Low-NOx dry and wet deslagging dual-swirl coal-dust combustion device for

A pulverized coal combustion, solid-liquid technology, applied in the direction of burner, combustion method, combustion type, etc., can solve problems such as unsmooth slag discharge, shutdown of furnace, frequent load changes, etc., achieve huge social benefits of emission reduction, and improve service life , The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

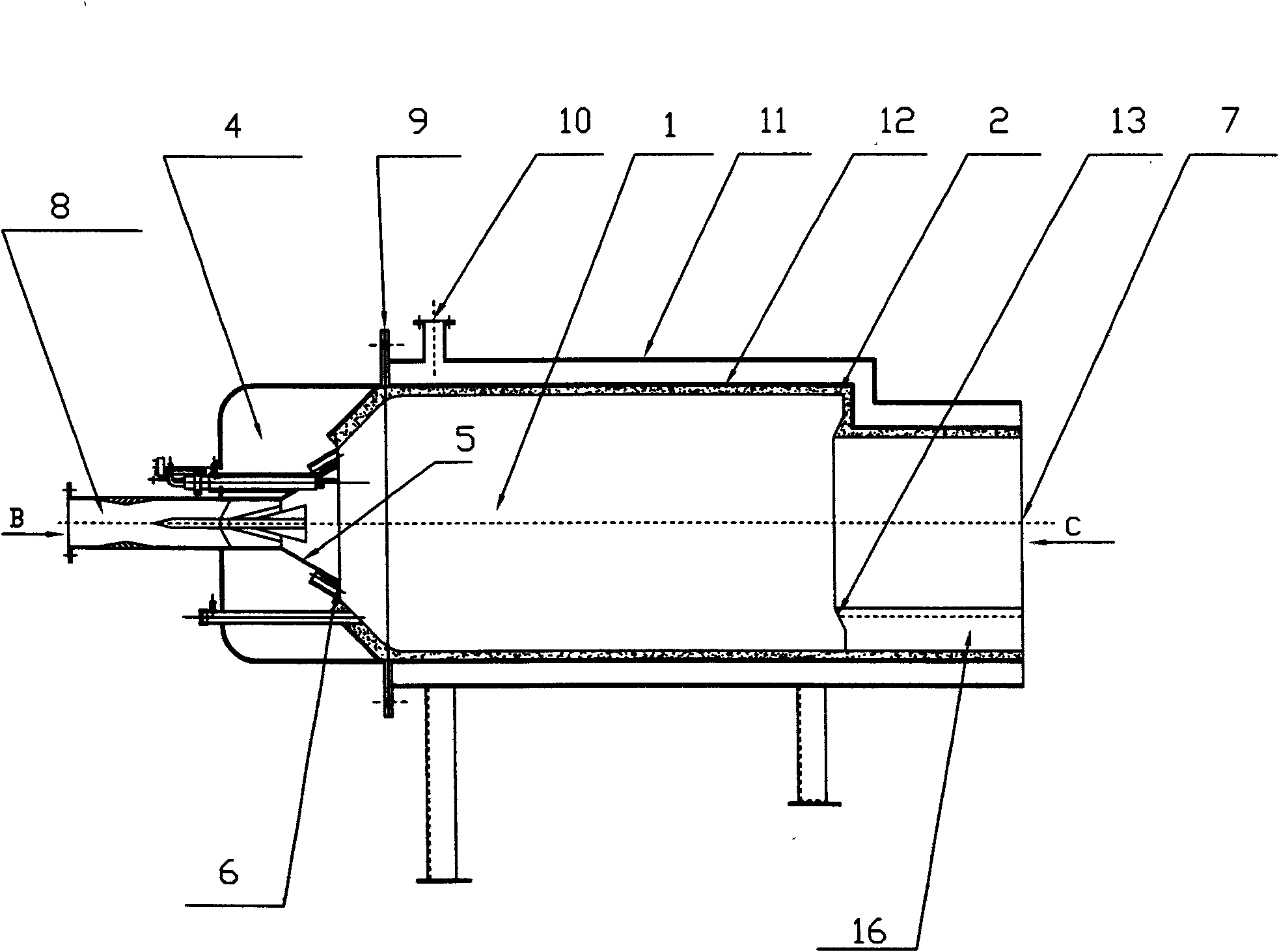

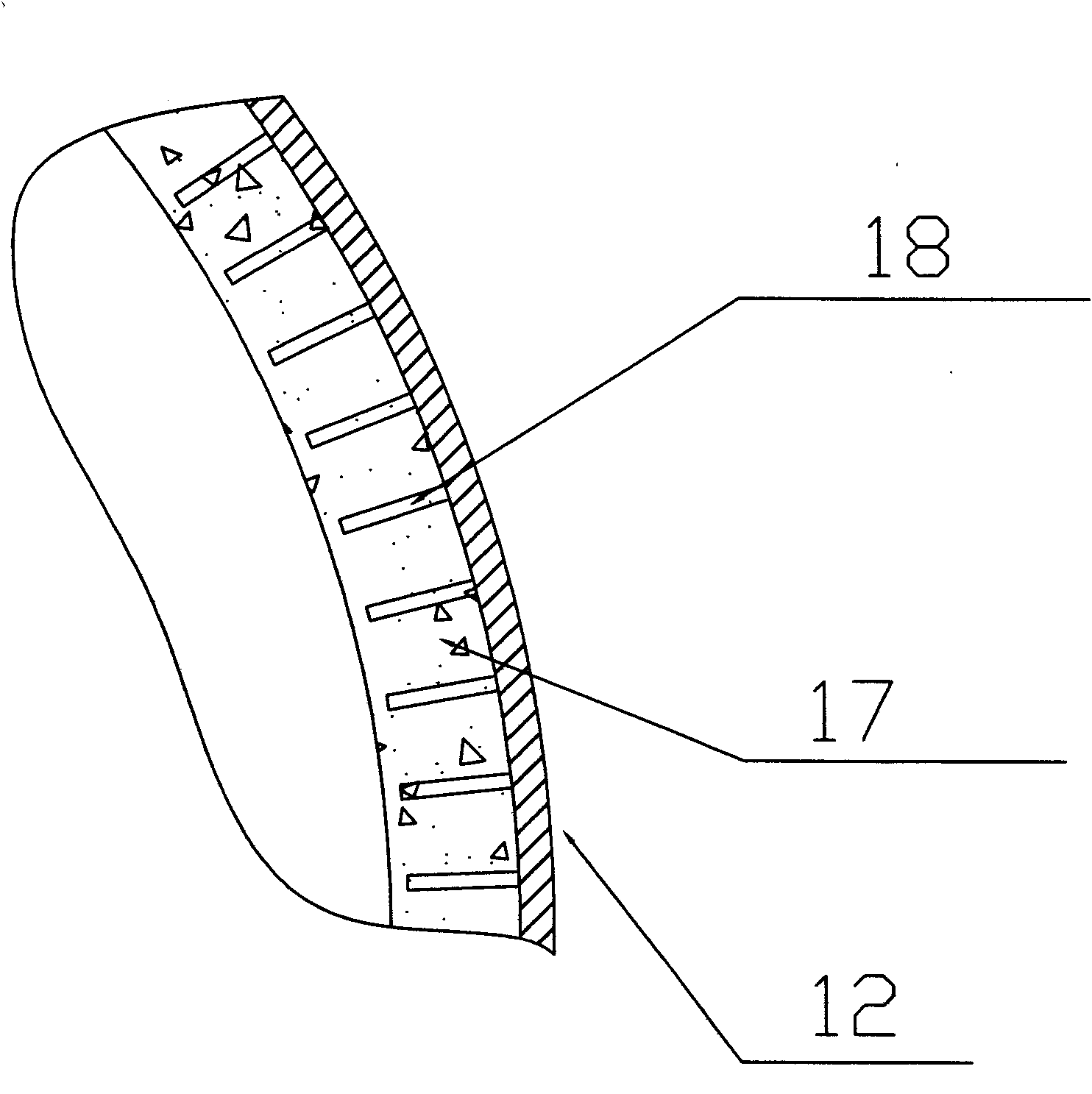

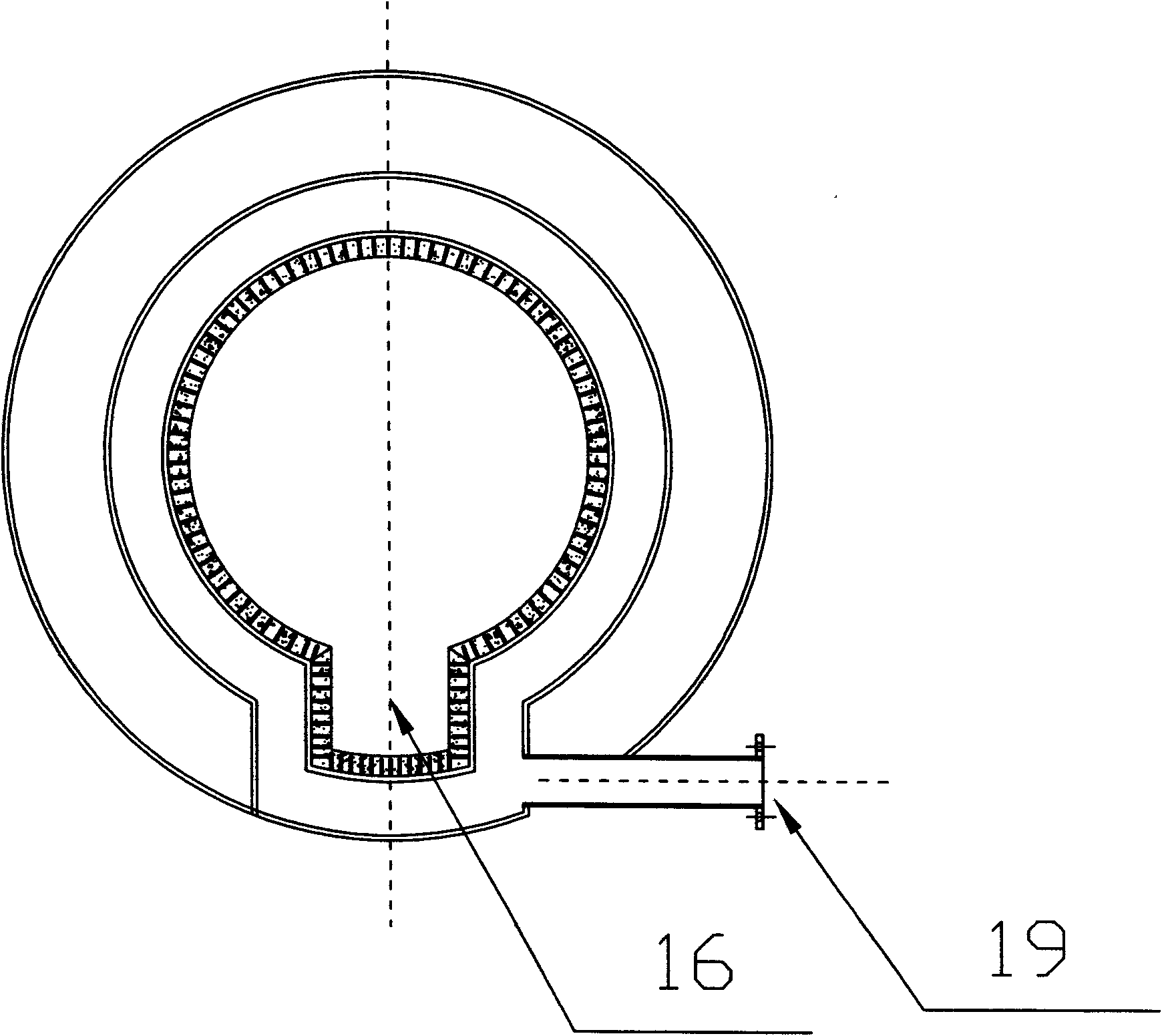

[0034] Such as figure 1 As shown, a kind of low NOx solid-liquid slagging double-swirl pulverized coal combustion equipment provided by the present invention comprises a combustion chamber assembly 1, and the front end of the combustion chamber assembly 1 is provided with a burner port 7, which is connected with the combustion chamber assembly 1. The ratio of the diameter of the chamber assembly 1 is 35%-85%. The rear end of the combustion chamber assembly 1 is connected to the secondary air chamber 2, the primary air / coal powder nozzle 5 of the combustion chamber assembly 1 is set in the secondary air chamber 2, and the combustion chamber assembly 1 is wrapped with a working lining 2 , a cooling water kit 3 is wrapped outside the working lining 2, a swirl cascade 6 is arranged on the primary air / powdered coal nozzle 5, and the axial relative position of the annular swirl cascade 6 and the primary air / powdered coal nozzle 5 0-650 mm, the diameter of the annular secondary air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com