Accurate combustion control system

A combustion system and precise control technology, applied in the control of combustion, combustion chamber, combustion method, etc., can solve the problems of insufficient combustion of organic macromolecules, increased content of combustibles in flue gas, low combustion efficiency, etc., to achieve clean combustion, The effect of reducing combustible content and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

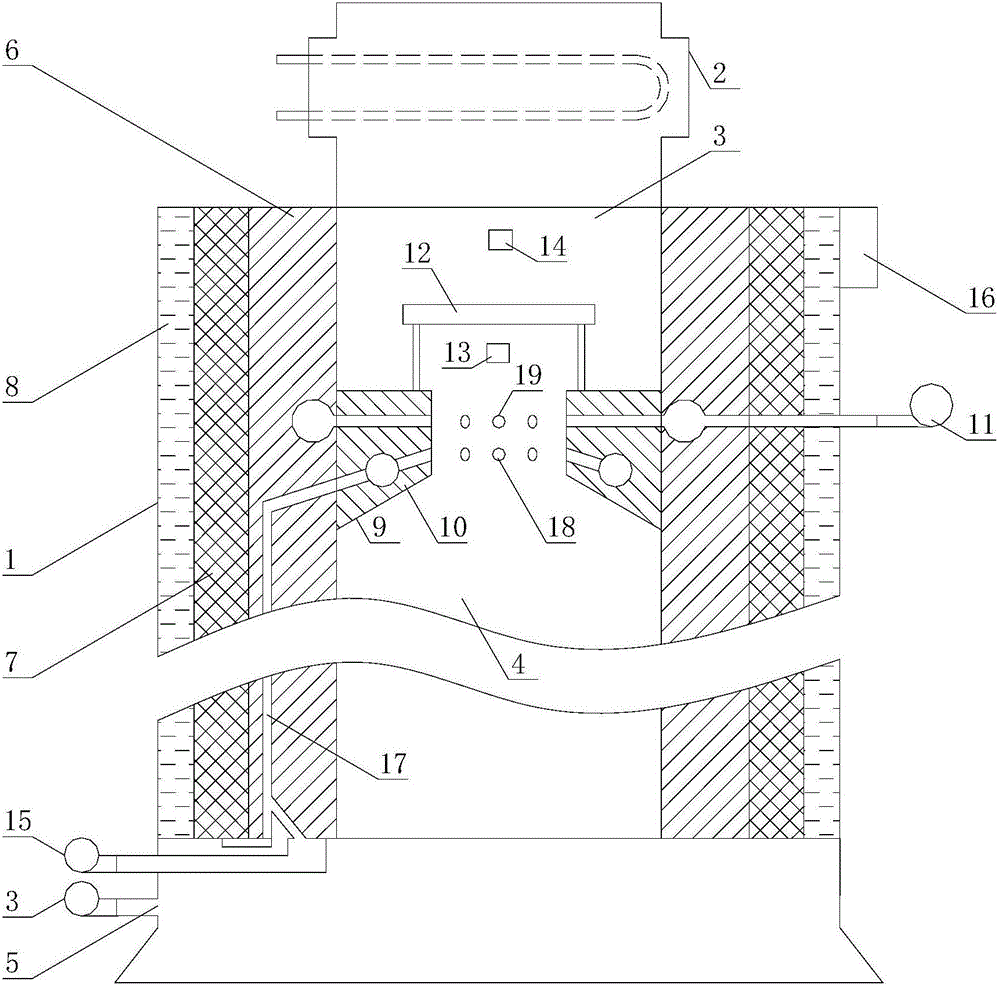

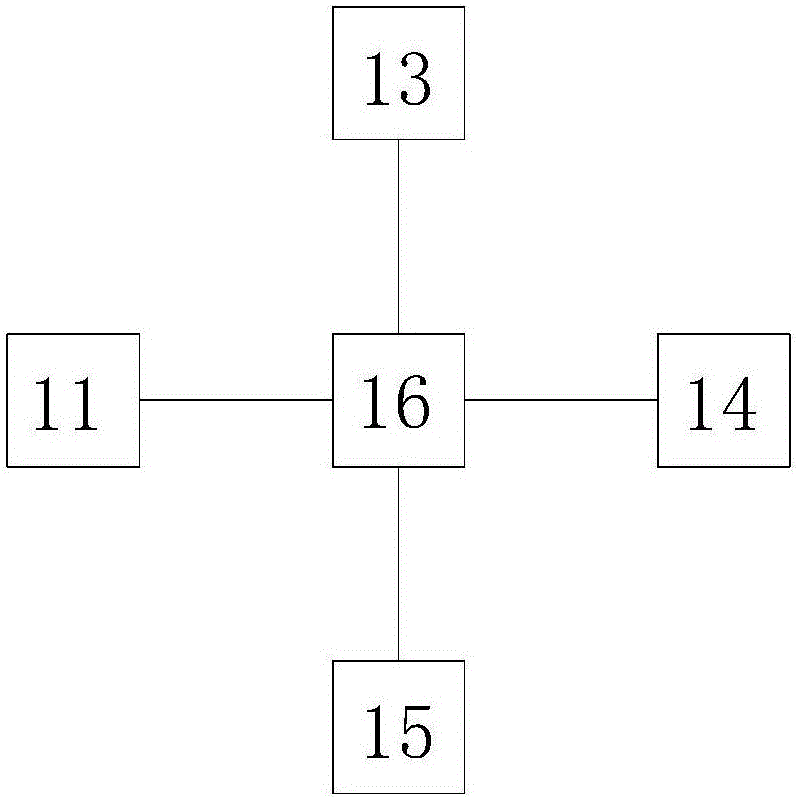

[0013] Embodiment 1: as figure 1 and figure 2 As shown, the combustion system is accurately controlled, which includes a top opening, a hollow combustion device body 1 and a heat exchanger 2, the top opening of the combustion device body 1 is the smoke exhaust port 3; the inner cavity of the combustion device body 1 is the combustion chamber 4 The bottom of the combustion device main body 1 is provided with an air inlet 5 communicating with the combustion chamber 4; the smoke exhaust port 3 is communicated with the heat exchanger 2; Heat layer 8; an auxiliary combustion device 9 is provided in the combustion chamber 4 above; the auxiliary combustion device 9 includes a heat collecting cylinder 10 with upper and lower openings and a hollow interior, a cooling fan 11, a combustion-supporting plate 12, a temperature sensor 13, and CO content detection instrument 14, air supply blower 15 and precise combustion controller 16; the outer wall of the heat collecting cylinder 10 and ...

Embodiment 2

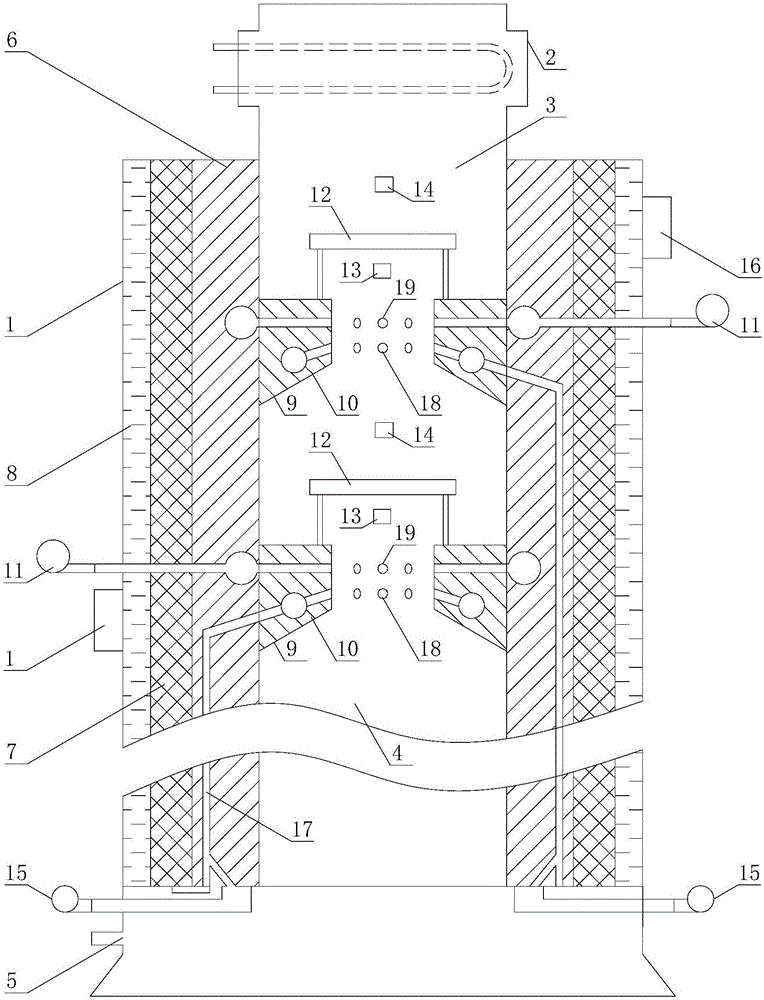

[0015] Embodiment 2: as figure 2 and image 3 As shown, the combustion system is accurately controlled, which includes a combustion device body 1 with a top opening and a hollow interior and a heat exchanger 2. The top opening of the combustion device body 1 is a smoke exhaust port 3; the inner cavity of the combustion device body 1 is a combustion chamber 4 The bottom of the combustion device main body 1 is provided with an air inlet 5 communicating with the combustion chamber 4; the smoke exhaust port 3 is communicated with the heat exchanger 2; Thermal layer 8; two auxiliary combustion devices 9 are arranged up and down in the combustion chamber 4 above, the auxiliary combustion device 9 below is a primary auxiliary combustion device, and the auxiliary combustion device 9 above is a secondary auxiliary combustion device; each auxiliary combustion device The combustion device 9 includes a heat-gathering cylinder 10 with upper and lower openings and a hollow interior, a coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com