Patents

Literature

102results about How to "Achieve clean combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

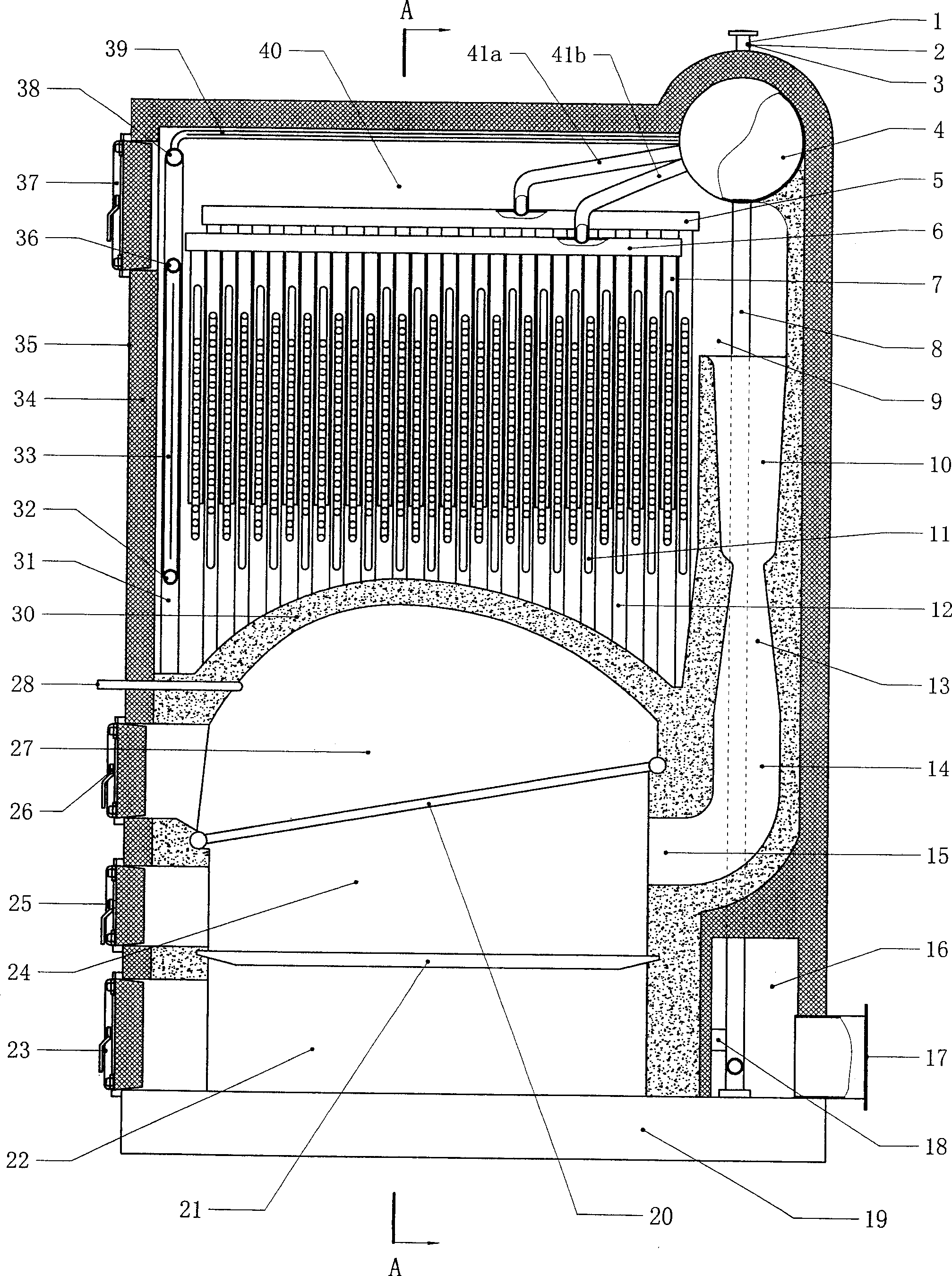

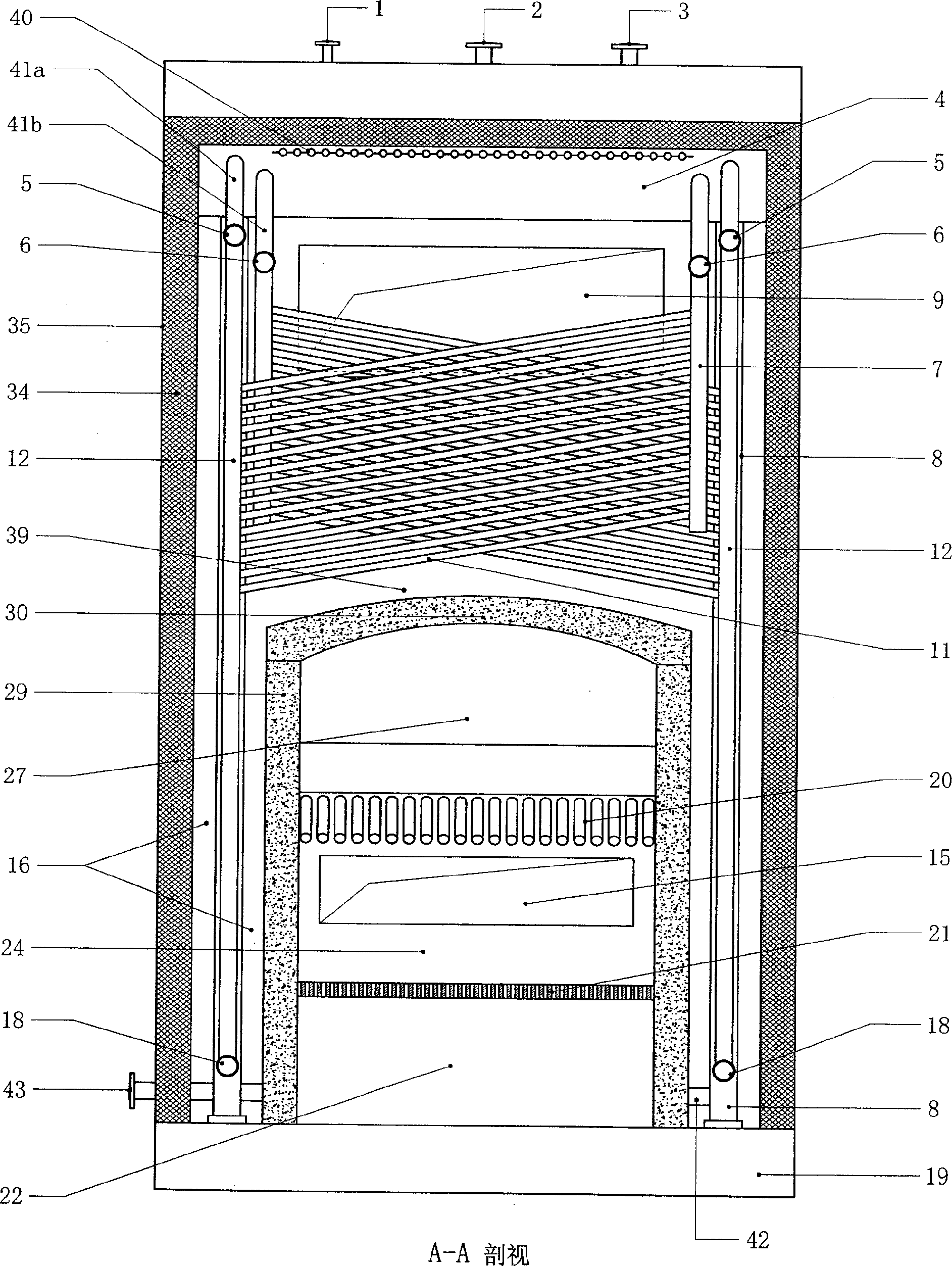

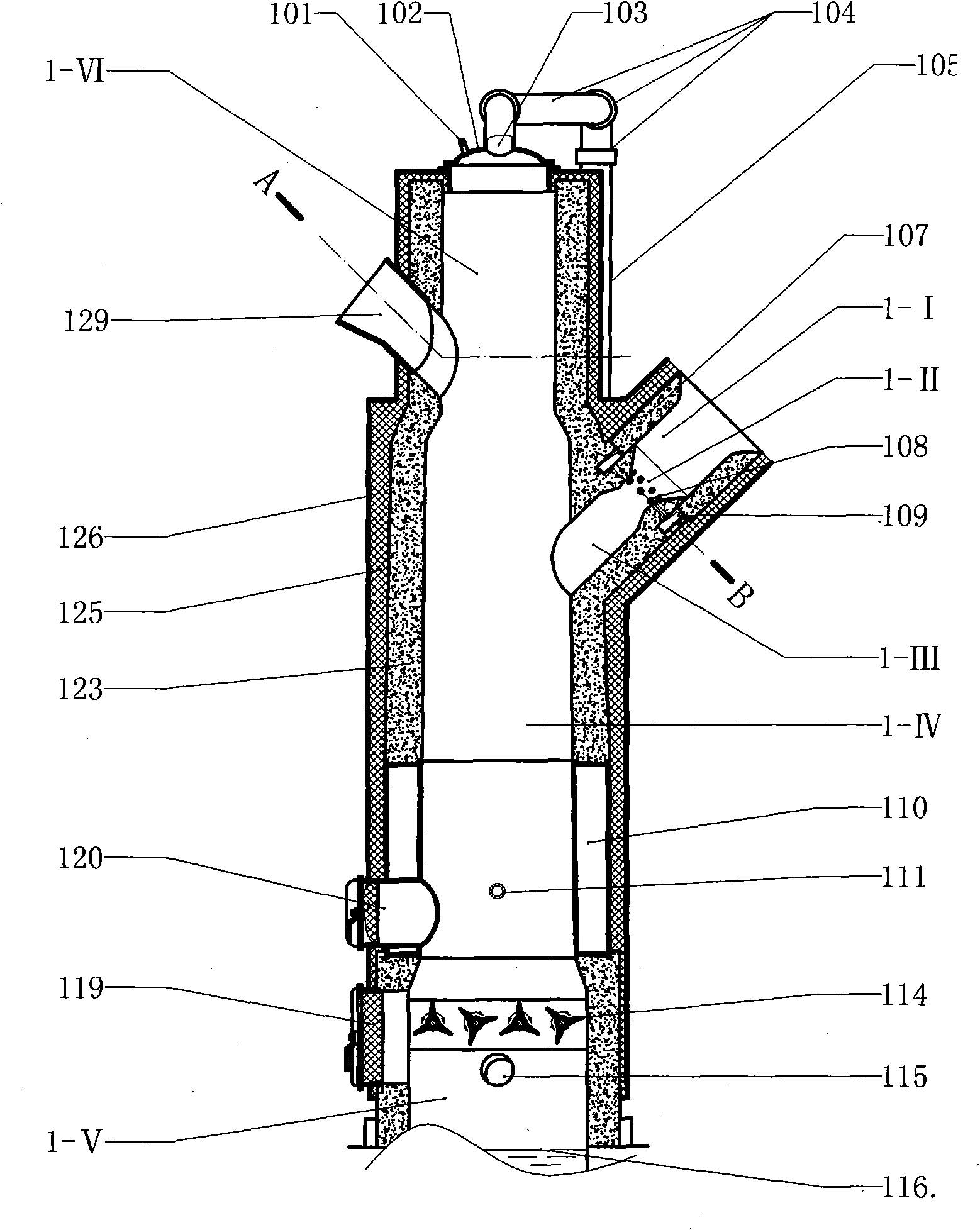

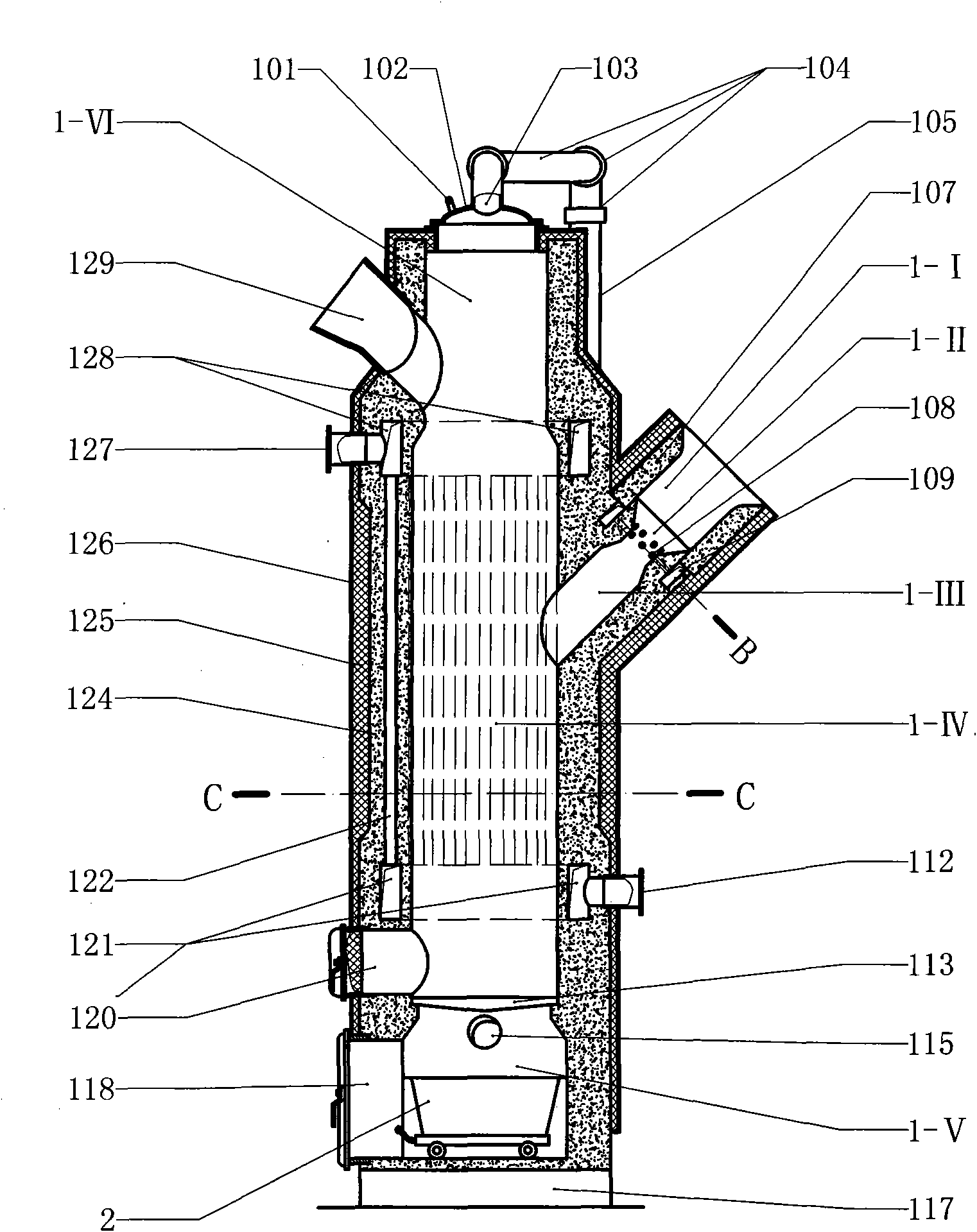

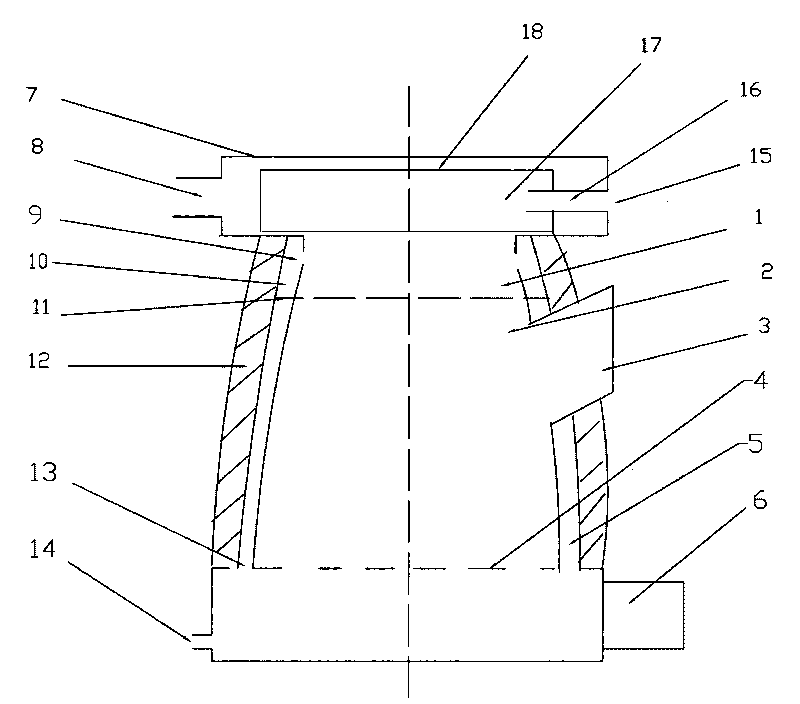

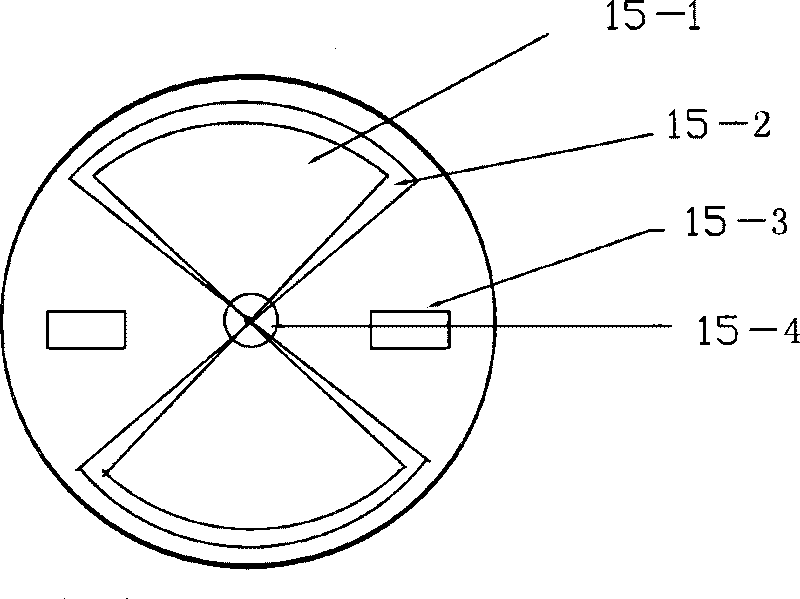

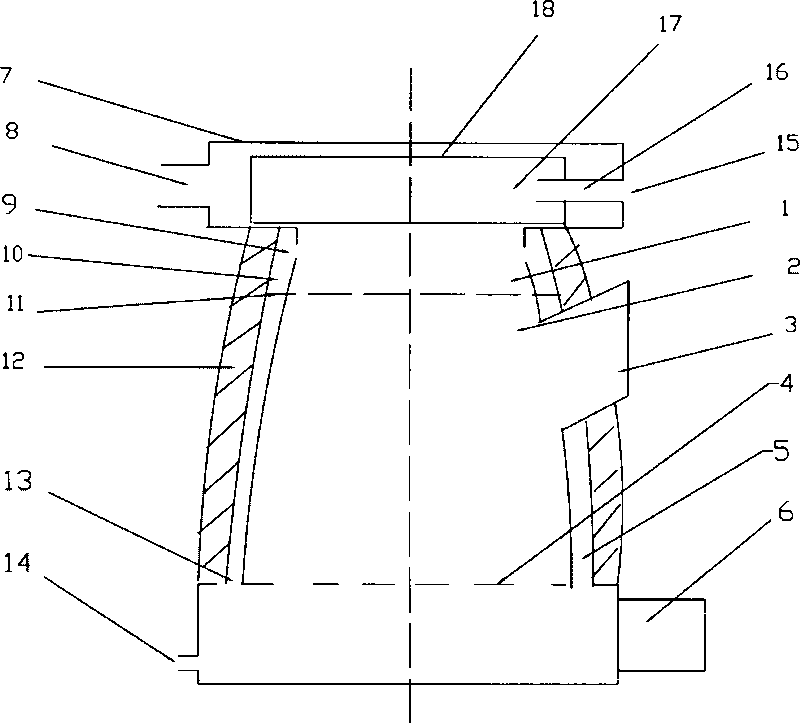

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490AAchieve clean combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

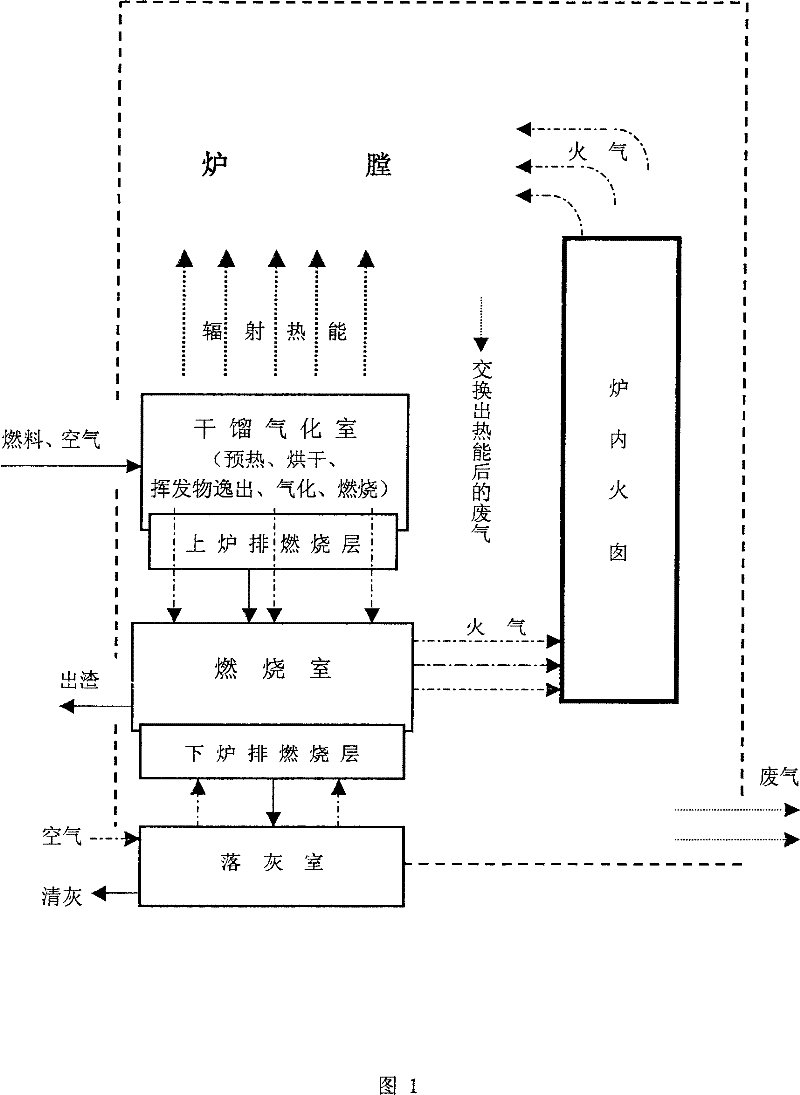

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

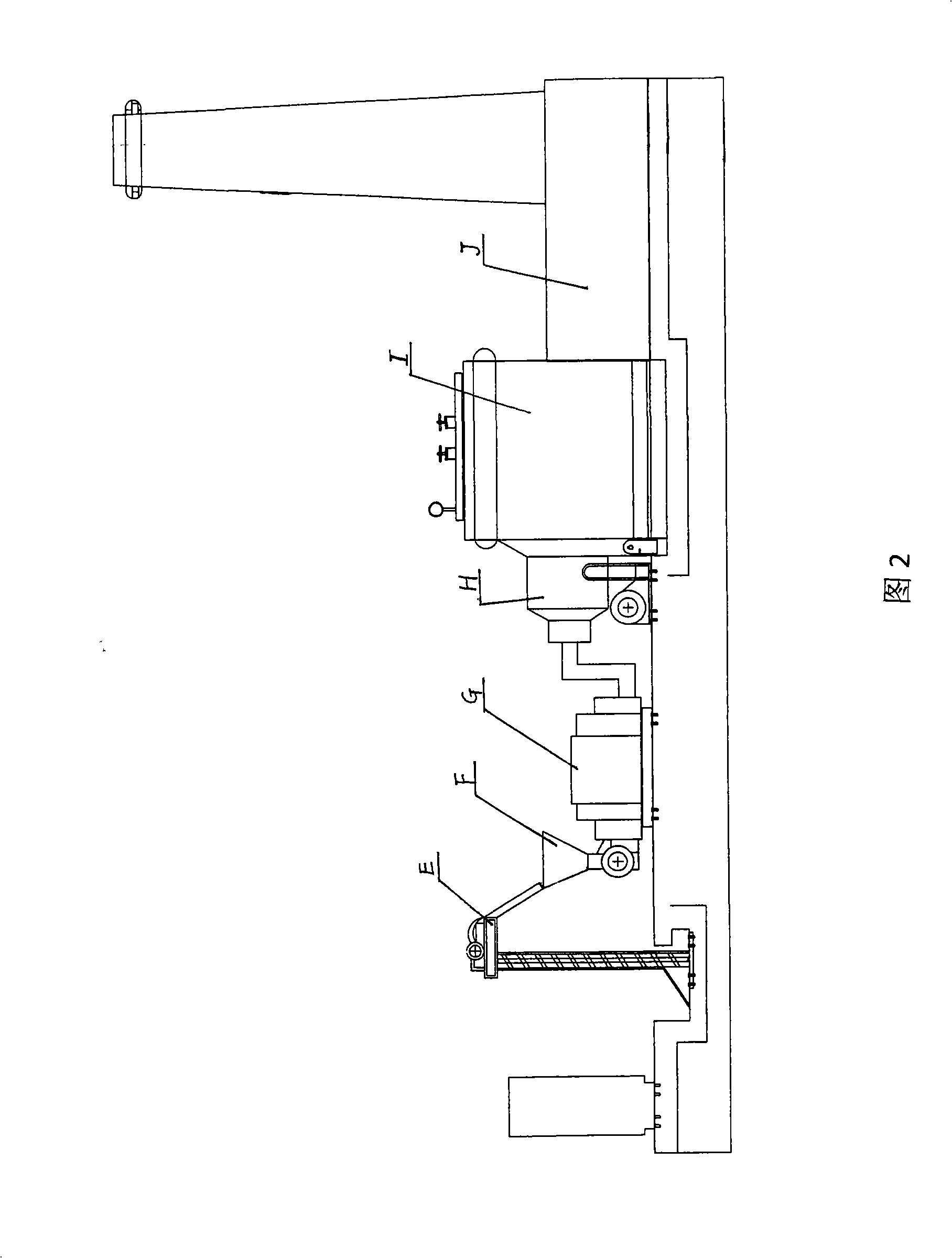

Industrial boiler combustion method

The invention relates to a combusting method for an industrial boiler, which is characterized in that an old style boiler adopts the method that a fire grate at the bottom of the old style boiler is removed, to form a pure furnace chamber I; at least one combustor H is installed at one side of the pure furnace chamber I; coal powder E enters into the combustor H after entering into an electronic scale G through a coal scuttle F; the coal powder E performs the complete process of mixture with the air, firing, reinforced combustion, deoxidization of NOx, combustion into ash, liquid slugging and low NOx discharging inside the combustor H, and finally the pure high temperature fume is transmitted to the pure furnace chamber I and absorbed and utilized through a smoke flue J; a novel boiler adopts the method that a boiler with a pure furnace chamber is manufactured; the second to the forth steps are identical to the combusting method of the old style boiler. The combusting method has advantages that the combustion is sufficient, the effects of energy conservation and discharge reducing are remarkable, the pollution is reduced, and the service life is prolonged.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

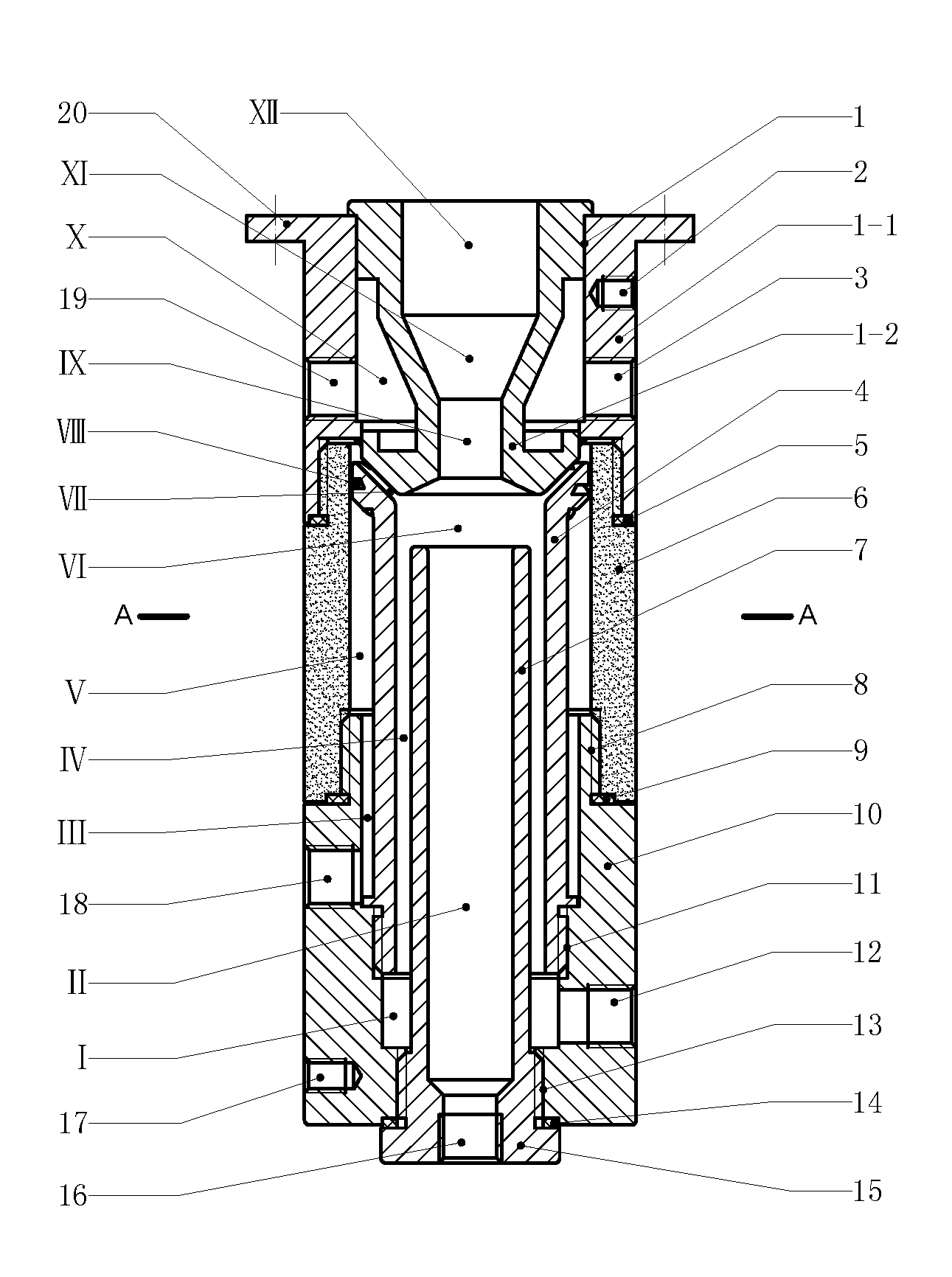

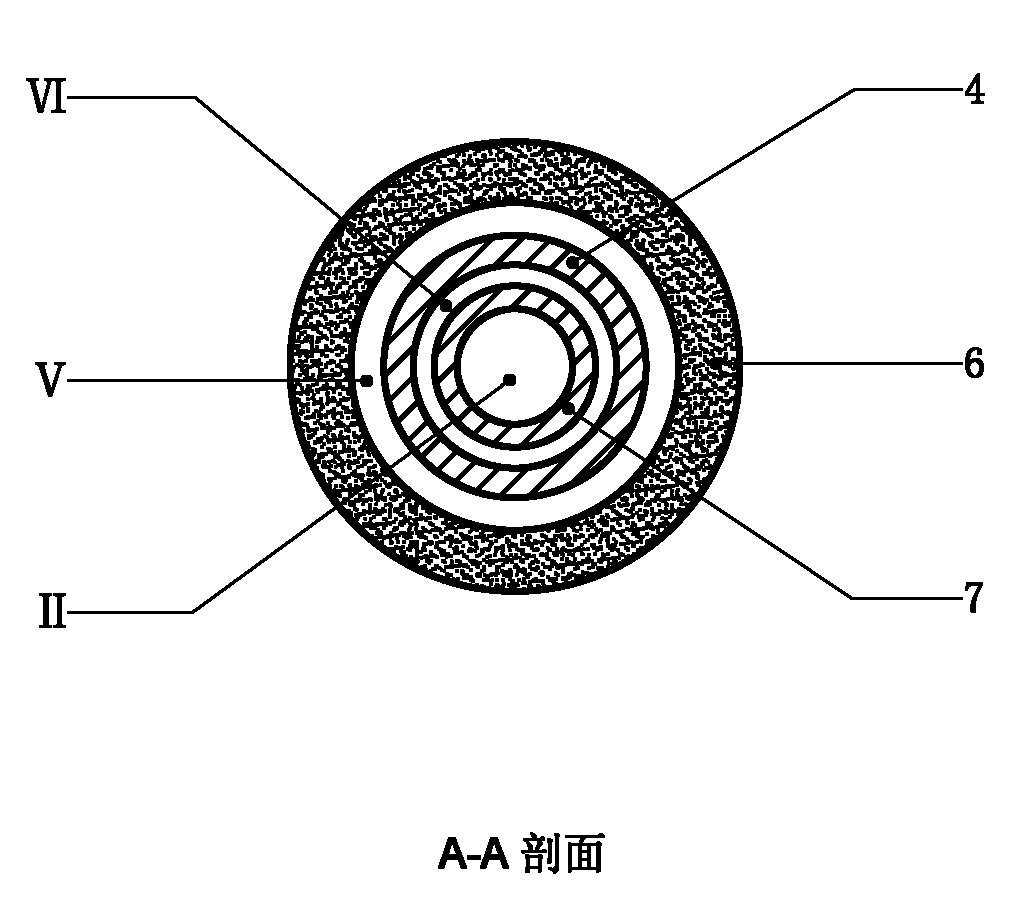

Plasma heating decomposer

ActiveCN103987183AAchieve clean combustionProtect environmentPlasma techniqueEcological environmentHazardous substance

The invention relates to a plasma heating device, in particular to a plasma heating decomposer. The plasma heating decomposer is composed of an anode sleeve, an anode, a cathode substrate, a cathode and an insulating frame, wherein the anode is of a horn-shaped revolution solid structure, a diffusion cavity is formed in a horn-shaped inner space, a compression pore channel is formed by a throat at the rear end of the diffusion cavity, the anode is embedded into the anode sleeve, and a water jacket b is formed by the space between the outer wall of the anode and the anode sleeve; the cathode substrate is of a revolution solid structure with the center shaft protruding forwards, the cathode is embedded into the inner space of the center shaft of the cathode substrate, and a water jacket a is formed by space between the outer wall of a rod body of the cathode and the inner wall of the center shaft of the cathode substrate; the insulating frame is a connecting component between the anode sleeve and the cathode substrate, the anode sleeve is installed at the front end of the insulating frame, the cathode substrate is installed at the rear end of the insulating frame, a shrinking cavity is formed by the space between the front end of the center shaft of the cathode substrate and the compression pore channel at the rear end of the anode, and the head end of the cathode is arranged in the shrinking cavity. The plasma heating decomposer is suitable for production lines for hydrogen production through water pyrolysis or for treatment of hazardous substance and protects the ecological environment.

Owner:付顺坤

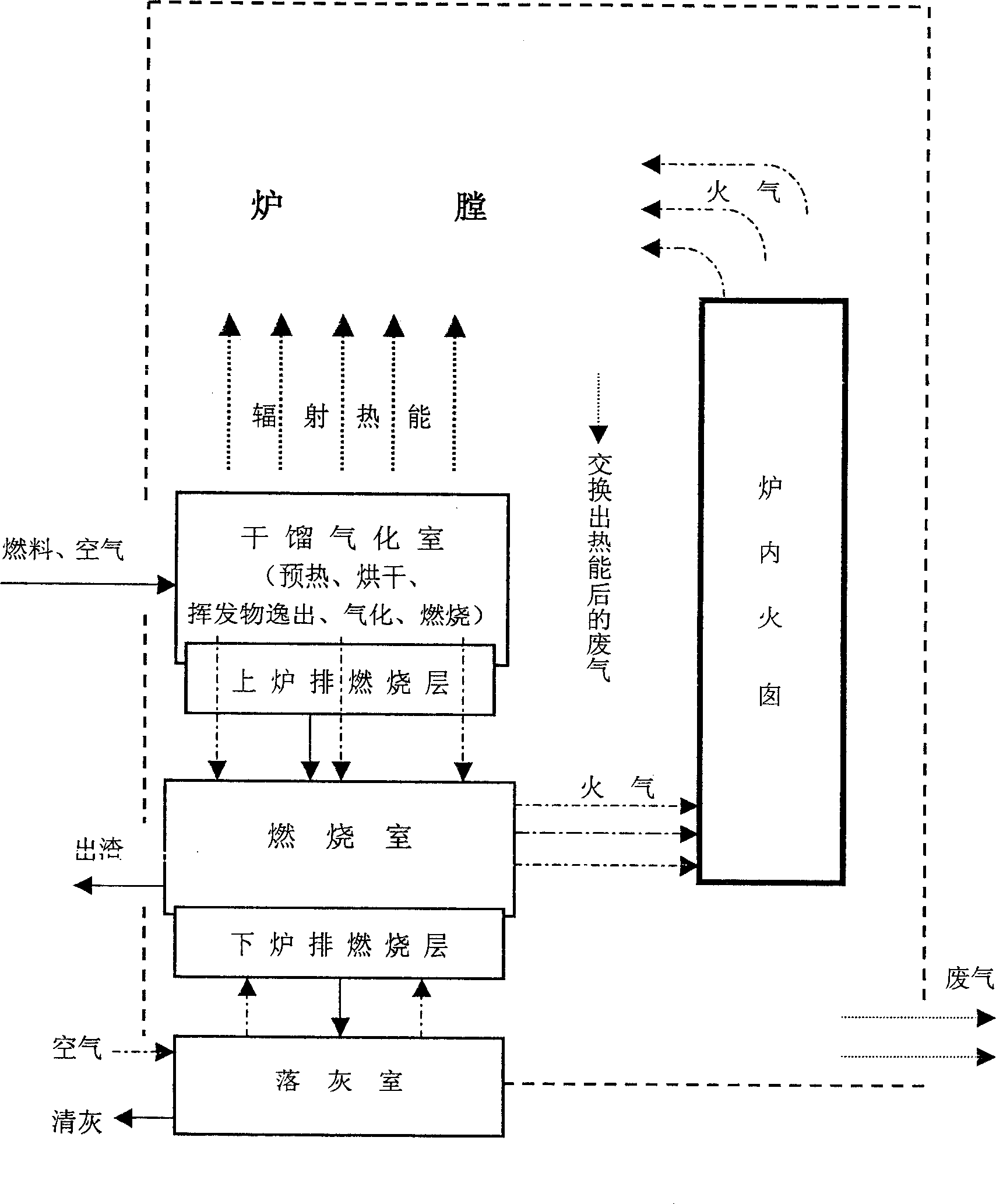

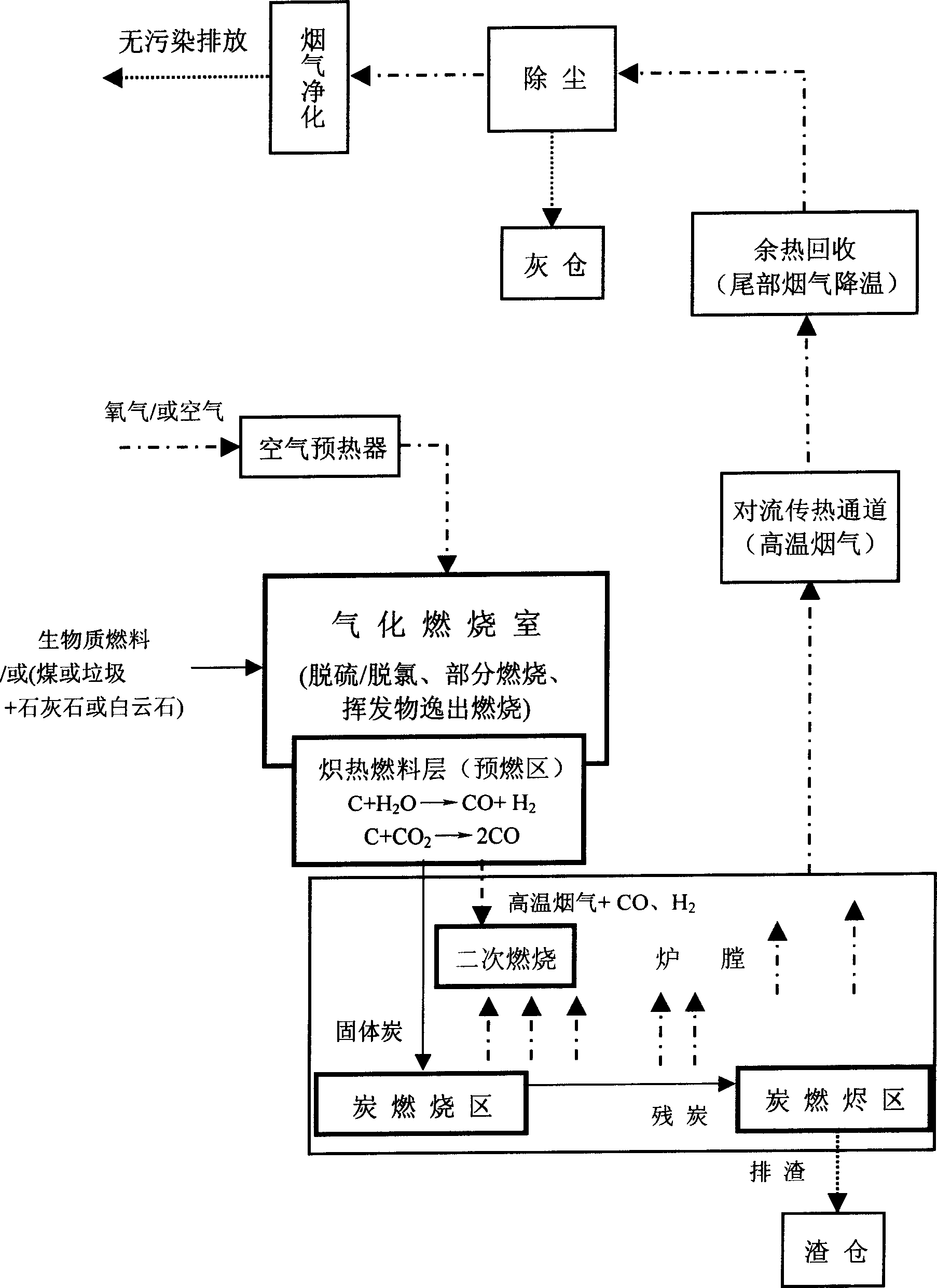

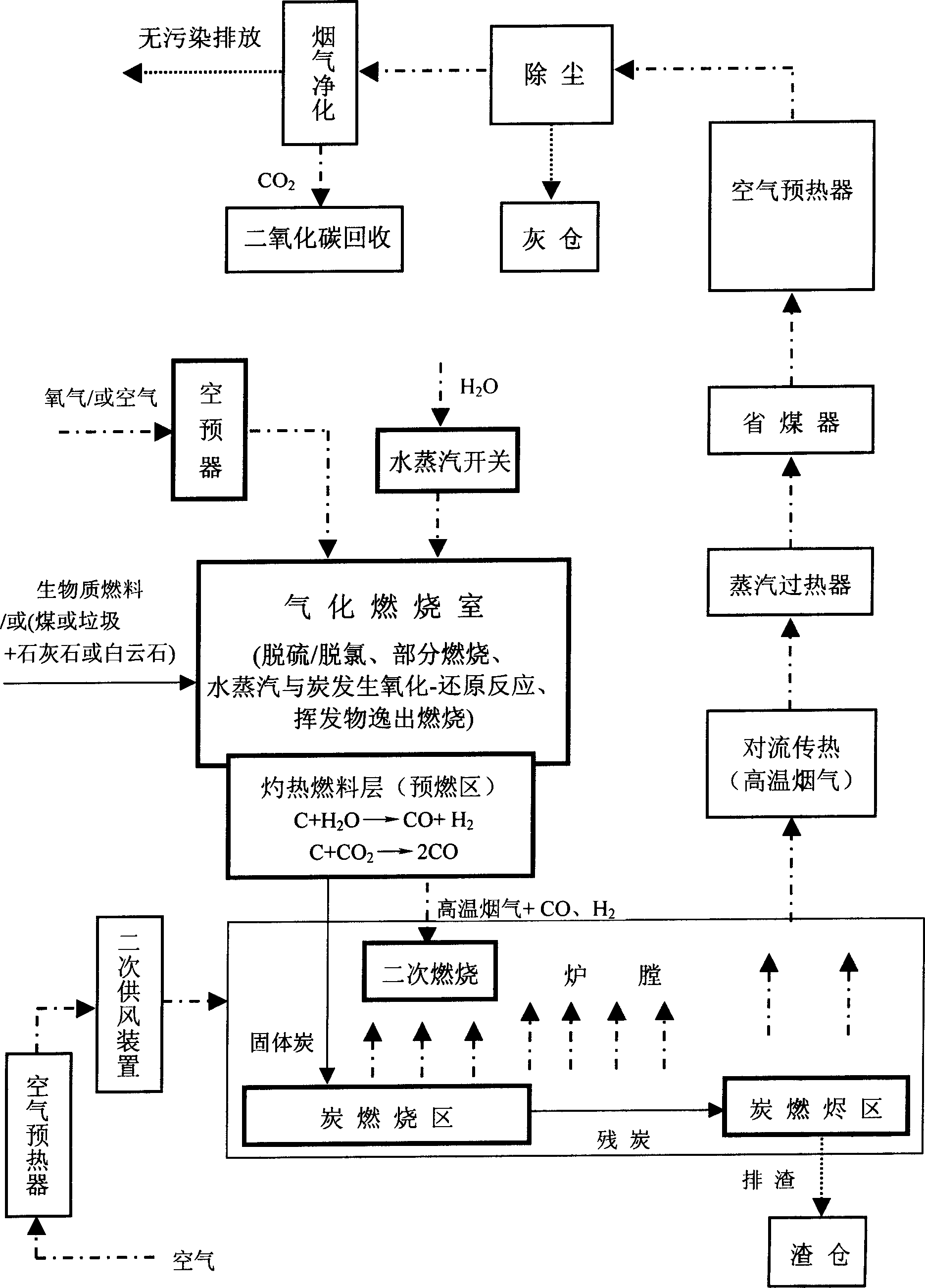

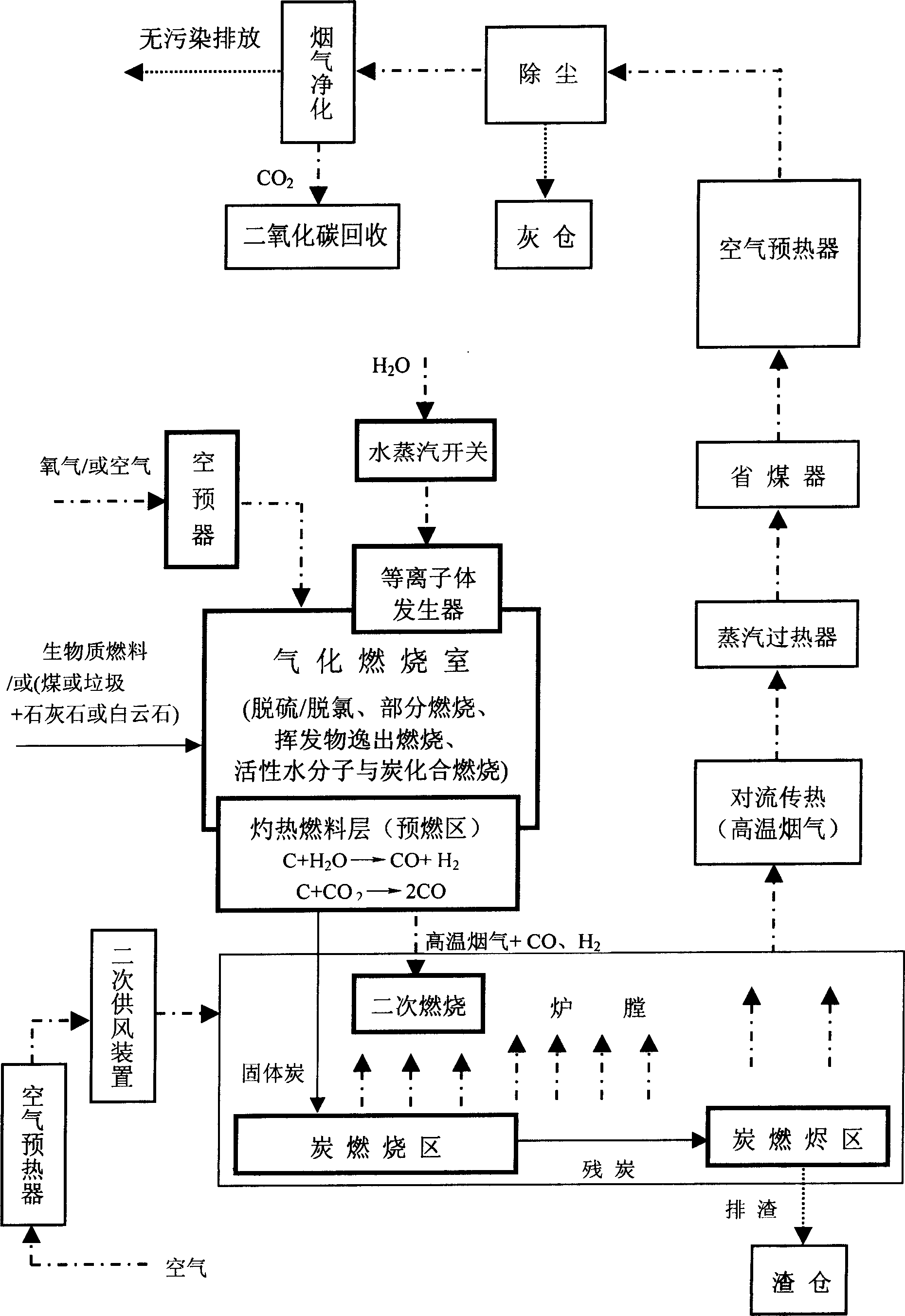

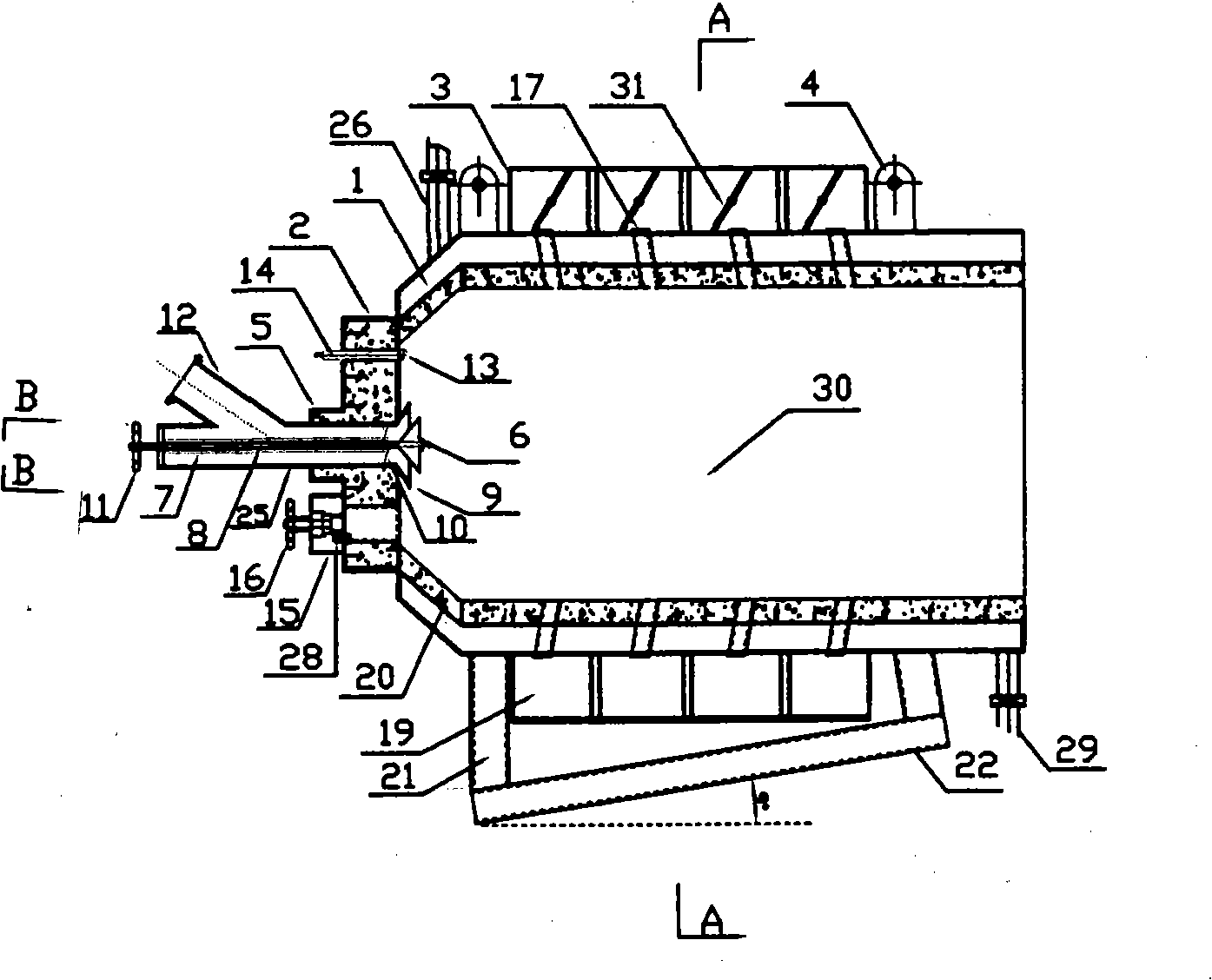

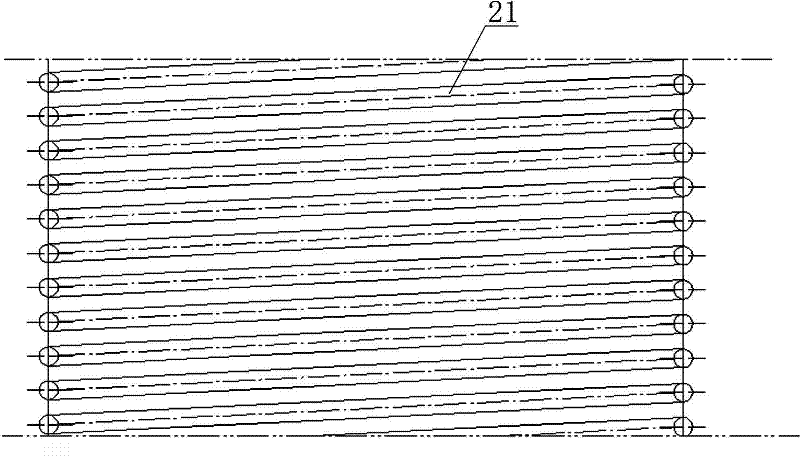

Process and its device for clean burning and value gaining burning of solid fuel

InactiveCN1900590AAchieve clean combustionRealize value-added burningSolid fuel combustionNon-combustible gases/liquids supplyAir preheaterThermal energy

The invention related to heat energy device by using coal, garbage, and biomass as fuel. The firing system is composed of fuel supply system, water vapor input unit, gasification firebox, hearth, water-cooling type or wind-cooling type fire grate in up layer, fixed grate or moving grate in low layer, primary and secondary air supply arrangement etc. Gasification firebox is in quasi-closed position. Water vapor input unit includes water vapor nozzle or plasma generator. In gasification firebox, solid fuel carries out following procedures: preheating, drying, gasifying, desulfurizing, dechloridizing, burning by exsilient volatile, and burning from fuel bed. Passing through full hot fuel bed on fire grate in up layer, flue gas in high temperature enters into hearth to carry out second time of burning so as to eliminating coal smoke. Being fed to gasification firebox, water vapor is in use for restraining generation of coal smoke to implement clean burning and value added burning.

Owner:周开根

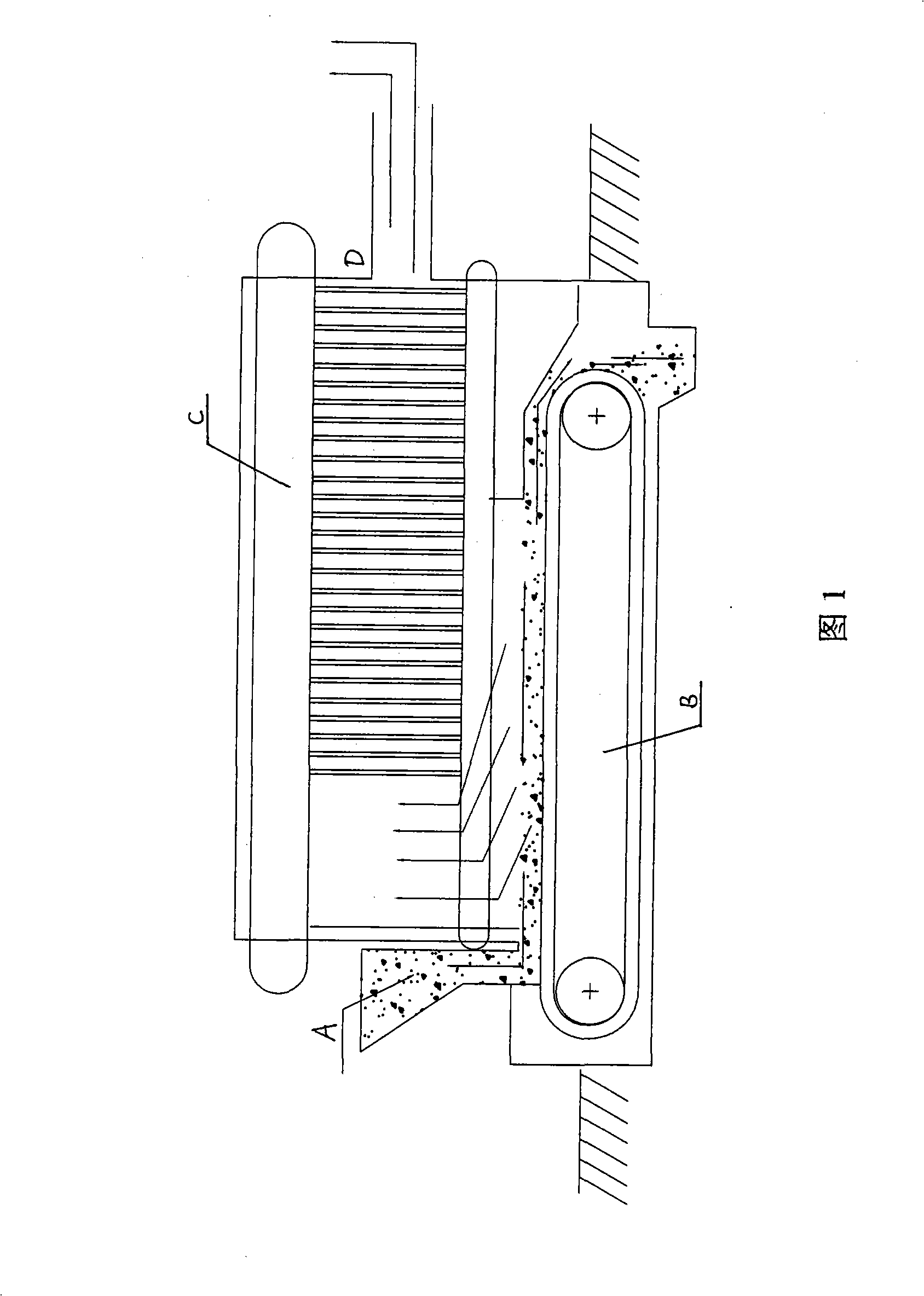

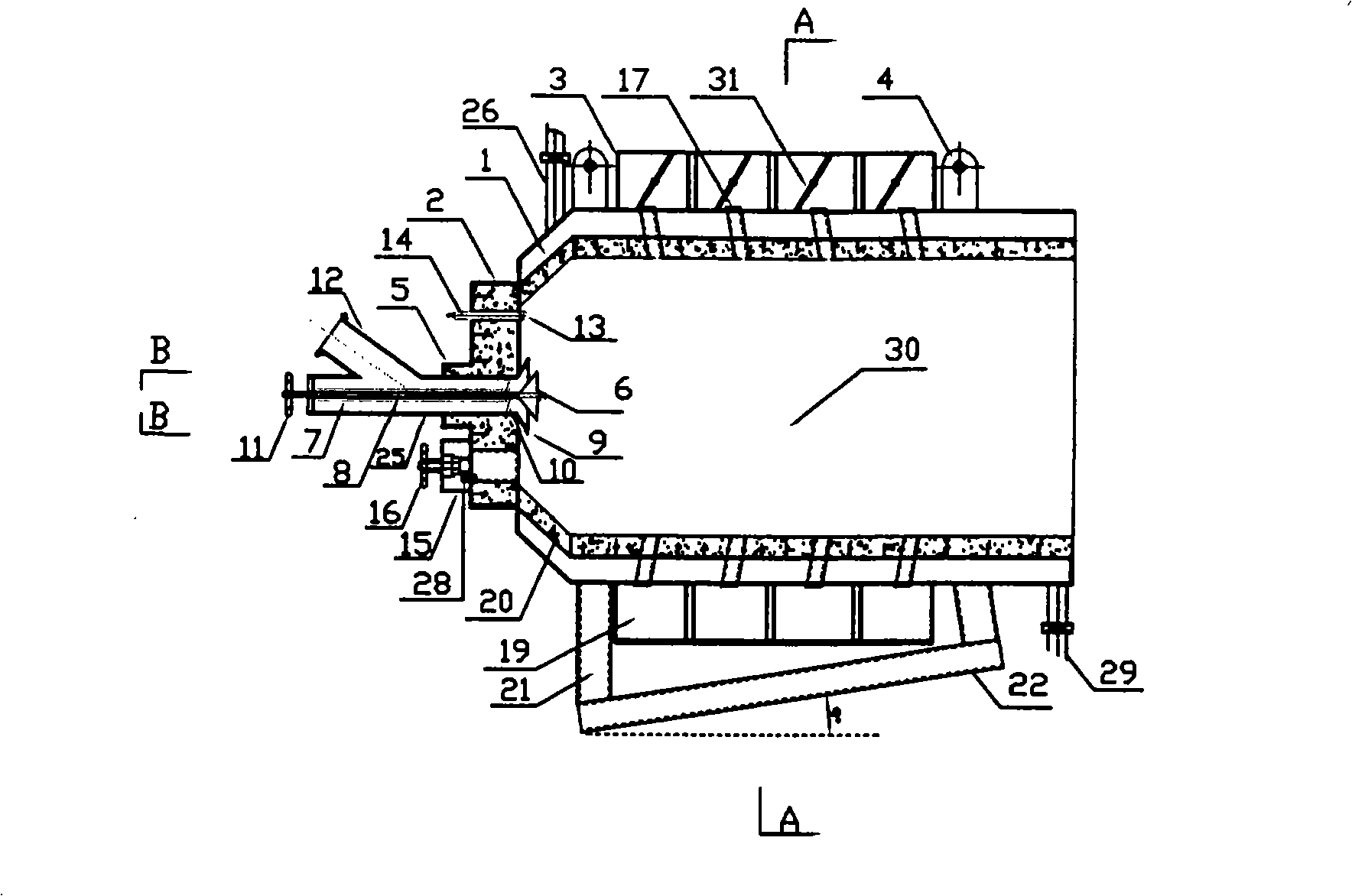

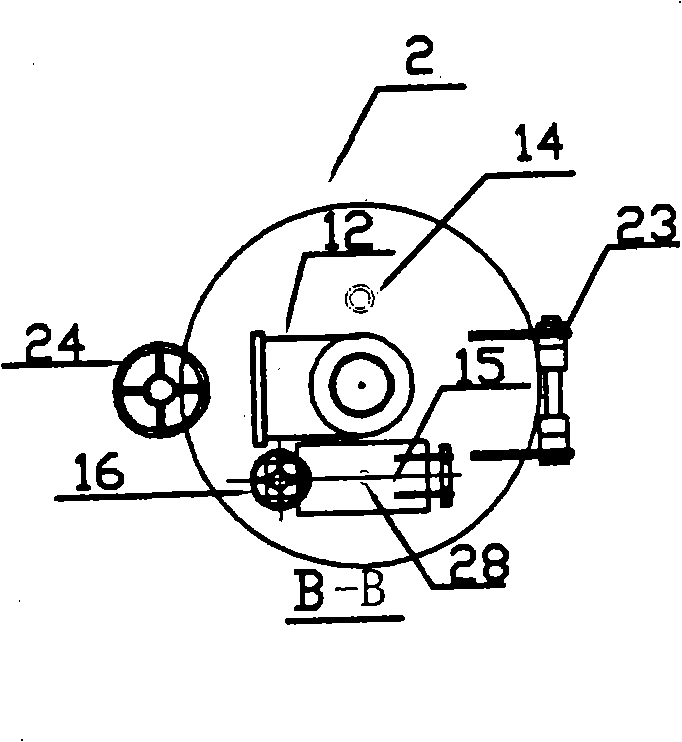

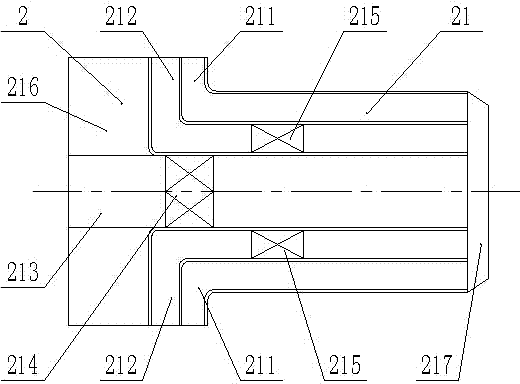

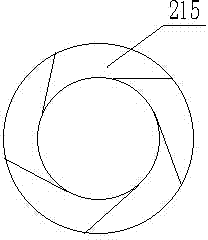

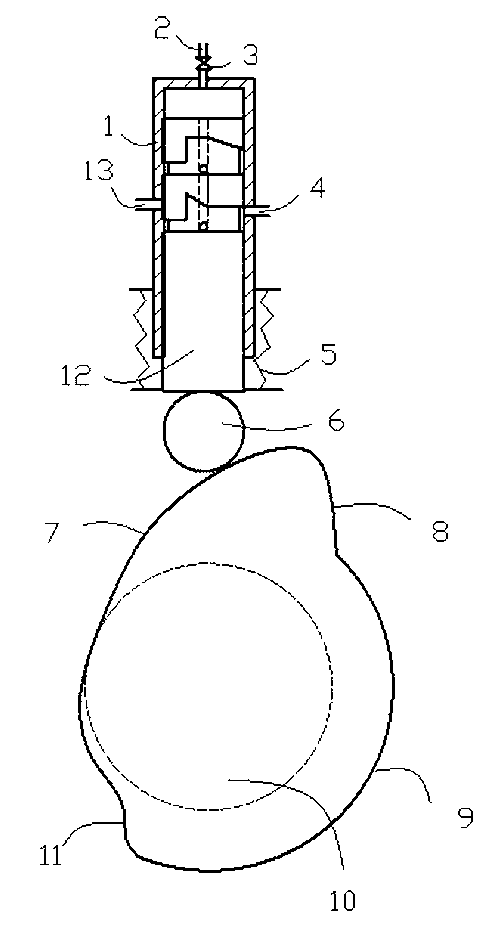

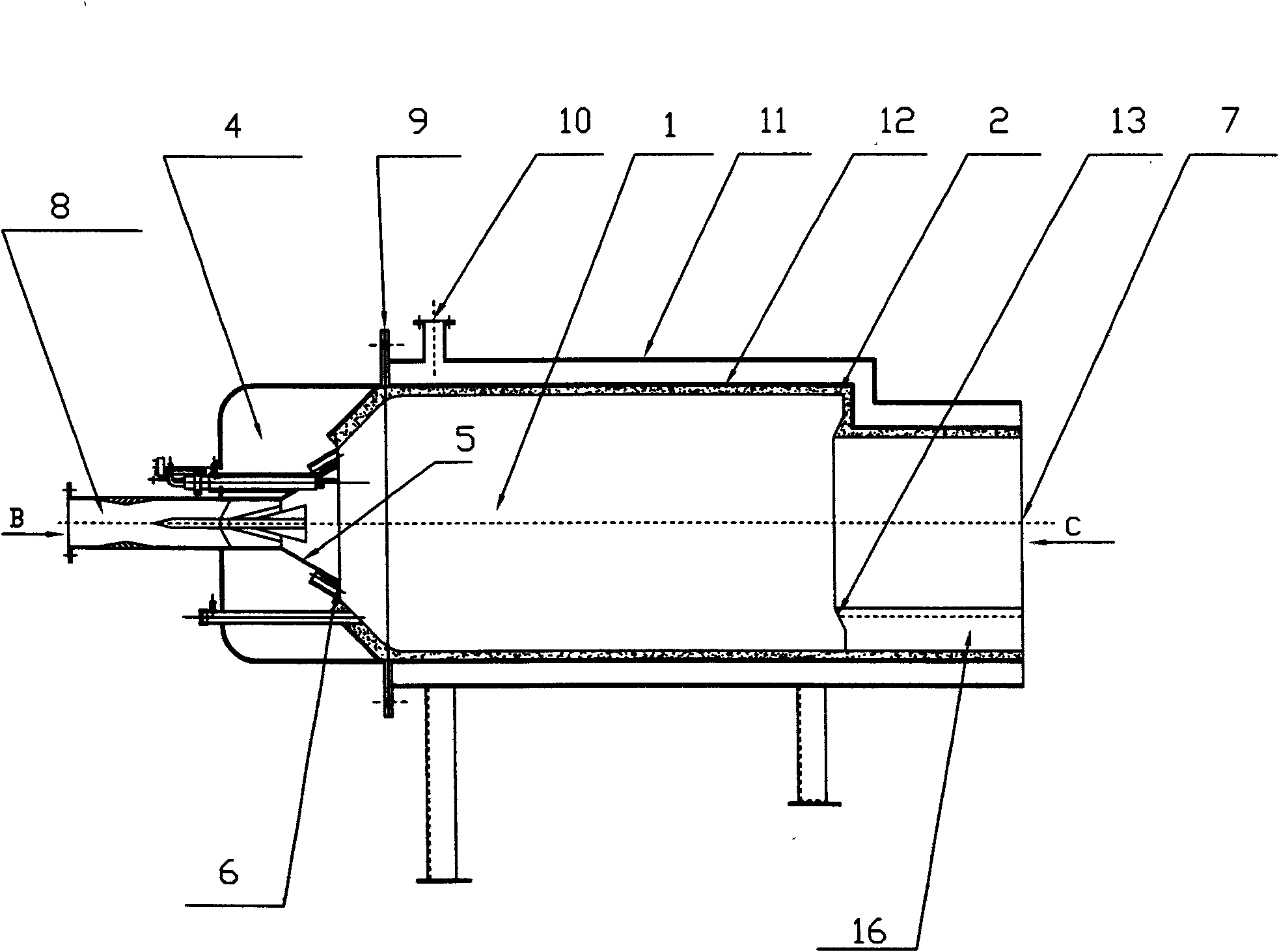

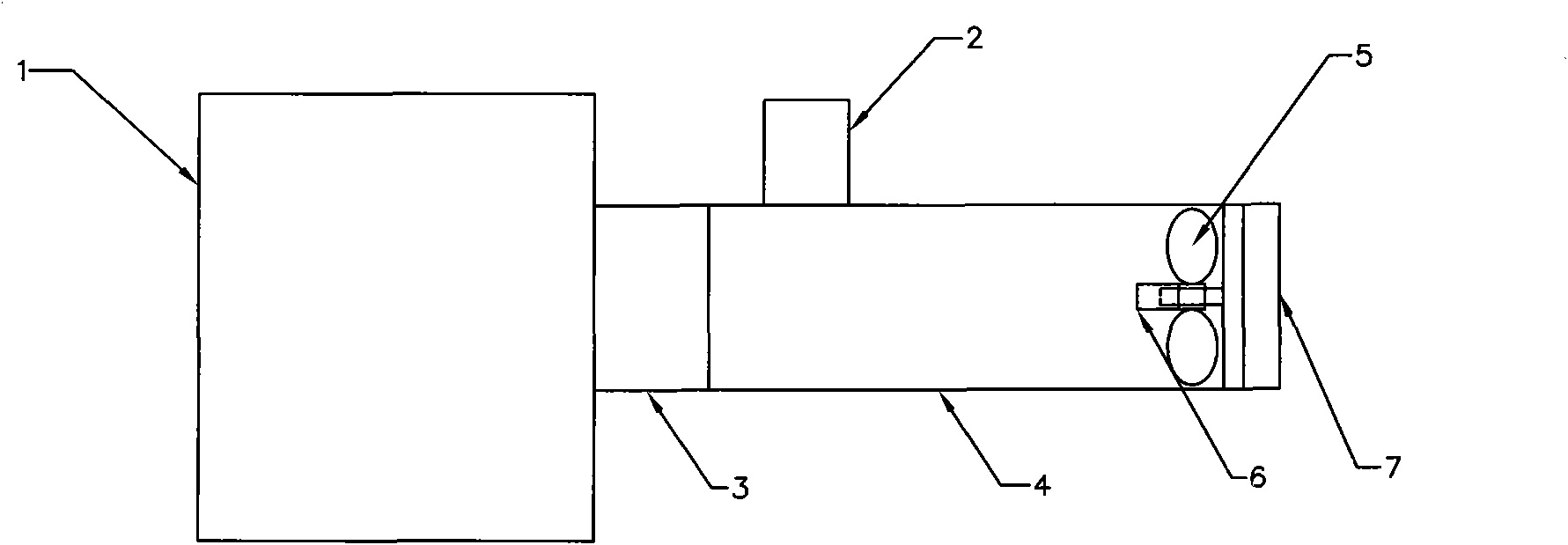

Low NOx liquid state slag-off double-eddy flow coal-powder combustor

ActiveCN101324334ABurn fastReduce smoke and dust emissionsPulverulent fuel combustion burnersSlagCoal

The invention relates to a low-NOx slag tapping double-swirl pulverized coal burner, which is suitable for 2-35 ton steam and hot water boiler and burning devices desired for heat energy for various kinds of industrial productions such as furnace, forging, steel making, road and bridge mixing station, and cold aggregate heating. The low-NOx slag tapping double-swirl pulverized coal burner comprises an adjustable burning device and a cylindrical burning chamber and is characterized in that the housing of the burning chamber is a heat insulating layer; a cooling water channel or a secondary air heat exchange fin is arranged between the housing the burning chamber and a secondary air chamber; a cooling water outlet pipe and a cooling water inlet pipe are respectively arranged on the upper and the lower ends of the cooling water channel; and a primary gas axial flow generator is arranged on the top of the jacket of an adjusting screw. The low-NOx slag tapping double-swirl pulverized coal burner has the advantages of sufficient burning and improved service life.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

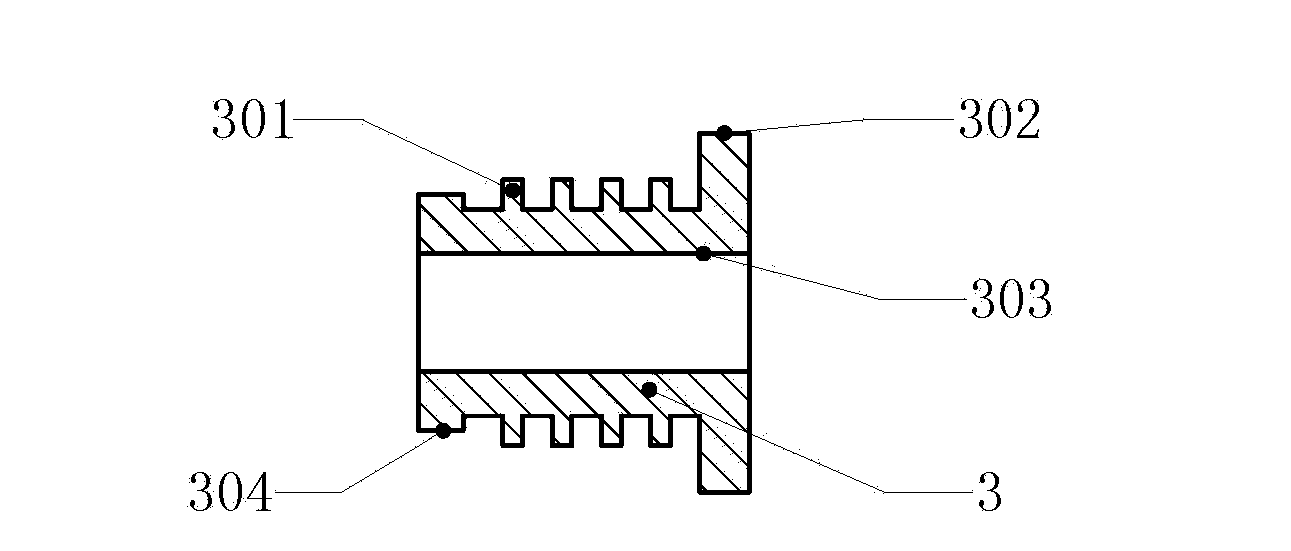

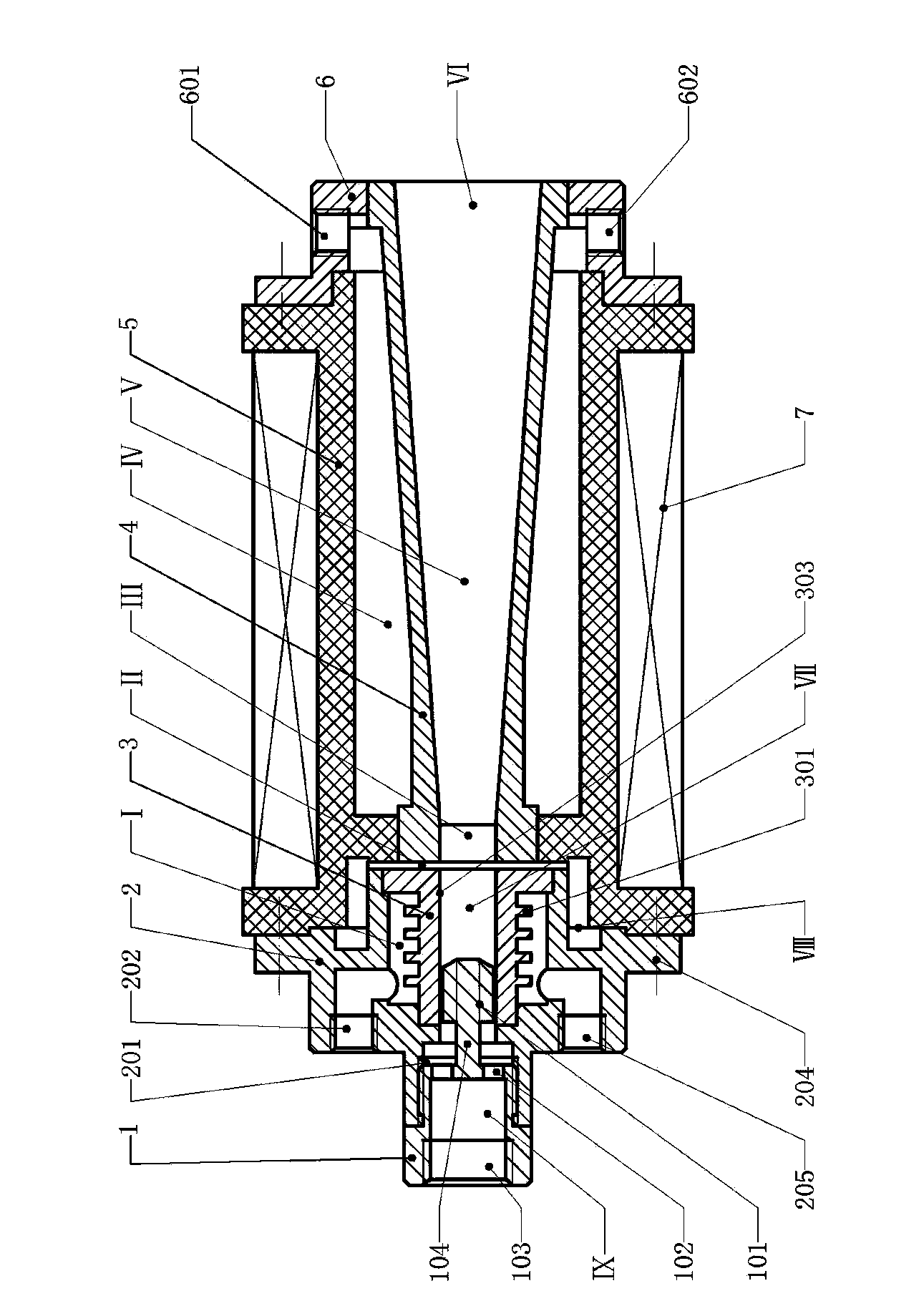

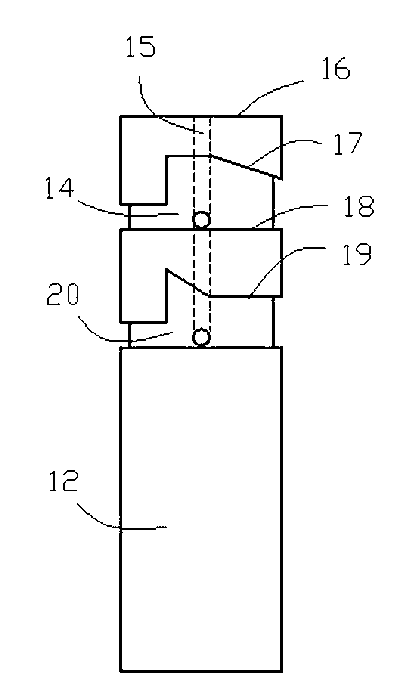

Revolved body cathode with cooling rib rings

ActiveCN103929872AAchieve clean combustionProtect environmentPlasma techniqueEngineeringWater jacket

The invention provides a revolved body cathode with cooling rib rings, and relates to a cathode of plasma spray guns. A through cylindrical hole channel in the front and back direction is formed in the axial center of the revolved body cathode, the inner wall of the front end of the cylindrical hole channel forms an inner ring discharging surface, the outer wall of the front end of the revolved body cathode forms an embedding surface a, the outer wall of the rear end of the revolved body cathode forms an embedding surface b, and the protruding cooling rib rings are arranged on the outer wall of a revolved body between the embedding surface a and the embedding surface b. The revolved body cathode is mounted in a cathode base in an embedding mode, the space between the inner wall of the cathode base and the outer wall of the revolved body cathode forms a cooling water jacket, an embedding port a is formed in the wall of the front end of the cathode base, the embedding surface a of the revolved body cathode is tightly embedded into the embedding port a of the wall of the front end of the cathode base, an embedding port b is formed in the wall of the rear end of the cathode base, and the embedding surface b of the revolved body cathode is tightly embedded into the embedding port b of the wall of the rear end of the cathode base. Through the application of the revolved body cathode with the cooling rib rings in plasma heating spray guns, the defect that the cathode is prone to being ablated is overcome.

Owner:甘肃永鸿染化有限公司

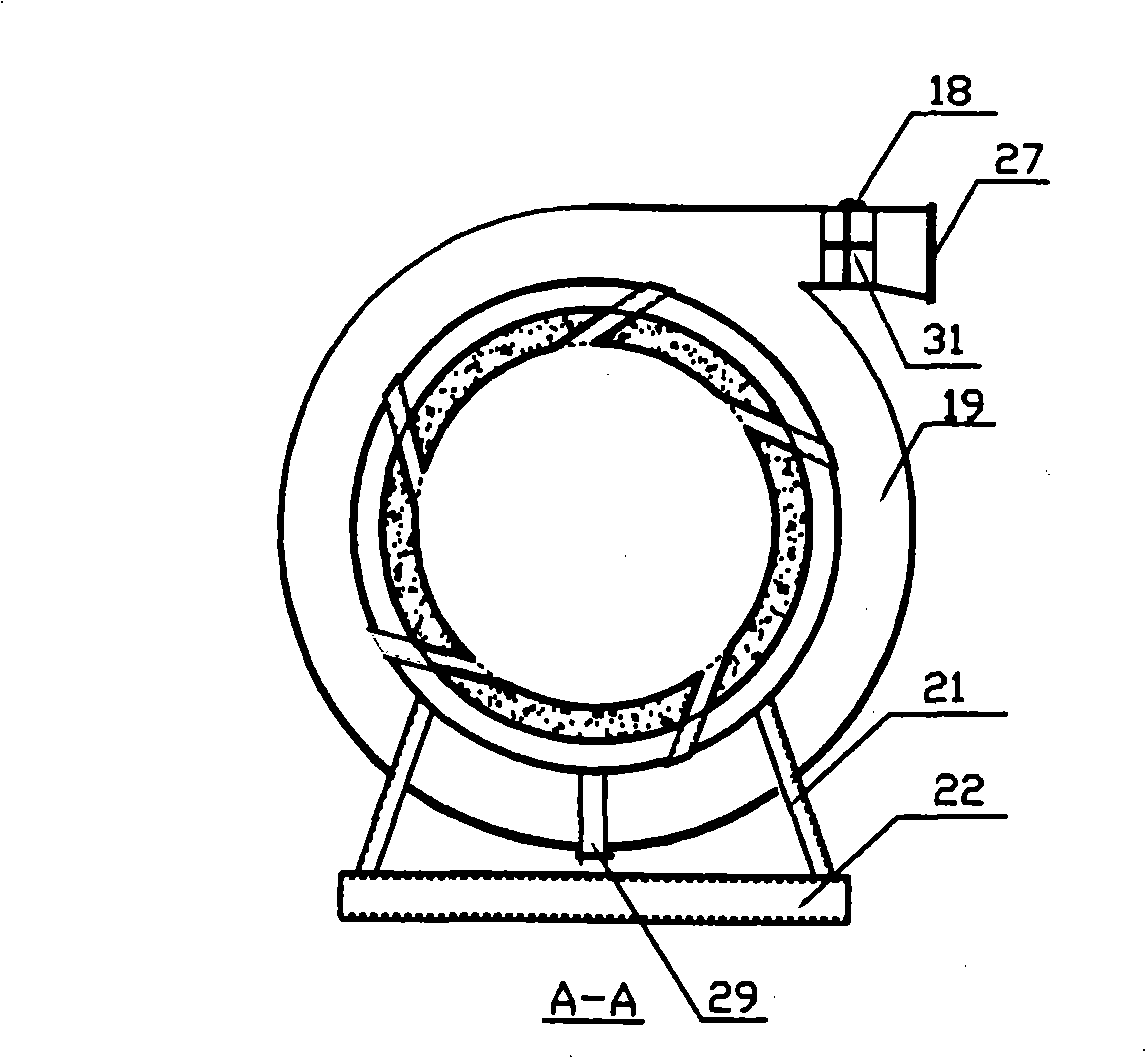

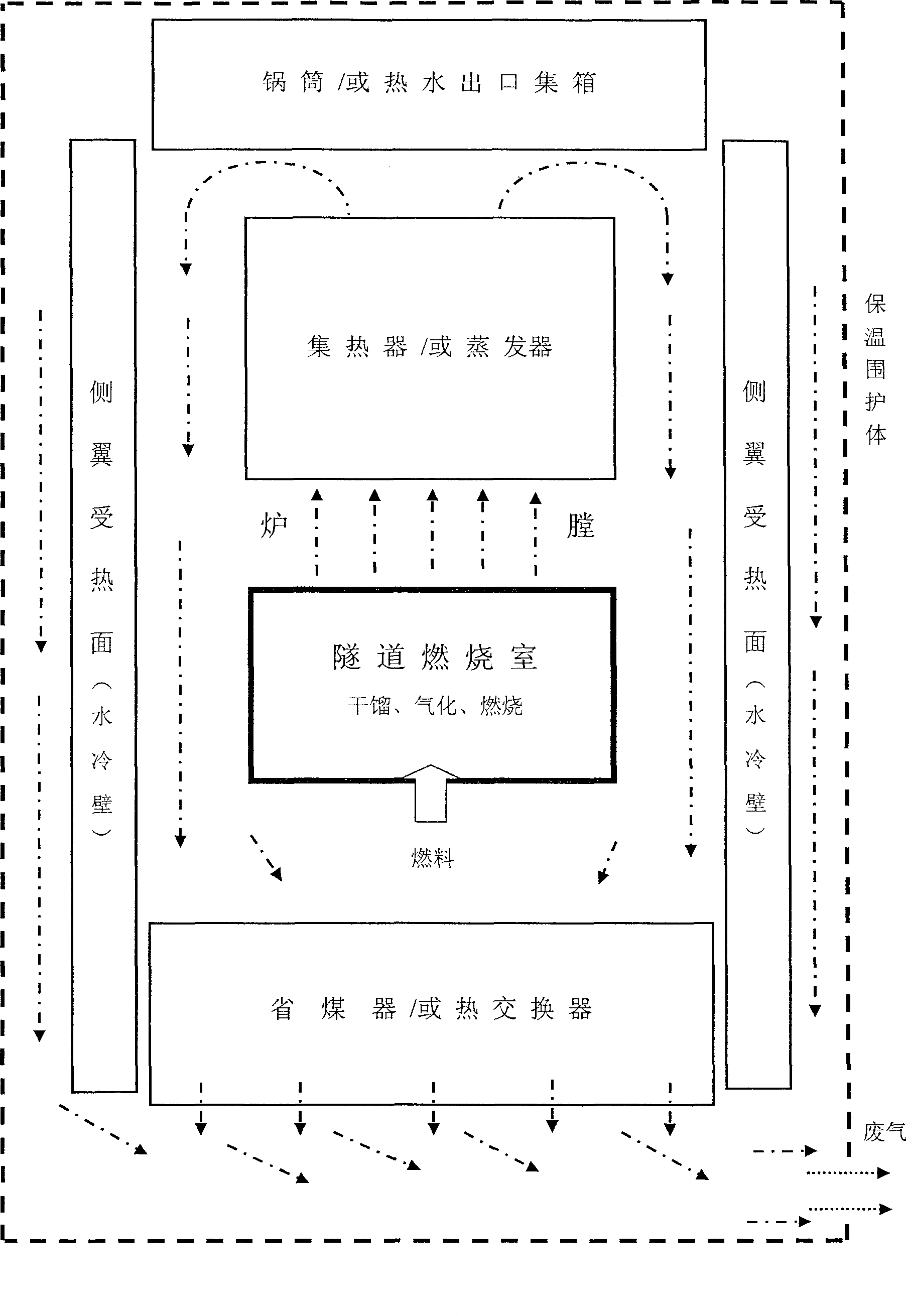

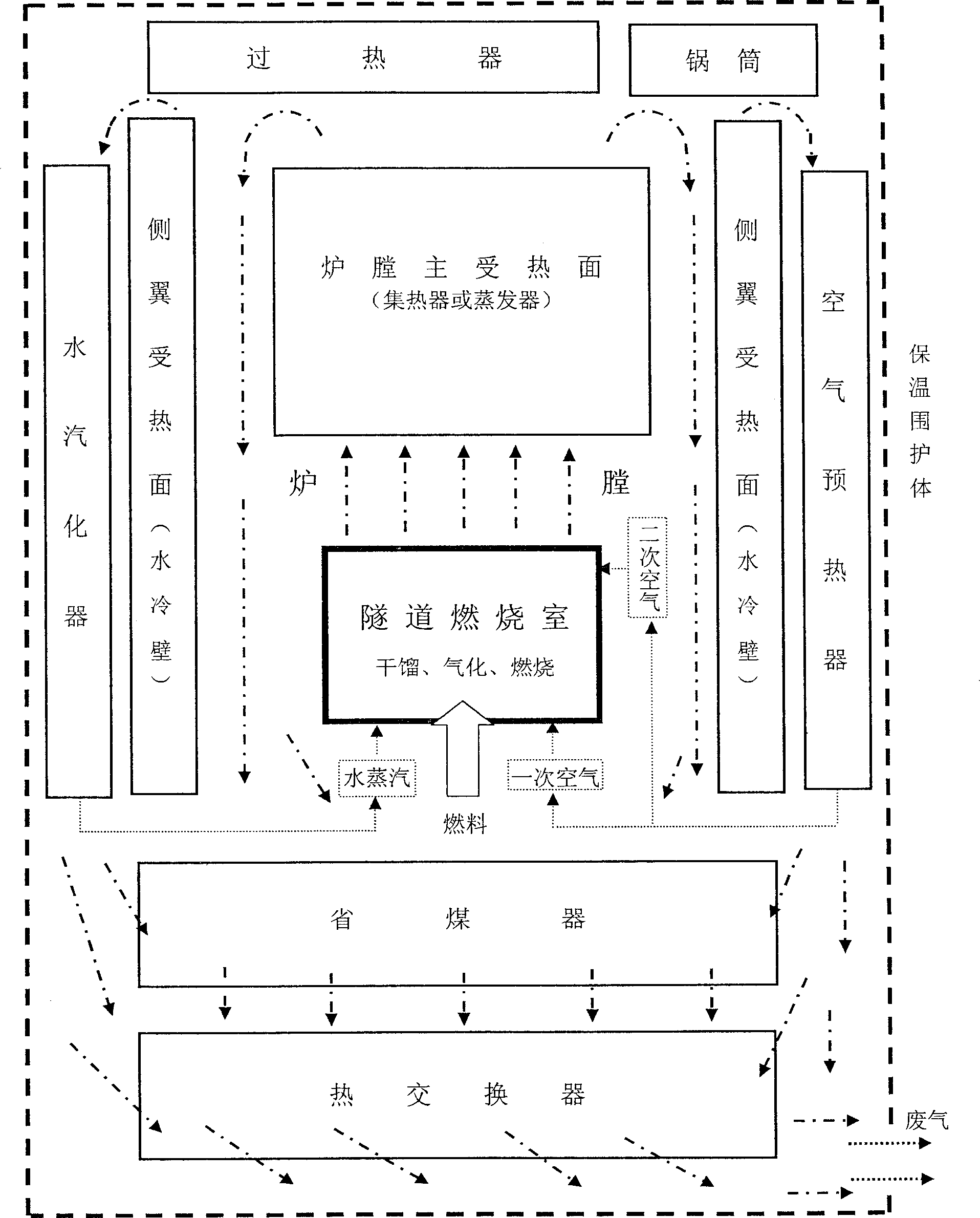

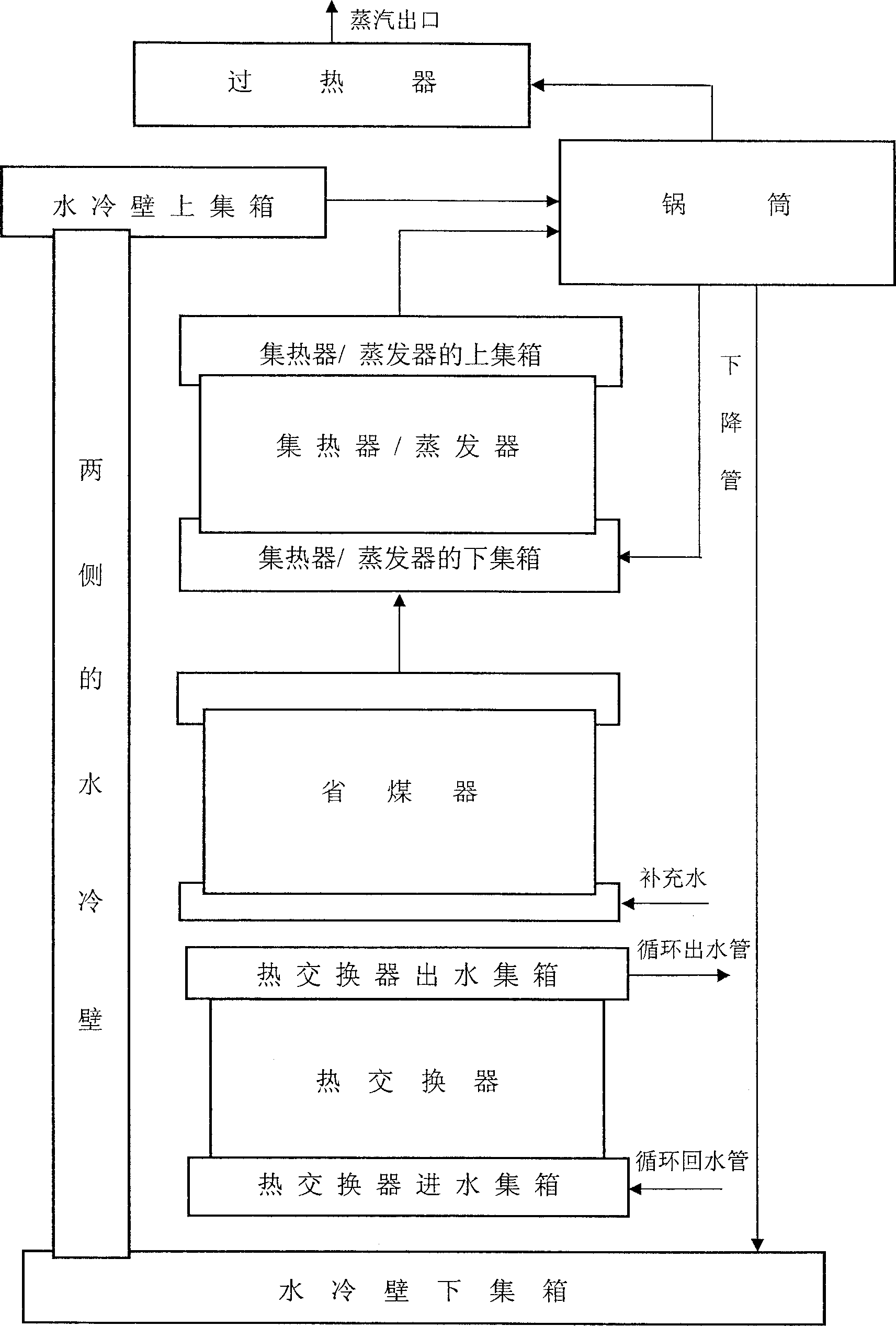

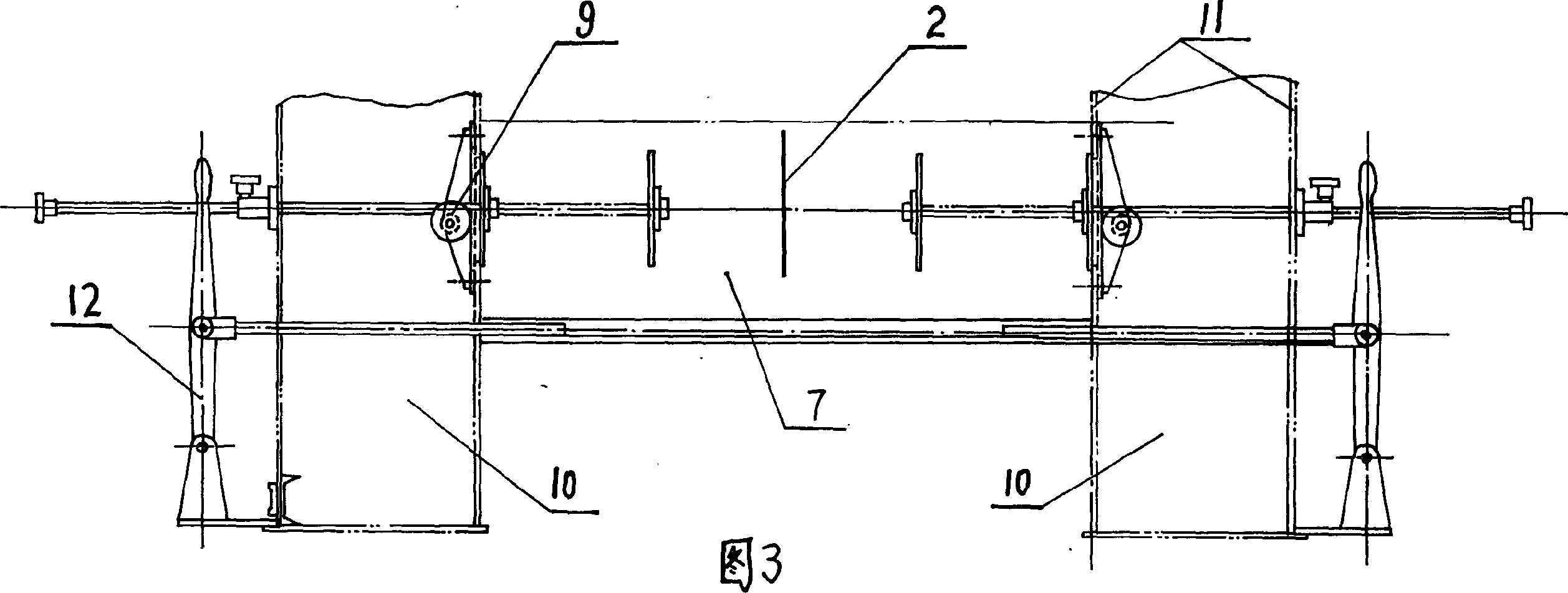

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

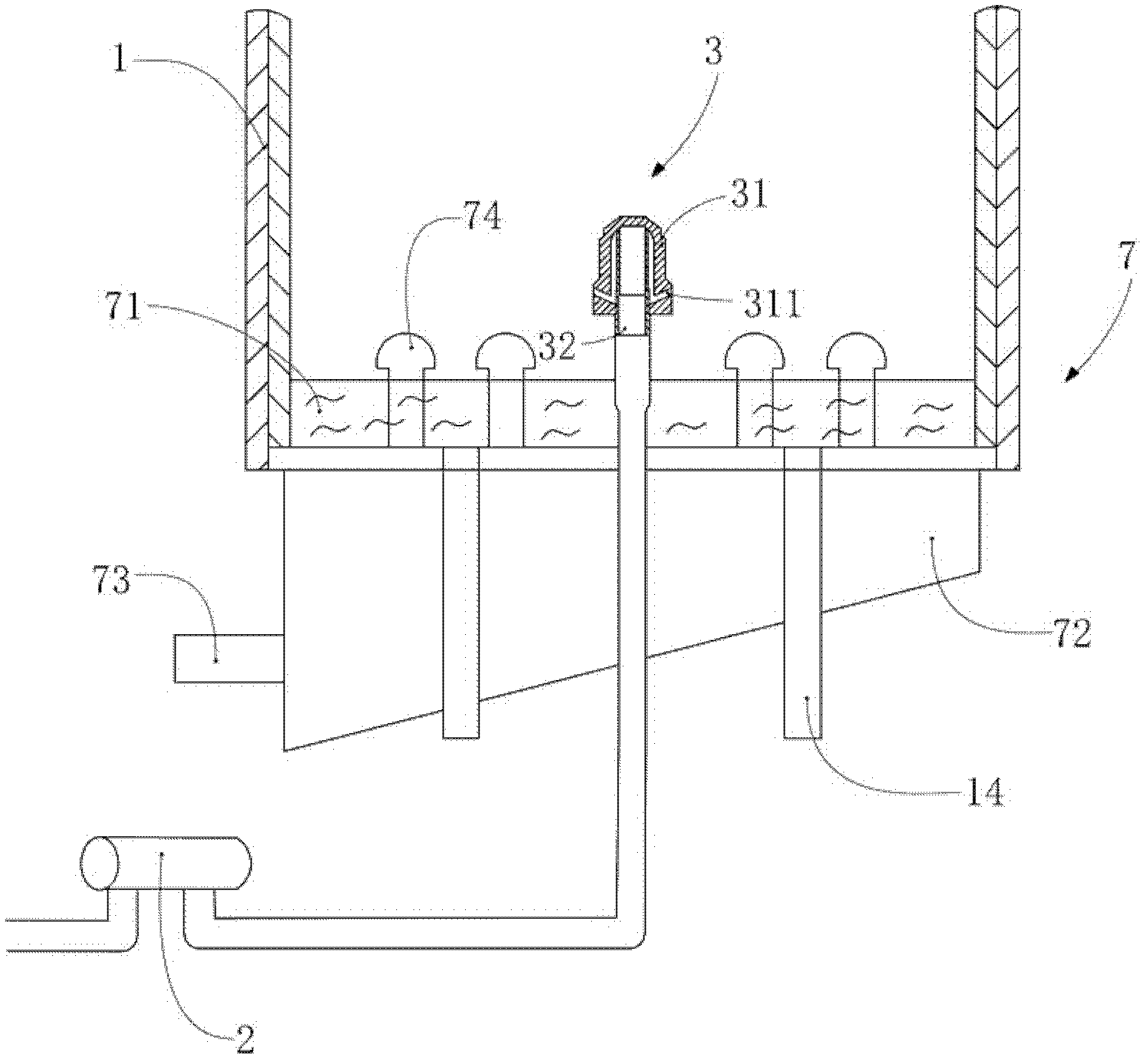

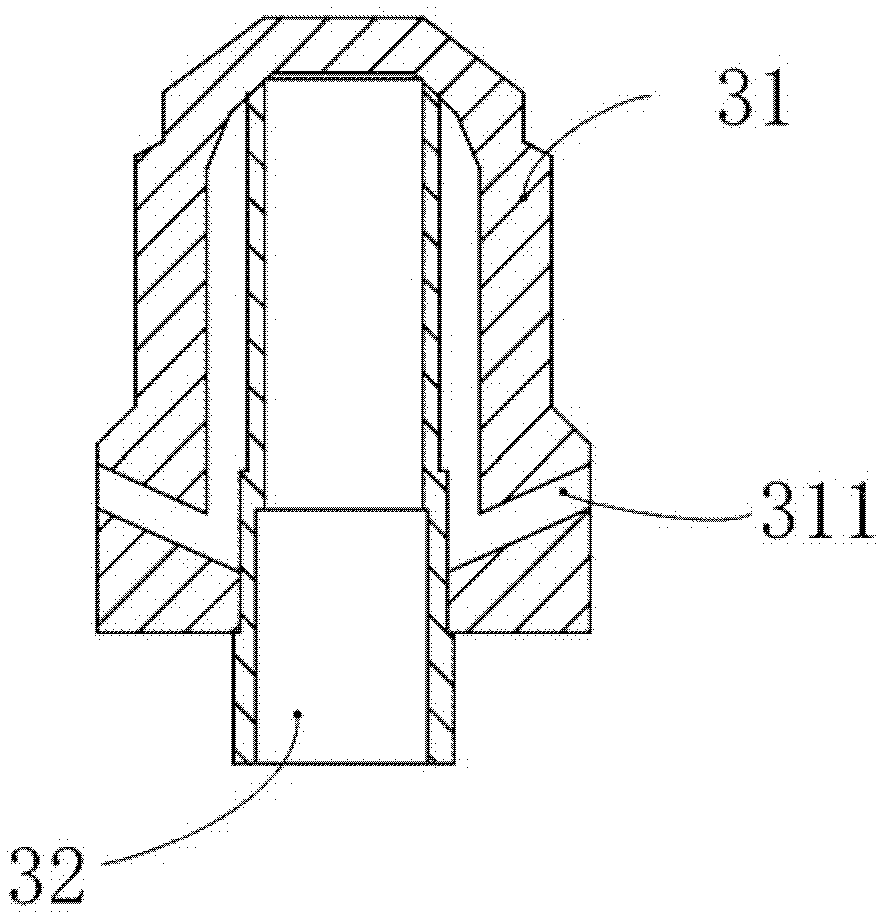

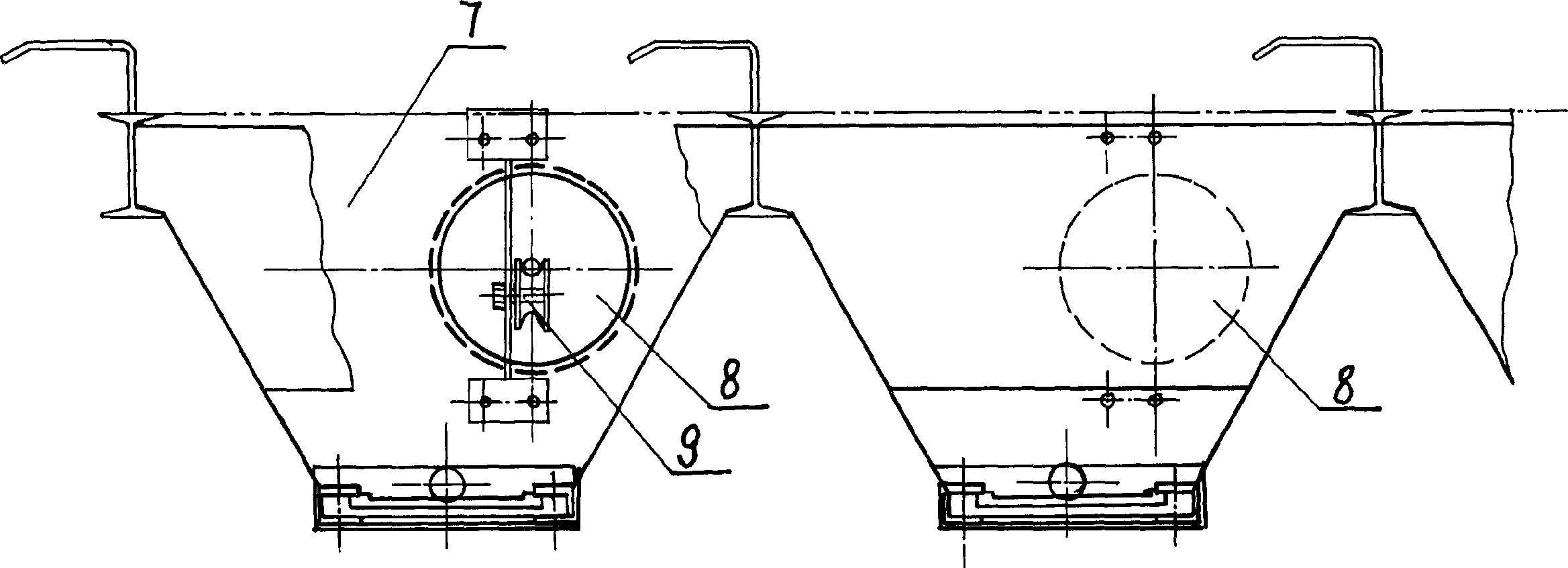

Gas combustion-supporting device of recirculating fluidized bed and combustion control device of recirculating fluidized bed

InactiveCN102353044AResolve Insufficient CombustionSolve the landfill problemFluidized bed combustionDirect carbon-dioxide mitigationCombustion systemCombustion chamber

The invention relates to the technical field of fluidized bed combustion, and in particular relates to a gas combustion-supporting device of a recirculating fluidized bed and a combustion control device of the recirculating fluidized bed. The combustion-supporting device comprises a fluidized bed combustion chamber and a gas compression device; the gas compression device is communicated with the fluidized bed combustion chamber through a pipeline, and gas is introduced into the fluidized bed combustion chamber; and the top end of the pipeline is provided with a gas compression ejector. Through the gas combustion-supporting device of the recirculating fluidized bed provided by the invention, the problem of insufficient combustion brought by the calorific value, less than 2500kcal / kg, of the recirculating fluidized bed of fuel material (mud) can be solved effectively, thus the combustion is fuller, and the desulfurization and deslagging operations are easier, and clean combustion is realized; simultaneously the emission of carbon dioxide is reduced effectively, and the tail gas treating cost is lowered; and in addition, the sufficient combustion of fuel materials in the fluidized bed enables the fuel material waste residue to be decreased greatly, the problem of land occupation by landfill of waste residue is solved effectively, the comprehensive benefit is good, and the device and the system accord with the principles of reduction, harmlessness and resource utilization of mud treatment.

Owner:北京君达能源投资有限公司

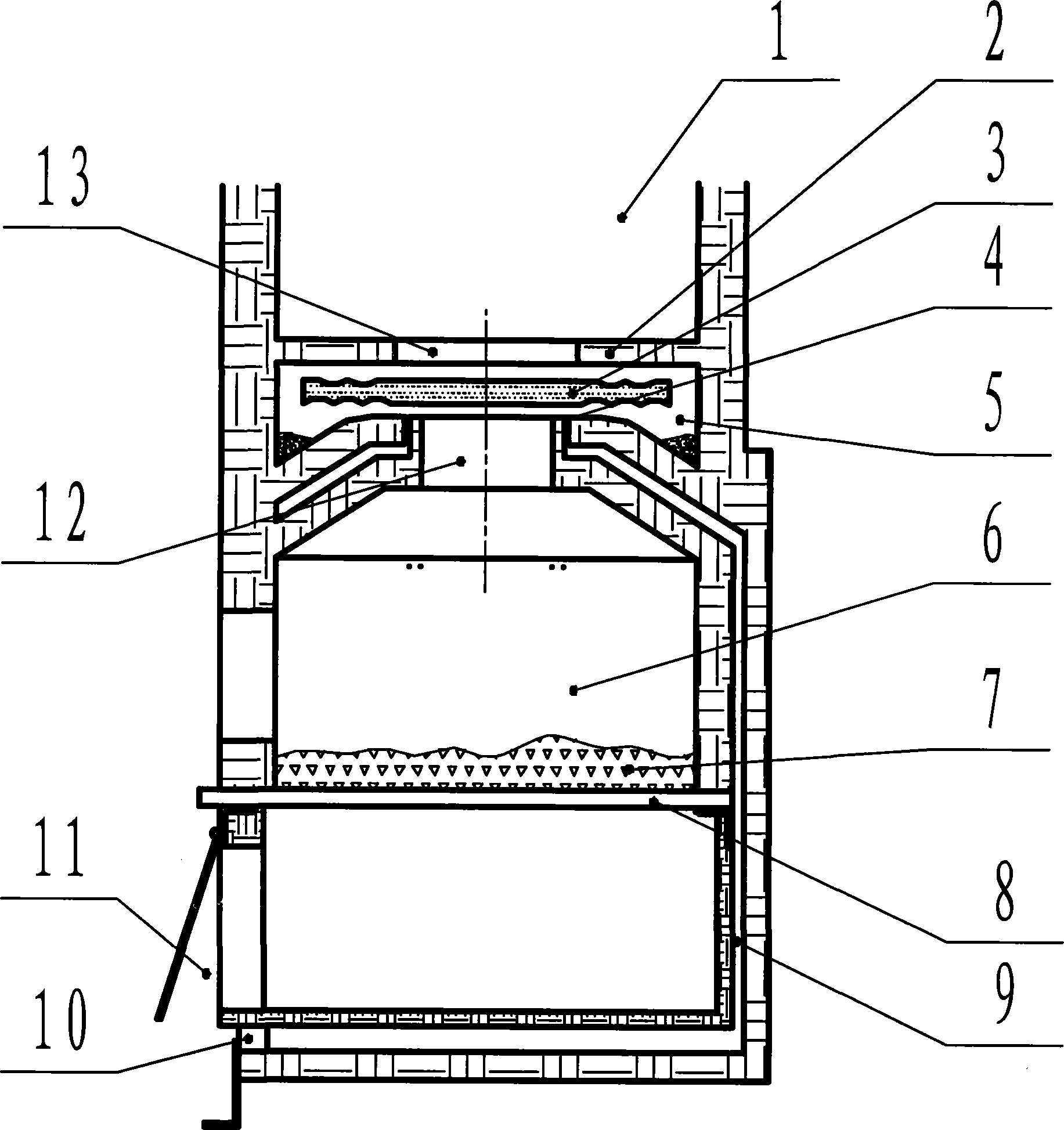

Boiler provided with dual-register pulverized coal burner on top

InactiveCN104121579AThorough heat exchangeReduce energy consumptionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlueCoal

The invention discloses a boiler provided with a dual-register pulverized coal burner on the top, belonging to the technical field of boilers, and aiming at providing a U-shaped flame boiler which is provided with the dual-register pulverized coal burner on the top and is high in combustion efficiency. According to the technical scheme, the boiler provided with the dual-register pulverized coal burner on the top comprises a boiler body and an ash falling pit, wherein the ash falling pit is formed in the bottom of the boiler body, a membrane type water-cooling wall is arranged on the inner wall of the boiler body, a first partitioning wall is arranged on the top in the boiler body and is used for partitioning the boiler body into a combustion chamber and a waste gas chamber, the lower parts of the combustion chamber and the waste gas chamber are communicated with each other to form a first pair of flue channels, the dual-register pulverized coal burner is arranged at the top of the combustion chamber, a second partitioning wall is arranged at the bottom of the waste gas chamber and is used for partitioning the waste gas chamber into a left chamber and a right chamber, the upper parts of the left chamber and the right chamber are communicated with each other, and a flue discharging channel is arranged at the bottom of the side wall of the right chamber. The boiler is high in heat utilization rate and less in waste gas emission.

Owner:BEIJING DABANG SHICHUANG ENERGY SAVING TECHSERVICE

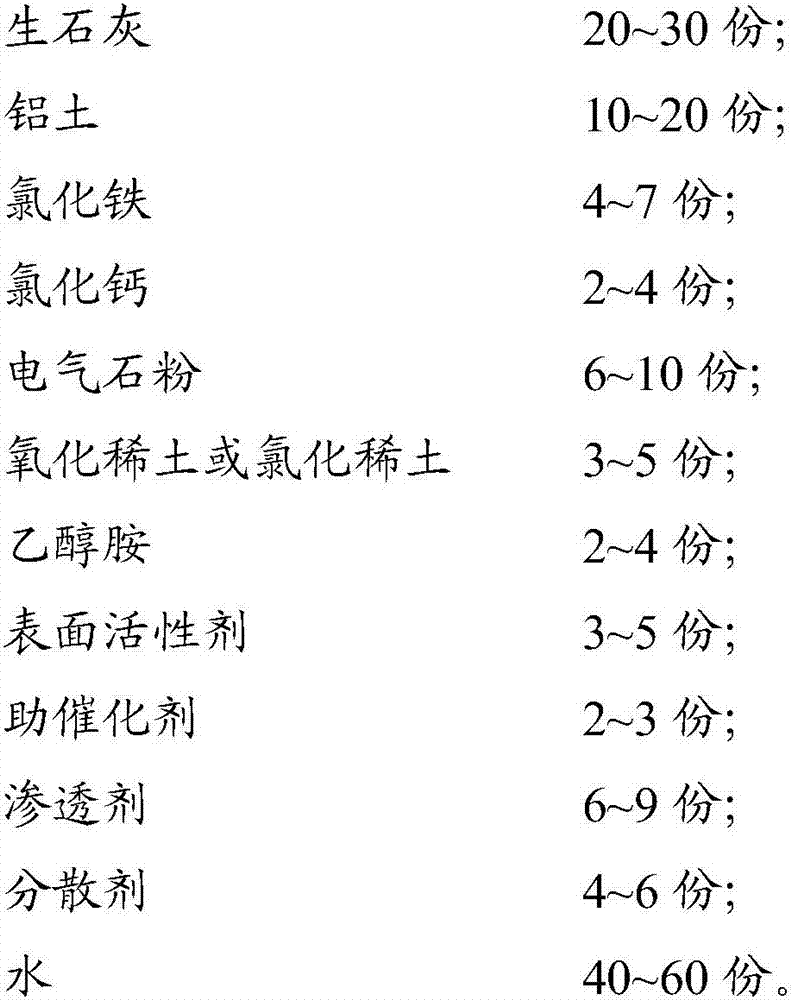

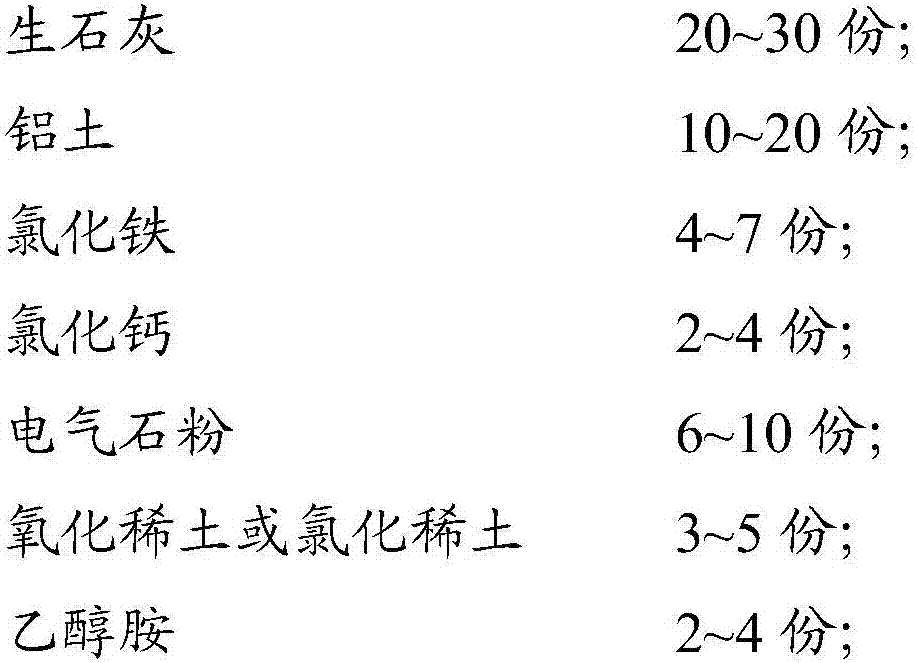

Coal combustion catalyst and preparation method thereof

InactiveCN107362831ABurn quicklyImprove combustion efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsSolid fuelsRare earthStone dust

The invention discloses a coal combustion catalyst and a preparation method thereof; the coal combustion catalyst is made from, by weight, 20-30 parts of quick lime, 10-20 parts of bauxite, 4-7 parts of ferric chloride, 2-4 parts of calcium chloride, 6-10 parts of tourmaline powder, 3-5 parts of rare earth oxide or rare earth chloride, 2-4 parts of ethanolamine, 3-5 parts of a surfactant, 2-3 parts of a co-catalyst, 6-9 parts of a penetrant, 4-6 parts of a dispersant, and 40-60 parts of water. The coal combustion catalyst is prepared by proportionally mixing the quick lime, bauxite, ferric chloride, calcium chloride, tourmaline powder, ethanolamine, the surfactant, the co-catalyst, the penetrant, rare earth oxide, rare earth chloride and water; the coal combustion catalyst allows full contact between coal and oxygen; redox is achieved under the catalytic action; quick combustion and full combustion of coal are achieved; coal combustion efficiency is improved, pollutant emission is decreased, and clean combustion of coal is achieved accordingly.

Owner:合肥隆延科技有限公司

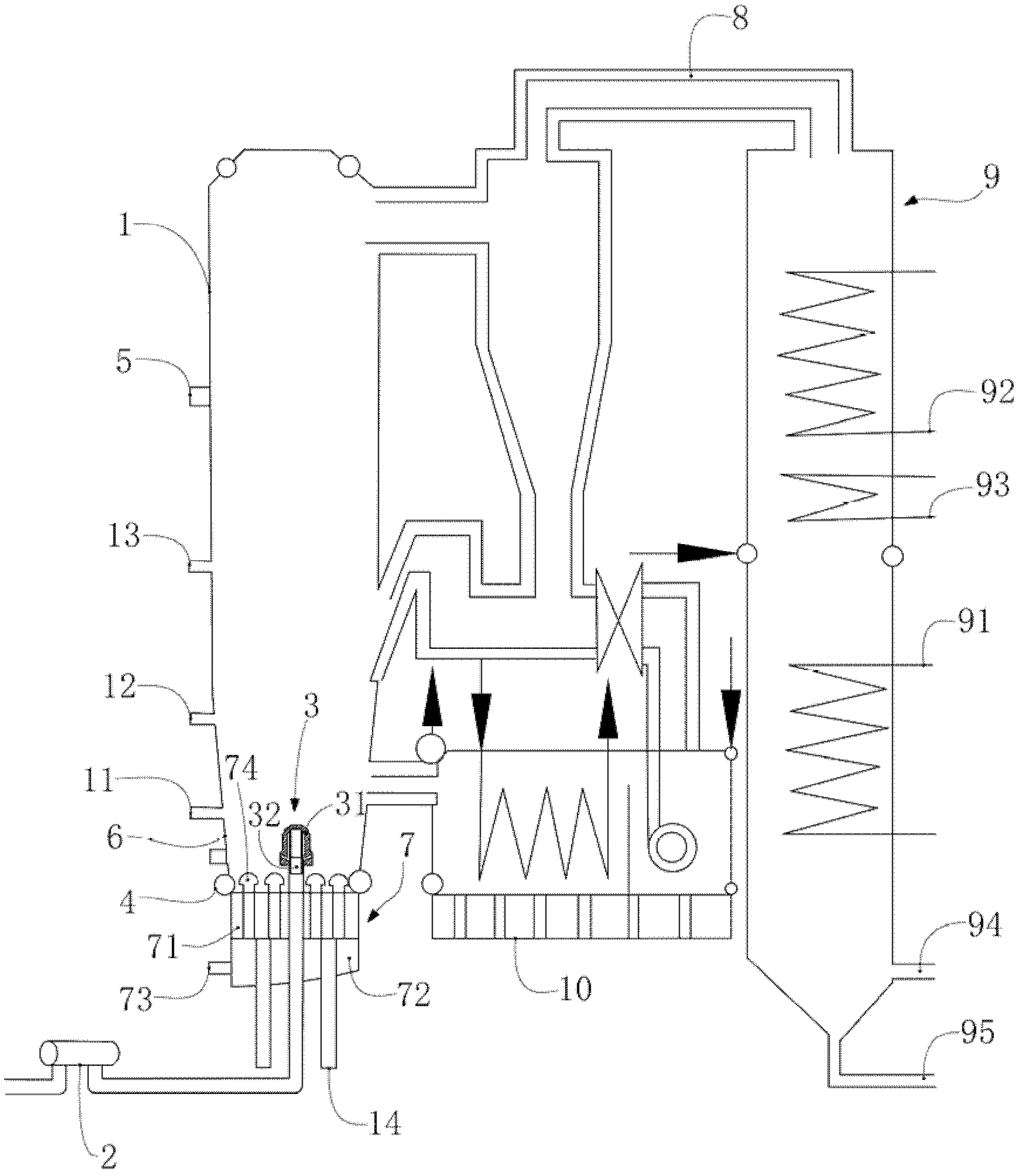

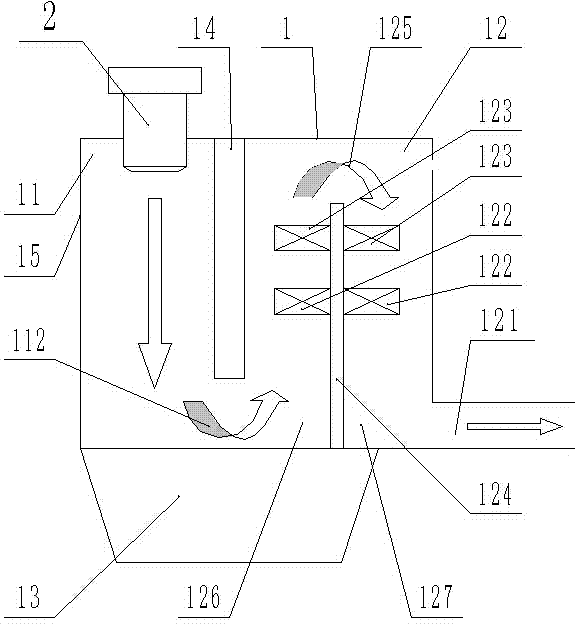

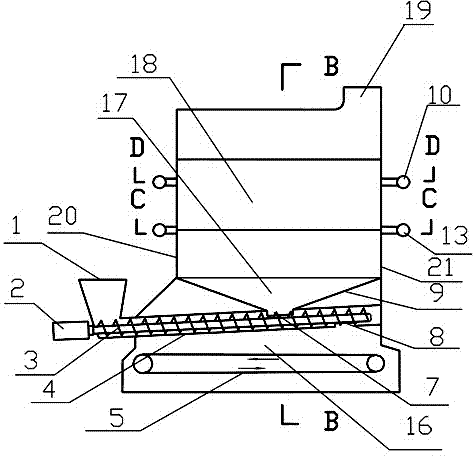

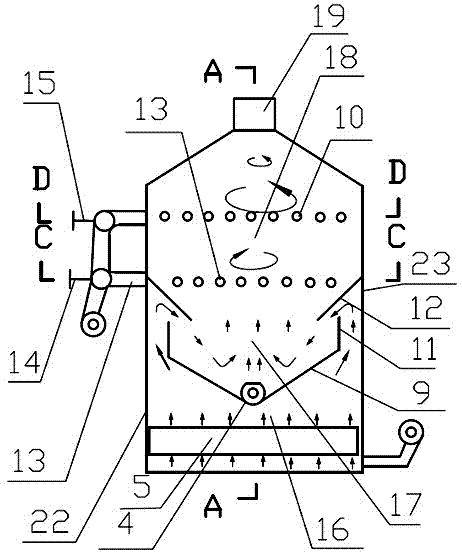

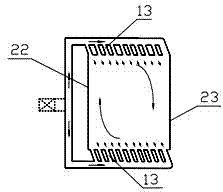

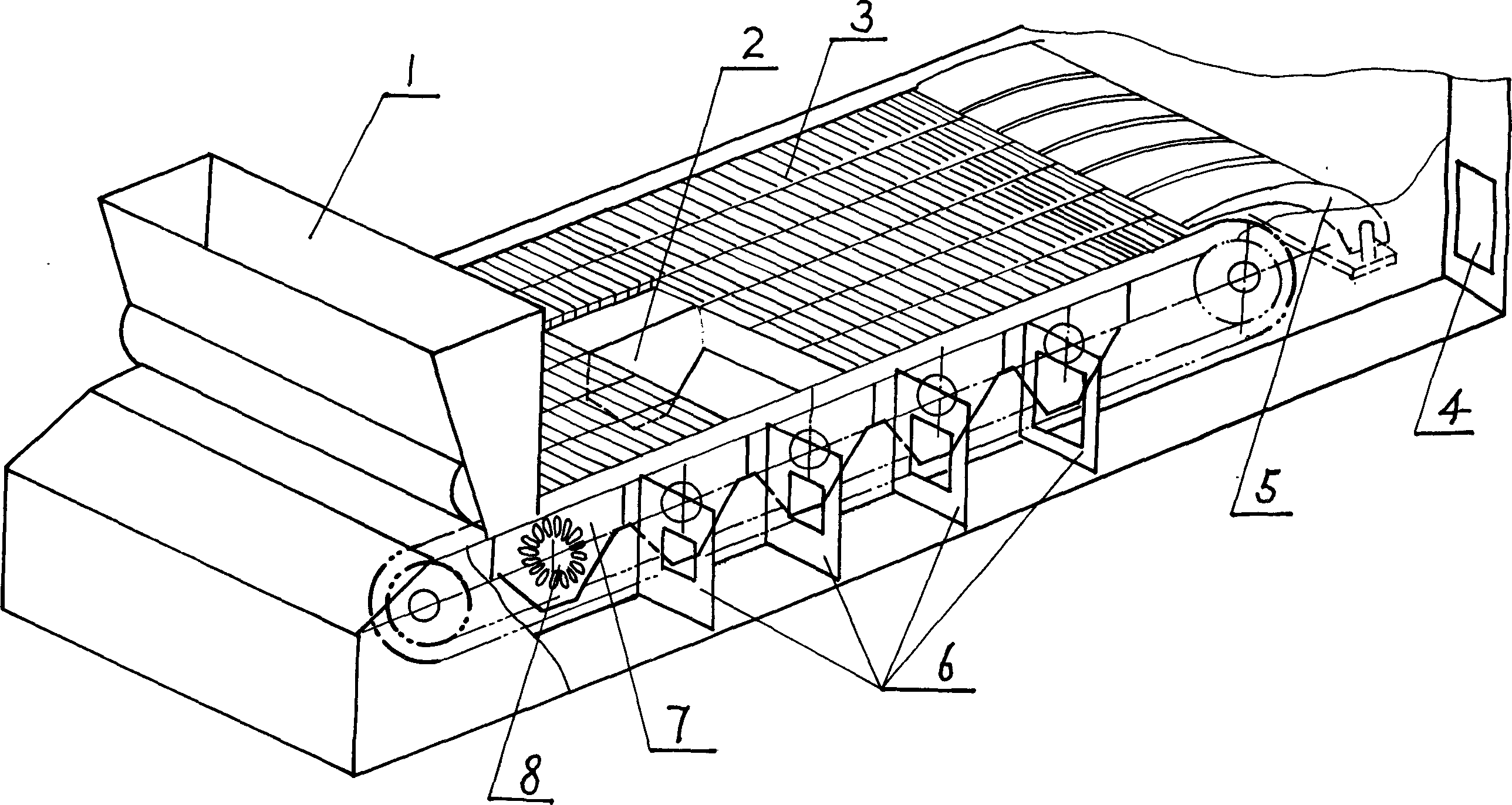

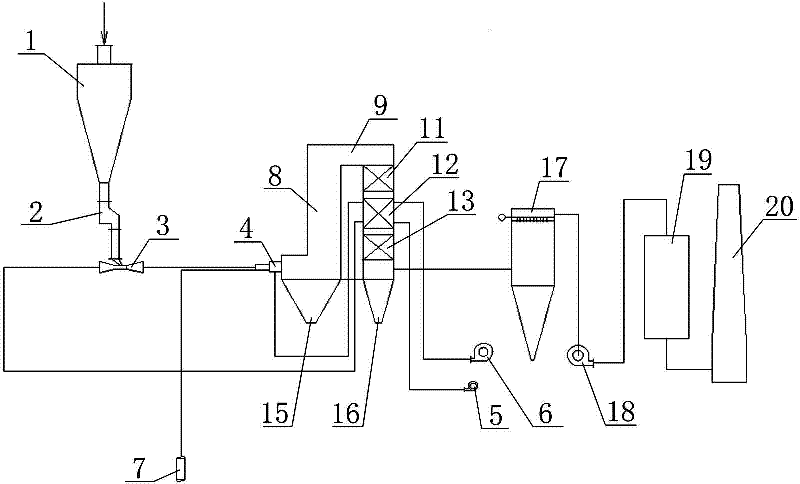

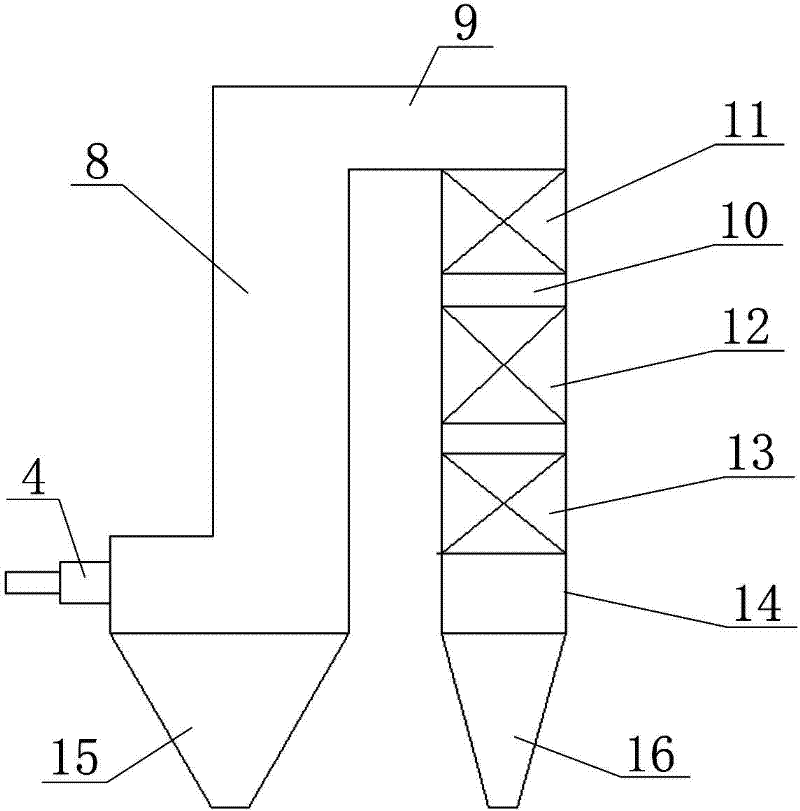

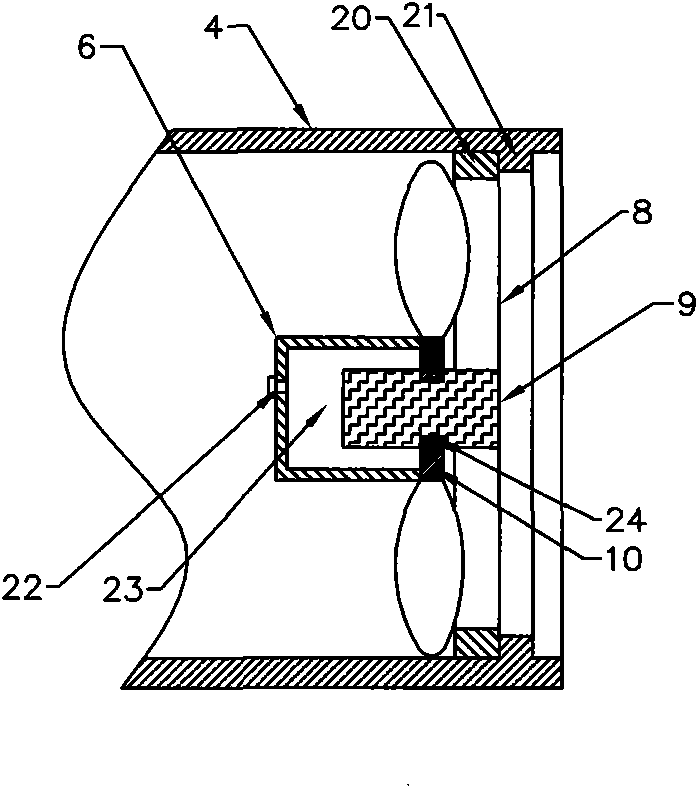

Gas-solid separation and re-coupling type biomass clean combustion device and combustion method

ActiveCN104713078AAchieve separationAchieve combustionSolid fuel combustionLump/pulverulent fuel feeder/distributionGas solidCombustion chamber

A gas-solid separation and re-coupling type biomass clean combustion device comprises a spiral feeding system, a chain furnace grate, a solid combustion chamber, a reduction reaction chamber, a gas combustion chamber, a solid combustion air supply system, a primary gas combustion air supply system, a secondary gas combustion air supply system and a cuboid hearth. The spiral feeding system comprises an open hopper, a drive motor, a feeding shaft with a spiral fin and a spiral pipe. The device is provided with the independent reduction reaction chamber, the independent solid combustion chamber and the independent gas combustion chamber. A combustion method of the gas-solid separation and re-coupling type biomass clean combustion device includes the steps that biomass is firstly dissolved into gas and solid through self heat supply, dust of smoke generated after solid combustion is removed, a reduction reaction is conducted on the smoke and gas generated after thermolysis, and NOx is reduced; primary combustion and secondary combustion are conducted, generation of NOx is controlled, and combustion is thorough.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

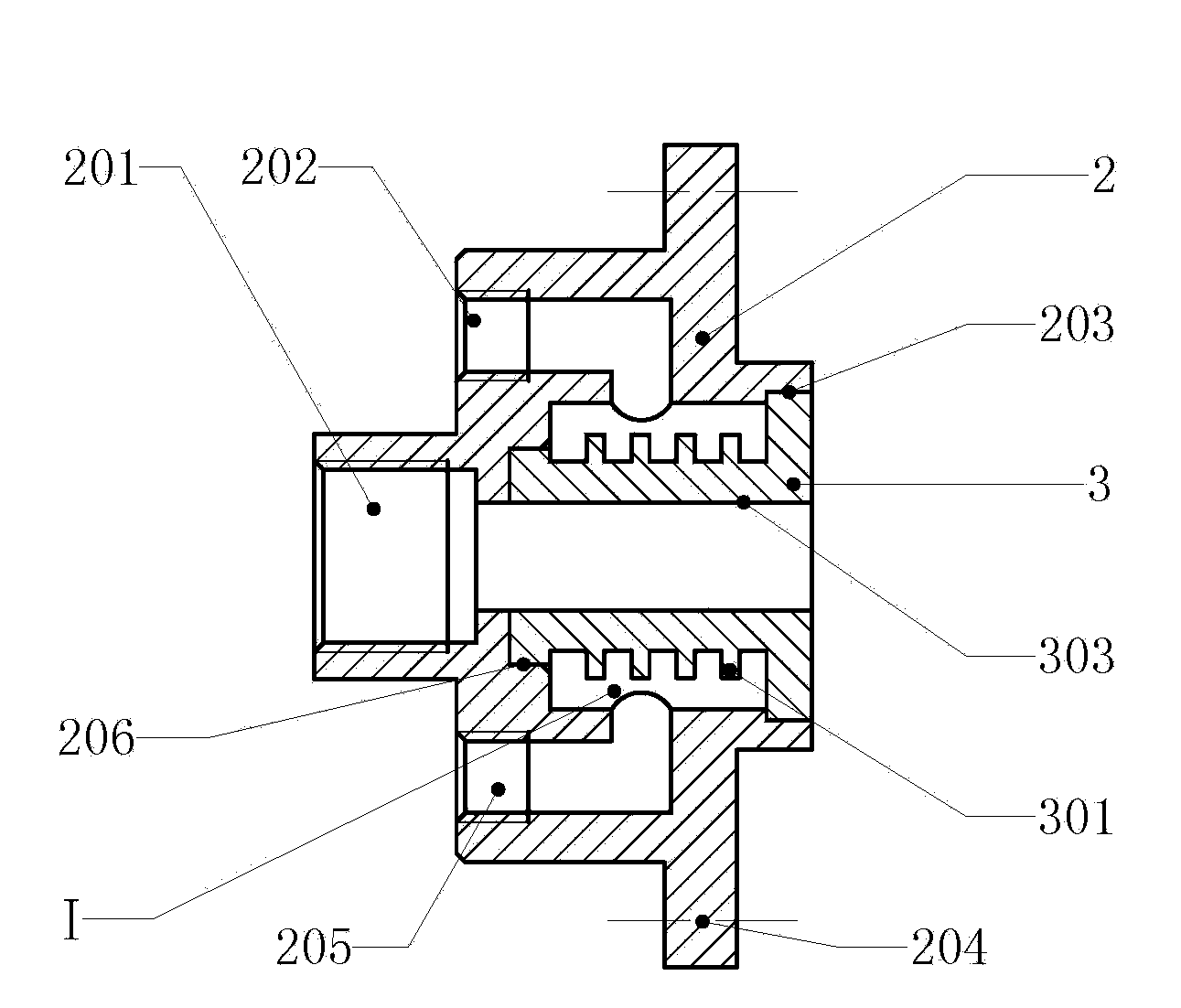

Plasma heavy oil burner

The invention discloses a plasma heavy oil burner, and relates to burning equipment. The plasma heavy oil burner mainly comprises an anode, an insulation connecting piece, a cathode, an inner sleeve and a rear seat, wherein the rear end of the anode is connected with the rear seat through the insulation connecting piece; the cathode is arranged in an inner space of the insulation connecting piece; the lower end of the cathode is connected to the rear seat; the inner sleeve extends into and enters an inner cavity of the cathode from the rear end of the rear seat; an axis through hole of the anode forms a compression duct; a cooling water sleeve is arranged in the anode; a torch outlet is formed at the front end of the anode; a tapered protruding structure at the rear end of the anode extends into the inner space of the insulation connecting piece; the upper end of a cylinder body of the cathode is bell-mouthed; a rotational flow groove is formed at the outer edge of a bell mouth; a space between the inner edge of the bell mouth at the upper end of the cathode and the tapered protruding structure at the rear end of the anode forms an annular airflow channel; the rear seat is provided with a revolving body structure; and an annular oil cavity is arranged in the revolving body structure, and communicated with the inner cavity of the cathode. The plasma heavy oil burner allows heavy oil fuel to be burnt completely, improves the burning efficiency of heavy oil, and reduces the environmental pollution.

Owner:南通东湖国际商务服务有限公司

Granular biomass fuel and preparation method thereof

The invention discloses a granular biomass fuel which comprises a biomass raw material and an additive, wherein the additive is calcium carbonate, magnesium carbonate or a mixture of calcium carbonate and magnesium carbonate; and the weight of the additive is 0.1%-1.8% of that of the biomass raw material. According to the granular biomass fuel disclosed by the invention, acidic volatile gas can be prevented from volatilizing into atmosphere; the problems of environmental pollution caused by the acidic volatile gas and insufficient combustion of the granular biomass fuel are solved; and the combustion efficiency of the granular biomass fuel is improved.

Owner:海聚高分子材料科技(广州)有限公司 +2

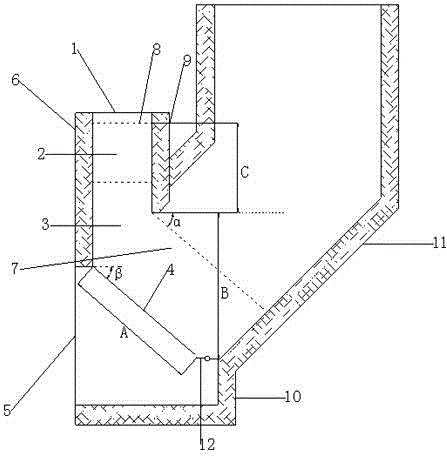

Coal gasified supercharging reverse-combustion flaming type coal combusting device

InactiveCN101235964AAchieve clean combustionIncrease profitSolid fuel combustionCombustion apparatusBoiler furnaceBack-fire

The invention relates to a coal-fired burner, in particular to a coal gasification pressurizing back-fire spitfire type coal-fired burner, which resolves the problem in prior art that coal combustion efficiency of coal gasification coal-fired burner is remained to be increased. The coal gasification pressurizing back-fire spitfire type coal-fired burner comprises a shell and a coal gas combustion chamber provided with a fire bar at lower portion. The invention is characterized in that a sealing chamber arranged at the lower portion of the fire bar is connected to a primary air agent air-delivery system via a primary tuyere, the top portion of the coal gas combustion chamber is connected to a pressurizing air air-delivery system via pressurizing tuyere, an outwards spitfire tuyere is arranged in the position of the burning zone, and the spitfire tuyere is connected with a secondary air air-delivery system via a secondary tuyere. The coal-fired burner is simple in structure, easy in use and low in cost, and can match with various boiler furnaces and barbecue ovens, thereby realizing clean coal combustion, improving bunker coal utilization rate and discharging pollutants measured up to environment standard strictly, and the coal-fired burner is a coal-fired burner with practical value.

Owner:芦书鹏

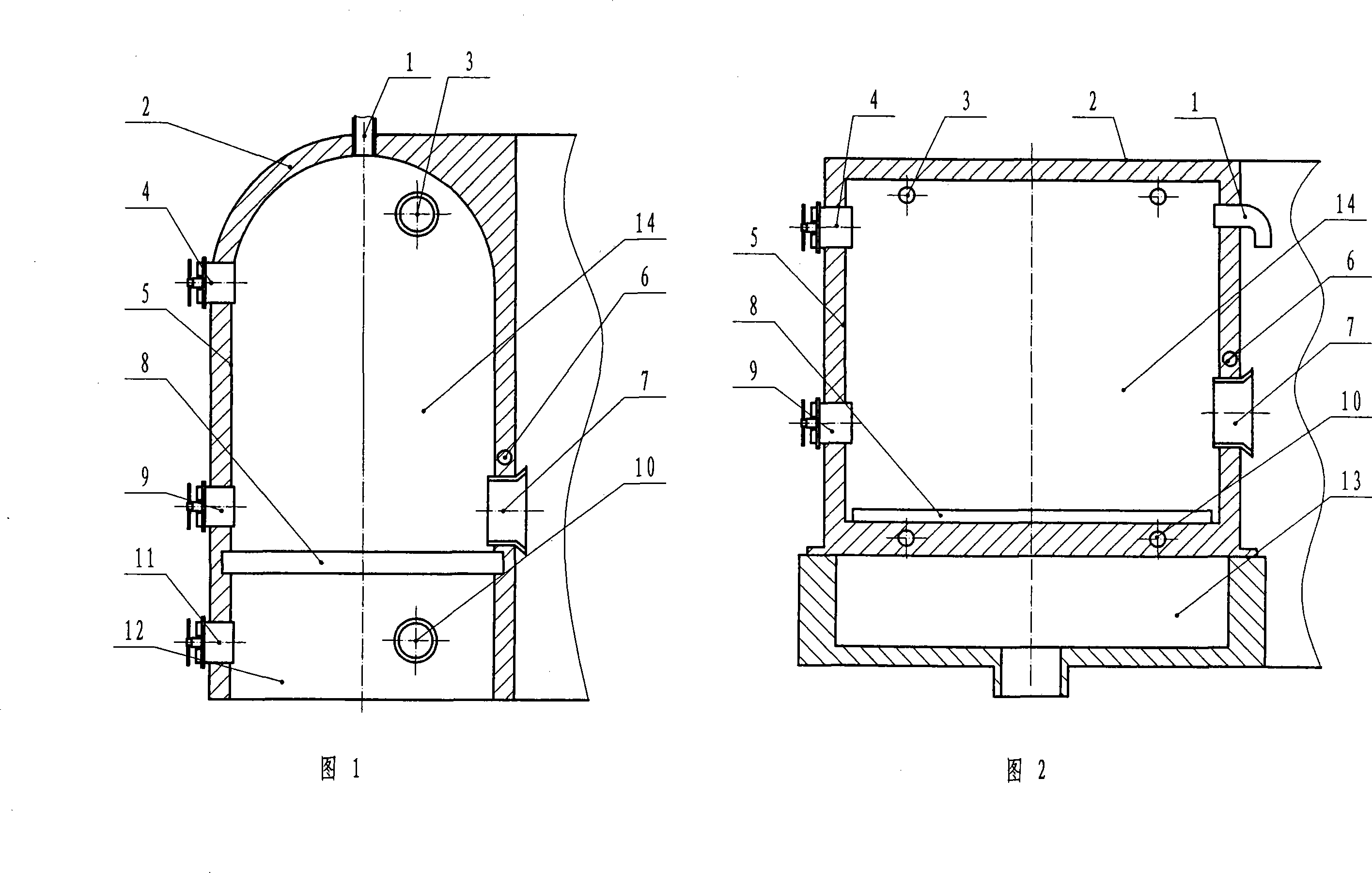

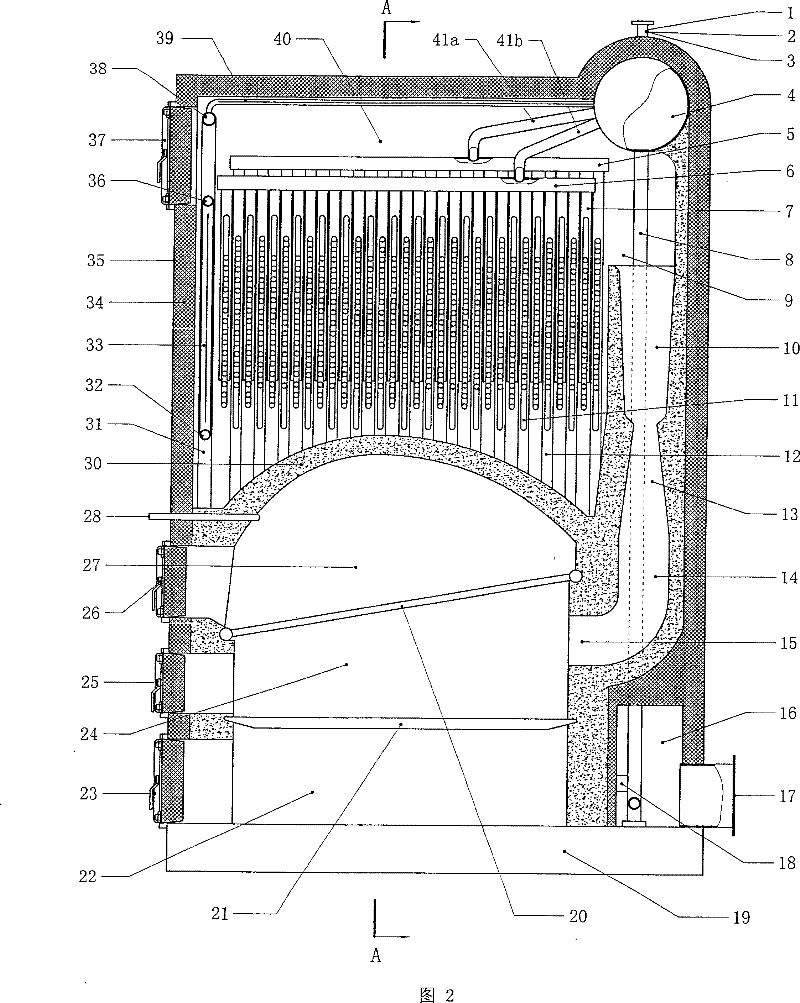

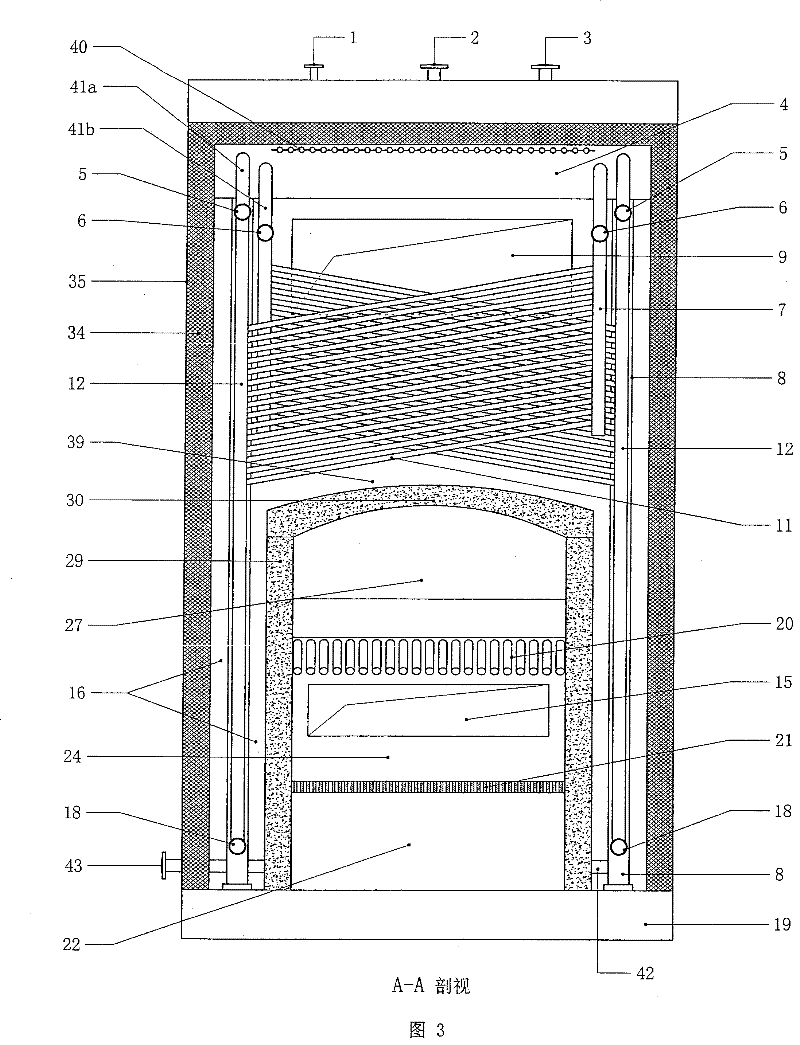

Environmental protection destructive distillation coal gasification laminar burning boiler

InactiveCN1793720AGuaranteed uptimeHigh outputSolid fuel combustionCombustion apparatusCombustion chamberEngineering

The invention relates to an environmental-protection coal carbonization-gasification layered fired boiler, comprising water-filling compression component water-cooling system, firepot, burning device, ash hopper, measuring meter and control valve all mounted in a boiler body, the front roaster of the firepot is high and the rear roaster is low, and between them, there are front, middle and rear partition walls partitioning the firepot into carbonization- gasification chamber, main combustion chamber, auxiliary combustion chamber and burnout chamber, the upper part of the front partition wall is provided with nozzle and the bottom plane of the front partition wall nears but does not contact with the coal layer surface on grate of combustion equipment, secondary air duct is arranged above the top wall of the front roaster, a channel communicating the primary and auxiliary combustion chambers is arranged below the middle partition wall, and the auxiliary combustion chamber is connected with the burnout chamber through the auxiliary nozzle. The advantages are simple operation and, low-synthetic cost, high power output and thermal efficiency and can reduce environmental pollution.

Owner:沈阳前进锅炉厂

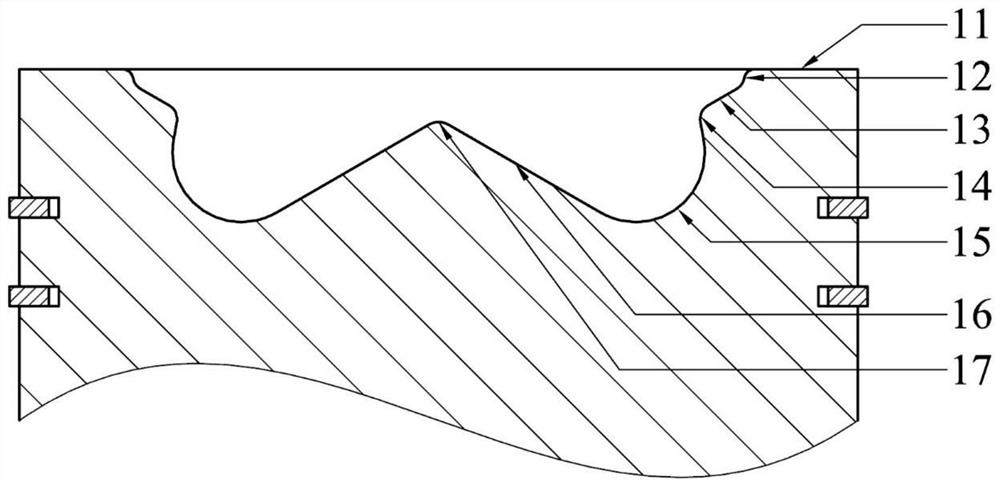

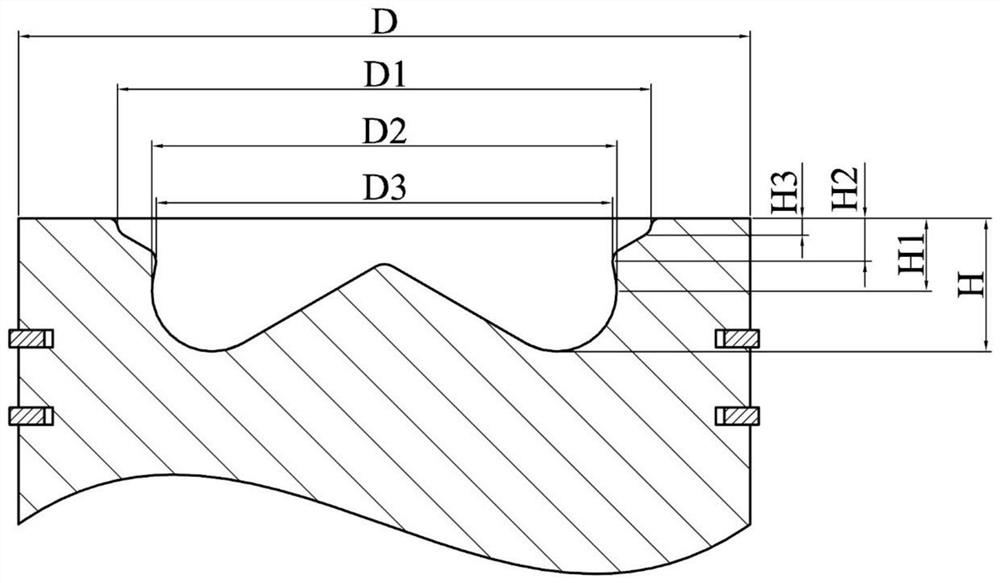

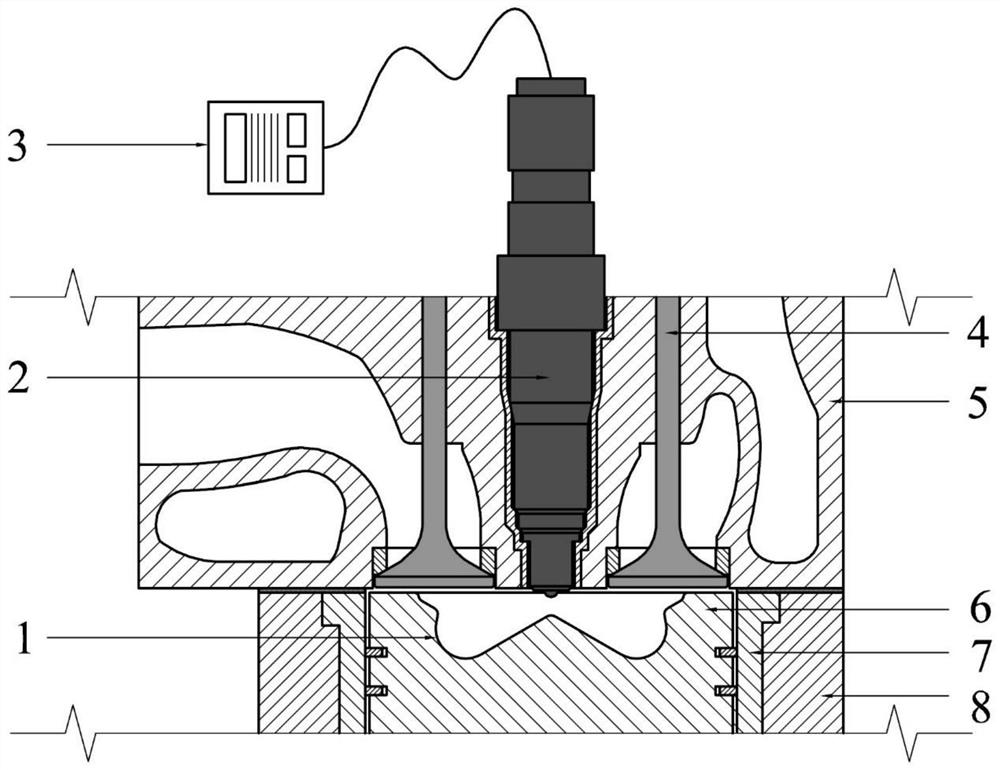

Combustion chamber special for marine diesel engine, combustion system and combustion method

ActiveCN111764996AWell mixedPromote oxidationElectrical controlInternal combustion piston enginesCombustion systemCombustion chamber

The invention provides a combustion chamber special for a marine diesel engine, a combustion system and a combustion method, in order to solve the problem that oil and air are not mixed thoroughly dueto the fact that the structure of a necking W-shaped combustion chamber adopted in the prior art is unreasonable. The combustion chamber is characterized in that the combustion chamber comprises a W-shaped combustion chamber, a step inclined surface and a vertical diversion surface, wherein the step inclined surface and the vertical diversion surface are in arc transition connection with a necking part of the upper portion of the W-shaped combustion chamber in sequence, fuel oil moves upwards along the step inclined surface to be sufficiently mixed with air in the upper space of the W-shapedcombustion chamber, mixed fuel oil is obtained, then, the mixed fuel oil s guided through the vertical diversion surface to move in the direction of motion of an air cylinder, and the fuel oil does not impact the wall surface of the air cylinder. According to the combustion chamber, mixing of oil and air in the combustion chamber can be effectively facilitated, the high temperature zone and the high concentration oil-air zone are decreased, accordingly, emission of exhaust contaminant of the diesel engine is reduced, and clean combustion is achieved.

Owner:HENAN DIESEL ENGINE IND

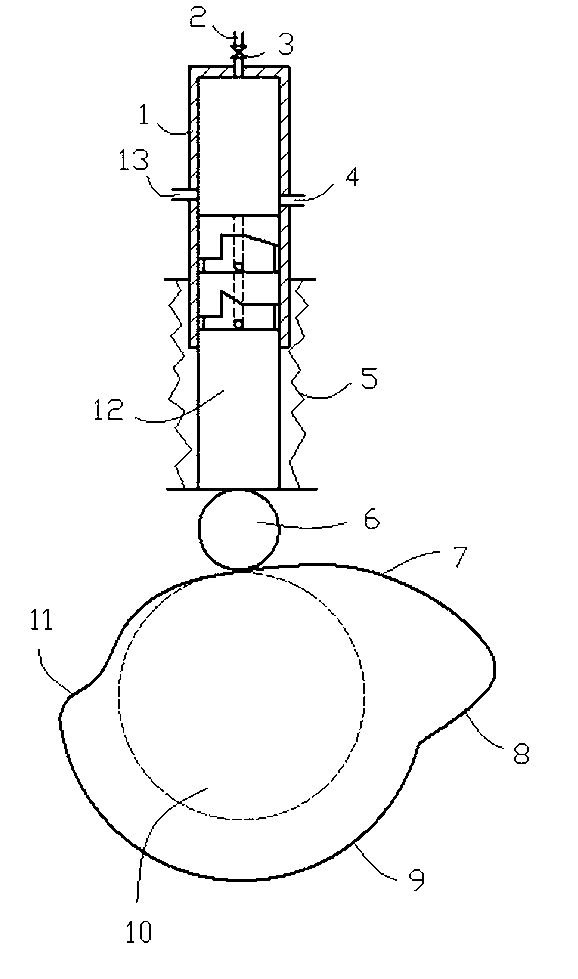

Plunger type twice fuel injection pump

InactiveCN103133207AIncrease output powerHigh thermal efficiencyMachines/enginesFuel injecting pumpsCombustionNitrogen oxides

A plunger type twice fuel injection pump comprises a plunger (12) matched with a plunger sleeve (1) and provided with two fuel injection operation sections and a two-section lifting outline section and a drive cam (10). The drive cam rotates for a circle so that the plunger is pushed to achieve primary fuel injection for premixing before engine exhaust emission and the plunger is pushed for a second time to achieve secondary fuel injection for ignition before a compressing top dead center. According to the plunger type twice fuel injection pump, clean combustion of diesel oil is achieved so that soot emission is reduced by 63%, non-soot emission is even achieved, nitrogen oxide emission is reduced greatly as well and output power and thermal efficiency of the engine are respectively improved at a certain degree.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Rotary and sliding fire grate air conditioner of chain

InactiveCN1779325AReasonable air distributionUniform air distributionDamper arrangementAir/fuel supply for combustionAir volumePush pull

The invention relates to a rotary push-pull chain grate air-delivering air-controlling device, in which the air-delivering device has five plenums. A blast-regulating plate is arranged in the air passage on both sides of the plenum and a rotary push-pull damper air-regulating assembly is disposed at the air inlet of each plenum. The fuel and the air are mixed well via the air-regulating device to make the fuel burn up.

Owner:HENAN UNIVERSITY

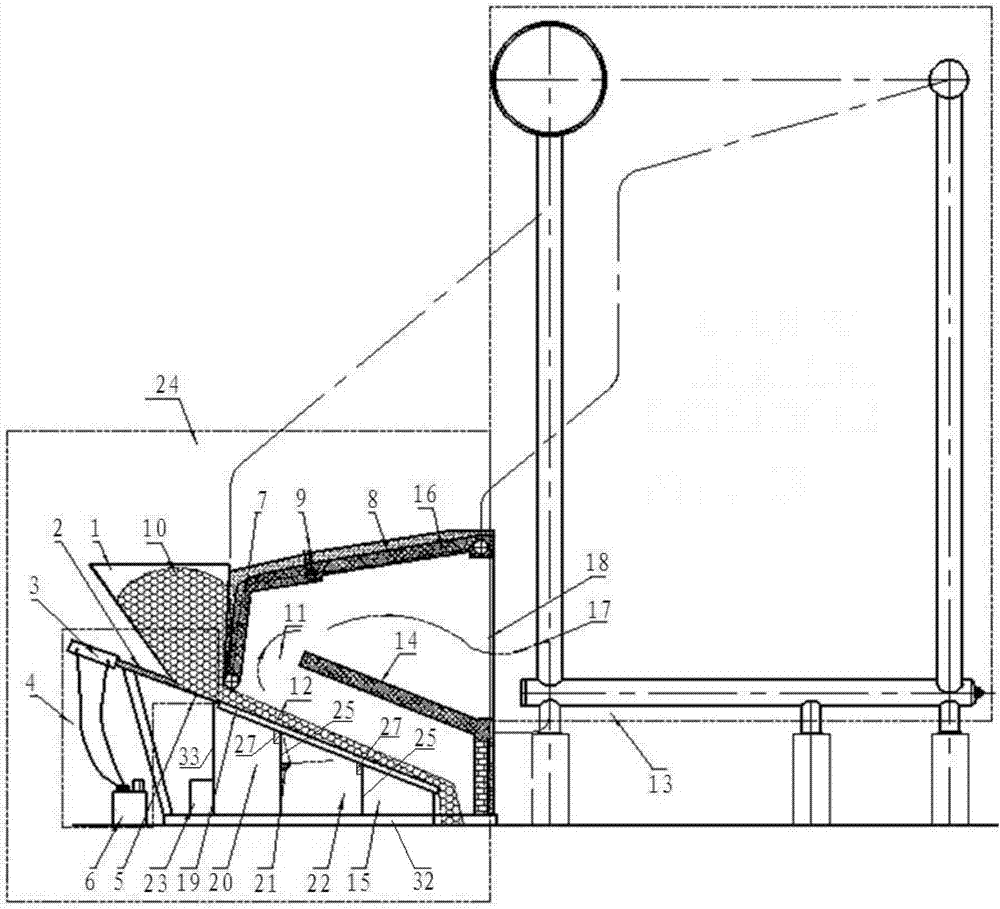

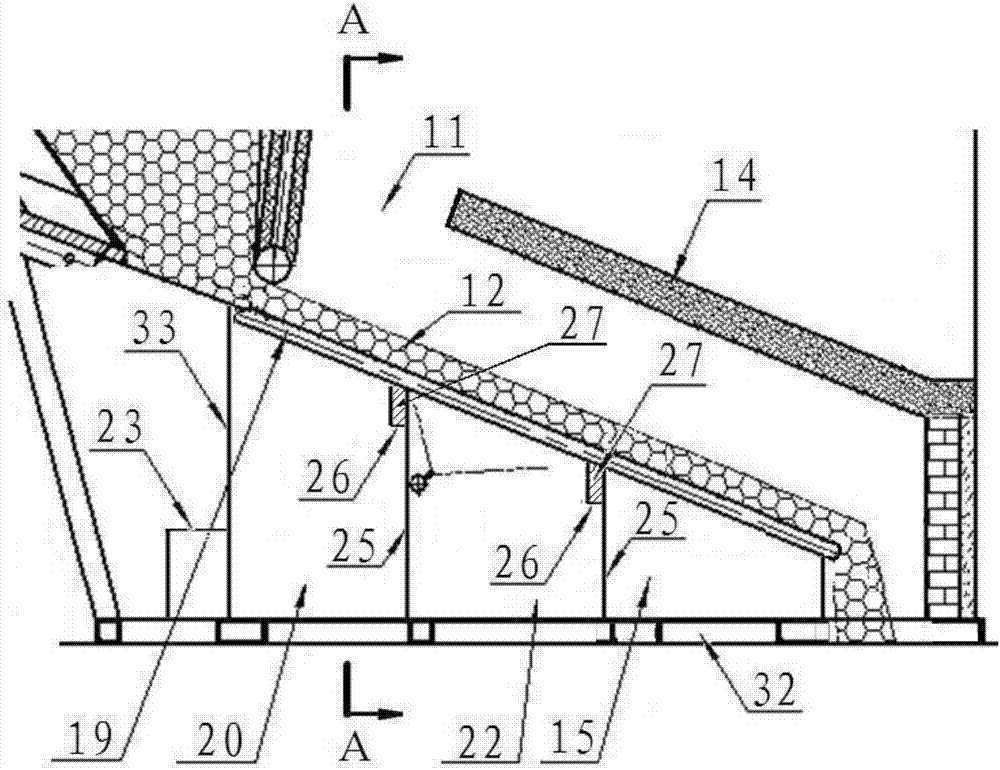

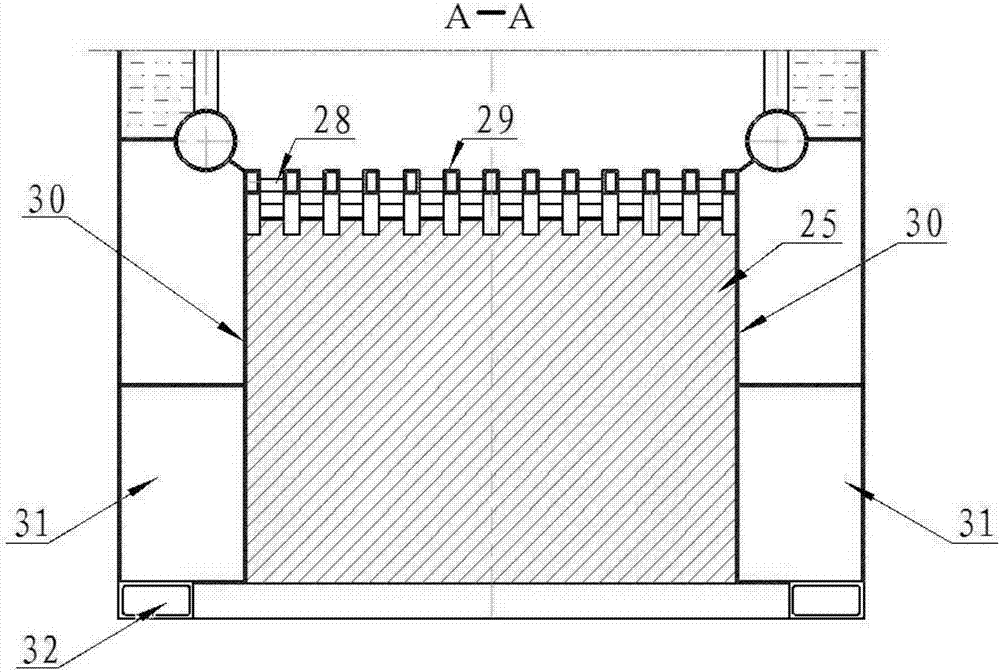

Solid fuel combustion device with fire grate obliquely arranged and combustion method

ActiveCN104019445AImprove combustion efficiencyStable temperature fieldInclined grateSolid fuel combustionSolid fuelEngineering

The invention discloses a solid fuel combustion device with a fire grate obliquely arranged. The solid fuel combustion device comprises a furnace body, wherein an upper air inlet is formed in the upper portion or the top of the furnace body, a lower air inlet is formed in the lower portion of the furnace body, and a furnace chamber is formed in the furnace body; a fire outlet is formed in the side of the furnace body, the fire gate is obliquely arranged in the furnace chamber, the upper air inlet and the fire outlet are located in one side of the fire gate, and correspondingly the lower air inlet is located in the other side of the fire gate; the space, located on the fire gate, in the furnace chamber is a solid fuel containing cavity which is divided into a combustion preparing area and a combustion area from top to bottom, the height of the combustion preparing area is larger than 150 mm, the ratio of the largest breadth width of the fire gate to the height of the fire outlet is not larger than 1.5, and the height difference of the solid fuel containing cavity and the fire outlet is not smaller than 150 mm. The invention further discloses a solid fuel clean combustion method. Due to the device and the method, the clean combustion process of solid fuel can be achieved.

Owner:XUZHOU ZHONGKAI MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

Adequate, clean combustion equipment

InactiveCN101093076AEmission reductionIncrease heat productionSolid fuel combustionIndirect carbon-dioxide mitigationNuclear engineeringCombustible gas

This invention relates to a fully burning device composed of a hearth, a fully burning zone and a heat-utilizing part, in which apart from burning in the heart, smoke is burnt completely in the fully burning zone, and the dust is deposited, in which the fully burning zone secures full contact of combustion gas, combustion particles and oxygen and provides high temperature and reaction time necessary for complete burning so as to guarantee complete burning, besides, heat in the zone is radiated to the hearth, thus solid combustibles in it are baked and requirement to solid combustibles in the hearth is low and no combustibility components are left in ash.

Owner:王延明 +1

Solid fuel gasification and combustion device and boiler

InactiveCN102141254AImprove combustion efficiencyImprove thermal efficiencySteam generation heating methodsCombustion processSolid fuelEngineering

The invention relates to a solid fuel gasification and combustion device and a boiler, and relates to the combustion device. The combustion device and the boiler are characterized in that a gasification furnace is composed of the inner space of a vertical type revolved body furnace wall; an air duct is arranged above the gasification furnace; a charging opening and an air inlet are arranged on a side wall between the air duct and the gasification furnace; an ignition door is arranged at the lower part of the gasification furnace; an air chamber is arranged below the gasification furnace; the outlet of gasification objects is arranged from the middle section of the gasification furnace; a secondary combustion device comprises an air entraining channel, an annular air chamber d, an air hole b, a fire opening and a combustion stabilizing chamber, wherein the air inlet end of the air entraining channel is connected to the outlet of the gasification objects of the gasification furnace; the air outlet end of the air entraining channel is connected to the fire opening; the fire opening is connected to the combustion stabilizing chamber; the combustion stabilizing chamber is composed of the inner space of a combustion stabilizing ring; the furnace wall body at the fire opening section is provided with the annular air chamber d; the annular air chamber d is connected by a blast hole; and the annular air chamber d is communicated with the fire opening through the air hole b. In the invention, the solid fuel is subjected to gasification combustion, the combustion efficiency of the solid fuel is improved, clean combustion is realized, and the pollution to environment is reduced.

Owner:QUZHOU YUNRUI IND DESIGN

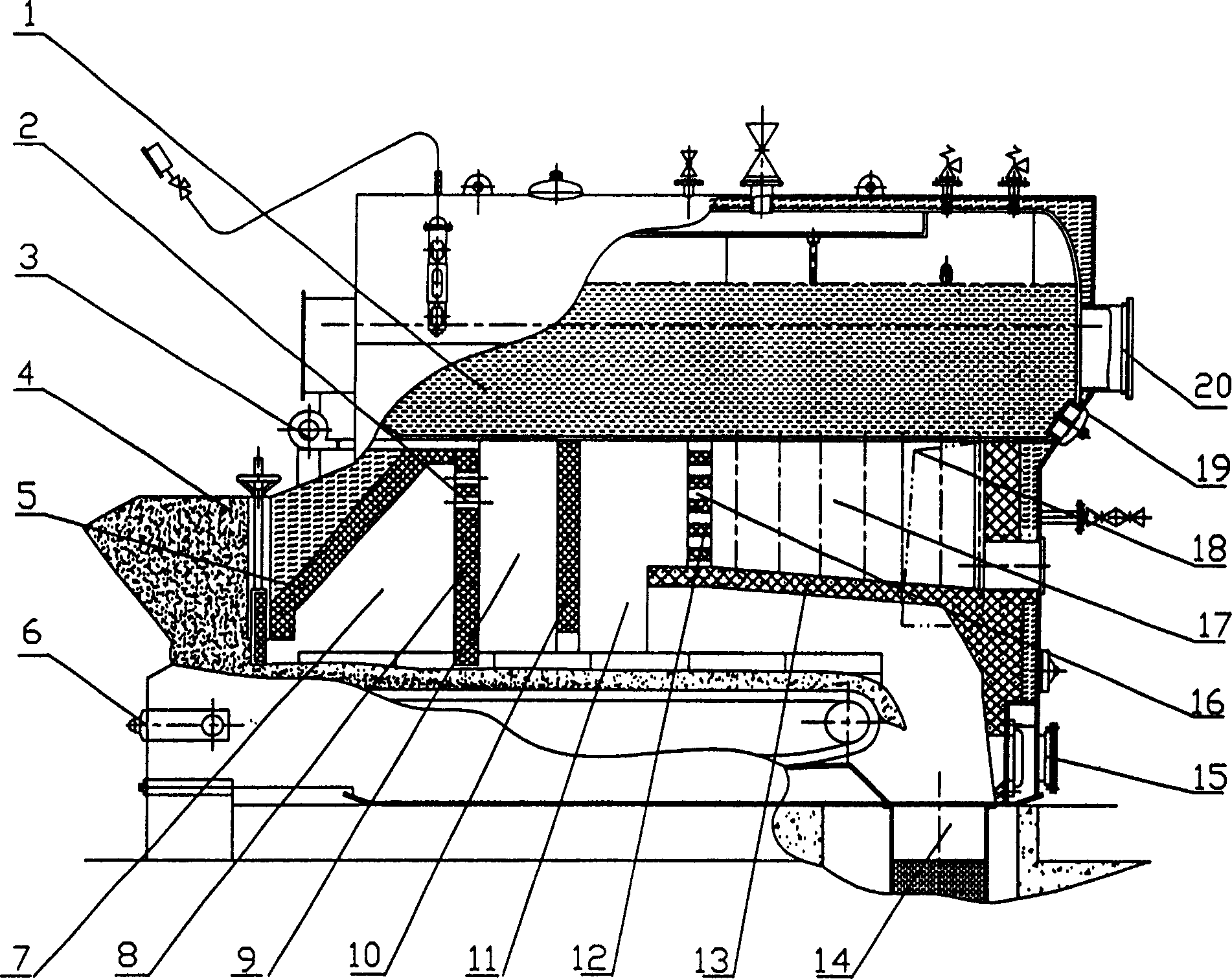

Oil field gas injection boiler taking pulverized coal as fuel

The invention relates to an oil field gas injection boiler, in particular to an oil field gas injection boiler taking pulverized coal as fuel, and solves the problems that the conventional coal-fired oil field gas injection boiler has low efficiency and the discharge quantity of atmospheric pollutants is large. The oil field gas injection boiler taking the pulverized coal as the fuel comprises a pulverized coal combustion system, a boiler body and flue gas treatment equipment, wherein the pulverized coal combustion system comprises an intermediate powder storehouse, a pulverized coal feeder, a mixer, a pulverized coal combustor, a primary air fan, a secondary air fan and a liquefied petroleum gas tank; the boiler body comprises a J-shaped hearth, a furnace top and a convection flue; and the flue gas treatment equipment comprises a bag-type dust collector, a draught fan, a devulcanizer and a chimney. Coal is cleanly combusted on the basis of a novel structure, saturated vapor is produced under subcritical pressure, and the oil field gas injection boiler is suitable for the thermal recovery process of crude oil in an oil field.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

Multicomponent catalyzer for ammonia catalytic combustion and preparation method thereof

InactiveCN101172236AAchieve clean combustionComplete crystal formGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsHypochloritePotassium

Owner:TIANJIN XINHE CHUANGZHAN HIGH & NEW TECH DEV

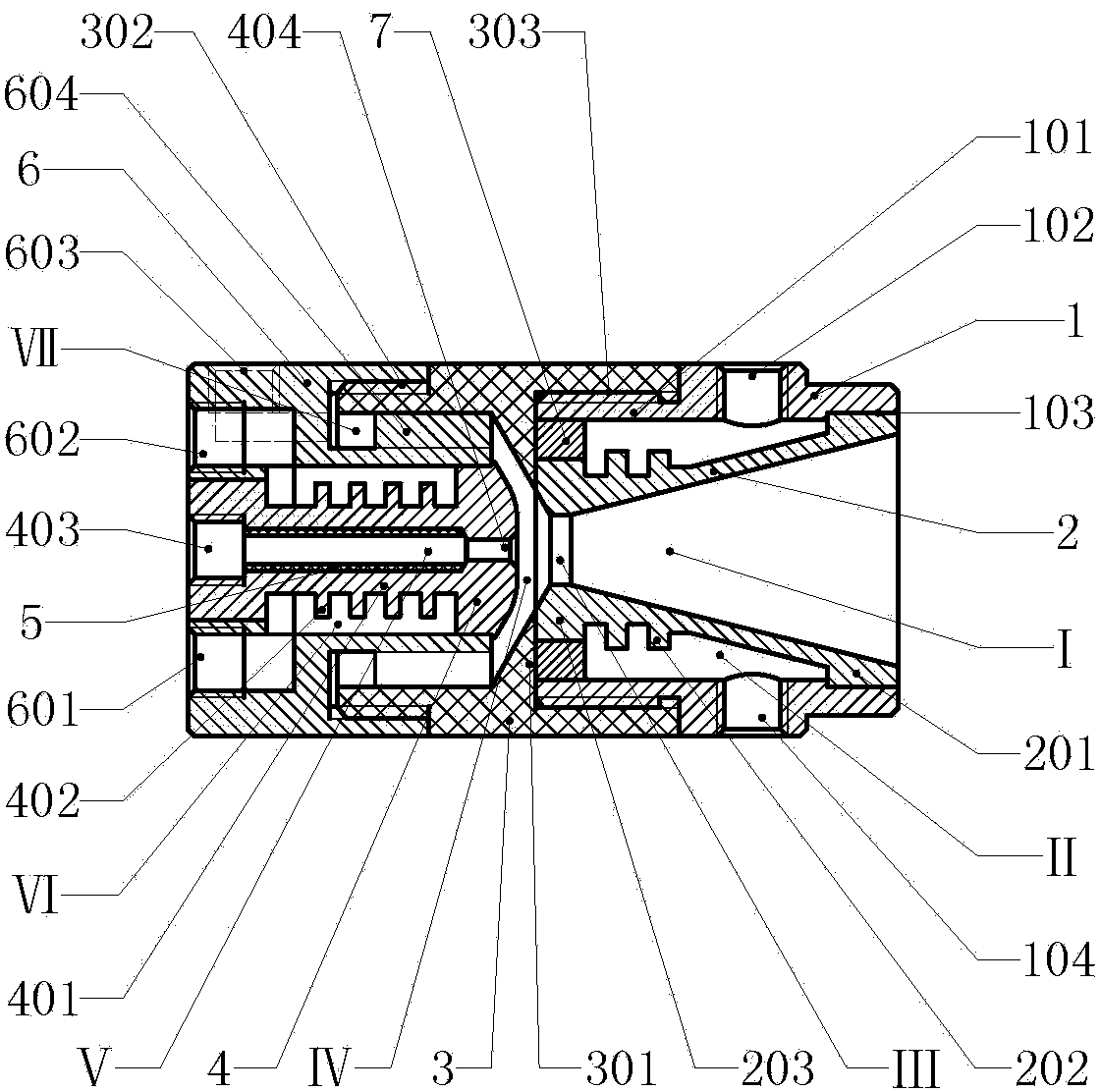

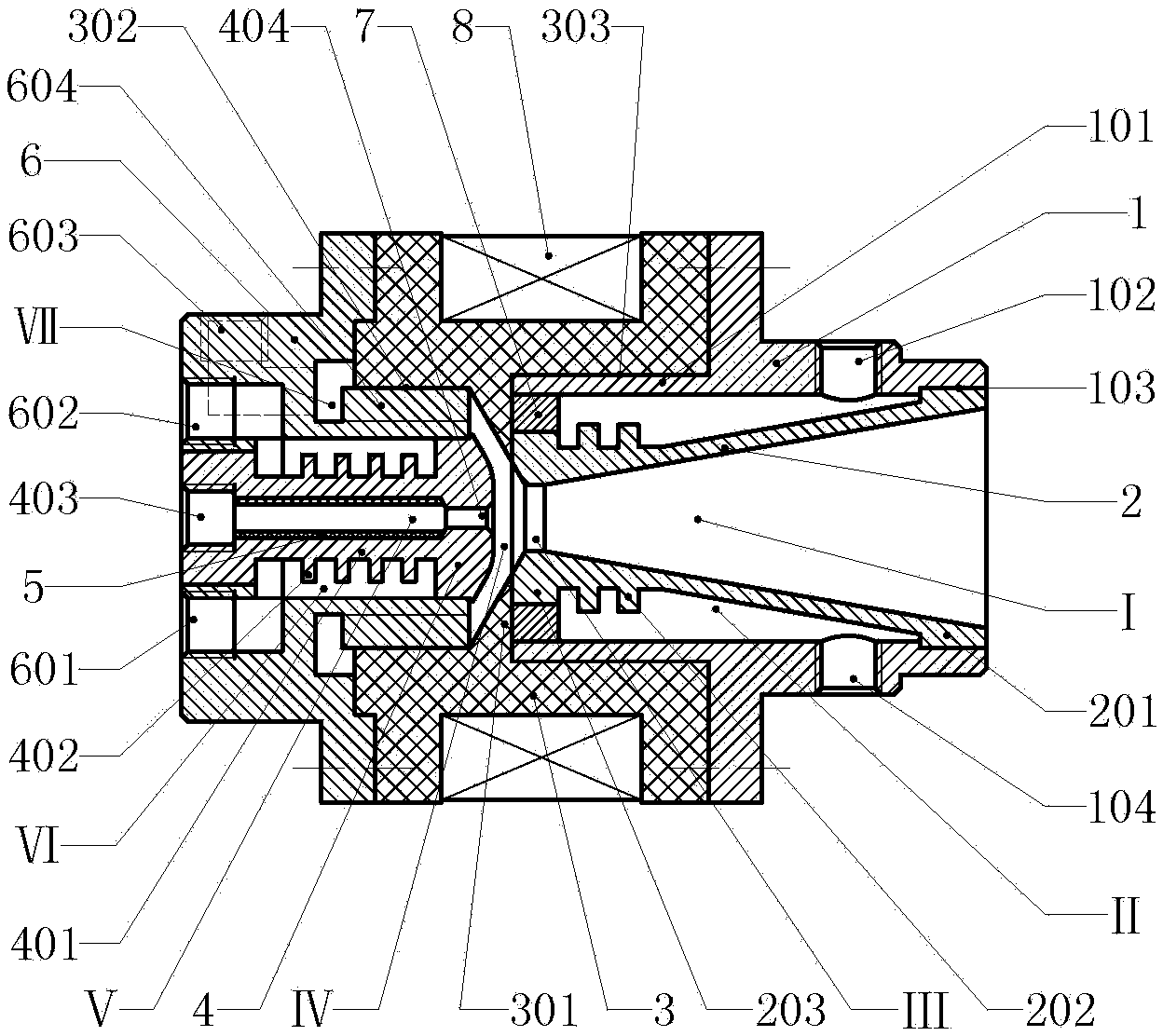

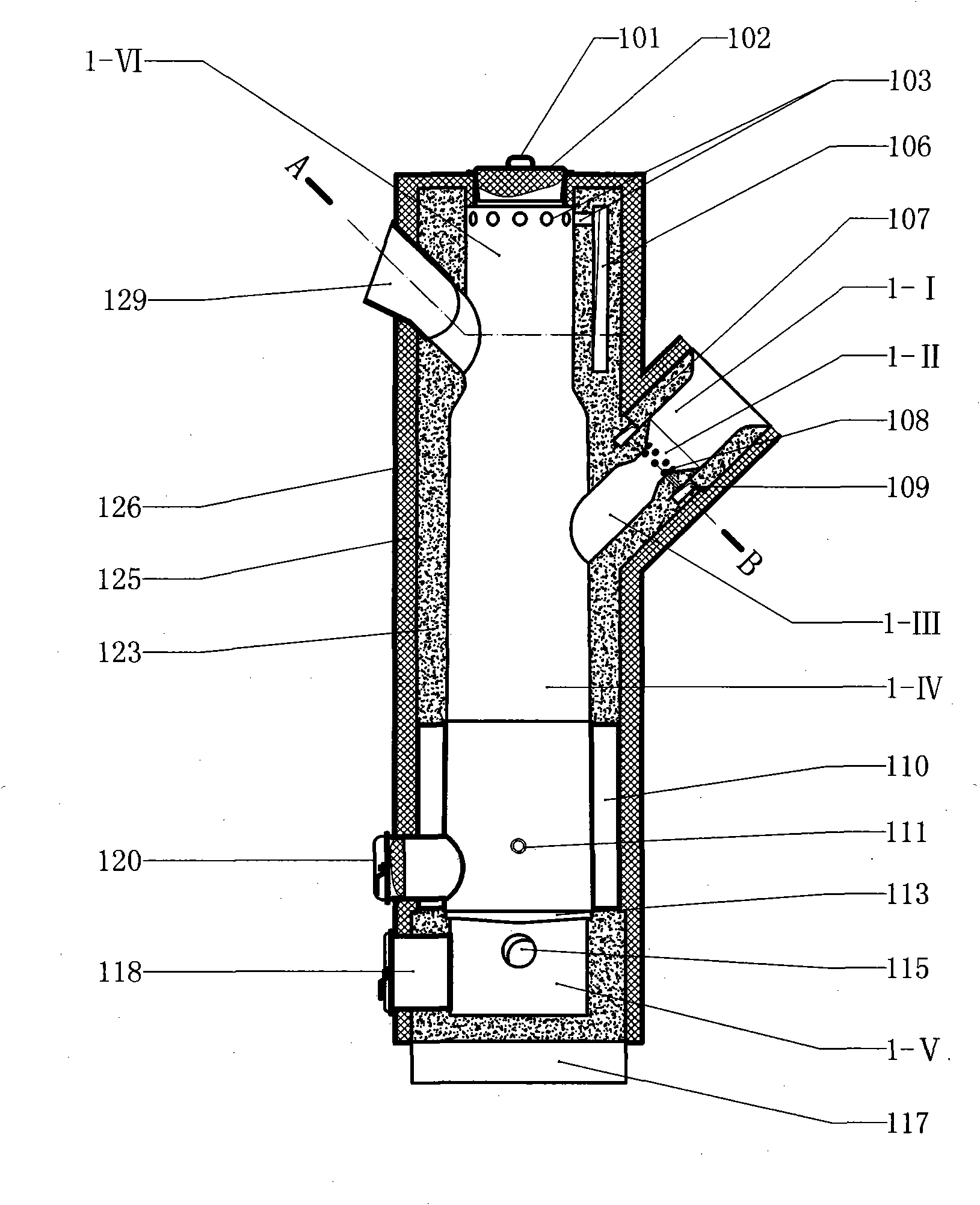

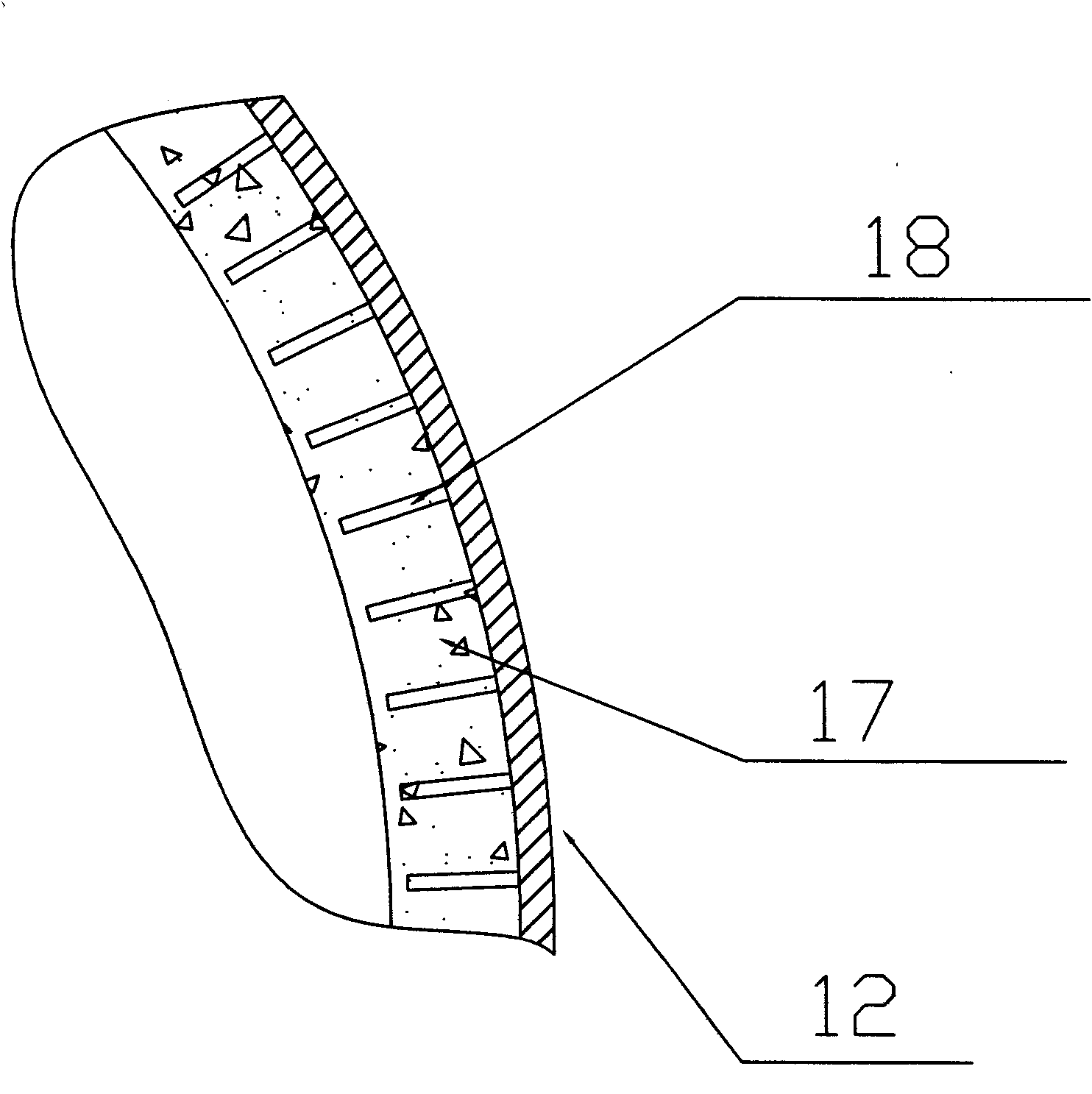

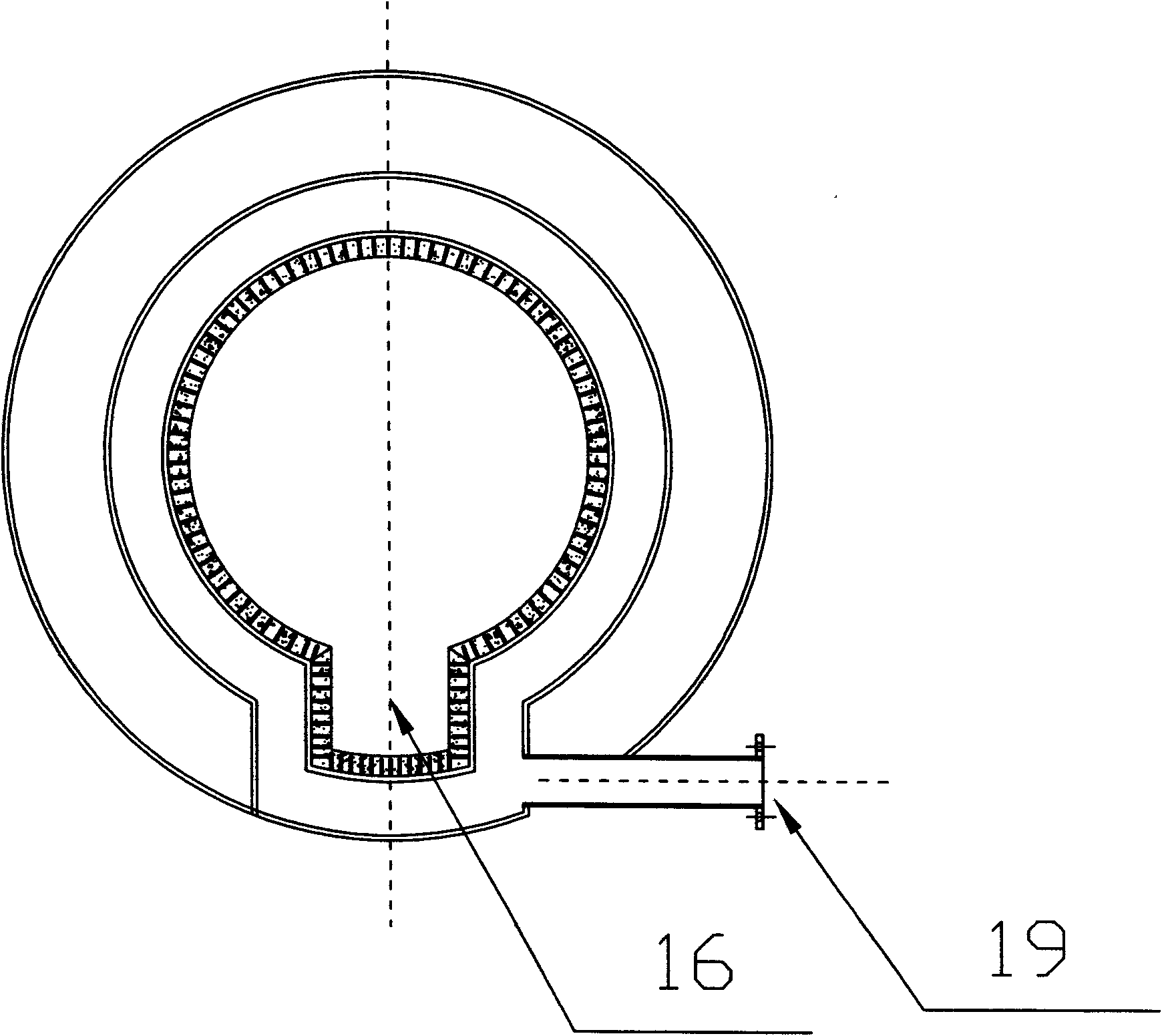

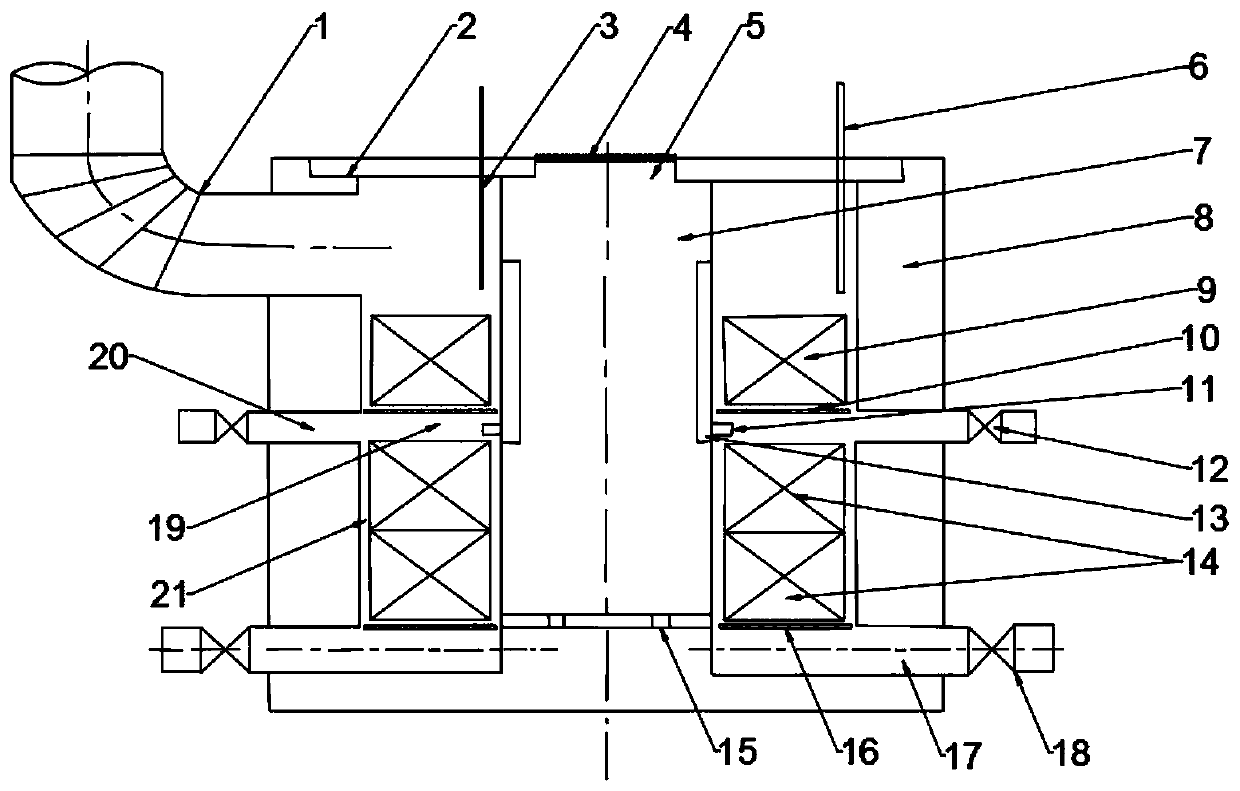

Low-NOx dry and wet deslagging dual-swirl coal-dust combustion device for

ActiveCN101915420AExtended service lifeBurn fullyPulverulent fuel combustion burnersSocial benefitsCombustion chamber

The invention relates to a low-NOx dry and wet deslagging dual-swirl coal-dust combustion device, which comprises a combustor assembly, wherein a breaking-out opening is arranged on the front end of the combustor assembly; the back end of the combustor assembly is connected with a secondary air room; and a primary air or coal-dust nozzle of the combustor assembly is arranged in the secondary air room. The low-NOx dry and wet deslagging dual-swirl coal-dust combustion device is characterized in that the combustor assembly is covered by a working lining; the working lining is covered by a cooling water suite; a rotational-flow vane grid is arranged on the primary air or coal-dust nozzle; and a primary air or coal-dust feeding device is connected with the primary air or coal-dust nozzle. The low-NOx dry and wet deslagging dual-swirl coal-dust combustion device has the advantages of fully combustion, remarkable energy saving and emission reduction effect and long service life. At present, tens of thousands of 2 to 35 tons of steam or hot-water industrial boilers, furnaces and kilns are used in China. The boilers, the furnaces and the kilns are improved according to the low-NOx dry and wet deslagging dual-swirl coal-dust combustion device to generate great emission-reduction social benefits and obtain amazing energy-saving economic achievements.

Owner:上海题桥能源科技发展有限公司

Water gas generation-combustion integrated combustion method and combustion equipment thereof

InactiveCN106895431AReduce carbon contentGeneration of controlGaseous fuel feeder/distributionChemical industryBoiler furnaceCoke

The invention relates to a water gas generation-combustion integrated combustion method and combustion equipment thereof. The combustion equipment is mainly applied to a boiler. The combustion method comprises the following steps: (S1), semi-coke is ignited in a primary combustion zone of a boiler furnace and the temperature of the primary combustion zone is increased to 1100 DEG C or above, wherein the primary combustion zone is covered with a fire grate of a furnace arch; and (S2) sufficient air and saturated steam are injected into the primary combustion zone, so that the semi-coke can react with the injected air and saturated steam in the primary combustion zone, and water gas can be generated from the reaction and combusted; along with the improvement of the semi-coke and water gas combustion speed in the primary combustion zone, the feeding amount of air and saturated steam is gradually increased in the primary combustion zone, so that the water gas generation and combustion speed can be improved, and then the effect that water gas is combusted immediately after being generated can be achieved; and both high-temperature flame generated after the combustion of water gas in the primary combustion zone and unburned high-temperature flame enter the boiler furnace from the arch mouth of the furnace arch, and are further burned out in the boiler furnace under the coordination with secondary air. The combustion method and the combustion equipment provided by the invention are high in heat efficiency, safe, environmentally friendly, and low in operation and maintenance cost.

Owner:孟氏锅炉(北京)有限公司

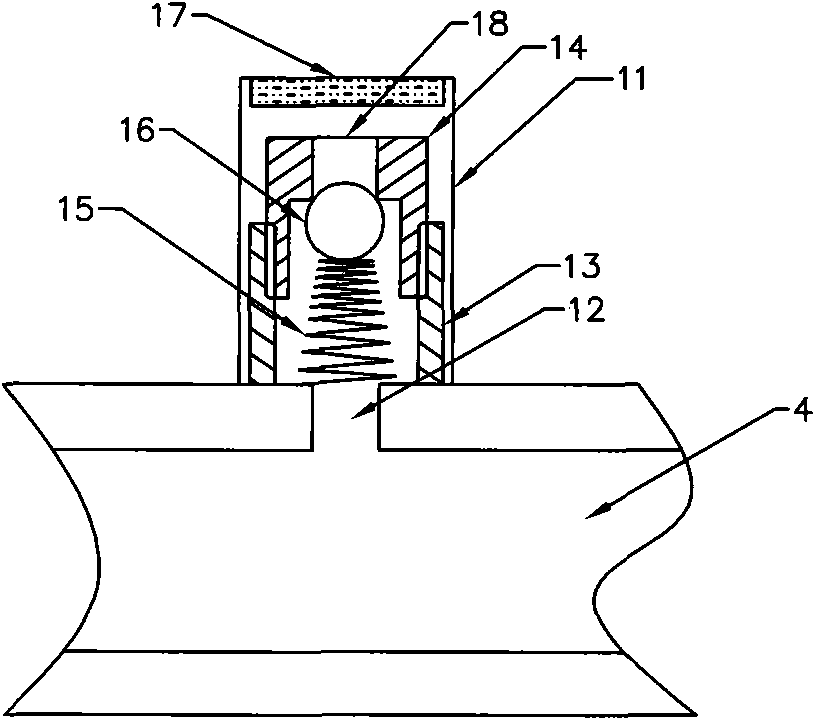

Automatic-control fuel feeding device of internal combustion engine and installation method thereof

InactiveCN101798971AReduce consumptionReduce carbon build-upFuel re-atomisation/homogenisationMachines/enginesCombustionAutomatic control

The invention relates to an automatic-control fuel feeding device of an internal combustion engine and an installation method thereof, in particular to a fuel mixing and optimizing device of an internal combustion engine and a manufacturing method thereof. The device of the invention comprises an automatic valve and an atomizing fan, wherein the automatic valve is installed on the wall of the oil outlet pipe of a carburetor, and the atomizing fan is installed in the oil outlet end of the oil outlet pipe. In the technical scheme of the invention, the device can adopt different automatic control valves according to actual requirements, automatically adjusts the air inflow according to the pressure change every time, reduces the error of the fuel mixture ratio, utilizes a sealing cavity installed on the atomizing fan to contain lubrication oil, keeps automatic lubrication when the atomizing fan works, reduces the working deviation caused by abrasion, automatically reduces the acceleration consumption under the normal conditions, automatically improves the efficiency, prolongs the service life of an engine, reduces the fuel consumption and automatically and simultaneously reduces the emission of harmful gases such as carbon monoxide, carbon dioxide, hydroxides, hydrocarbons and the like, thereby achieving the purpose of clean combustion.

Owner:张普华

Multifunctional integrated furnace for enhancing combustion of synchronously pyrolyzed garbage

PendingCN110953590ARealize resourcesAchieve reductionIncinerator apparatusThermodynamicsCombustion chamber

The invention relates to the field of garbage treatment, in particular to a multifunctional integrated furnace for enhancing combustion of synchronously pyrolyzed garbage. The furnace comprises a furnace body; a detachable heating chamber is arranged in the furnace body; a combustion chamber uniformly arranged in the circumferential direction of the outer side wall of the heating chamber is arranged in a cavity between the furnace body and the heating chamber; the combustion chamber comprises a first combustion chamber and a second combustion chamber positioned above the first combustion chamber; a fixed grate is arranged at the bottom of the first combustion chamber; a primary air inlet duct is connected below the fixed grate; a primary air inlet adjusting door is arranged at an inlet ofa pipeline of the primary air inlet duct; a movable grate is detachably arranged at the bottom of the second combustion chamber; a pyrolysis gas combustion-supporting area is arranged between the first combustion chamber and the movable grate; the pyrolysis gas combustion-supporting area is connected with a secondary air inlet duct; and a secondary air inlet adjusting door is arranged at an inletof a pipeline of the secondary air inlet duct.

Owner:江苏地质矿产设计研究院 +1

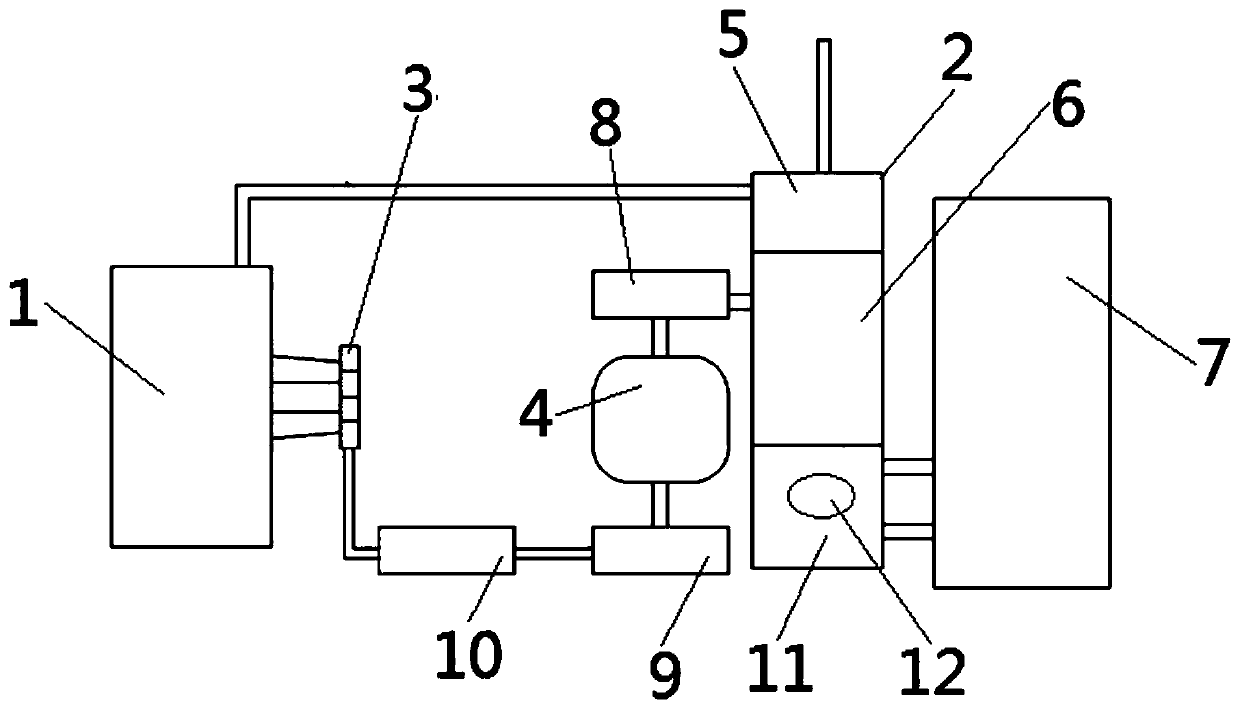

Methanol fuel engine

InactiveCN111219245AEasy to startClean burningInternal combustion piston enginesFuel supply apparatusPhysicsThermal efficiency

The invention provides a methanol fuel engine applied to the technical field of new energy cars. A hydrogen nozzle (3) of an engine body (1) of the methanol fuel engine communicates with a hydrogen storage tank (4), a methanol water solution tank (7) communicates with a methanol water steam reforming hydrogen production reactor (6), an exhaust pipe of the engine body (1) communicates with a wasteheat recycling device (5) which communicates with the methanol water steam reforming hydrogen production reactor (6), and the hydrogen storage tank (4) communicates with the methanol water steam reforming hydrogen production reactor (6). The methanol fuel engine is simple in structure, engine tail gas during engine work is used, methanol water solution online hydrogen production is achieved, the prepared hydrogen serves as fuel to be supplied to the engine to work, when the engine is started, the problem of difficult cold starting of the engine does not exist, meanwhile, engine heat efficiencycan be improved, and clean combustion is achieved.

Owner:JAPHL POWERTRAIN SYST

Biomass semi-gasification furnace and manufacturing method thereof

InactiveCN101737808AEliminate dead endsReduce resistanceDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention discloses a biomass semi-gasification furnace comprising a burner, a vaporizing chamber, a filling mouth, a flame bridge, an ash receiving and ventilating chamber, a secondary air inlet channel, a panel fire surrounding cover and a flue, a circumference space, an insulating layer, a fireproof ring, an air blower mouth and the like. The invention prefabricates accessories, such as the burner, the vaporizing chamber, the panel fire surrounding cover, the flue, the filling mouth, the secondary air inlet channel, the flame bridge and the like which have different specifications and are matched as well as prefabricates square or round metal furnace periphery or cooking bench periphery built by bricks and mud; all accessories are connected, and the insulating layer is built by fire clay. The invention eliminates a dead space formed on the joint of the burner and the vaporizing chamber and increases the flammable gas rising flowability; secondary air inlet is high-temperature wind so as to greatly improve combustion-supporting efficiency; third air inlet supplements the insufficiency of secondary supply air rate when fuel with a higher gas production rate is burnt, so that biomass raw material can be more evenly and completely burnt. The accessory of the product of the invention can be produced in a standardized and industrialized mode, thus lowering cost and bringing convenience for popularizing products.

Owner:山西炜轩科技有限公司

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490BSolve the problem of air pollutionPollution realizedSolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com