Adequate, clean combustion equipment

A combustion device and full combustion technology, applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems that solid combustibles cannot be used, increase heat production costs, limit fuel sources, etc., to achieve large heat production, Fuel saving and thorough decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

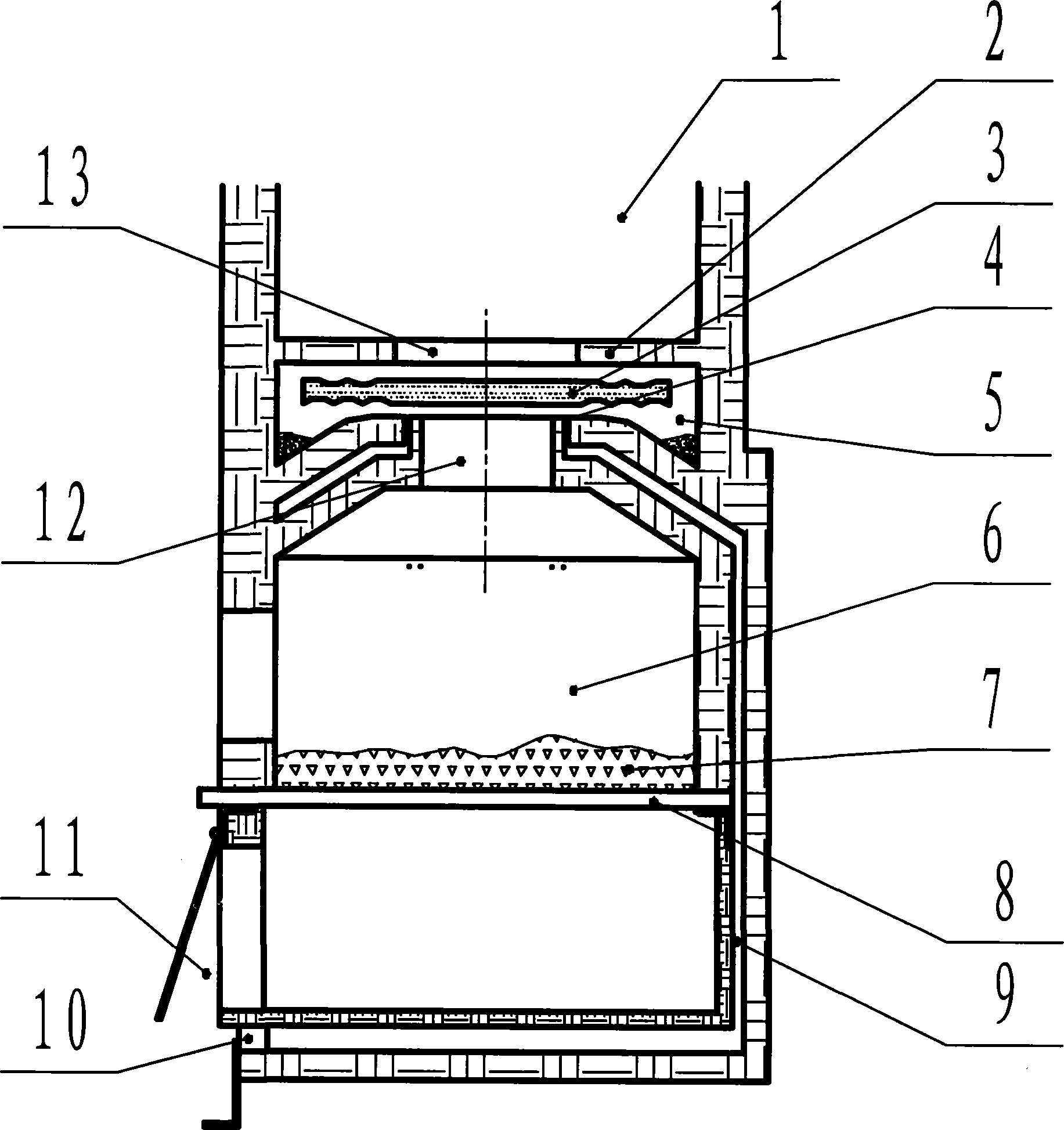

[0008] Solid combustibles (7) are put into the furnace (6), and enter the primary air combustion under the fire grate (8). The size of the primary air is regulated by the primary air inlet (11), which is usually less than the air intake under the unregulated fire grate (8), so the smoke dust raised is also less. When the flame enters the full combustion zone (5) from the full combustion zone inlet (12), it first encounters the obstruction of the disc (3), and the air flow changes from rising to horizontal diffusion. At this time, the larger solid particles entrained by the airflow are thrown down one after another due to the lack of updraft lift, eliminating part of the source of smoke and dust. The flame then enters the narrow slot below the disc (3) and immediately encounters hot air gushing from the secondary air outlet (4). The size of the secondary air is controlled through the secondary air inlet (10), and the secondary air is high-temperature air heated in the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com