Coal gasified supercharging reverse-combustion flaming type coal combusting device

A technology of coal combustion and coal gasification, which is applied in the combustion of solid fuel, combustion equipment, and the manufacture of combustible gas, etc., to achieve the effect of clean coal combustion, low cost, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

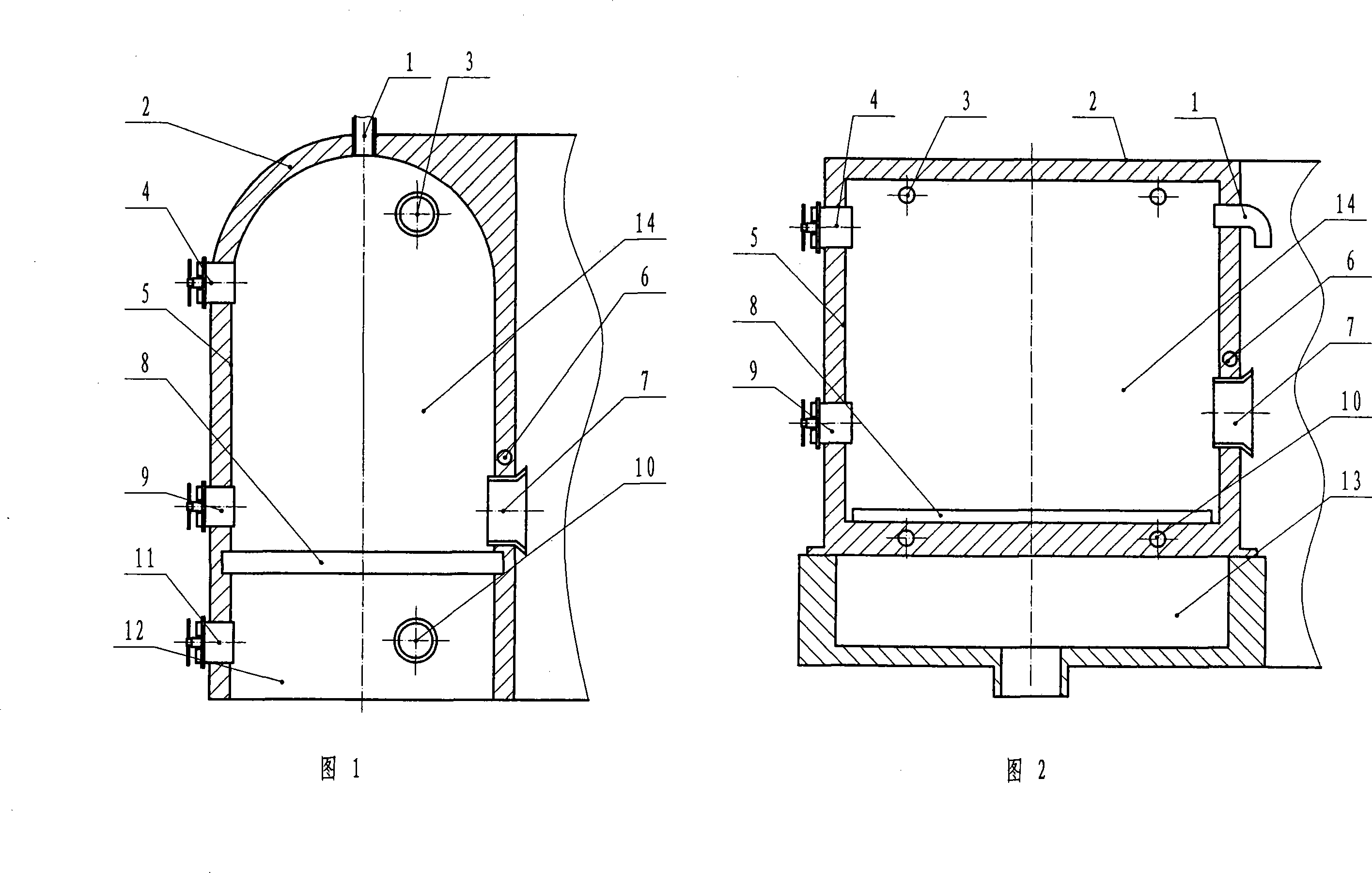

[0011] The embodiments of the present invention will be further described in conjunction with the accompanying drawings, and the embodiments are used to illustrate the present invention, but not to limit it in any way.

[0012] The present invention comprises shell 2, the liner 5 that is made up of water jacket and refractory layer, and inner cavity of liner 5 is gas generation combustion chamber 14, and the lower part of gas generation combustion chamber 14 is furnace bar 8, and the bottom of furnace bar 8 is sealed chamber. The gas generation combustion chamber 14 top is provided with a feed sealing door 4, and has a gas release port 1; the gas generation combustion chamber 14 bottom is provided with a slag removal sealing door 9. The sealed chamber has a dust-cleaning sealed door 11 . The side wall of the dry-type sealed chamber 12 is provided with a dust-cleaning sealed door. The bottom of the water-type sealed chamber 13 is provided with a dust-cleaning sealed door. Fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com