Fuel-atomizing integrated igniter

A fuel atomization and igniter technology, which is used in combustion ignition, combustion methods, lighting and heating equipment, etc., can solve the problems of forming a stable ignition source in the area that is not easy to return, unable to ensure stable combustion, and flame blowing out, etc. Achieve reliability, easy replacement of parts, and reliable ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

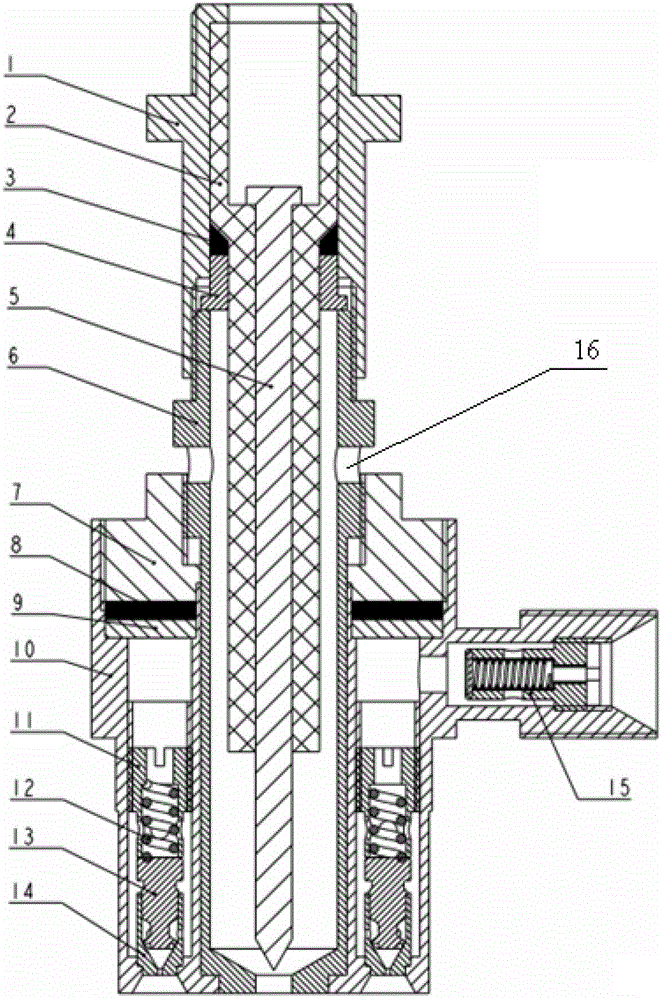

[0019] The structural composition of the fuel atomization integrated igniter of the present invention mainly includes: power connector 1, ceramic insulating medium 2, graphite sealing ring 3, support ring 4, inner electrode 5, grounding electrode 6, compression cover 7, sealing gasket 8 , Compression ring 9, fuel atomization assembly housing 10, fixed hollow nut 11, support spring 12, swirler 13, swirler housing 14, oil filter 15, air guide hole 16.

[0020] An air plasma igniter composed of an inner electrode 5 located in the center, a ground electrode 6 located outside the inner electrode, a ceramic insulating medium 2 between the inner electrode and the ground electrode, and a power connector 1. A supporting ring 4 is arranged between the ground electrode and the ceramic insulating medium, a certain gap is formed between the ground electrode and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com