Plasma heating decomposer

A thermal decomposer and plasma technology, applied in the direction of plasma, electrical components, etc., can solve the problems that electrodes are easily ablated, absorb a large amount of heat energy, and have a short service life, so as to overcome the easy ablation of electrodes and protect The effect of ecological environment and clean combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

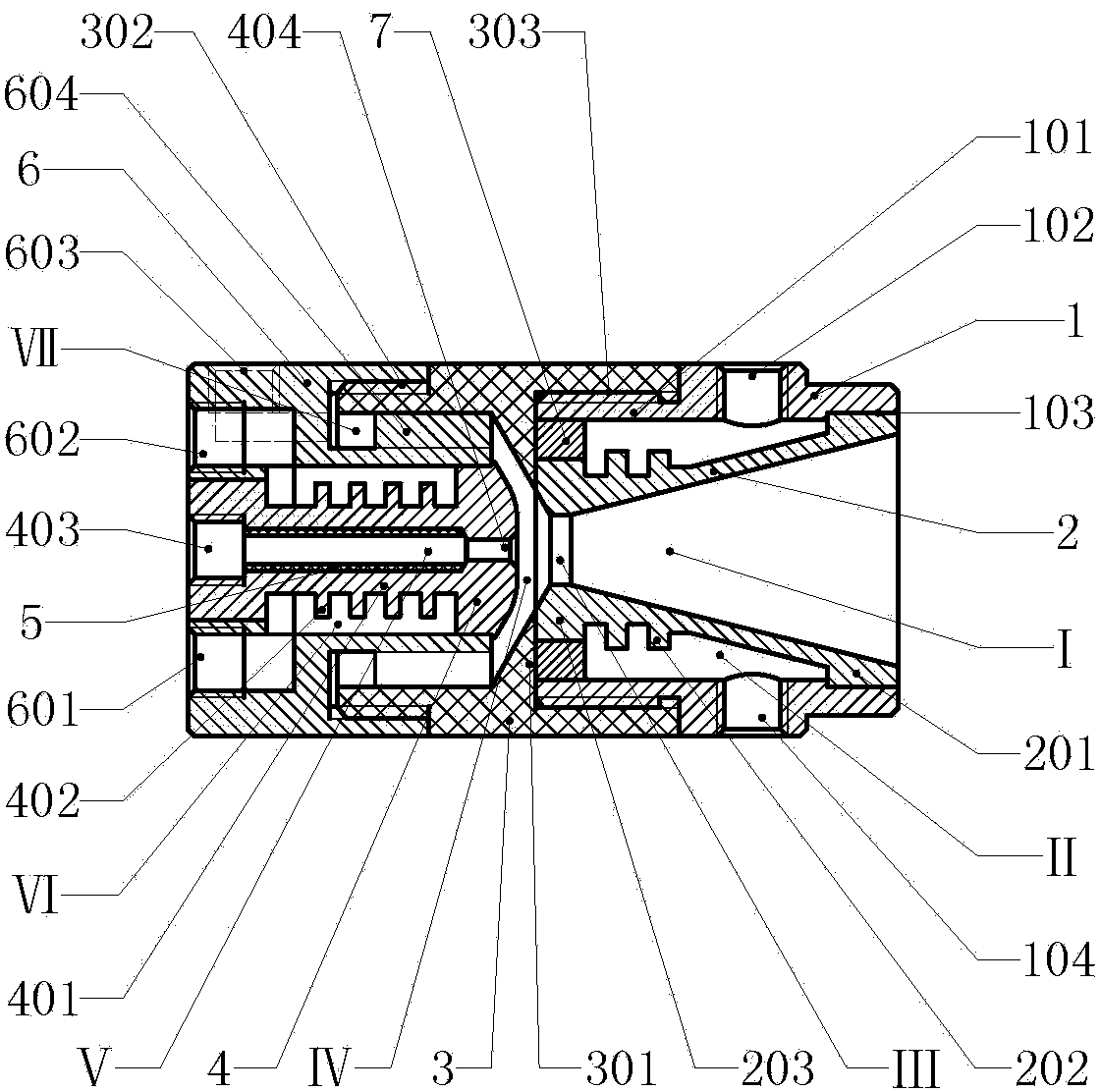

[0014] Example 1 figure 1In the shown embodiment, the plasma thermal decomposer is composed of anode casing (1), anode (2), cathode base (6), cathode (4) and insulating frame (3), wherein the anode casing (1) It is a circular sleeve structure, the front part of the anode sleeve (1) has a socket (103); the anode (2) is a trumpet-shaped rotary structure, and the anode (2) includes a front head (201), a trumpet-shaped wall and a rear The end (203), the trumpet-shaped inner space of the anode (2) constitutes a diffusion chamber (I), and the throat at the rear end of the diffusion chamber (I) constitutes a compression channel (Ⅲ), the compression channel (Ⅲ) is a circular straight hole, and the anode (2) Embedded in the anode sleeve (1), the front end (201) of the anode (2) is tightly assembled with the socket (103) at the front of the anode sleeve (1), and the outer wall of the anode (2) is connected to the anode sleeve ( There is a space between the inner walls of 1), and the sp...

Embodiment 2

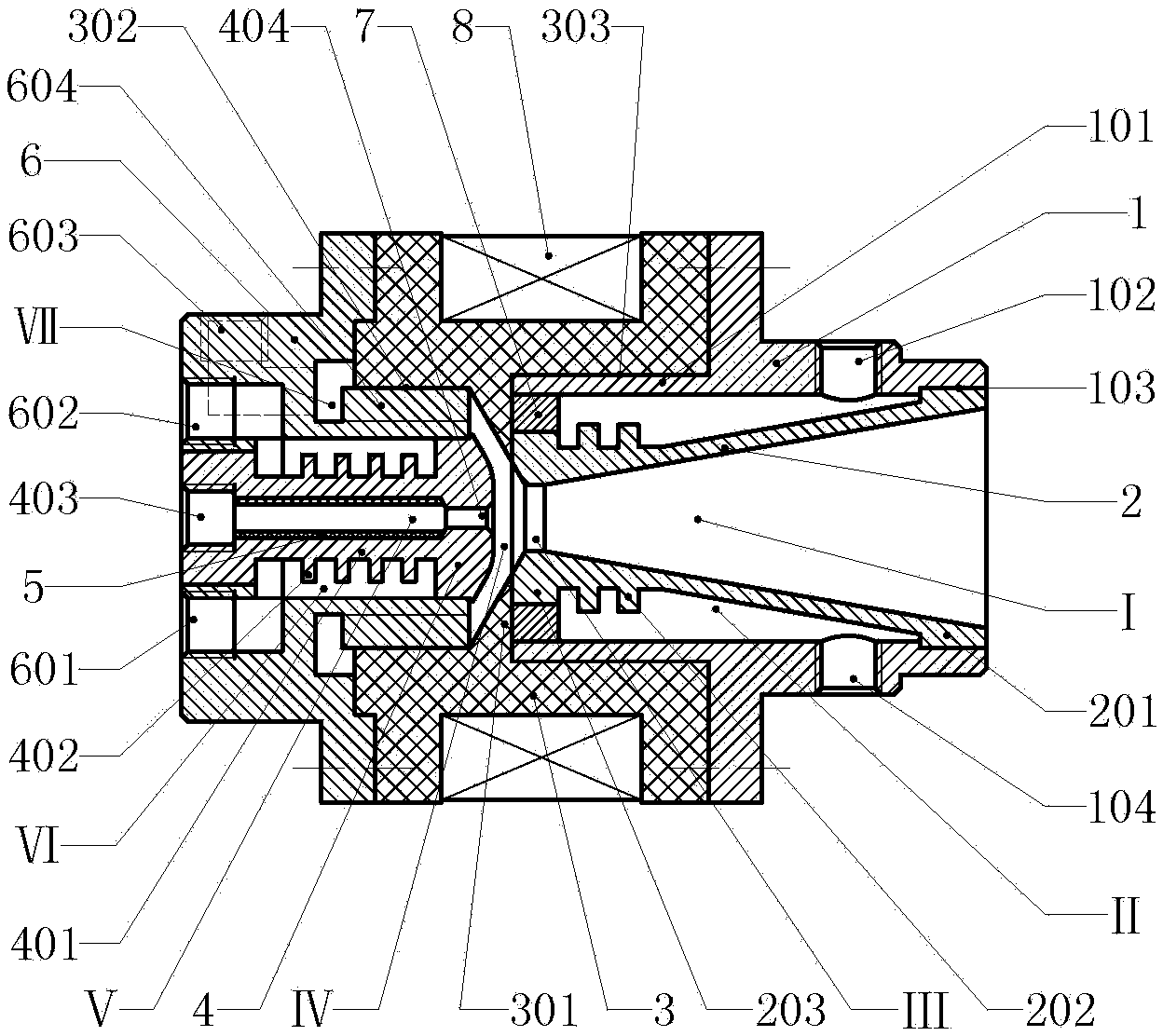

[0015] Example 2 figure 2 In the embodiment shown, the anode sleeve (1), insulating frame (3) and cathode base (6) are connected by means of flange connection, and the insulating frame (3) is used as a coil skeleton at the same time. 3) An electromagnetic coil (8) is arranged on the periphery. When working, the magnetic field generated by the electromagnetic coil (8) shrinks the ion arc inward to obtain a higher torch temperature. Other aspects are the same as those of the first embodiment, and will not be repeated here.

[0016] In the above embodiment, the anode cover (1) and the cathode base (6) are made of stainless steel, the anode (2) and the cathode (4) are made of red copper, and the insulating frame (3) is made of bakelite or polytetrafluoroethylene The material is made, and the thermal insulation bushing (5) is made of polytetrafluoroethylene material for use.

[0017] The above-mentioned embodiments are used as pyrolysis water hydrogen production equipment or as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com