A kind of dicumyl peroxide condensation tail gas closed loop system

A technology of dicumyl peroxide and circulation system, which is applied in the preparation of peroxygen compounds, organic compounds, organic chemistry, etc. It can solve the problems of long process flow, waste of raw materials, secondary pollution, etc., and achieve treatment and recycling The process is simple, the consumption of raw materials is reduced, and the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

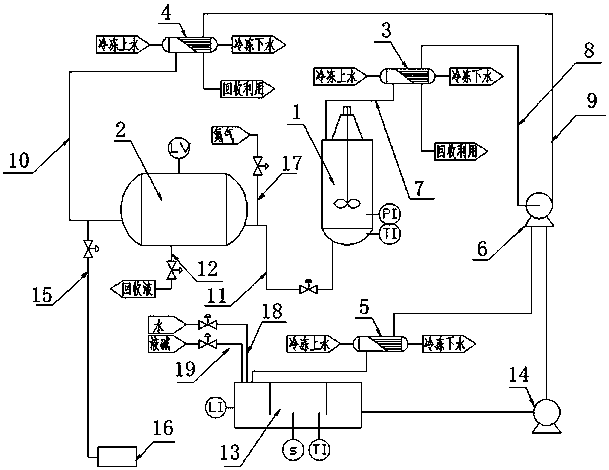

[0024] Such as figure 1 Shown: a kind of dicumyl peroxide condensation tail gas closed-circuit circulation system provided in this embodiment, including condensation kettle 1, tail gas bag 2, first condenser 3, second condenser 4, third condenser 5, water Ring vacuum pump 6, the top gas outlet of the condensation kettle 1 is connected with a first pipeline 7, the first pipeline 7 is connected with the air inlet of the first condenser 3, and the gas outlet of the first condenser 3 A second pipeline 8 is connected, and the second pipeline 8 is connected with the air inlet of the water ring vacuum pump 6, and the air outlet of the water ring vacuum pump 6 is connected with a third pipeline 9, and the third pipeline 9 is connected with the water ring vacuum pump 6. The air inlet of the second condenser 4 is connected, and the gas outlet of the second condenser 4 is connected with a fourth pipeline 10, and the fourth pipeline 10 is connected with the inlet of the exhaust gas bag 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com