Solid fuel combustion device with fire grate obliquely arranged and combustion method

A solid fuel and combustion device technology, which is applied in the combustion, combustion method, combustion chamber and other directions of solid fuel, can solve the problems of inability to achieve clean combustion of solid fuel, inability to achieve balanced combustion of fuel, volatile matter and fixed carbon, and achieve reasonable Aerodynamics, avoid local carbon deposits, improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

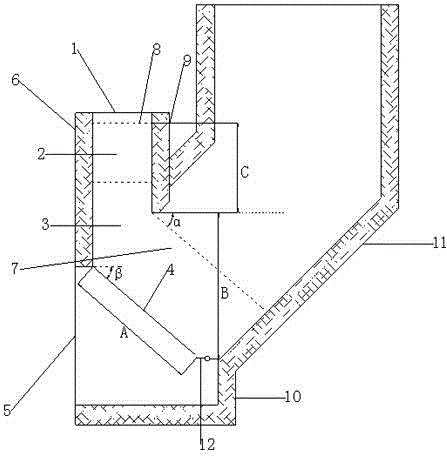

[0037]The solid fuel clean combustion device with inclined grate of the present invention comprises a furnace body 6, an upper air inlet 1 is arranged on the upper part or the top of the furnace body 6, and a lower air inlet 5 is arranged on the lower part, inside the furnace body 6 A furnace cavity is provided; in this embodiment, the upper air inlet 1 is disposed on the top of the furnace body 6 . The fire outlet 7 is arranged on the side of the furnace body 6, the setting position of the fire outlet 7 is lower than the upper air inlet 1, and the height of the fire outlet 7 is within the conventional selection range in this field. In this embodiment, Among them, the height of the fire outlet 7 is not less than 200mm. The positional relationship between the lower air inlet 5 and the fire outlet 7 can be set as required. In this embodiment, the lower air inlet 5 and the fire outlet 7 are arranged on both sides of the furnace body 6, and the fire outlet 7 The upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com