Composite type multifunctional straight-flow combustor

A multi-functional, burner technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of affecting combustion stability, large rotational momentum of secondary air, and reducing combustion efficiency, etc., to achieve low flying The effects of ash slag combustible content, low nitrogen oxide emissions, and wide application range of coal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

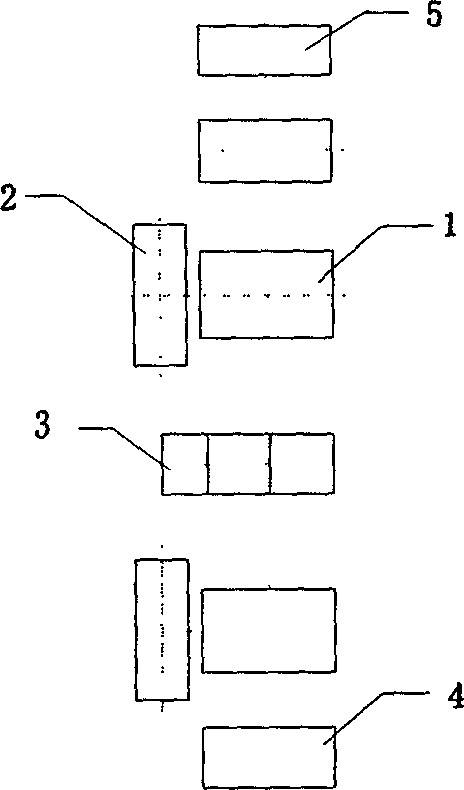

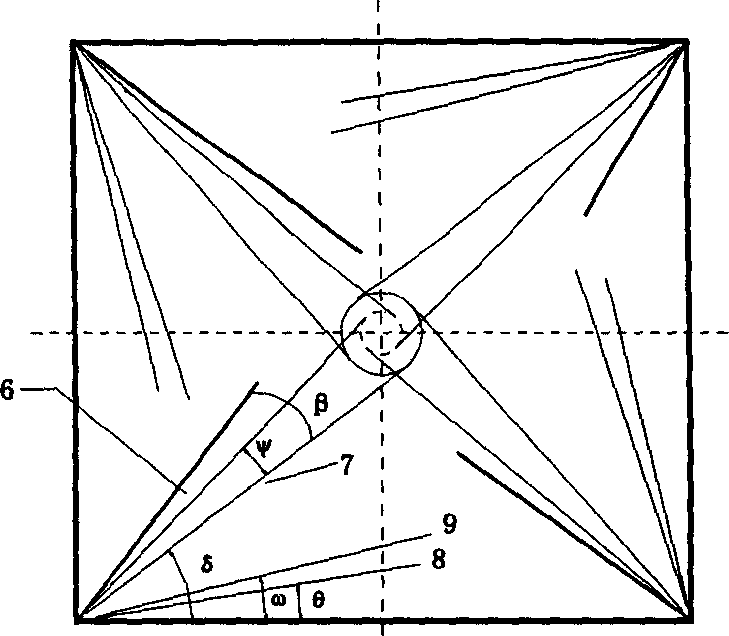

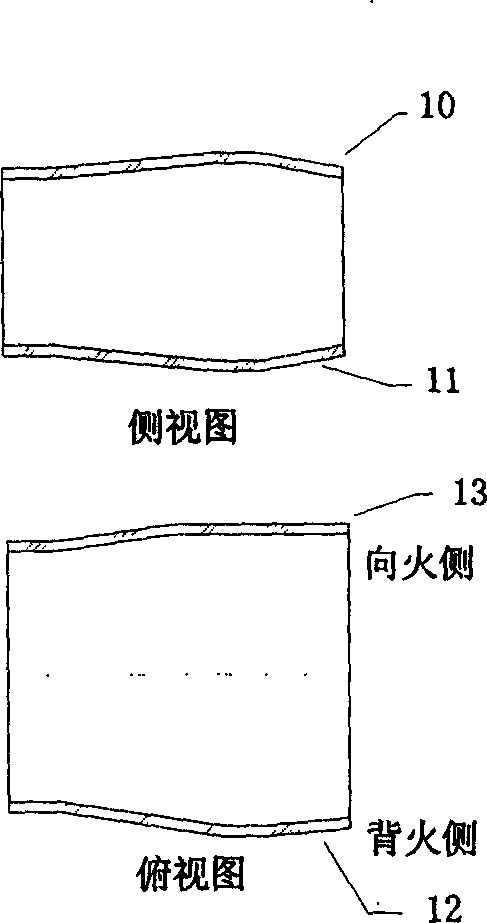

[0009] The composite multi-functional direct-flow burner has performance regulating air III nozzle 5, secondary air nozzle 4, primary air nozzle 1 with coal powder level concentration on the upper and lower sides and back fire side tapered, performance regulating air II nozzle 3, upper and lower sides and back fire side The primary air nozzle 1 and the secondary air nozzle 4 of the pulverized coal level density that gradually shrinks on the back fire side, and the primary air nozzle 1 of the pulverized coal level density that gradually shrinks on the upper and lower sides and the back fire side are provided with performance adjustment air I nozzle 2 on the back fire side, The primary air nozzle 1 axis deviates from the secondary air nozzle 4 axis, the performance adjustment air II nozzle 3 adopts a folding nozzle, and a part of the flow channel is bent to the side of the water cooling wall.

[0010] The taper angle of the primary air nozzle 1 is 2-15 degrees, the angle between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com