Coal combustion catalyst and preparation method thereof

A technology for combustion catalysts and co-catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc. Combustion performance and other issues to achieve the effect of improving combustion efficiency and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a kind of preparation method of coal combustion catalyst, comprises the following steps:

[0039] Add quicklime, bauxite, ferric chloride, calcium chloride, tourmaline powder, ethanolamine, surfactant, co-catalyst, penetrating agent, rare earth oxide or rare earth chloride into water, and ultrasonically mix for 80-120 minutes to obtain a coal combustion catalyst.

[0040] The above-mentioned quicklime, bauxite, ferric chloride, calcium chloride, tourmaline powder, ethanolamine, surfactant, promoter, penetrating agent, rare earth oxide, and rare earth chloride are all the same as above, and will not be repeated here.

[0041] In the above technical solution, the catalyst is a water-soluble concentrated liquid, which is convenient to add, has strong operability, and has a wide application range; the catalyst has good stability and can be stored for a long time without affecting the use effect. The prepared catalyst can improve coal comb...

Embodiment 1

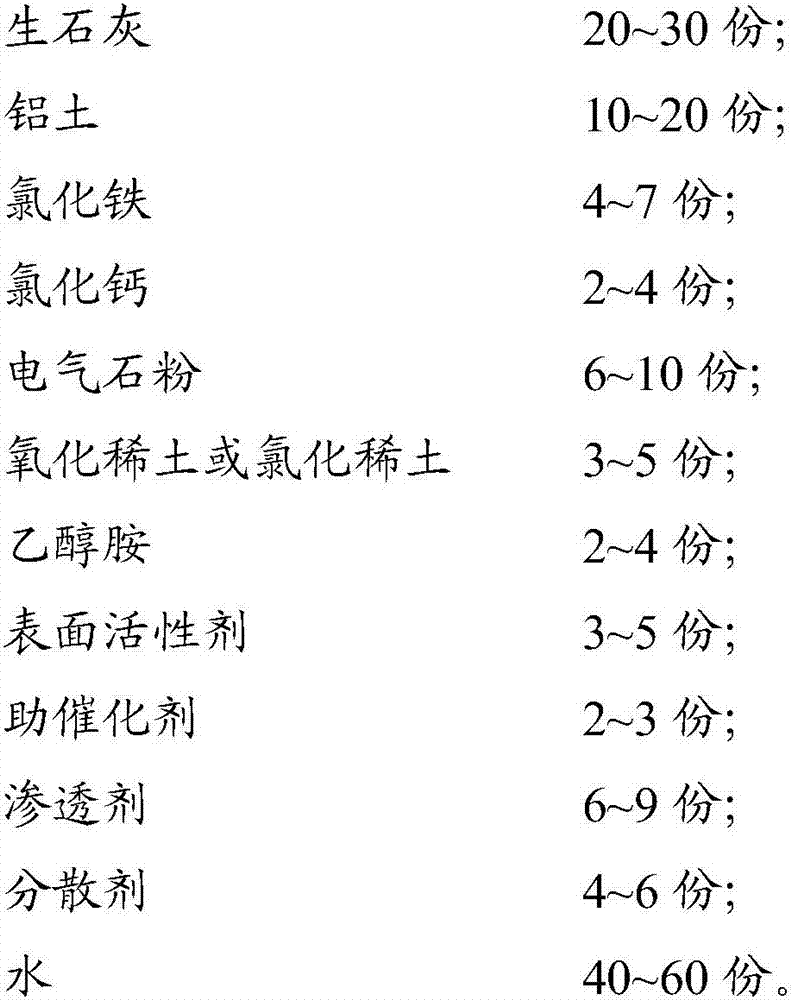

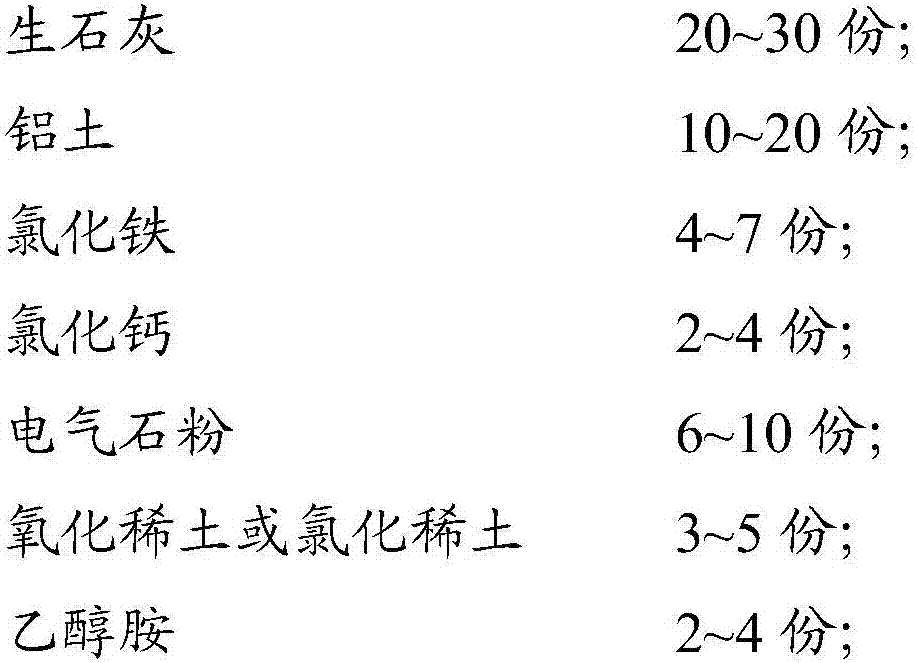

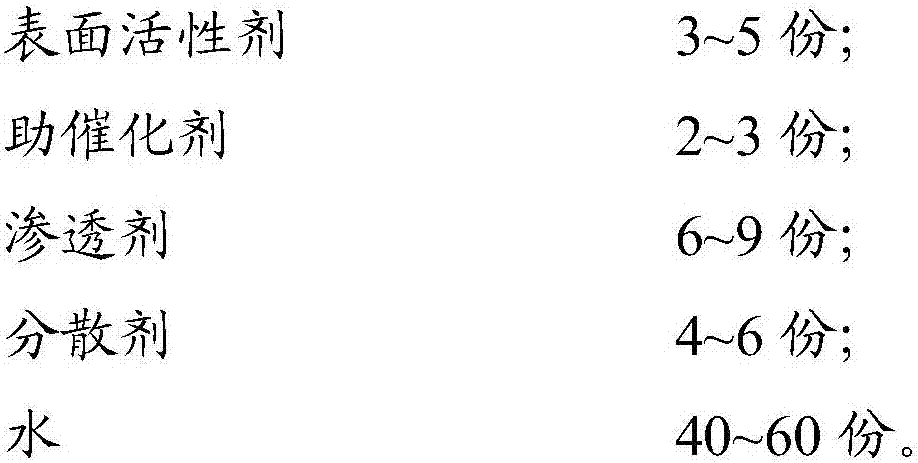

[0044] The coal combustion catalyst includes the following raw materials in parts by weight:

[0045] 28 parts of quicklime, 14 parts of bauxite, 5 parts of ferric chloride, 2.8 parts of calcium chloride, 8.5 parts of tourmaline powder, 1.9 parts of yttrium oxide, 1.9 parts of cerium oxide, 2.8 parts of N-ethyldiethanolamine, 3.5 parts of dehydration Sorbitan monostearate, 2.4 parts of nickel nitrate, 7 parts of polyvinylpyrrolidone, 4.8 parts of zinc stearate and 48 parts of water;

[0046] The preparation method of coal combustion catalyst comprises the following steps:

[0047] Add quicklime, alumina, ferric chloride, calcium chloride, tourmaline powder, N-ethyldiethanolamine, sorbitan monostearate, nickel nitrate, polyvinylpyrrolidone, zinc stearate, and yttrium oxide to water and cerium dioxide, ultrasonically mixed for 80 minutes to obtain a coal combustion catalyst.

Embodiment 2

[0049] The coal combustion catalyst includes the following raw materials in parts by weight:

[0050] 26 parts of quicklime, 18 parts of bauxite, 4.5 parts of ferric chloride, 2.5 parts of calcium chloride, 7.5 parts of tourmaline powder, 2.1 parts of yttrium chloride, 2.1 parts of cerium dichloride, 3.6 parts of N-propyldiethanolamine, 4.5 parts Polyoxyethylene fatty alcohol ether, 2.2 parts of copper nitrate, 8 parts of sucrose alcohol, 4.5 parts of polyethylene wax and 45 parts of water;

[0051] The preparation method of coal combustion catalyst comprises the following steps:

[0052] Add quicklime, bauxite, ferric chloride, calcium chloride, tourmaline powder, N-propyldiethanolamine, polyoxyethylene fatty alcohol ether, copper nitrate, sucrose alcohol, polyethylene wax, yttrium chloride and dichloride to water Cerium, ultrasonically mixed for 120 minutes to obtain a coal combustion catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com