Revolved body cathode with cooling rib rings

A technology of rotating body and cooling ribs, which is applied in the direction of plasma and electrical components, can solve the problems of short service life, easy ablation of electrodes, and failure to meet the requirements of use, achieve good heating effect, and overcome easy ablation , the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

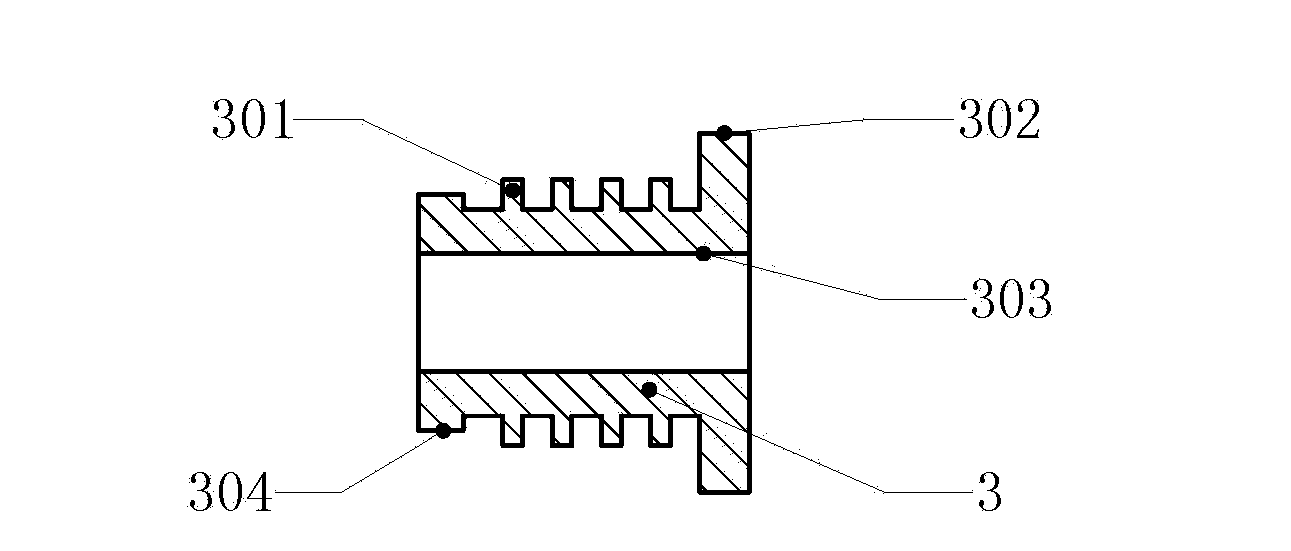

[0016] Example 1 figure 1 In the shown embodiment, the axial center of the rotator cathode (3) has a cylindrical channel through front and back, the inner wall of the front end of the cylindrical channel constitutes the inner ring discharge surface (303), and the outer wall of the front end of the rotator cathode (3) constitutes The embedded surface a (302), the outer wall of the rear end of the cathode (3) of the rotator forms the embedded surface b (304), and there is a raised ring on the outer wall of the rotator between the embedded surface a (302) and the embedded surface b (304) , the protruding rings on the outer wall of the rotating body constitute the cooling rib ring (301), and the cooling rib ring (301) is four rings. The rotary cathode (3) of this embodiment is used as one of the components of the plasma torch, installed in the cathode base at the rear of the plasma torch.

Embodiment 2

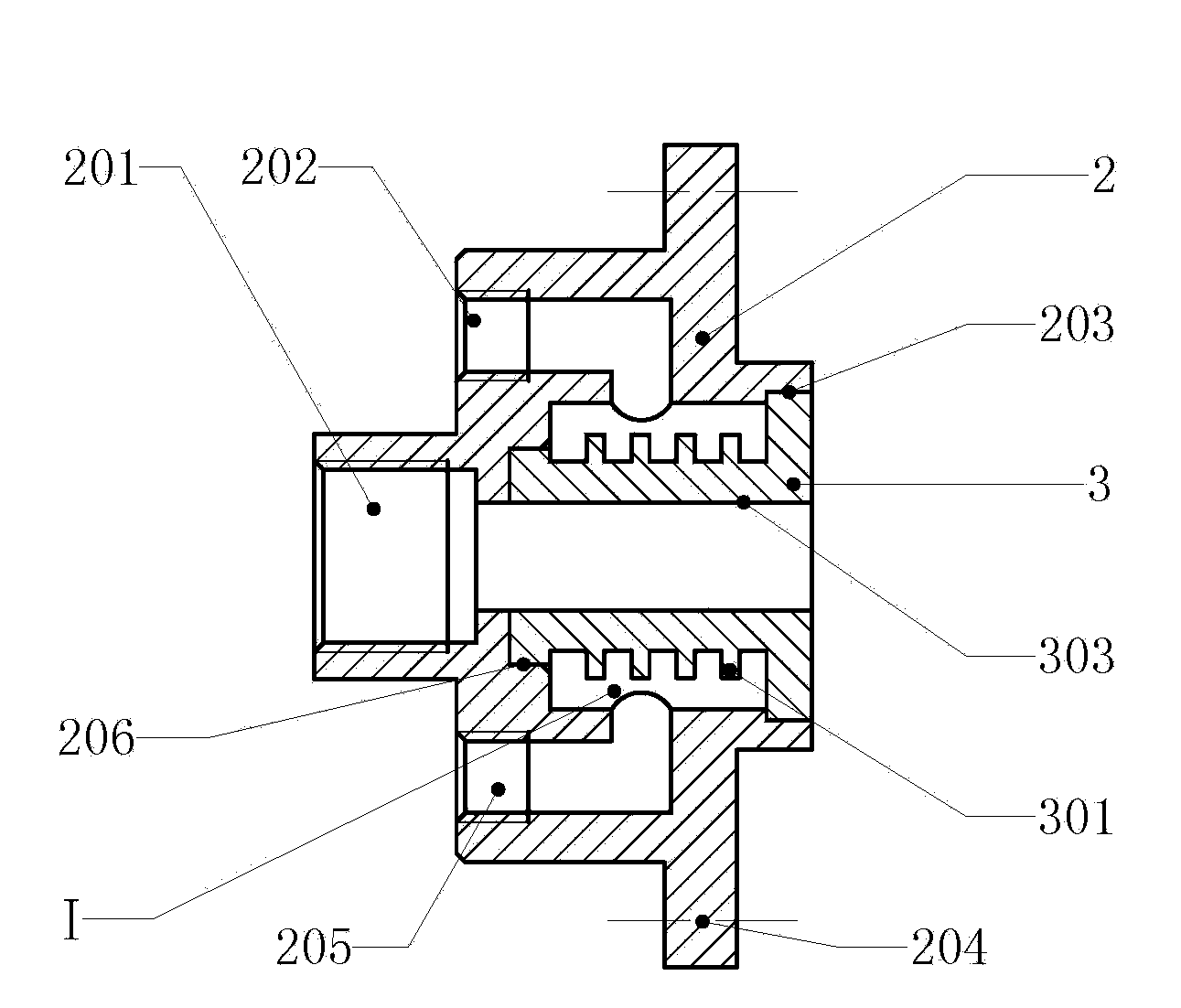

[0017] Example 2 figure 2 In the shown embodiment, the rotator cathode (3) is embedded in the cathode base (2), there is a space between the inner wall of the cathode pedestal (2) and the outer wall of the rotator cathode (3), and the cathode base The space between the inner wall of the seat (2) and the outer wall of the rotator cathode (3) forms a cooling water jacket (I), and the cooling water jacket (I) has a cooling water inlet port (205) connected to it and a cooling water outlet port (202) connected to it , there is an embedding port a (203) on the front wall of the cathode base (2), and the embedding face a (302) of the cathode (3) of the rotor is tightly embedded in the embedding port a on the front wall of the cathode base (2) In (203), there is an embedding port b (206) on the rear wall of the cathode base (2), and the embedding surface b (304) of the cathode (3) of the rotor is tightly embedded in the rear wall of the cathode base (2). Embedding port b (206) on th...

Embodiment 3

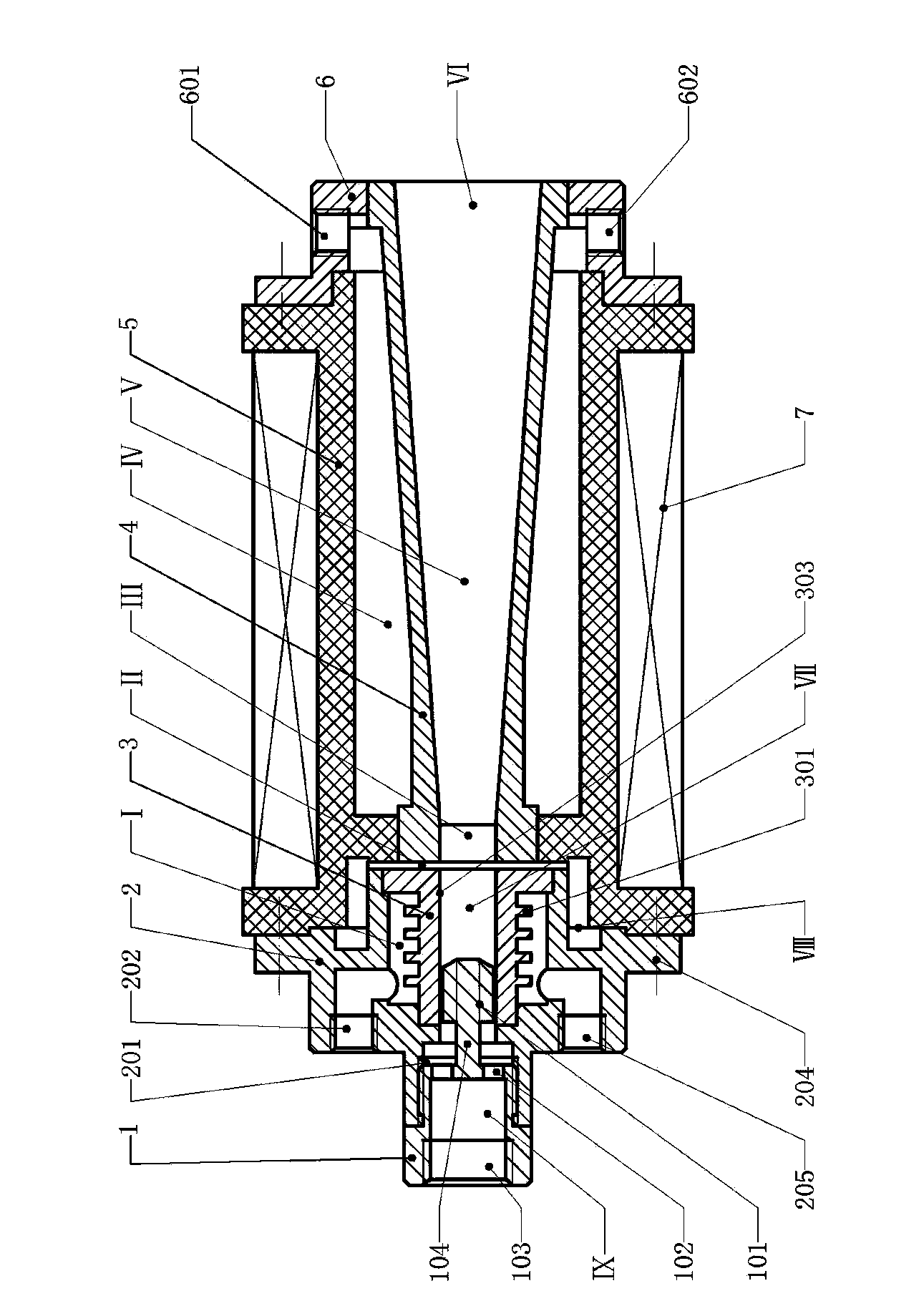

[0018] Example 3 image 3In the shown embodiment, a rotator cathode with a cooling rib ring is applied in a plasma heating torch, and the plasma heating torch includes a rotator cathode (3), a cathode base (2), an adapter (1) , an insulating frame (5), an anode (4), a front end (6) and a magnetic compression coil (7), wherein the structure of the rotor cathode (3) and the cathode base (2) is the same as that of the first embodiment and the second embodiment It is the same as that described in the embodiment and will not be repeated here. The adapter (1) is installed on the connection port (201) at the rear end of the cathode base (2), and the front end of the adapter (1) has a cyclone (101) protruding forward, and the cyclone (101) It has a rectangular thread or trapezoidal thread structure. The cyclone (101) extends into the cylindrical channel of the cathode (3) of the rotor. The pitch space of the cyclone (101) forms a spiral channel. The body of the adapter (1) Hollow ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com