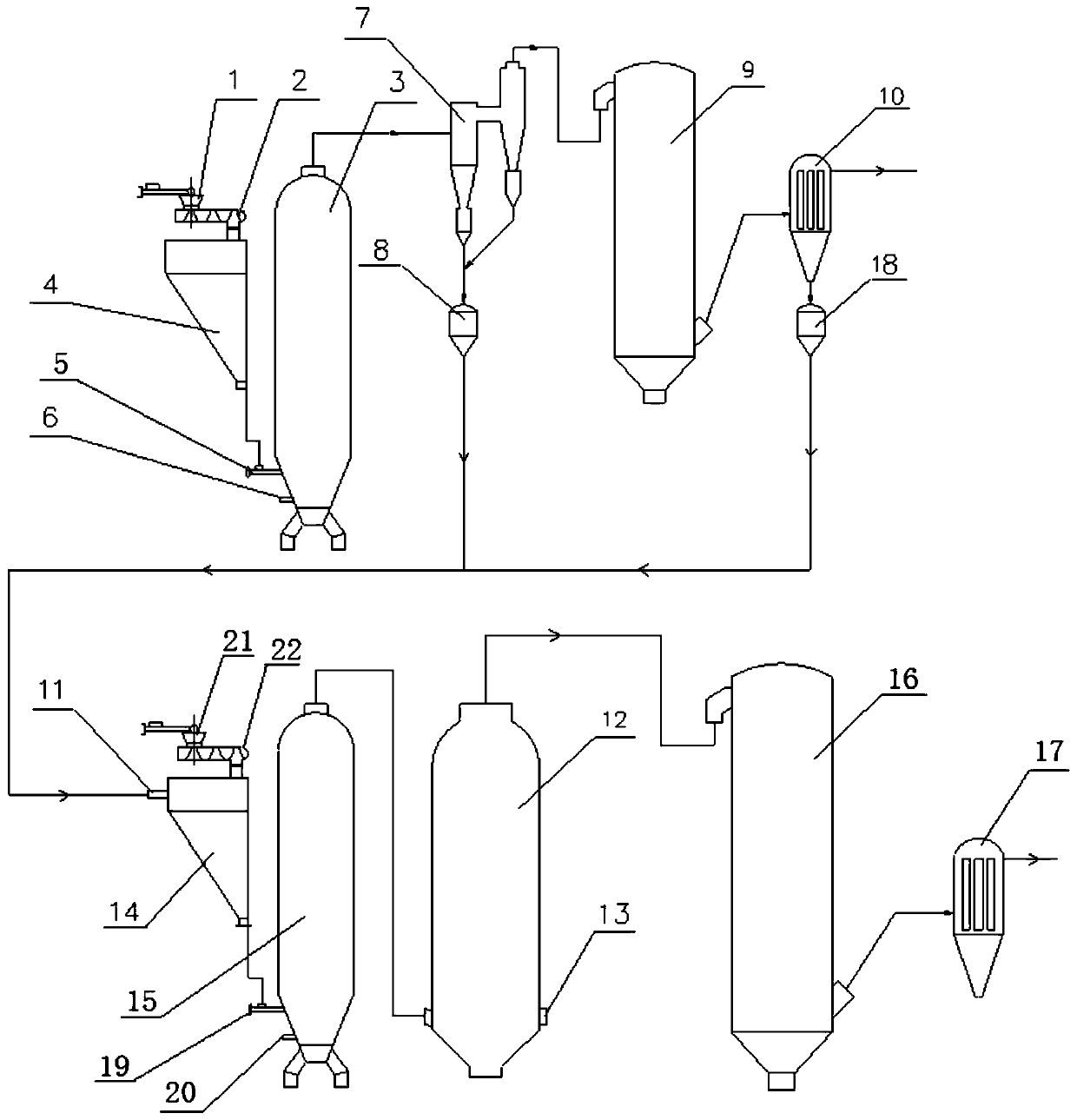

Ende staged gasification system for dry cleaning treatment of fly ash

InactiveCN110484301ALow ash contentImprove dust removal efficiencyEnergy inputGasification processes detailsBaghouseEngineering

The invention discloses an Ende staged gasification system for dry cleaning treatment of fly ash, and relates to an Ende staged gasification system. The problems that in the fly ash treatment processof an existing Ende gasification system, water consumption is large, generated black water is difficult to treat, and cost is increased are solved. The Ende staged gasification system comprises a first coal storage bin, a first Ende gasification furnace, a cyclone dust collector, a first ash bucket, a first waste heat boiler, a first multi-stage bag-type dust collector, a second ash bucket, a second coal storage bin, a second Ende gasification furnace, an entrained-flow bed gasification furnace, a second waste heat boiler and a second multi-stage bag-type dust collector. A first ash bucket isarranged below the cyclone dust collector; a second ash hopper is arranged below the first multi-stage bag-type dust collector, the first ash hopper and the second ash hopper are communicated with a second coal storage bin, the second coal storage bin is communicated with a second Ende gasification furnace, the top of the second Ende gasification furnace is communicated with an entrained-flow bedgasification furnace, the top of the entrained-flow bed gasification furnace is communicated with a waste heat boiler, and the waste heat boiler is connected with the second multi-stage bag-type dustcollector. The Ende staged gasification system is used in the field of coal gasification.

Owner:HARBIN INST OF TECH

Method for improving W-type flame boiler efficiency

InactiveCN107355803ABurn fullyImprove efficiencyAir supply regulationIndirect carbon-dioxide mitigationAnthraciteEngineering

The invention relates to a method for improving W-type flame boiler efficiency. The method comprises steps of conducting coaly element and industrial analysis to a selected coal type, presetting a boiler combustion strategy, conducting boiler fuel combustion simulation according to the preset combustion strategy to acquire a boiler work condition, comparing and analyzing boiler work conditions upon different combustion strategies to acquire an optimal boiler grading combustion coaly proportion and coal grinding machine coal powder injection way. A proportion of the burning coal and anthracite can be well determined during the boiler grading combustion by the use of the method.

Owner:中国大唐集团科学技术研究总院有限公司

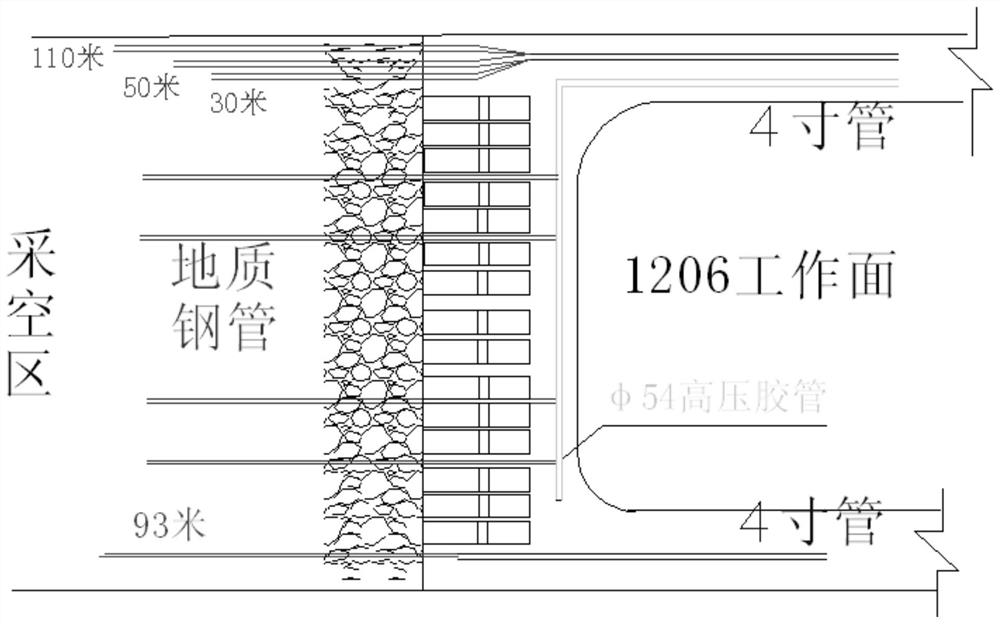

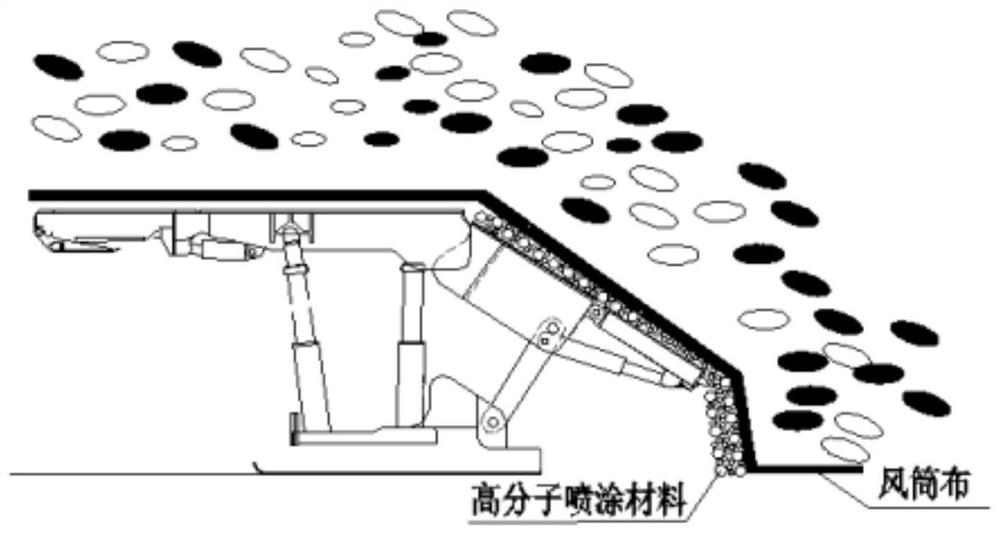

Safety retracement method for combined coal and oil shale mining

InactiveCN111794750AAvoid enteringReduce combustible contentMining devicesUnderground miningSpontaneous combustionMining engineering

The invention belongs to the technical field of mining safety retracement methods, and specifically discloses a safety retracement method for combined coal and oil shale mining. The method comprises the following step of S1, gas monitoring before laying the rope on the net. The safety retracement method for combined coal and oil shale mining controls the mining layer of a working face, prevents coal from entering a goaf, reduces the combustible content of the goaf, uses the working face again to lay air duct cloth above the support of the working face during the tailing of the working face, seals both corners of the working face to reduce air leakage in the goaf, and finally uses pipelines laid in advance to multiple locations in the goaf to inject inert gas and grouting to seal the goaf and reduce the temperature in the goaf, thereby fundamentally weakening or eliminating the basic conditions required for spontaneous combustion of coal, so as to reduce the safety pressure for fire prevention and achieve safe retracement.

Owner:LONGKOU MINING GRP

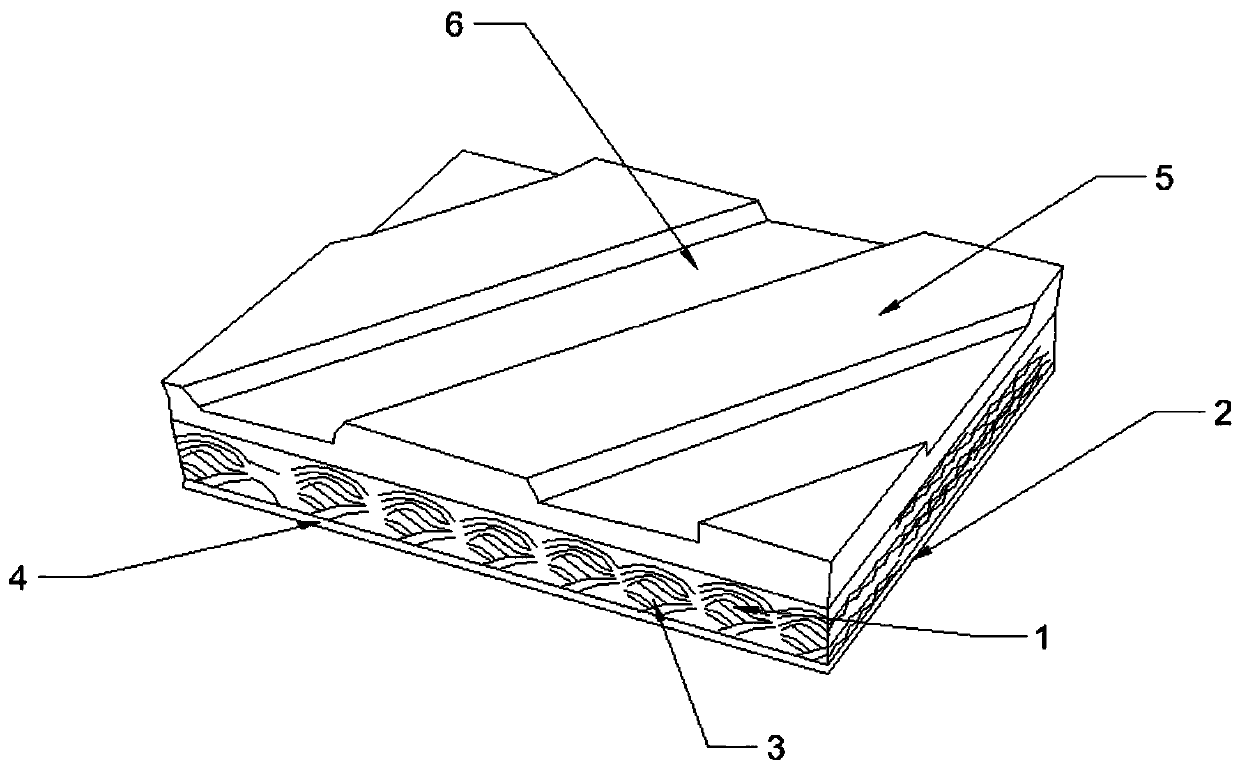

Basalt whole-core flame-retardant conveying belt

The invention discloses a basalt whole-core flame-retardant conveying belt. The basalt whole-core flame-retardant conveying belt comprises basalt fiber and cotton blended weft, radial cotton, radial ply basalt fiber, lower covering glue, upper covering glue and a flame-retardant groove. The basalt whole-core flame-retardant conveying belt has the beneficial effects that: the basalt fiber and cotton blended weft is fixedly connected with the radial ply basalt fiber, so that the flame-retardant conveying belt is integrated; the radial cotton is fixedly connected with the basalt fiber and cottonblended weft, and thus a belt core can be protected; the radial ply basalt fiber is fixedly connected with the inner side of the radial cotton, so that the flame-retardant degree of the conveying beltis effectively improved, and the structural strength is improved; the top end of the lower covering glue is fixedly connected with the radial cotton on the outer side of the belt core of the conveying belt through gluing, so that the adhesion degree of the belt surface and the belt core is improved; and the flame-retardant groove is fixedly connected with the upper covering glue, so that an effective flame-retardant structure and a cellular structure are provided, and the service life of the conveying belt is prolonged.

Owner:BAODING HUAYUE RUBBER BELTS

Novel boiler

InactiveCN106123016AImprove combustion efficiencyImprove the effect of energy saving and emission reductionCasings/liningsCombustion chamberEngineering

The invention discloses a novel boiler, which comprises a boiler main body, and the furnace wall of the combustion chamber in the boiler main body is successively composed of a refractory layer, a thermal insulation layer and a heat exchange layer from inside to outside. The advantage is that unlike traditional boilers that exchange heat in the combustion chamber, this application sets an insulation layer on the outside of the refractory layer so that the heat in the combustion chamber will not be easily lost, effectively ensuring the temperature in the combustion chamber, so that it can be used under high temperature conditions. The organic macromolecules that can be cracked and burned can be fully burned, and the heat exchange layer outside the insulation layer will fully absorb the heat emitted by the insulation layer. While ensuring the heat conversion efficiency, it improves the combustion efficiency of the boiler and the combustion utilization of coal. At the same time, it reduces the content of combustibles in the flue gas, reduces harmful emissions, and greatly improves the energy-saving and emission-reduction effects of the boiler.

Owner:常滏源 +2

A special sizing agent for glass fiber bulked yarn and its preparation method

The invention relates to a special impregnating compound for glass fiber swelled yarn. The special impregnating compound for glass fiber swelled yarn comprises the following components in proportion relative to the total mass of the impregnating compound: 0.2-0.4% of coupling agent, 0.3-0.6% of lubricating agent A, 0.01-0.1% of lubricating agent B, 0.1-0.3% of lubricating agent C, 1-2% of film-forming agent, 0.09-0.2% of ph value regulating agent, and the balance being deionized water. The impregnating compound provided by the invention adopts ultralow molecular weight epoxy emulsion as the film-forming agent, has the advantages of simpleness in preparation process and low cost. The swelled yarn for the mobile muffler padding, which is prepared from the impregnating compound provided by the invention, has an extremely high swelled rate being above 98%, greatly improves filling efficiency and greatly improves performance of a muffler.

Owner:SHANDONG FIBERGLASS GRP

How to Improve Furnace Efficiency of W Type Flame Boiler

InactiveCN107355803BBurn fullyImprove efficiencyAir supply regulationIndirect carbon-dioxide mitigationBoiler furnaceProcess engineering

The invention relates to a method for improving W-type flame boiler efficiency. The method comprises steps of conducting coaly element and industrial analysis to a selected coal type, presetting a boiler combustion strategy, conducting boiler fuel combustion simulation according to the preset combustion strategy to acquire a boiler work condition, comparing and analyzing boiler work conditions upon different combustion strategies to acquire an optimal boiler grading combustion coaly proportion and coal grinding machine coal powder injection way. A proportion of the burning coal and anthracite can be well determined during the boiler grading combustion by the use of the method.

Owner:中国大唐集团科学技术研究总院有限公司

Accurate combustion control system

InactiveCN106152111AGuaranteed temperatureImprove combustion efficiencySolid fuel combustionIndirect carbon-dioxide mitigationCombustion systemCombustion chamber

The invention discloses an accurate combustion control system which comprises a top opening, a combustion device body and a heat exchanger, wherein the interior of the combustion device body is hollow. The top opening of the combustion device body serves as a smoke vent. An inner cavity of the combustion device body serves as a combustion chamber. The smoke vent communicates with the heat exchanger. A shell of the combustion device body sequentially comprises a refractory layer, a heat preservation layer and a heat exchange layer from inside to outside. One or more auxiliary combustion devices are vertically arranged in the upper portion of the combustion chamber. The accurate combustion control system has the advantages that different from the mode that heat exchange is conducted in a combustion chamber of a traditional boiler, the heat preservation layer is arranged on the outer side of the refractory layer, heat in the combustion chamber cannot be dissipated easily, the temperature in the combustion chamber is effectively guaranteed, organic macromolecules which can be split and combusted only under the high-temperature condition are combusted sufficiently, the heat exchange layer on the outer side of the heat preservation layer sufficiently absorbs heat dissipated by the heat preservation layer, and the combustion efficiency of a boiler and the combustion utilization rate of coal are improved while the thermal conversion efficiency is guaranteed.

Owner:常滏源 +2

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089BHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

W-shaped flame boiler with two-stage over-fire wind

InactiveCN101476739BGuaranteed burnout rateGood for burnoutNon-combustible gases/liquids supplyCombustorSingle stage

The invention discloses a W-shaped flame boiler with two stages of burn-out wind, which relates to the W-shaped flame boiler and aims at the problems that the W-shaped flame boiler of the prior single-stage burn-out wind device has high content of fly ash inflammable matters and low burn-off rate of coal dust. The W-shaped flame boiler comprises a superior OFA nozzle (2) and an inferior OFA nozzle (4) which is arranged on a furnace arch (5) close to an hearth throat inlet, is communicated with a lower hearth (6), is arranged on the outer side of a burner (8), and is communicated with a secondary wind box (11). The W-shaped flame boiler not only can replenish air for the unburned coal dust in time to benefit the burnout of the coal dust and greatly reduce the content of the fly ash inflammable matters, but also can better achieve the fractional combustion of the coal dust and greatly reduce the emission of NOx.

Owner:HARBIN INST OF TECH

Combustion-supporting device of integrated smoke and dust eliminating truck and integrated smoke and dust eliminating truck

InactiveCN101696358BReduce energy consumptionEasy to operateOven incrustations prevention/removalIncinerator apparatusFurnace temperatureCombustion chamber

The invention discloses a combustion-supporting device of an integrated smoke and dust eliminating truck, which comprises a primary combustion chamber (1) and a gas increasing combustion-supporting chamber (4), wherein the gas increasing combustion-supporting chamber (4) is connected with a movable guide sleeve (15) and a furnace roof carbonization chamber (17) through a connecting pipe (11) and a guide flange (14); the bottom end of the gas increasing combustion-supporting chamber (4) is provided with an ash storage hopper (9) and an ash discharging flange (10); the upper end of the ash storage hopper (9) is also provided with a gas inlet pipe (7) and a flame nozzle (5); a supporting rib (6) is arranged above the gas inlet pipe (7); the supporting rib (6) and the furnace wall are provided with a high temperature fire-resistant heat storage layer (18); and an upper opening of the flame nozzle (5) extends out of the high temperature fire-resistant heat storage layer (18) on the supporting rib (6). The combustion-supporting device of the integrated smoke and dust eliminating truck can allow combustible materials to be ignited and combusted well in the combustion-supporting chamber under the condition that the furnace temperature and the temperature of raw coke oven gas are low, the flow rate of the raw coke oven gas is quick, the flow quantity is large and the combustible material content in the raw coke oven gas is low.

Owner:山东兖煤凯达环保机械股份有限公司

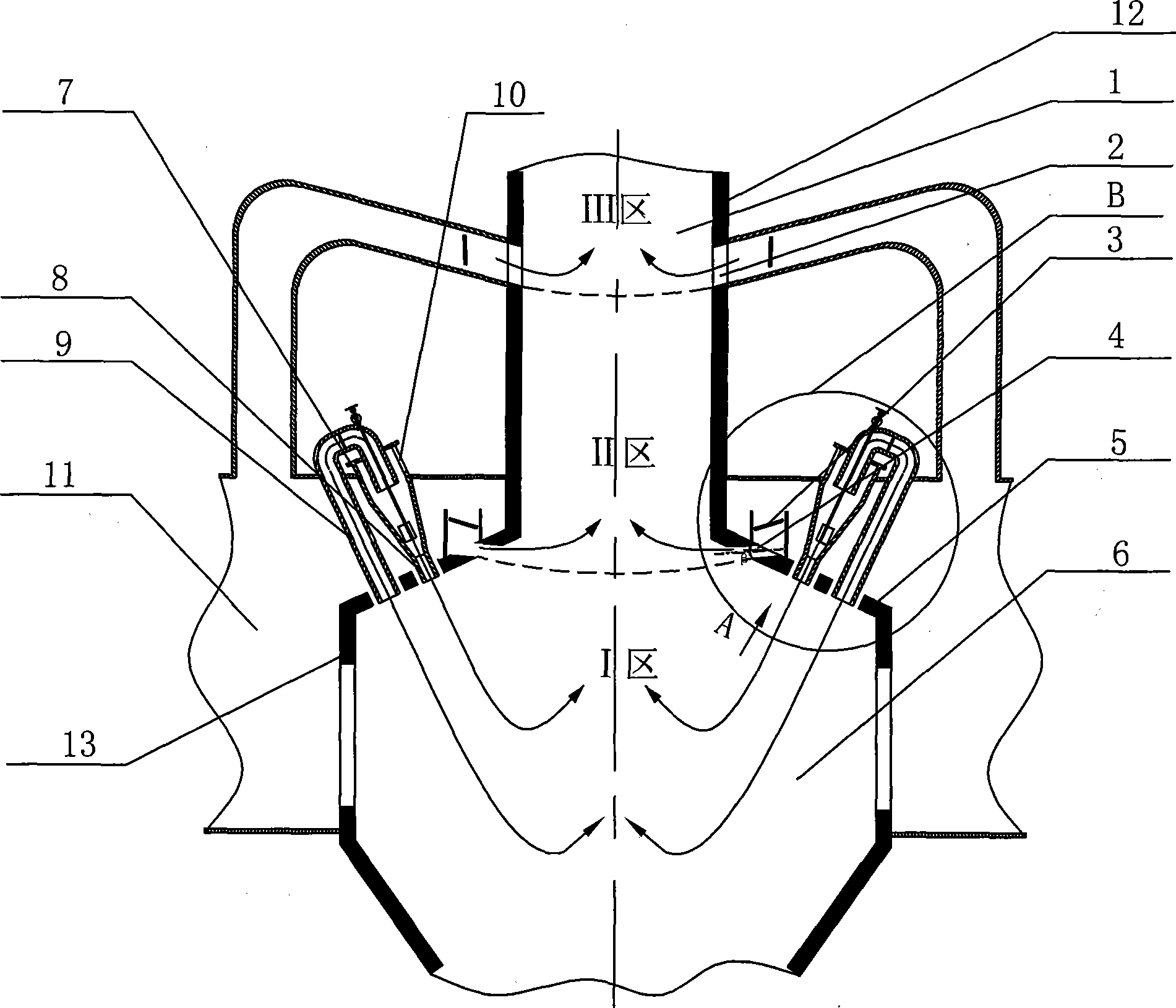

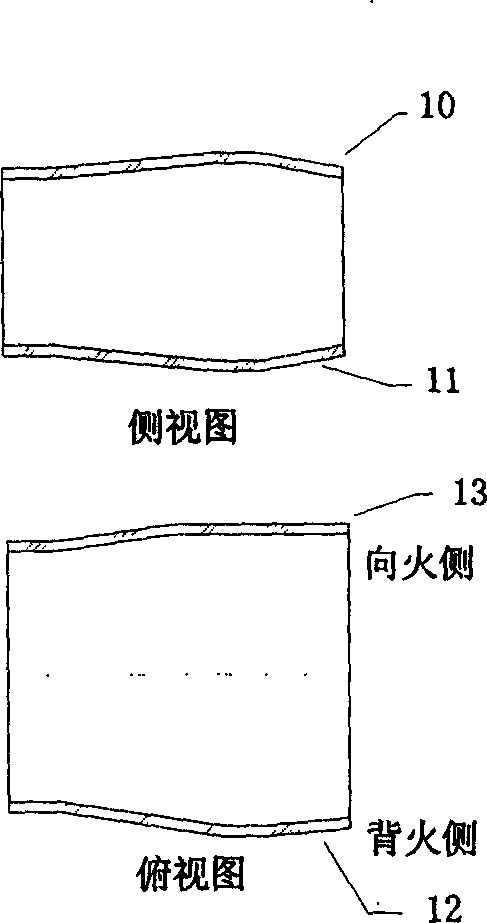

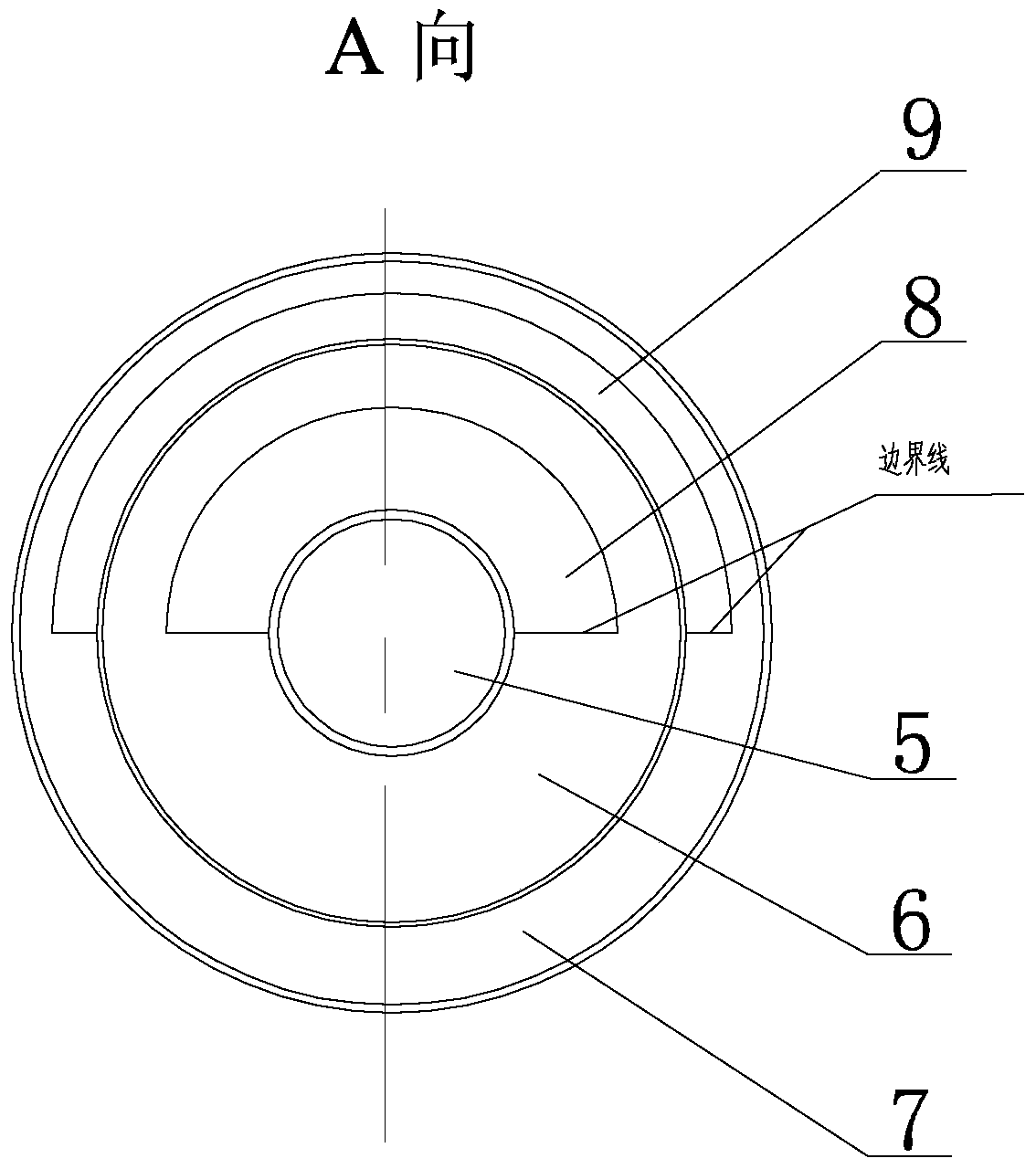

A swirl pulverized coal burner with secondary air offset for w-flame boiler

ActiveCN105423294BGood for early ignitionImprove flame stabilityPulverulent fuel combustion burnersCombustion apparatusCombustion chamberSlag

Disclosed is a secondary air offset whirl pulverized coal burner for a W flame boiler. The problems of high NOx discharge amount, high fly ash combustible matter content, slag-bonding to water walls of front and back walls of a lower combustion chamber and high temperature corrosion of the W flame boiler which is provided with an existing whirl pulverized coal burner on an arch are solved. A circular ring inner secondary air stop block in the circumferential direction is added in inner secondary air on a dividing cylinder of primary air and inner secondary air of the whirl pulverized coal burner; the angle of the circular ring inner secondary air stop block in the circumferential direction is 180 degrees; a circular ring outer secondary air stop block in the circumferential direction is added in outer secondary air on a dividing cylinder of the inner secondary air and the outer secondary air; the angle of the circular ring outer secondary air stop block in the circumferential direction is 180 degrees; the boundary line in the diameter direction of the circular ring inner secondary air stop block and the circular ring outer secondary air stop block is parallel to the front and back walls of the boiler; the circular ring inner secondary air stop block and the circular ring outer secondary air stop block are mounted on one side close to the center of a combustion chamber. The secondary air offset whirl pulverized coal burner is used for the W flame boiler.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com