Automatic-control fuel feeding device of internal combustion engine and installation method thereof

A supply device and internal combustion engine technology, applied in the field of mechanical power, can solve problems such as unreasonable structure and component wear, and achieve the effects of simple structure, enhanced air stamping effect, and reduced working deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

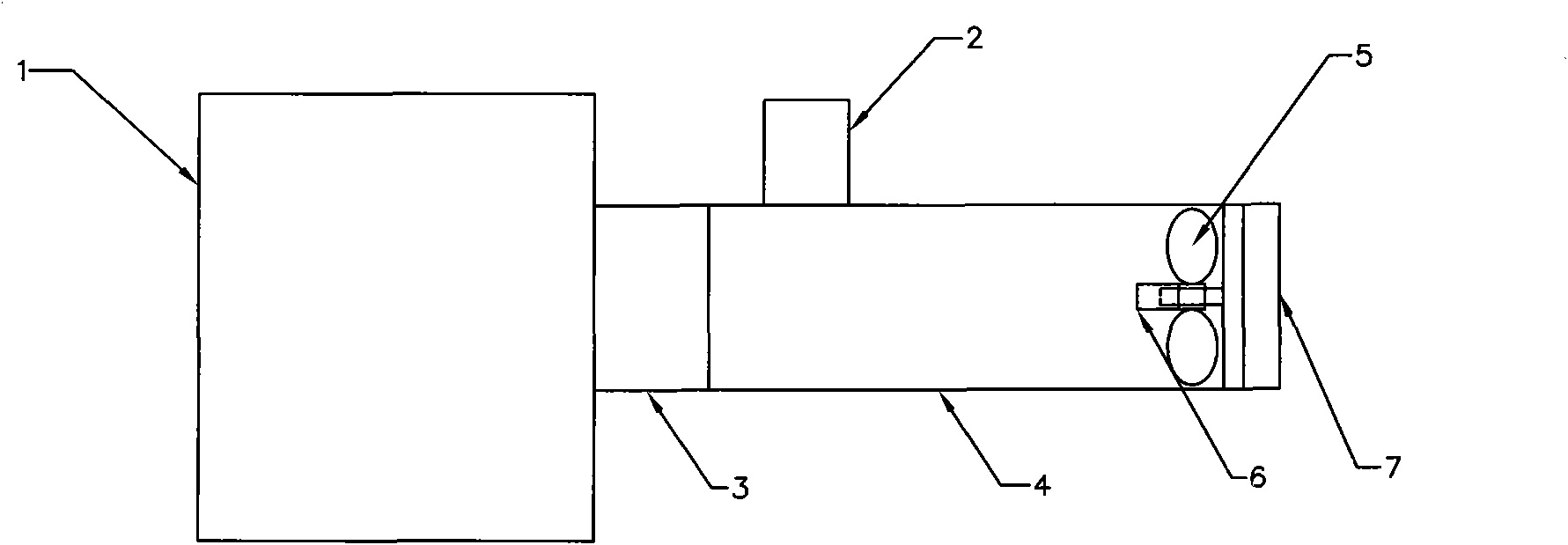

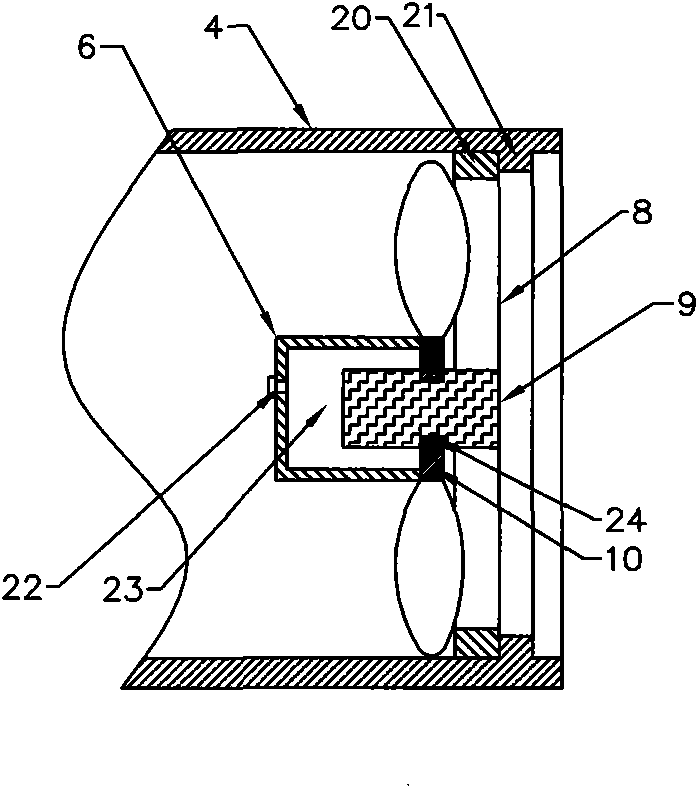

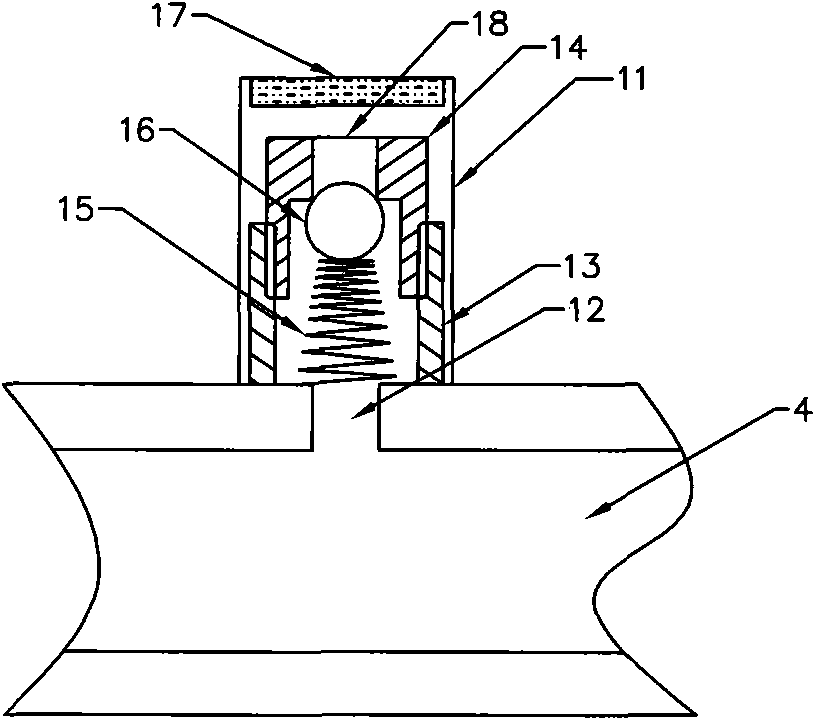

[0028] like figure 1 As shown, the internal combustion engine fuel atomization regulator of this program includes at least one automatic valve 2 and atomization fan, the automatic valve 2 is installed on the oil outlet pipe 4 at the oil outlet 3 of the carburetor 1, and the general through hole 12 is located at a distance from the outlet. At the 2 / 3 of the end of the oil pipe, more than two through holes need to be positioned symmetrically. When installing multiple fans and automatic valves, the distance between each automatic valve and the atomizing fan should not be less than the diameter of the through hole. The atomizing fan is installed in the outlet end 7 of the oil outlet pipe of the carburetor. The oil outlet pipe of the carburetor can be the body of the carburetor 1, or can be fixedly installed on the outlet of the carburetor 1 by means of welding, bolts or threads. Oil port 3, the equipment of this scheme can be flexibly installed depending on the size of the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com