Process and its device for clean burning and value gaining burning of solid fuel

A solid fuel, clean combustion technology, applied in the field of thermal energy equipment, can solve problems affecting combustion efficiency and environmental protection effects, mechanical incomplete combustion chemistry, incomplete combustion, etc., to reduce resource consumption, reduce fuel cost burden, and eliminate soot Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

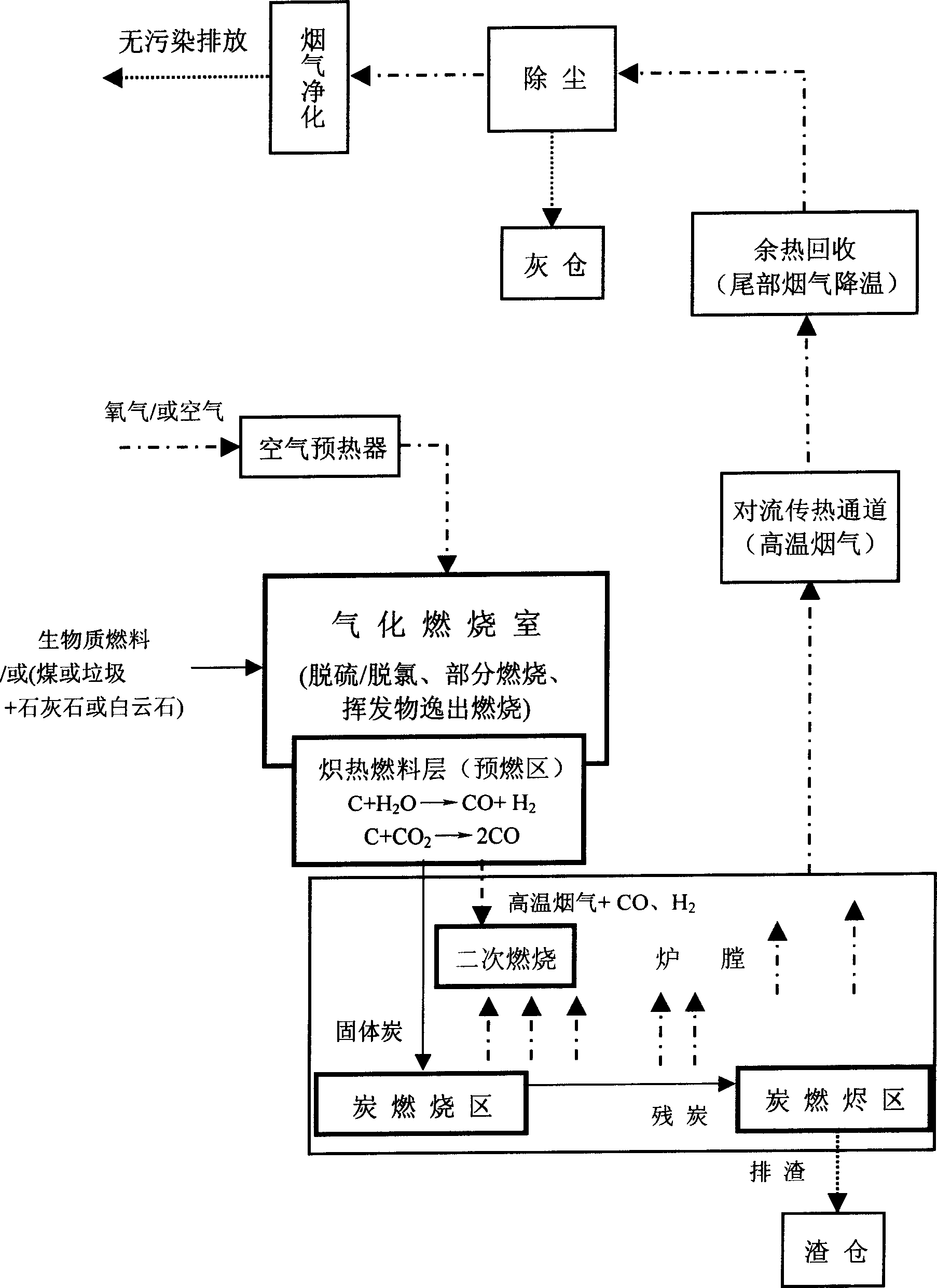

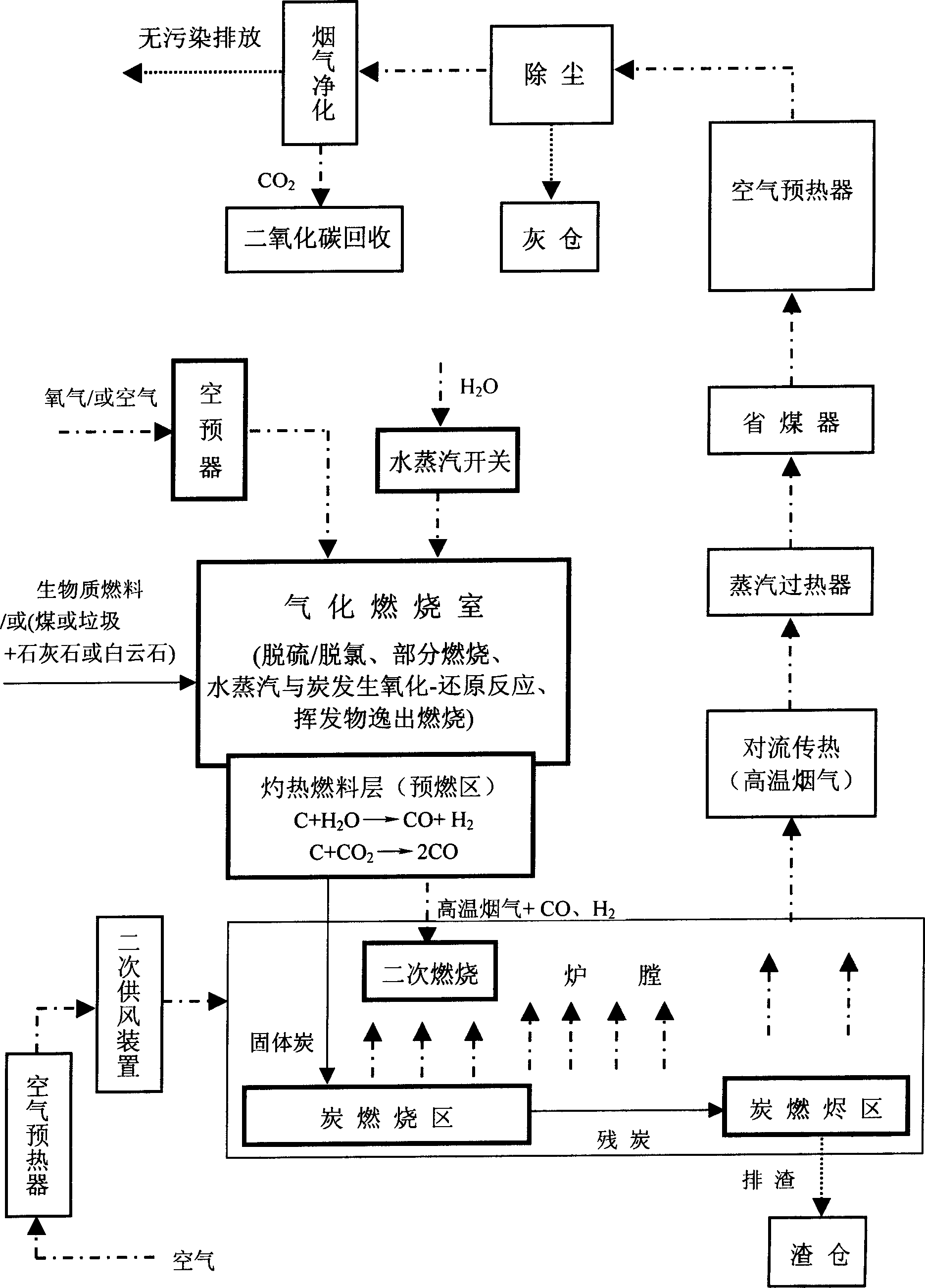

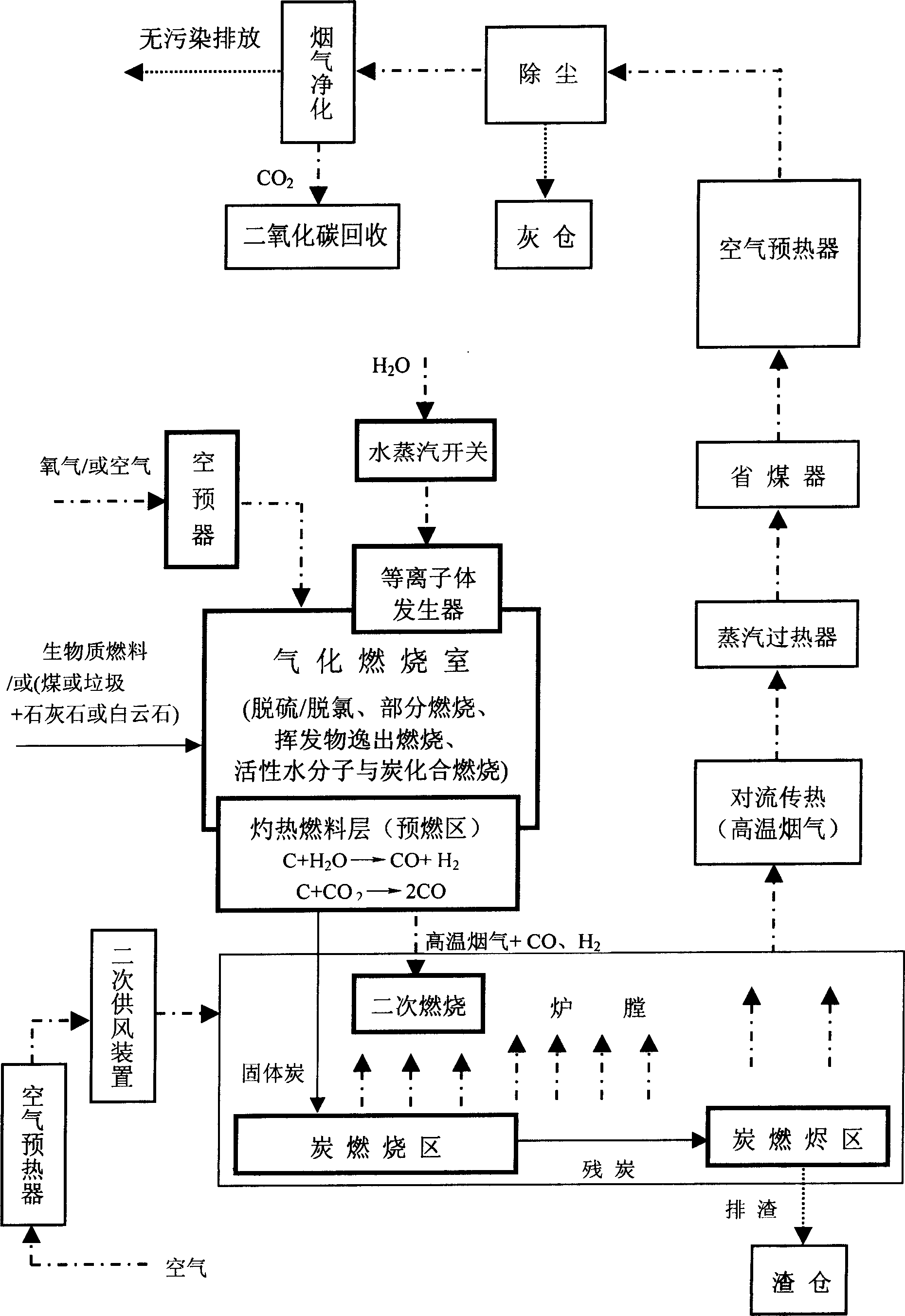

[0027] Figure 1 to Figure 4 It is a block diagram of boiler equipment composition and flue gas flow process in the embodiment of the present invention, wherein figure 1 The shown embodiment is the basic composition of the boiler of the present invention, which consists of a gasification combustion chamber, a pre-combustion zone, a charcoal combustion zone, a charcoal burnout zone, a furnace, an air supply device, a convective heat transfer channel, a tail waste heat recovery device, and a dust removal device , flue gas purification device, wherein the pre-combustion zone is at the junction of the gasification combustion chamber and the furnace, the fuel layer in the pre-combustion zone constitutes a physical isolation zone between the gasification combustion chamber and the furnace, the charcoal combustion zone and the charcoal burnt zone In the lower part of the furnace, the charcoal burning zone and the charcoal burning zone are formed by the relative positions of the grate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com