Plunger type twice fuel injection pump

A fuel injection pump and plunger type technology, which is applied in the field of plunger type double fuel injection pumps, can solve the problems of high soot NOX emission, inability to achieve double fuel injection, restrictions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

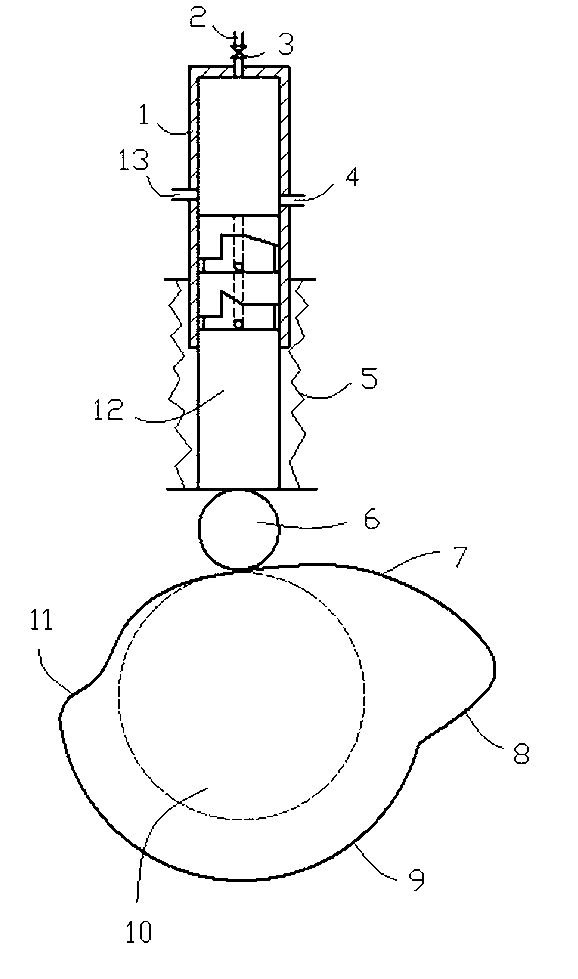

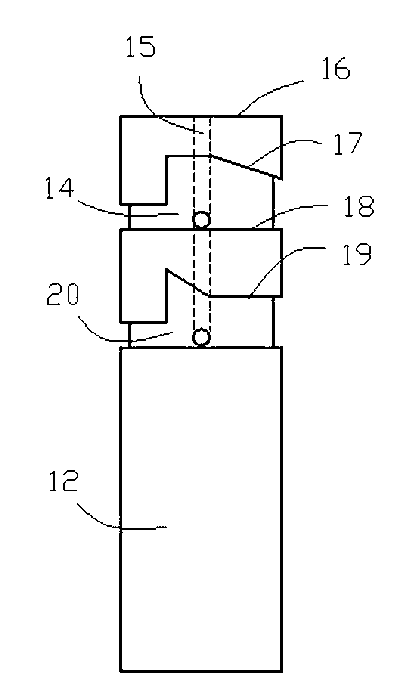

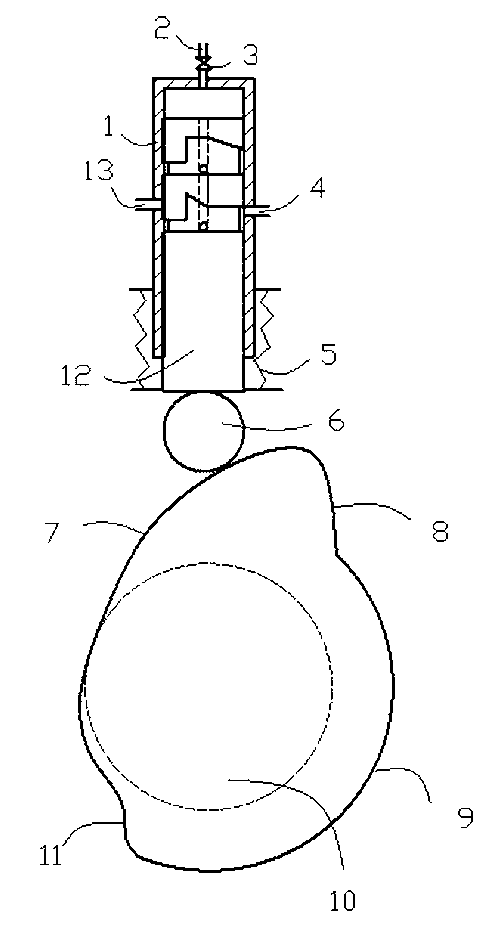

[0024] refer to figure 1 , figure 2 , the plunger-type double fuel injection pump provided by the present invention is composed of a plunger sleeve 1, a plunger 12 and a drive cam 10, wherein the plunger sleeve 1 has an oil inlet 13, a return oil outlet 4, a spring Valve 3 and high-pressure oil outlet 2; plunger 12 has two fuel injection working sections, among the two fuel injection working sections, the first fuel injection working section has the first oil supply edge 16 and the first oil stop edge 17 and the first section of helical oil groove 14, the second section of the oil injection working section has the second section of oil supply edge 18, the second section of oil stop edge 19 and the second section of helical oil groove 20, the first section of helical oil groove 14 and the second section The spiral oil grooves 20 are respectively communicated with the central oil hole 15 at the top of the plunger 12; there are two lift profiles in the driving cam 10, wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com