Plasma heavy oil burner

A heavy oil combustion and plasma technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of waste of resources, pollution of the environment, high requirements, etc., and achieve the effect of reducing pollution and clean combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

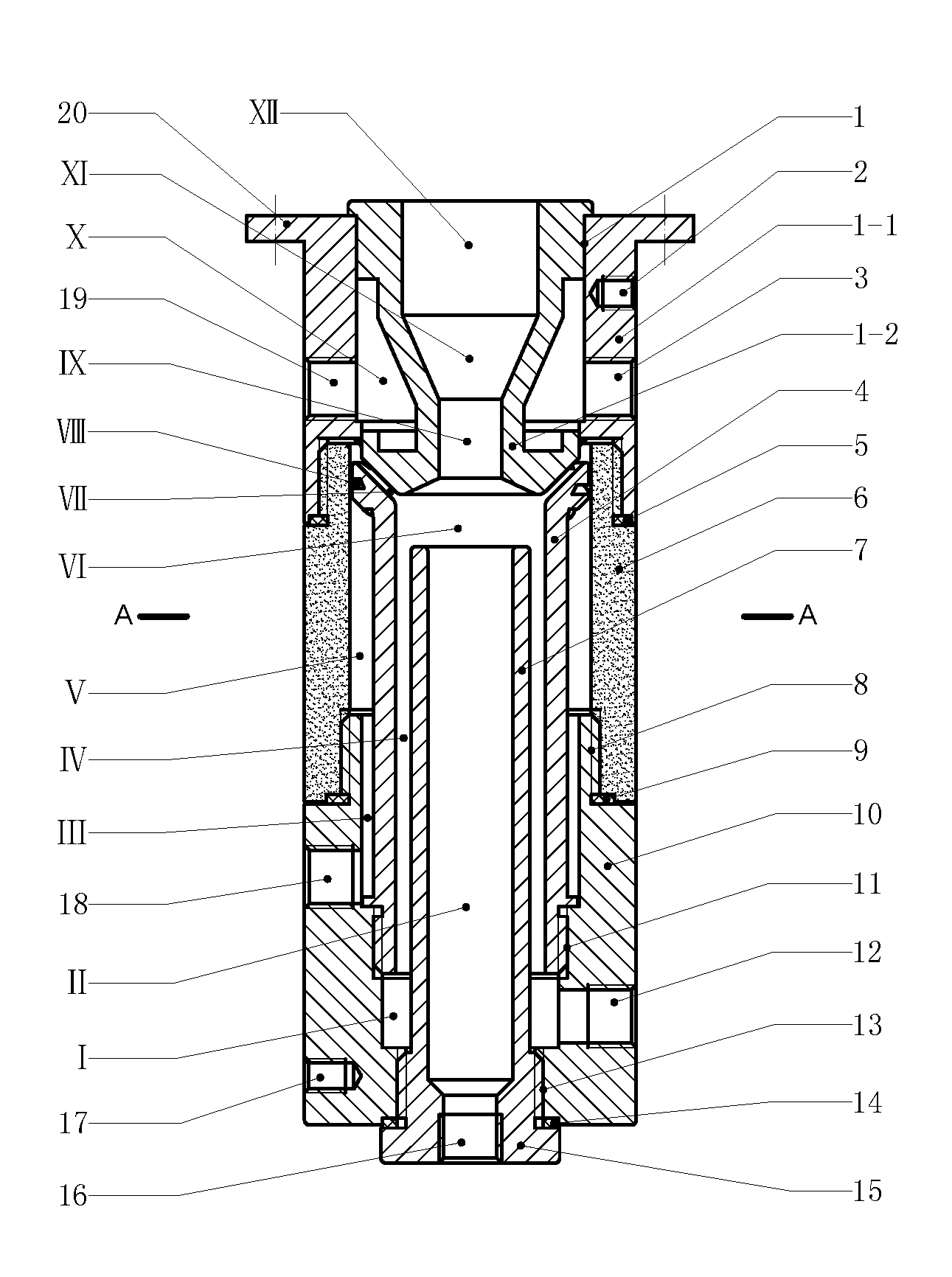

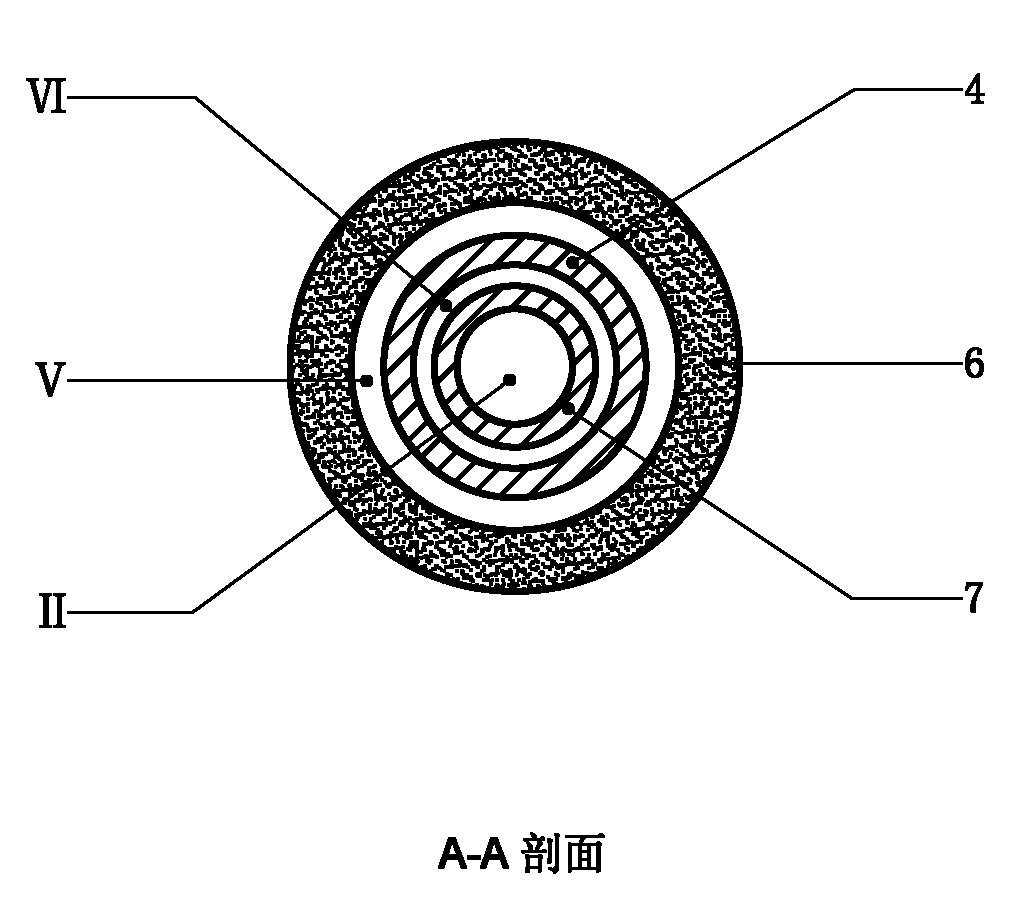

[0014] Example figure 1In the embodiment shown, the plasma heavy oil burner is mainly composed of the anode (1), the insulating connector (6), the cathode (4), the inner sleeve (7) and the rear seat (10), wherein the anode (1) , the insulating connector (6), the cathode (4), the inner sleeve (7) and the rear seat (10) are coaxially arranged, the insulating connector (6) is in a cylindrical structure, and the rear end of the anode (1) is connected through insulation The piece (6) is connected to the external connection port (8) at the front end of the back seat (10), the cathode (4) is set in the inner space of the insulating connector (6), and the lower end of the cathode (4) is connected to the back seat (10) On the internal connection port a (11), the inner sleeve (7) is a tubular body structure, and the inner sleeve (7) extends from the rear end of the rear seat (10) and enters the inner cavity (IV) of the cathode (4) , the rear end of the inner sleeve (7) is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com