Smokeless burning technique and equipment with fire fontanel being setup inside furnace

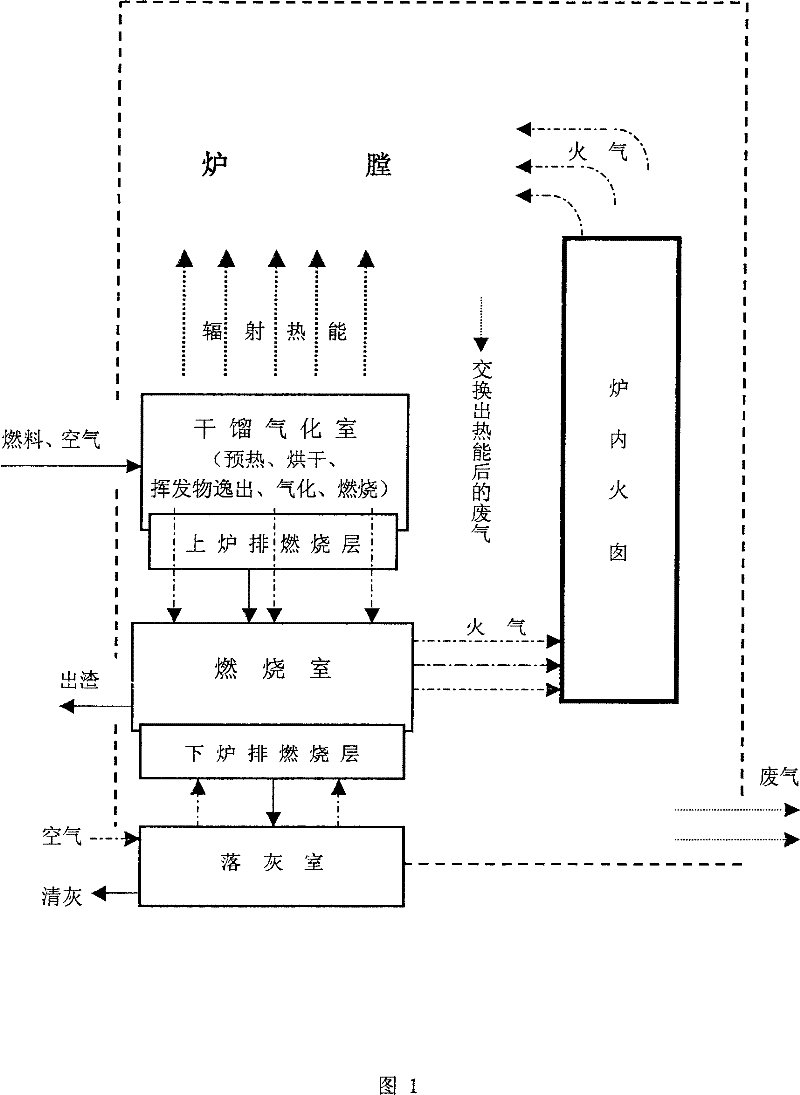

A smokeless combustion and chimney technology, which is applied in the fields of water heaters, kilns, organic heat carrier boilers, steam boilers, and civil boiling water boilers. It can solve the problems of slow ignition and combustion, poor ignition conditions, and narrow coal types, etc. problems, to achieve the effect of eliminating soot, avoiding heat loss from incomplete combustion of gas, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

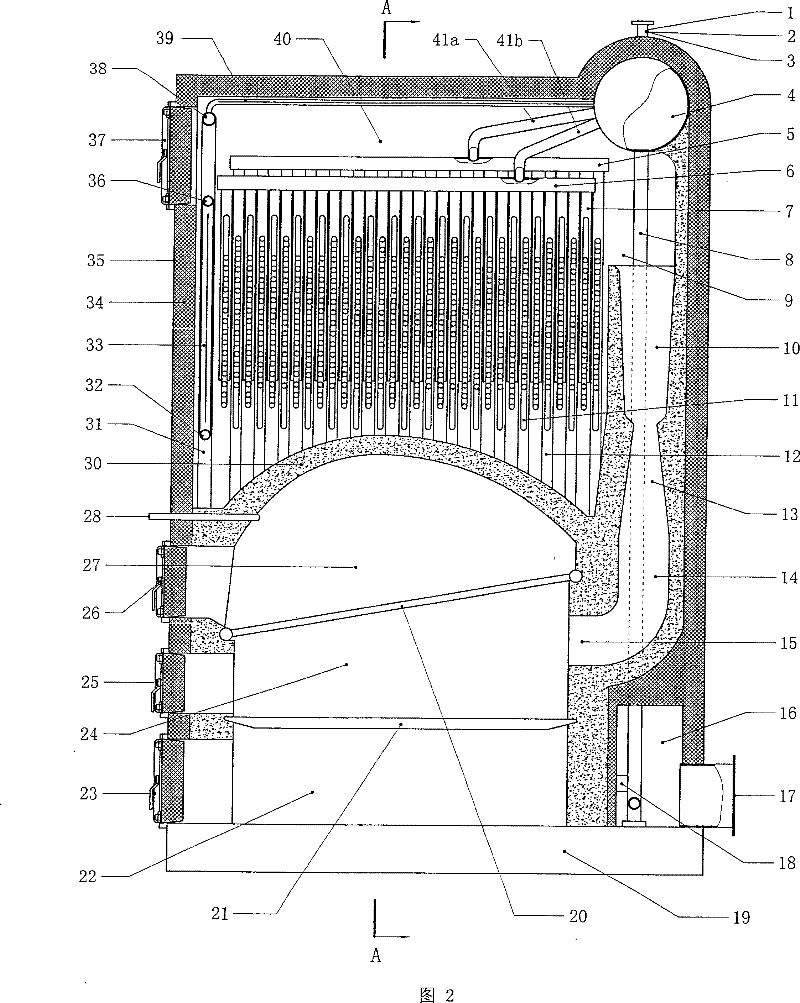

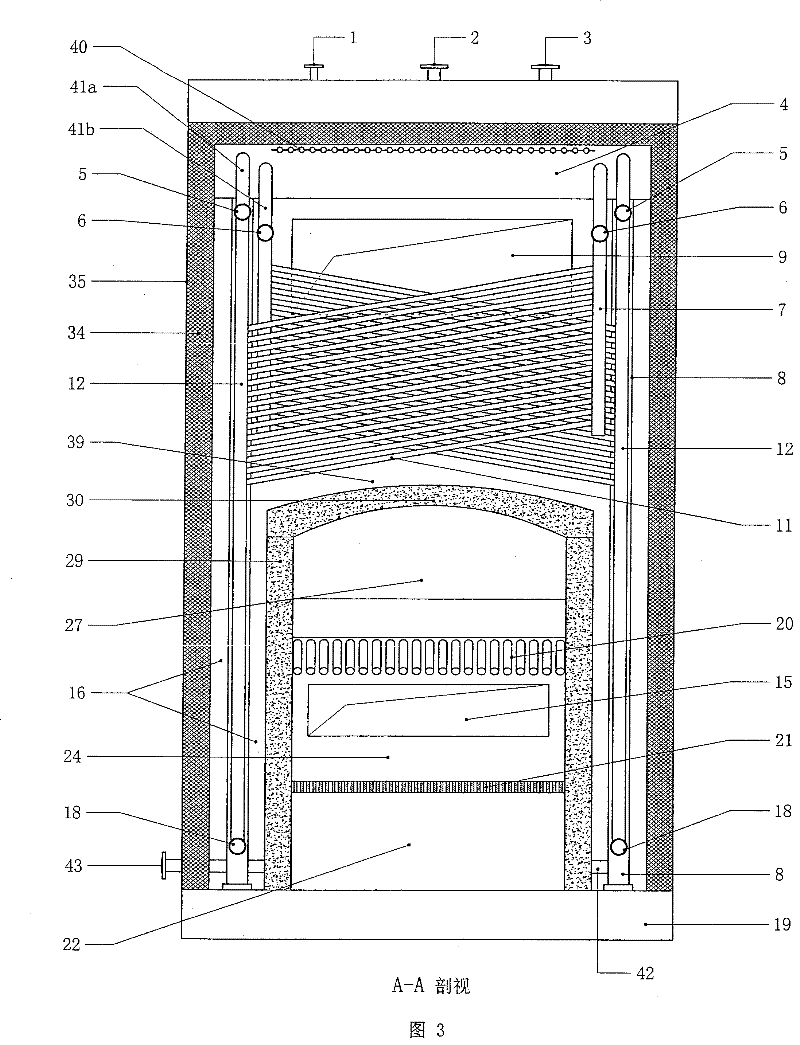

[0028] figure 2 The shown embodiment is the equipment body of the water heater and the organic heat carrier boiler of the present invention, which are mainly introduced by the flame of the dry distillation gasification combustion chamber (27), the second combustion chamber (24), the furnace (40), and the chimney. section (14), the Venturi fire section (13) of the chimney, the flame lead-out section (10) of the chimney, the upper grate (20), the lower grate (21), the hot water outlet header (4), Heat collecting pipe (11), vertical header of heat collecting pipe (7), water collecting tank of heat collecting pipe (6), water cooling wall (12), upper header of water cooling wall (5), lower header of water cooling wall (18) , downcomer (8), riser (31), lower header (32) of the front water wall, front water wall (33), upper header (36) of the front water wall, top water wall ( 39), ash chamber (22), waste gas descending channel (16), thermal insulation enclosure (34), shell (35), w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com