Patents

Literature

172results about How to "Guaranteed to burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetized diesel oil

This invention relates to synthetic diesel oil, which is produced by: (1) mixing isooctyl nitrate 30 wt.%, cyclohexylamine 30 wt.%, ferrocene 30 wt.%, and zinc peroxide 10 wt.% to obtain composite additive; (2) mixing fossil-grade diesel oil 10-40 parts and the composite additive 0.3-2 parts to obtain mother diesel oil; (3) mixing 200# solvent oil 10-30 parts and lightweight aviation kerosene 5-20 parts to obtain modified 200# solvent oil; (4) mixing fatty acid methyl ester or C9 10-60 parts, the mother diesel oil and the modified 200# solvent oil to obtain the synthetic diesel oil. The synthetic diesel oil has such advantages as low cost, simple process and abundant raw materials, and can be used for replacing standard fossil-grade diesel oil.

Owner:固安中德利华石油化学有限公司

Air volume self-adaptive gas water heater control system

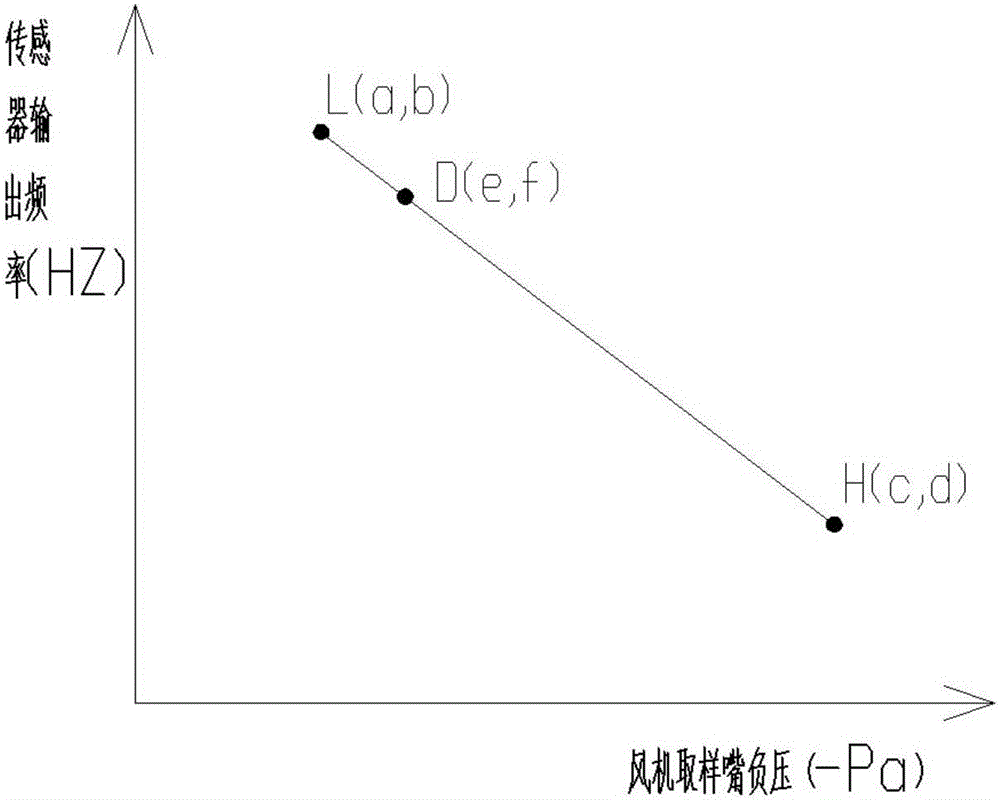

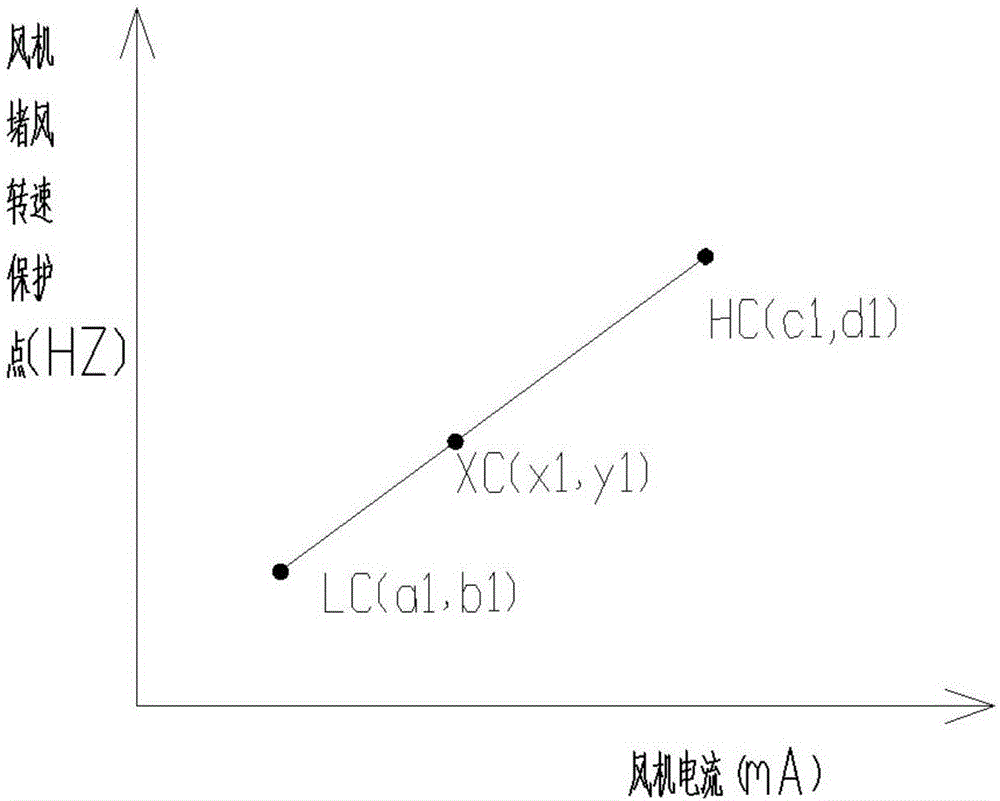

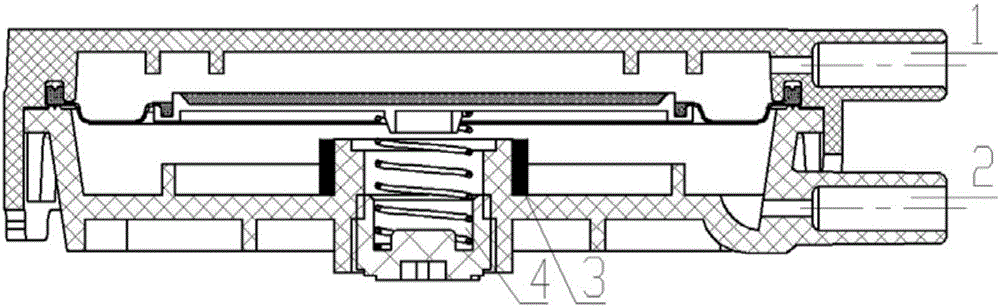

The invention discloses an air volume self-adaptive gas water heater control system which is characterized by comprising a main controller and an air pressure sensor connected with the main controller. By means of the main controller, all thermal loads of a gas water heater can correspond to output frequency of the air pressure sensor in a one-to-one mode; when the gas water heater is in a certain thermal load state, the main controller can change fan current to enable the output frequency of the air pressure sensor to be kept at a corresponding value all the time. According to the air volume self-adaptive gas water heater control system disclosed by the invention, a rotation speed of a fan is controlled according to frequency signals, the burning insufficiency phenomenon caused by factors of smoke exhaust block, altitude difference and the like is completely avoided, and adaptation, safety and high efficientibility of the gas water heater are wholly improved; when a low-cost motor is replaced in later, whether property and technical parameters of a replaced motor are completely identical with those of the low-cost motor need not be taken into consideration, and great convenience is brought to engineering design and after sale.

Owner:GUANGDONG MACRO GAS APPLIANCE

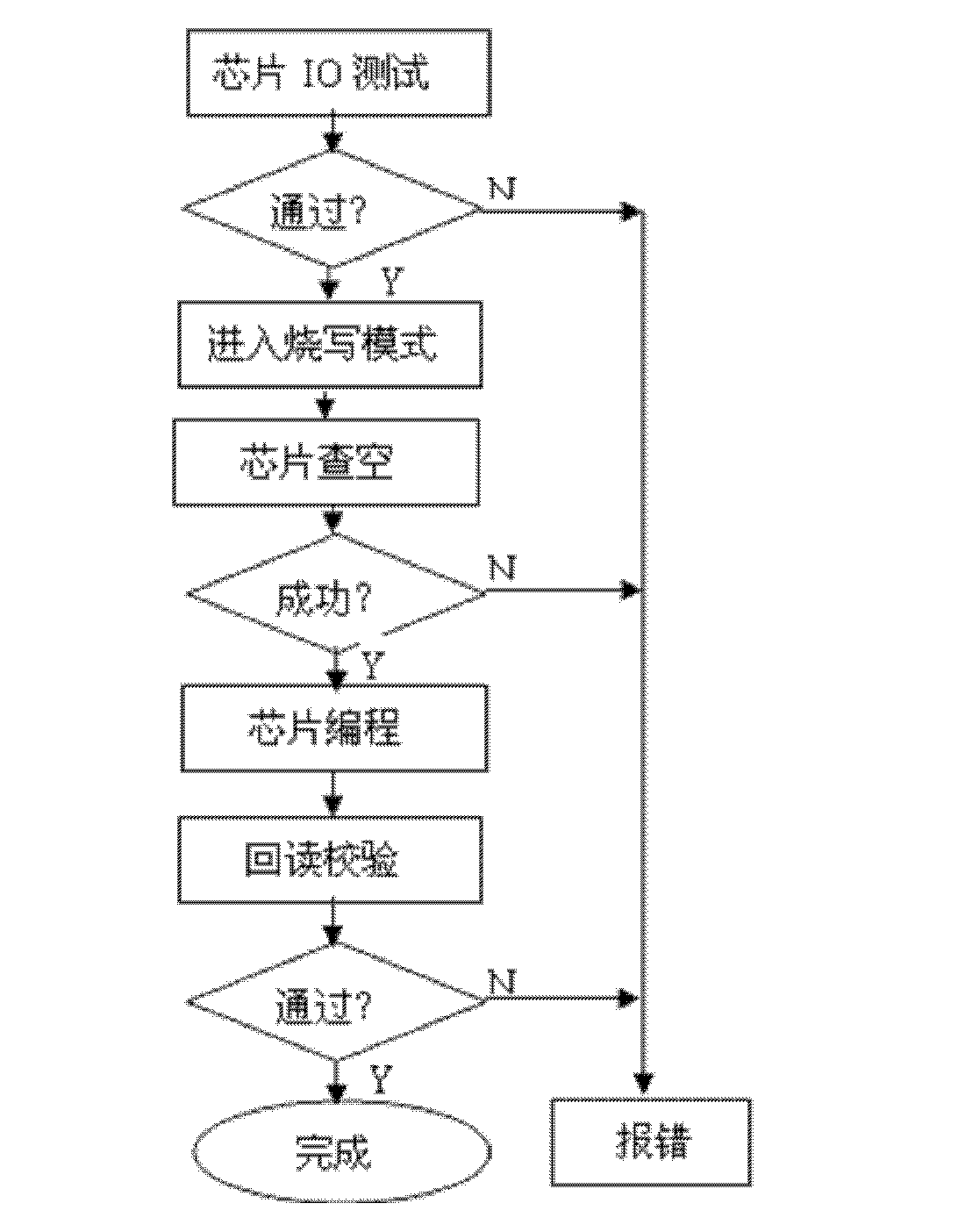

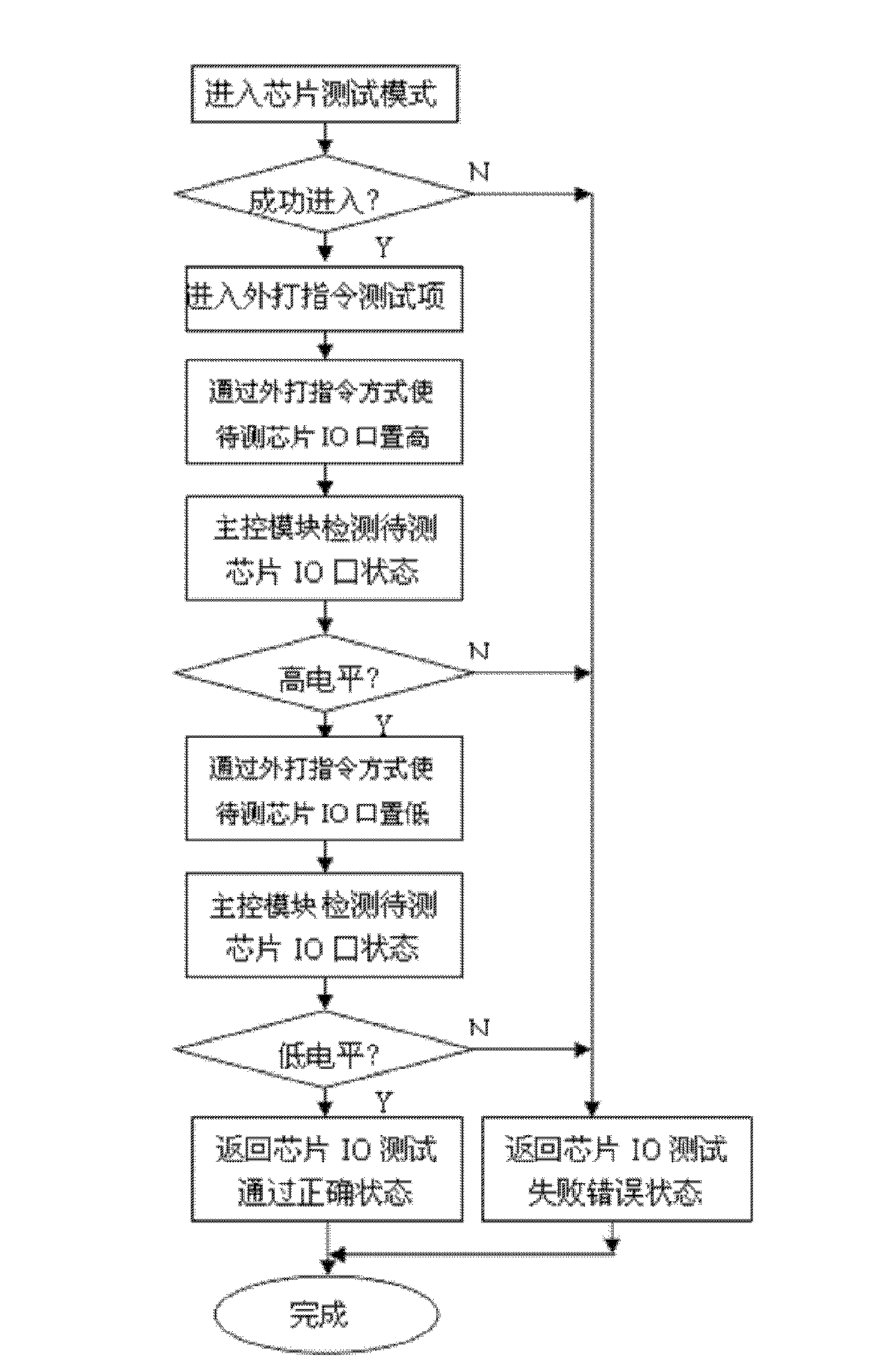

Burner with chip test function and burning method thereof

ActiveCN102568580AEliminate insertion errorsExclusionsRead-only memoriesElectrical testingHuman–machine interfaceEmbedded system

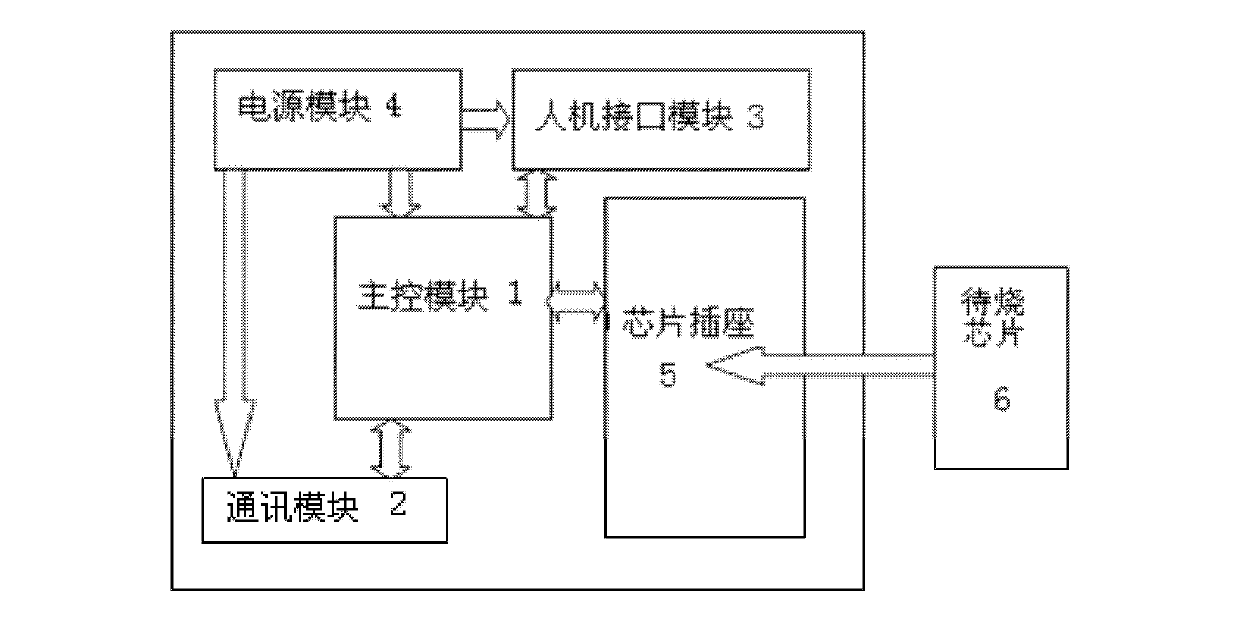

The invention discloses a burner with chip test function and a burning method of the burner. The burner comprises a main control module, a communication module, a human-machine interface module and a power supply module that provides a power supply to the above modules. The main control module is mainly used to control sending, receiving and storing communication data for the communication module and to interact with the human-machine interface module. The burner further comprises a chip socket connected with the main control module through a burning pin. A chip to be burned is inserted into the chip socket and controlled by the main control module. The pin for test is introduced from the chip socket end. The pin for test is further connected with the main control module. The main control module comprises a chip IO test program that monitors whether the IO interface of the chip to be burned can be placed in a high position and a low position under a test mode or not. The invention can eliminate conditions such as misplugging of the chip, reversed plugging and the like, and ensures that the chip to be burned and the internal elements in the burner are free from overburning.

Owner:CRM ICBG (WUXI) CO LTD

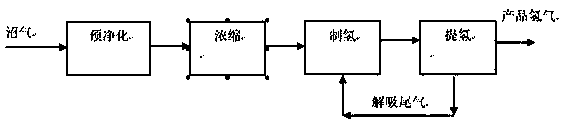

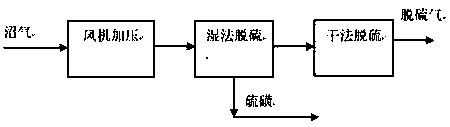

Method for producing hydrogen from biogas biomass

Owner:SICHUAN TECHAIRS

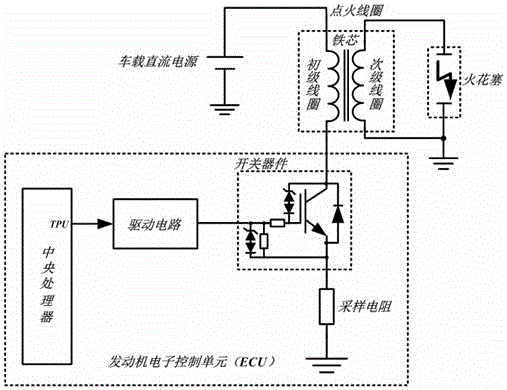

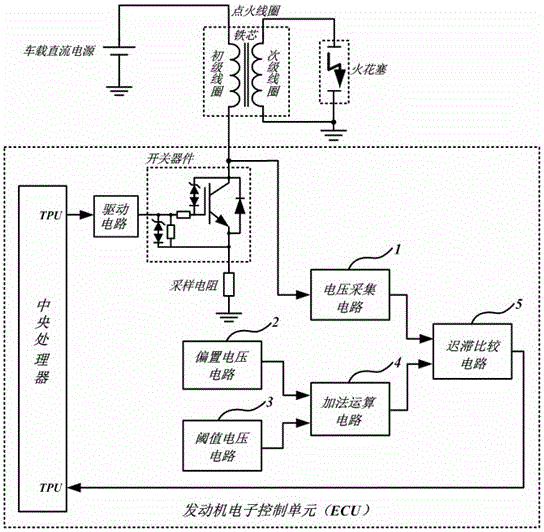

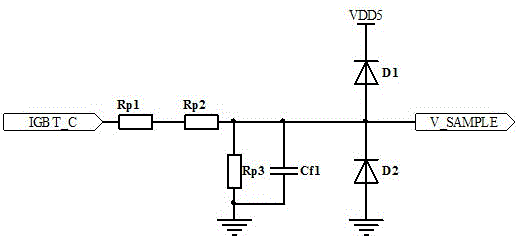

Spark duration time monitoring circuit for engine ignition system

ActiveCN106286072AReduced service lifeGuaranteed to burnOther installationsMachines/enginesIgnition coilEngineering

The invention relates to a spark duration time monitoring circuit for an engine electronic control ignition system. The spark duration time monitoring circuit is characterized in that a time processing unit channel of a central processing unit is connected with the grid electrode of a switching element IGBT through a drive circuit of the switching element IGBT; the collector electrode of the switching element IGBT is connected with the first end of an ignition primary coil; the second end of the ignition primary coil is connected with a vehicle-mounted direct-current power source; the collector electrode voltage of the switching element IGBT is connected to a time processing unit input port of the central processing unit after passing the spark duration time monitoring circuit, the central processing unit regulates the charging time, namely ignition energy of the primary coil in real time according to the monitored spark duration time, and the spark duration time is controlled within a certain range (please see the range in the specification). By means of feedback signals of the spark duration time monitoring circuit of the ignition system, the charging time, namely the ignition energy of the primary coil is regulated in real time, the spark duration time is controlled within a certain range, and the purposes that it is guaranteed that mixed gas in an air cylinder is completely burned every time when ignition of an engine is carried out, and the situation that erosion of electrodes of a sparking plug is accelerated due to tool much ignition energy is provided and the service life of the sparking plug is shortened is avoided are achieved.

Owner:CHINA FIRST AUTOMOBILE

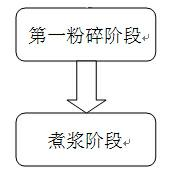

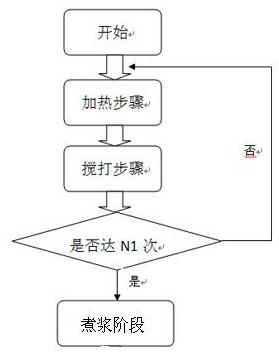

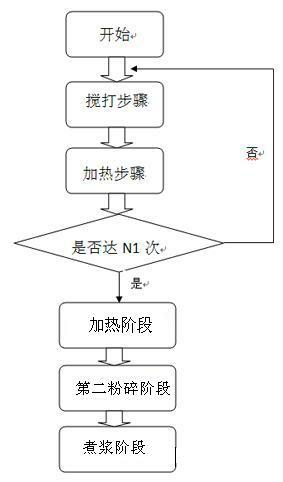

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

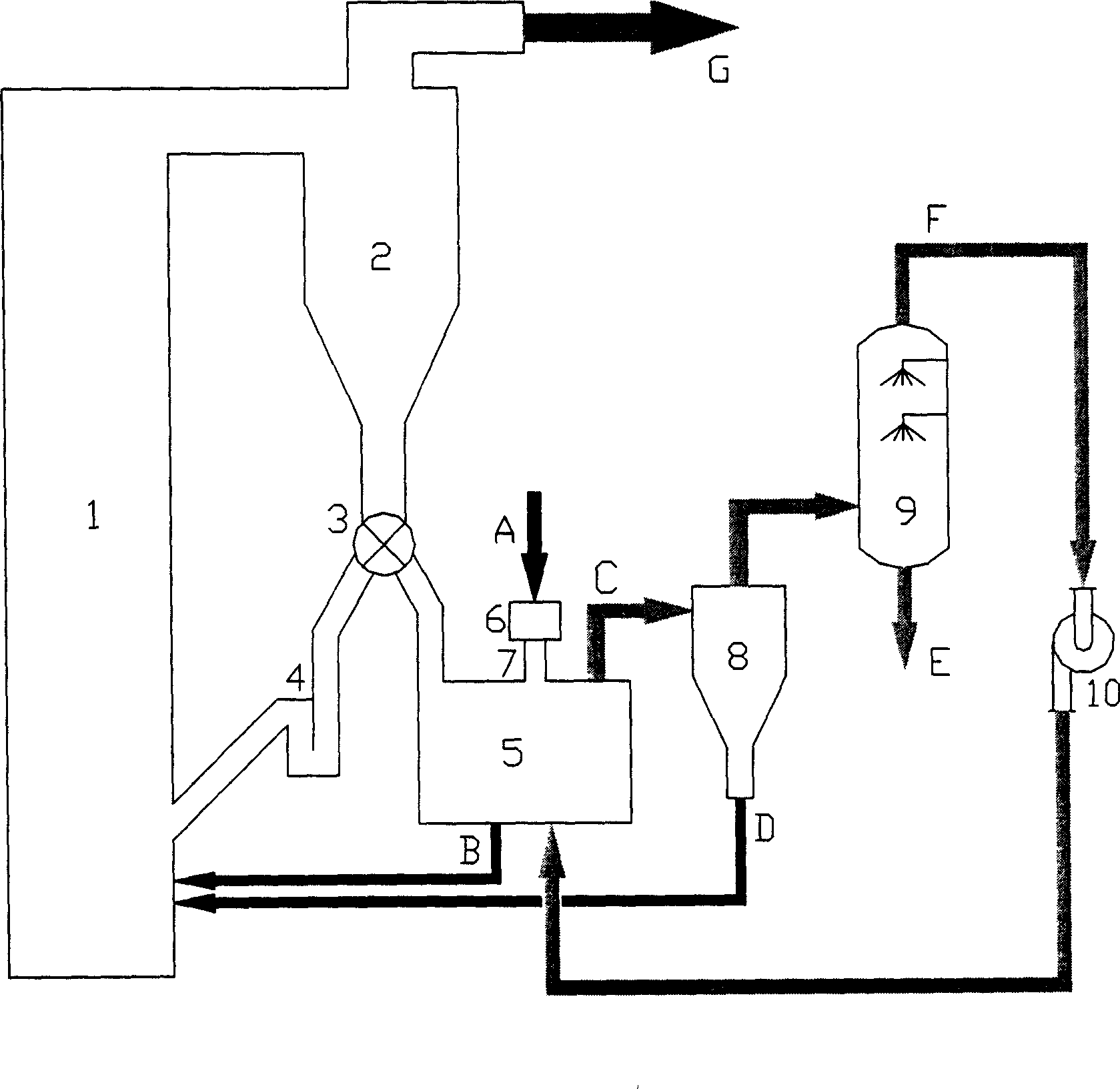

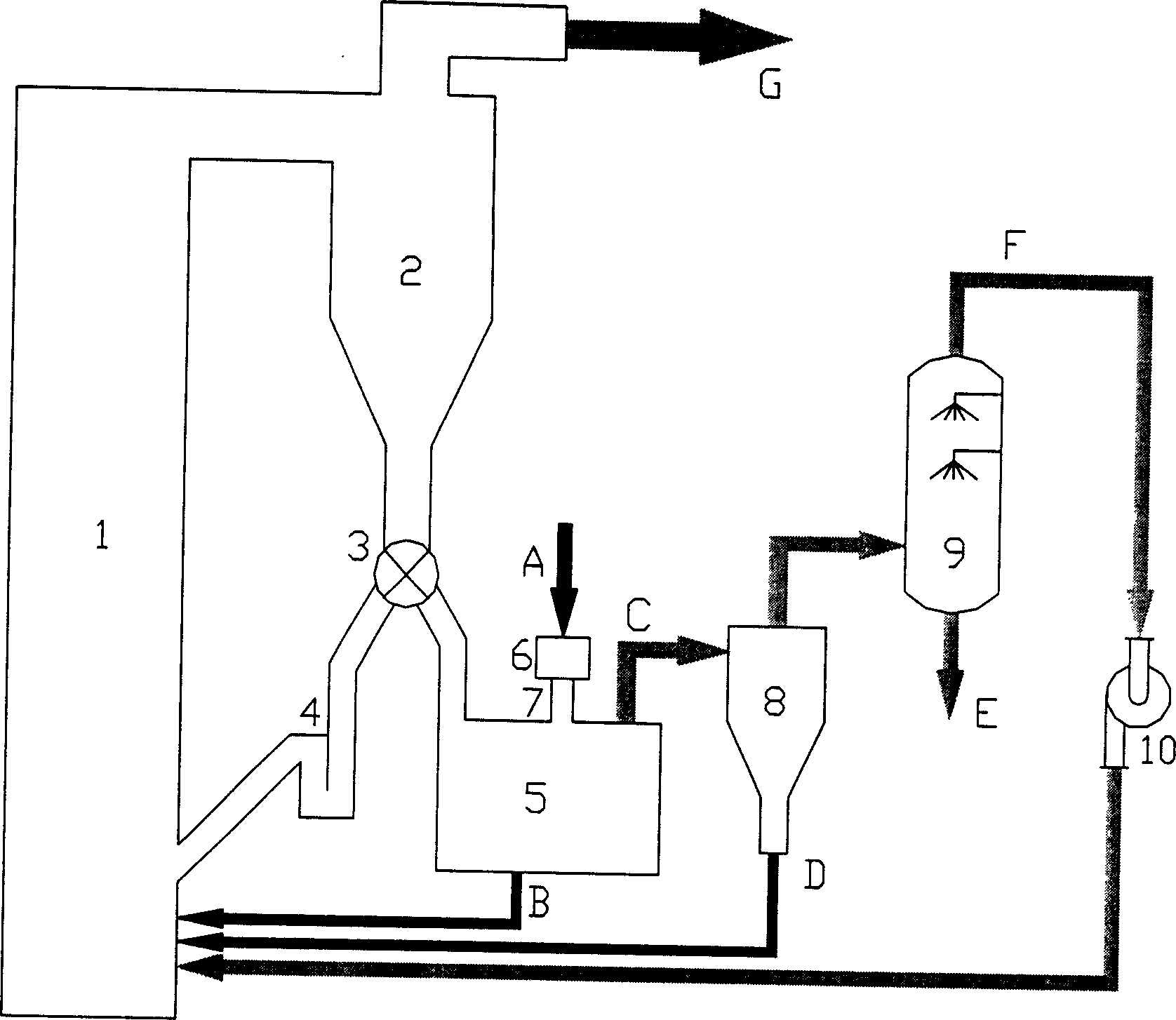

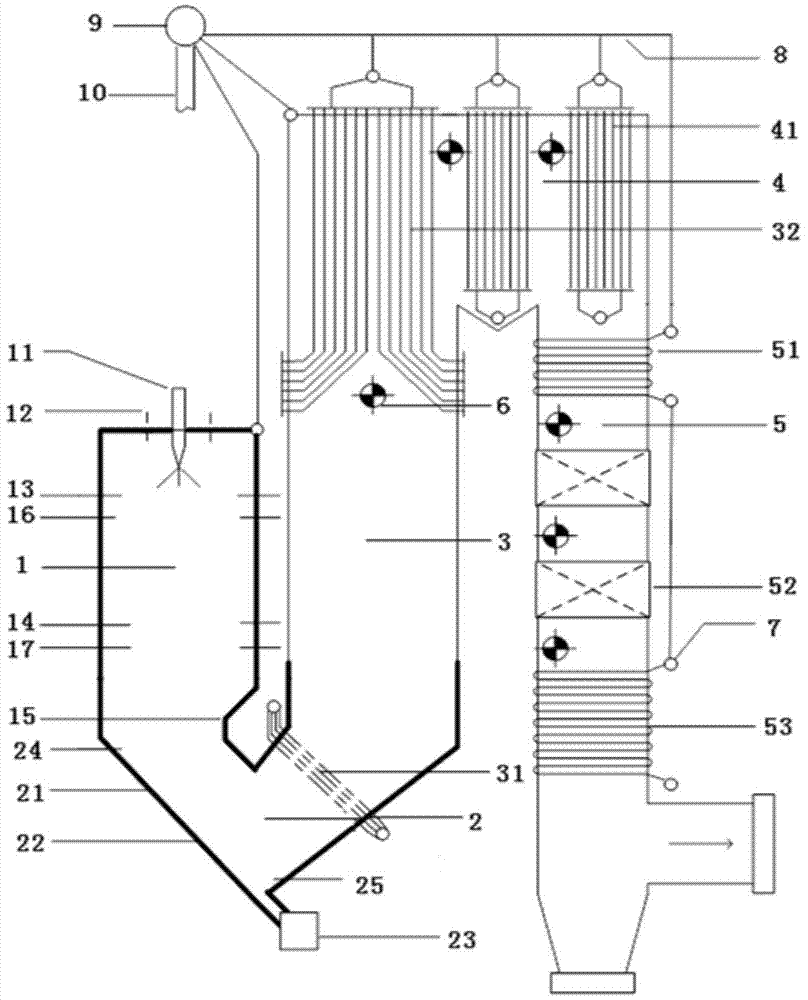

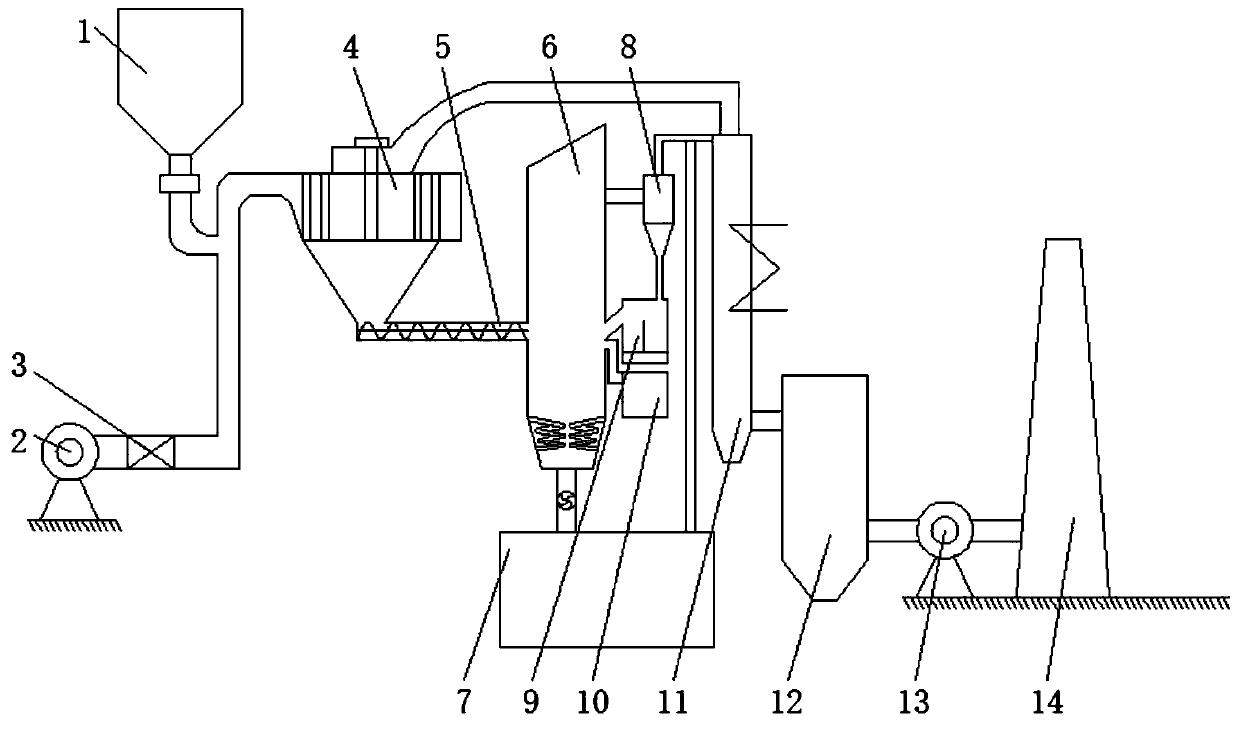

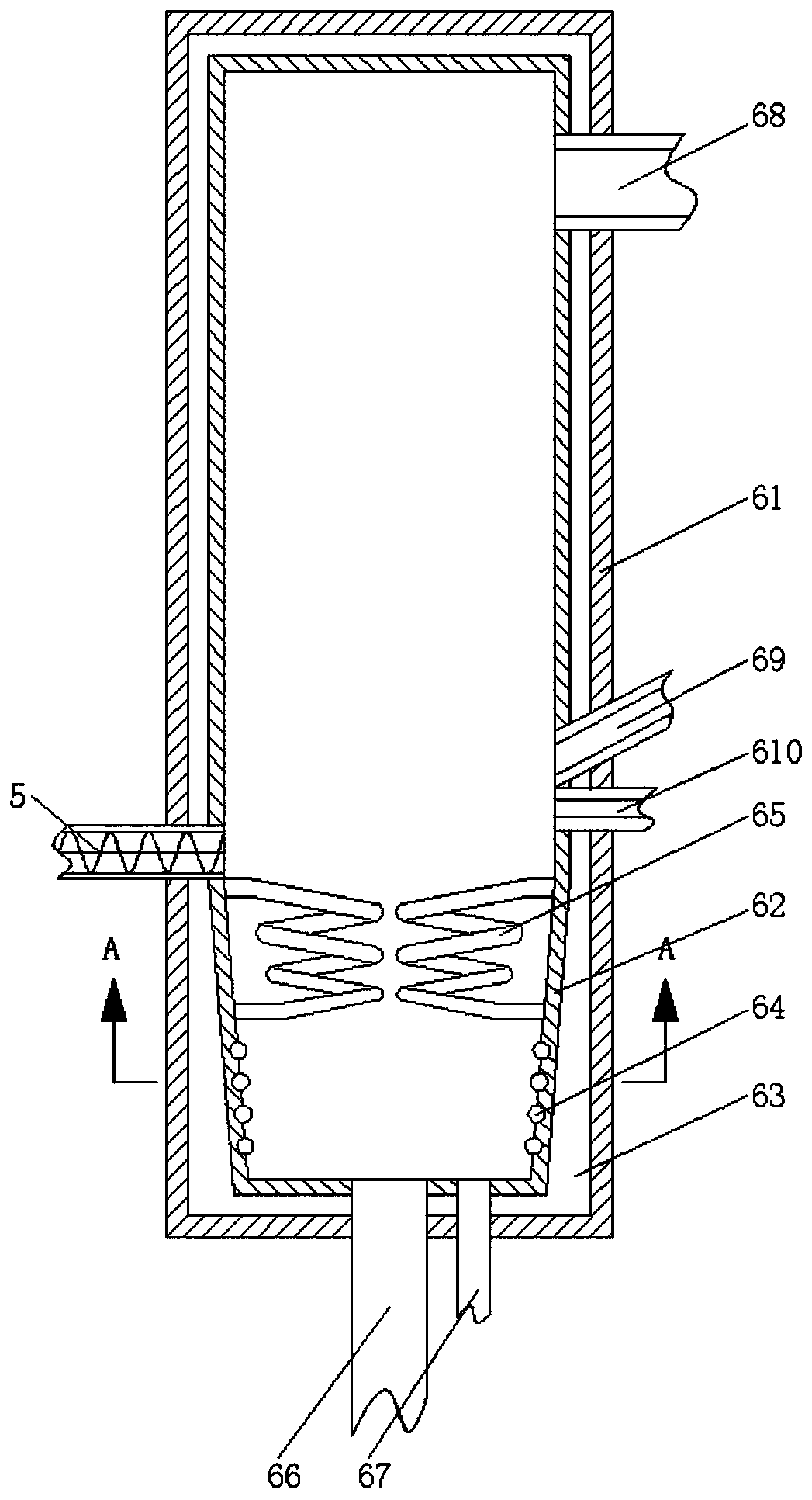

Wet sludge drying and incinerating treatment method employing circulating fluidized bed with particle dryer

ActiveCN1880849ALarge adjustment rangeAerodynamics won't happenIncinerator apparatusSludgeFluidized bed

The invention relates to a method for burning wet sludge with cycle fluid bed with grain drier, wherein in the cycle fluid bed burning furnace or the cycle fluid bed burning furnace burns the wet sludge whose water content is 60-90%; the drying and burning are integrated in one device; the wet sludge being dried in the grain drier is feedback to the hearth with cycle ash to be burnt, to avoid the water content of wet sludge into the tail smoke channel with the high temperature smoke of hearth, but be leaded out with the fluid airflow of grain drier, to reduce the heat loose; and the discharge gas of grain drier, via dust cleaning and wet removing, is used or fed into hearth to be burnt, without smelly gas in the process.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Solid fuel furnace with thermoelectric power generation device

InactiveCN104633713ABurn fullyImprove combustion thermal efficiencyBatteries circuit arrangementsDomestic stoves or rangesAir volumeFuel wood

The invention relates to a solid fuel furnace with a thermoelectric power generation device. The solid fuel furnace comprises a solid fuel furnace and a thermoelectric power generation device; the lower end of a blower box of the thermoelectric power generation device is provided with an exhaust room, and the exhaust room is provided with an air pipe for connecting an exhaust hole with the solid fuel furnace; the air exhaust room is further provided with an air volume balance hole, and an air flap and an adjusting handle are installed in the exhaust room; the air flap is adjusted to close the air exhaust hole or the air volume balance hole, and make that the total air volume is unchanged while the air exhaust volumes of the air exhaust hole and the air volume balance hole are in an inversely proportional relationship. The solid fuel furnace can externally provide stable and enough power source without externally connecting the power source; through reasonable distribution of primary and secondary air, the fuel is fully burned; the solid fuel furnace is featured by simple operation, high burning heat efficiency, and few smoke gas emission; the fuel adaption is wide, and it is especially applicable to various fuel wood and other biomass solid fuels; besides, the solid fuel furnace is simple, small and light in structure, and applicable to indoor cooking and outdoor cooking.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

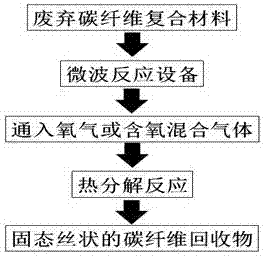

Method of recovering carbon fibers by low-temperature microwave efficient treatment of carbon fiber composite material

InactiveCN107216480AImprove the efficiency and effectiveness of recyclingHeating fastSolid productEnergy source

The invention relates to a method of recovering carbon fibers by low-temperature microwave efficient treatment of a carbon fiber composite material and belongs to the technical field of fiber composite materials. The method comprises the following steps: firstly, putting a waste carbon fiber composite material in a microwave heating device; introducing oxygen or oxygen-containing mixed gas; feeding microwaves, the frequencies of which are 2450+ / -50MHz or 915+ / -50MHz till the temperature is raised to 350-500 DEG C; performing low-temperature treatment for 0.1-1.0h; then naturally reducing the temperature to below 200 DEG C; and taking out the solid product to obtain the carbon fibers. The method is a method of uniformly and efficiently recovering high value carbon fibers from the waste carbon fiber composite material at a low temperature at a normal pressure. According to the method, organic matters of resin are oxidized to combust at the low temperature, and the integrity of the carbon fibers is ensured. The carbon fibers are regenerated and recycled while the mechanical property and recovery rate of the carbon fibers are increased, the reaction time is shortened, the reaction flow is simplified, the energy source is saved and the environment is protected.

Owner:KUNMING UNIV OF SCI & TECH

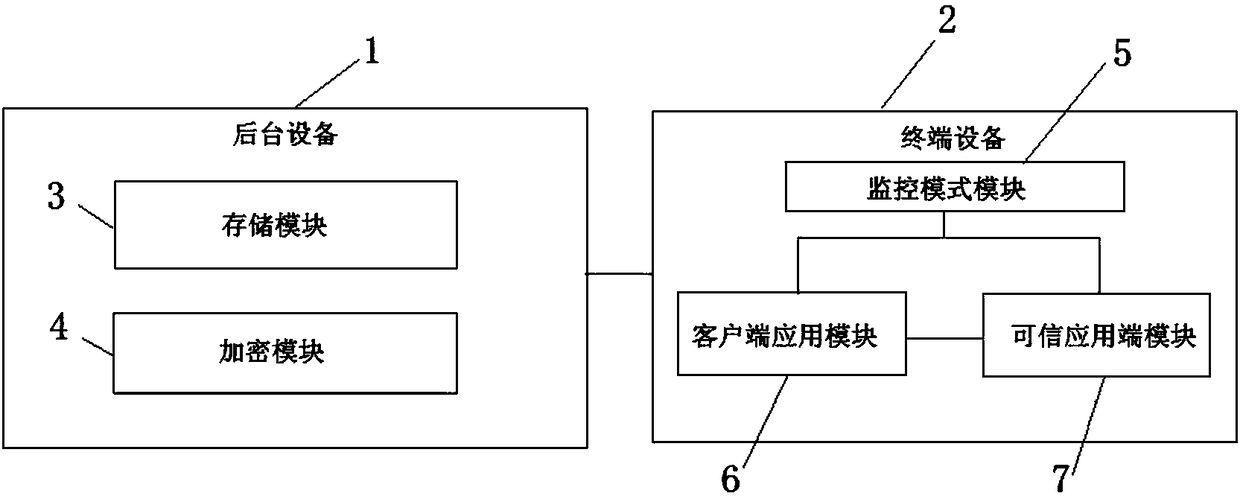

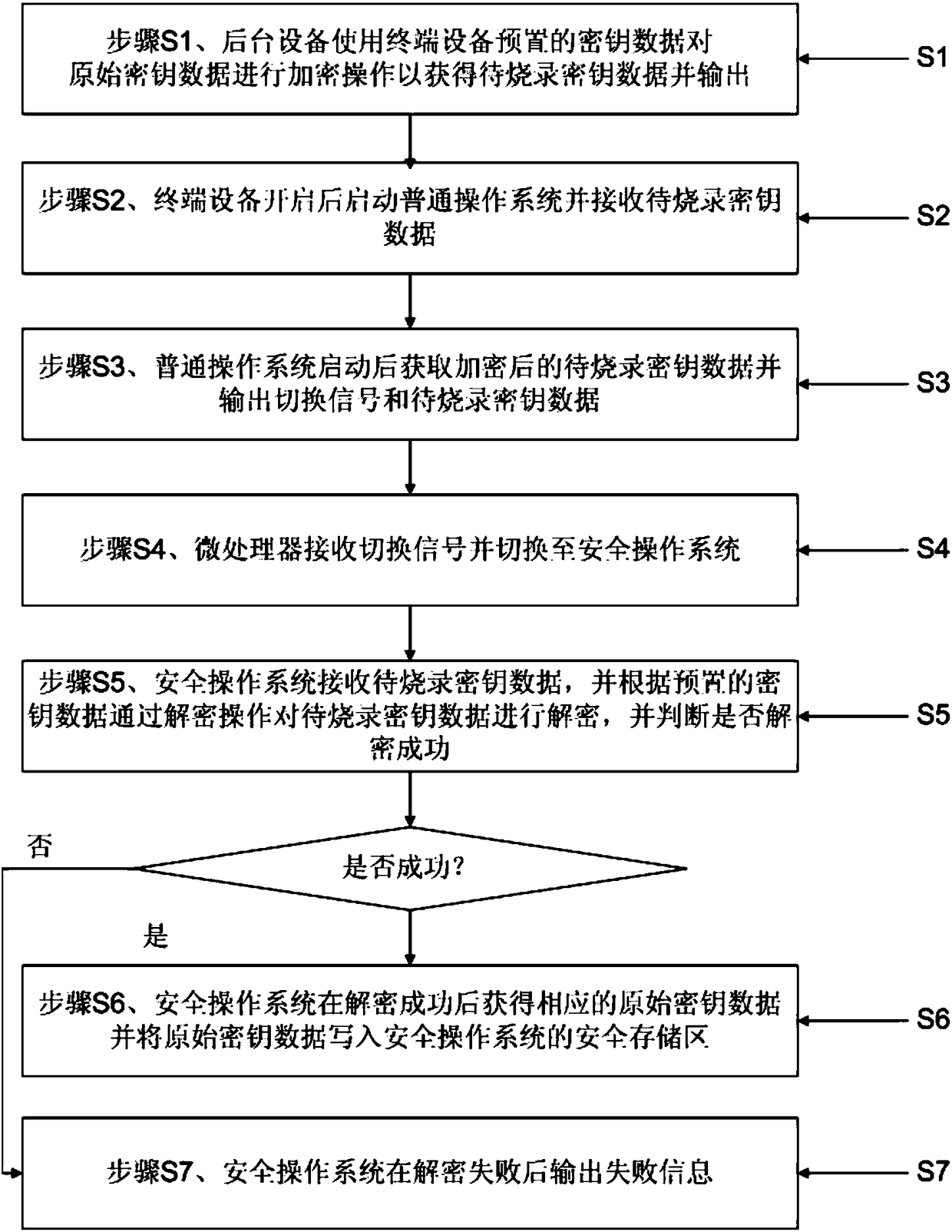

Trusted execution environment-based key burning system and method

InactiveCN108155986ABurn GuaranteeEnsure safetyKey distribution for secure communicationInternal/peripheral component protectionMonitor modeTransfer procedure

The invention provides a trusted execution environment-based key burning system, belonging to the field of data security. After a terminal device is enabled, a common operation system is started, thecommon operation system acquires to-be-burned key data and outputs a switch signal and the to-be-burned key data, a microprocessor receives the switch signal in a monitor mode, the processor is switched to a safe operation system from the common operation system, the safe operation system receives the to-be-burned key data and decrypts the to-be-burned key data according to preset key data, acquires corresponding original key data after success decryption and writes the original key data into a safe storage area of the safe operation system. The trusted execution environment-based key burningsystem has the beneficial effects that due to use of trusted execution environment-based key burning, the key is burned, stored and used safely, in addition, the cryptography protects the key from unexpected damage in transmission and keeps the key integral.

Owner:AMOLOGIC (SHANGHAI) CO LTD

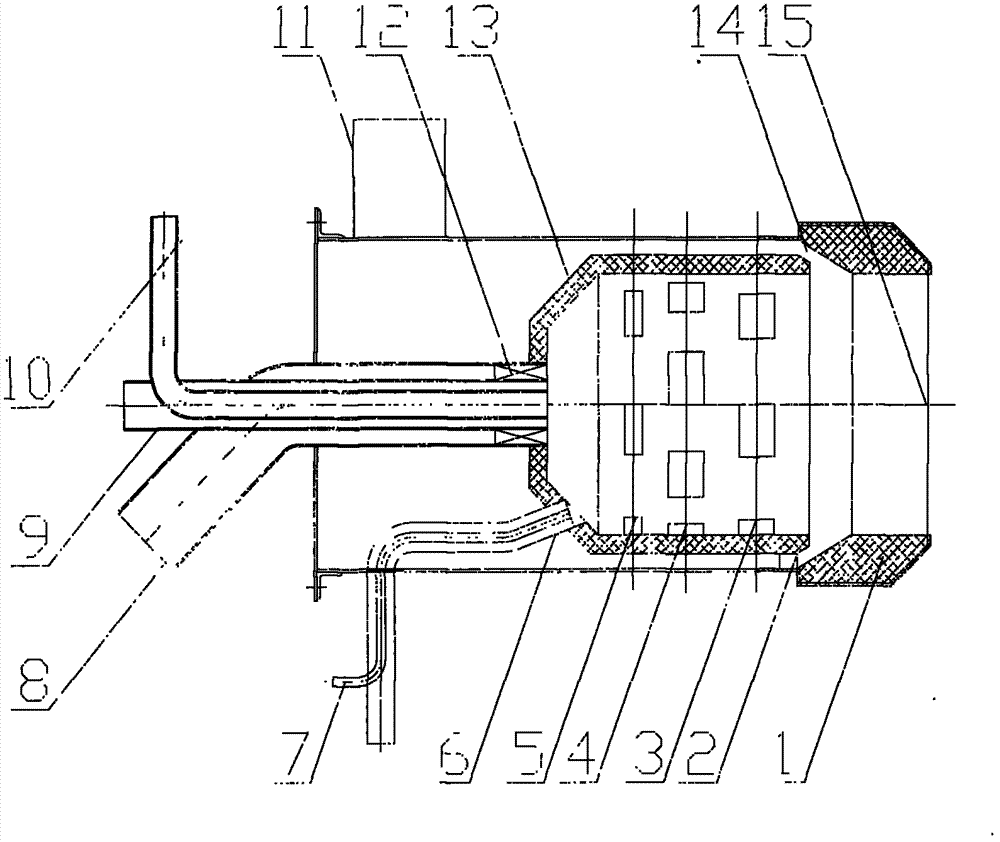

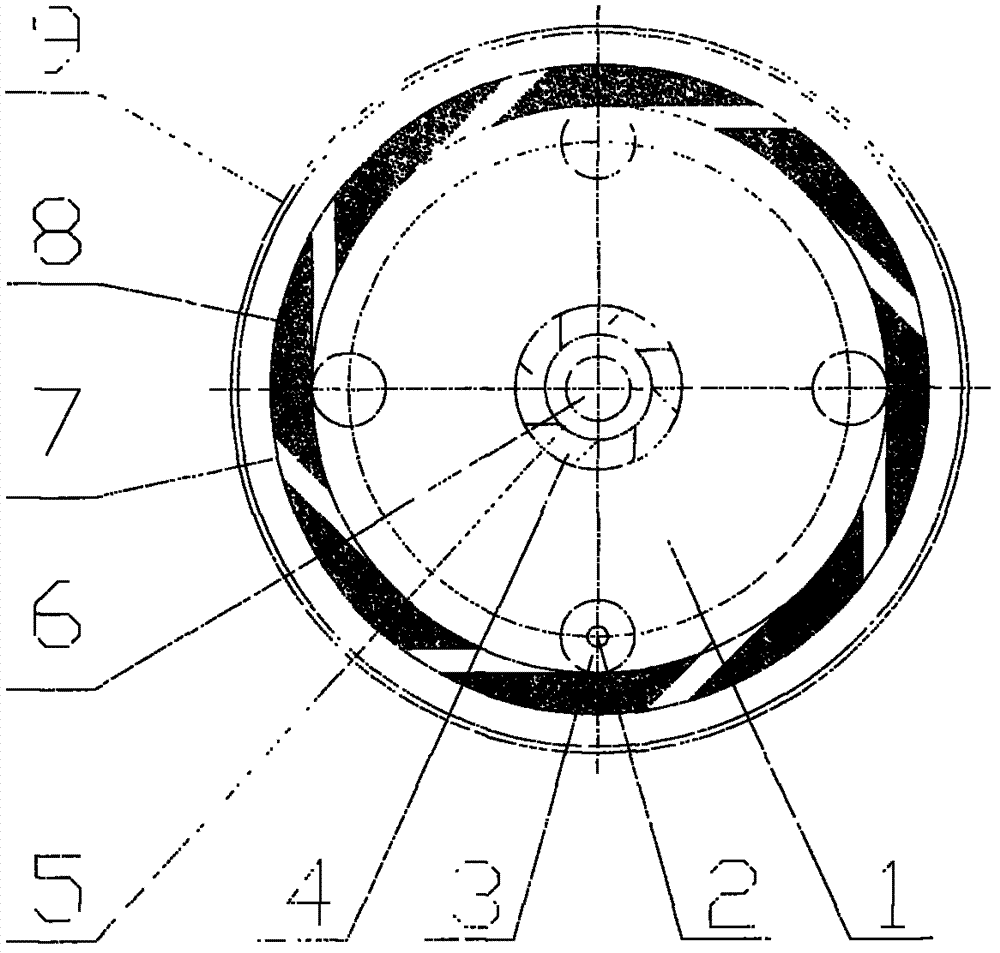

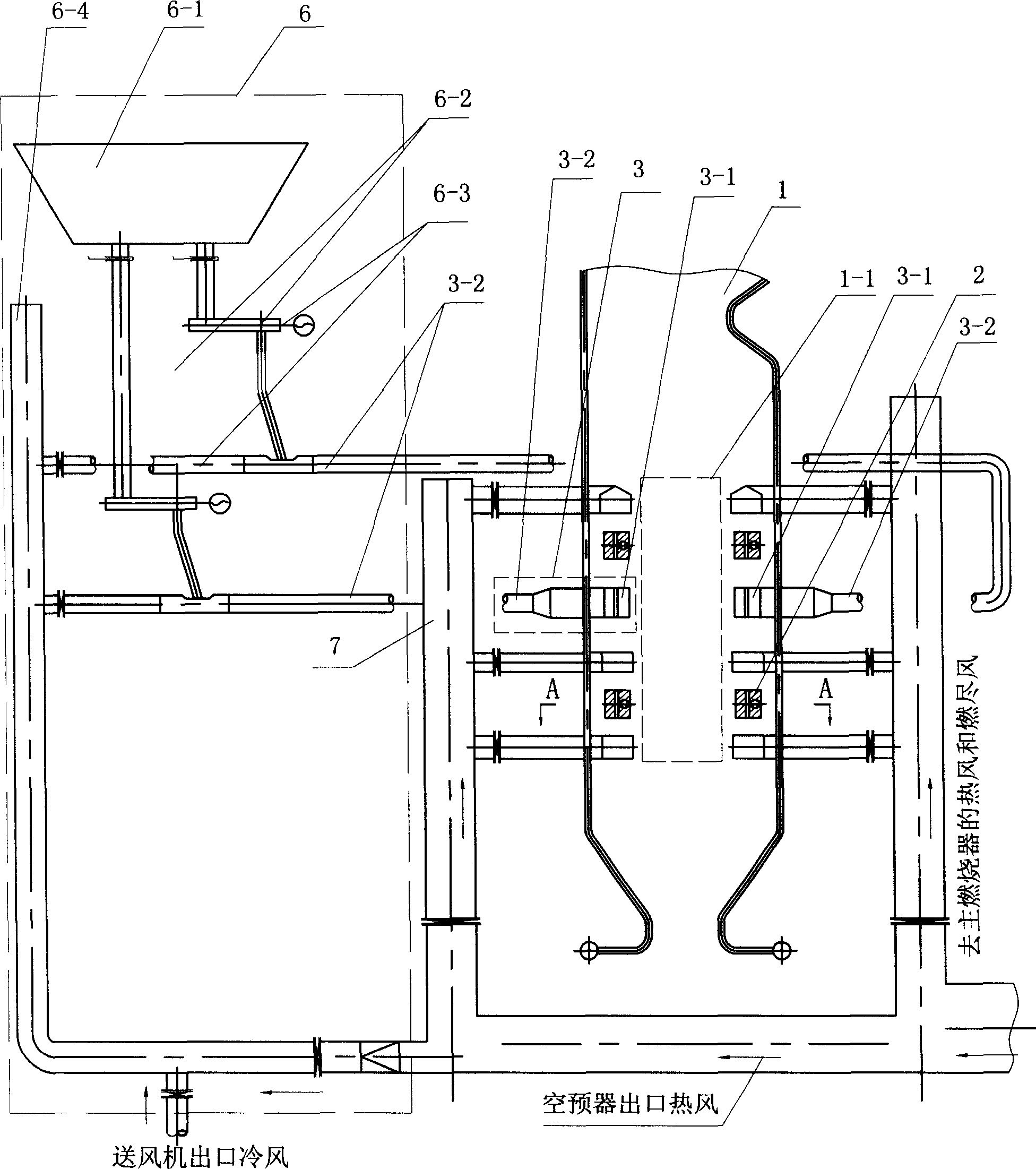

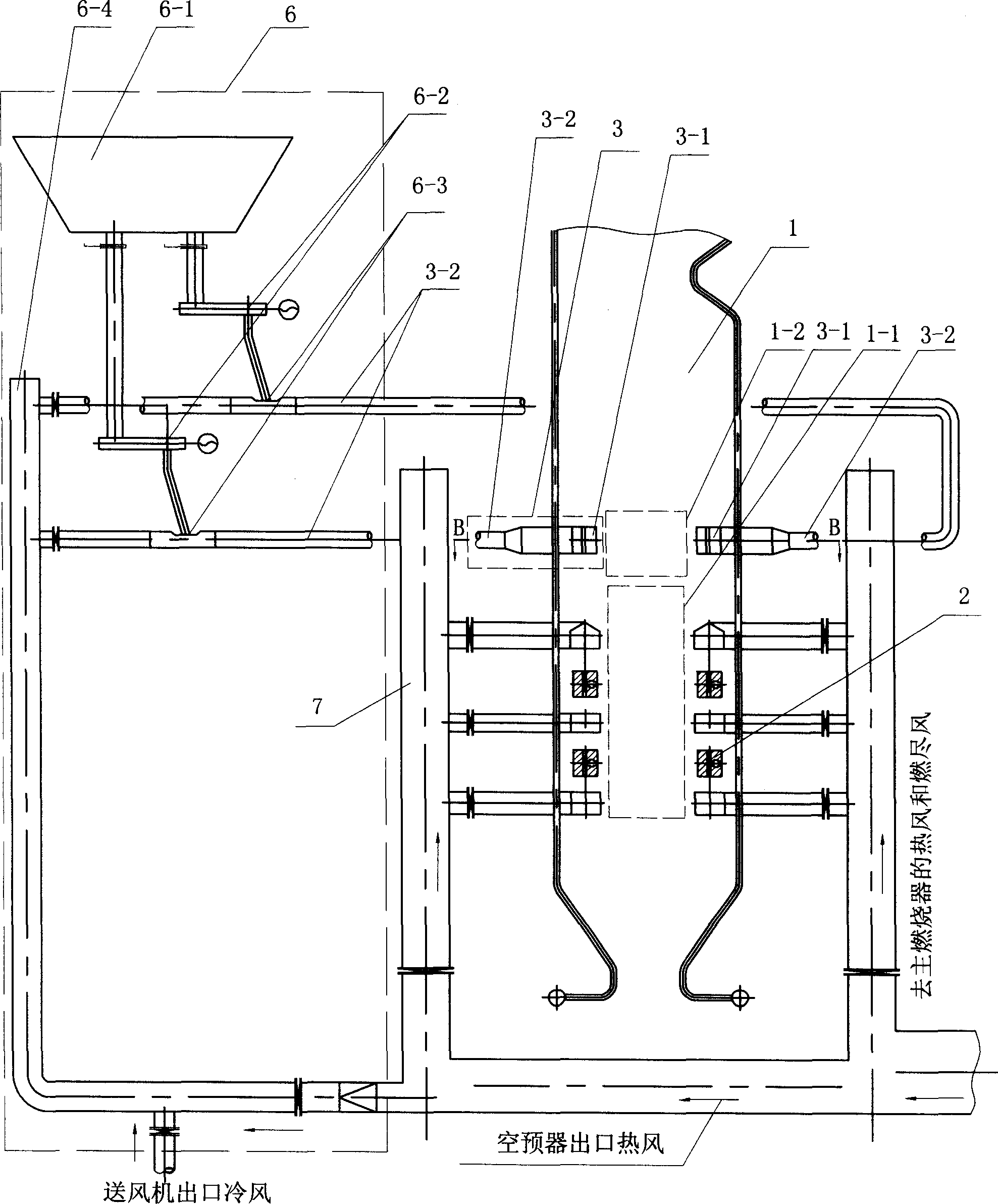

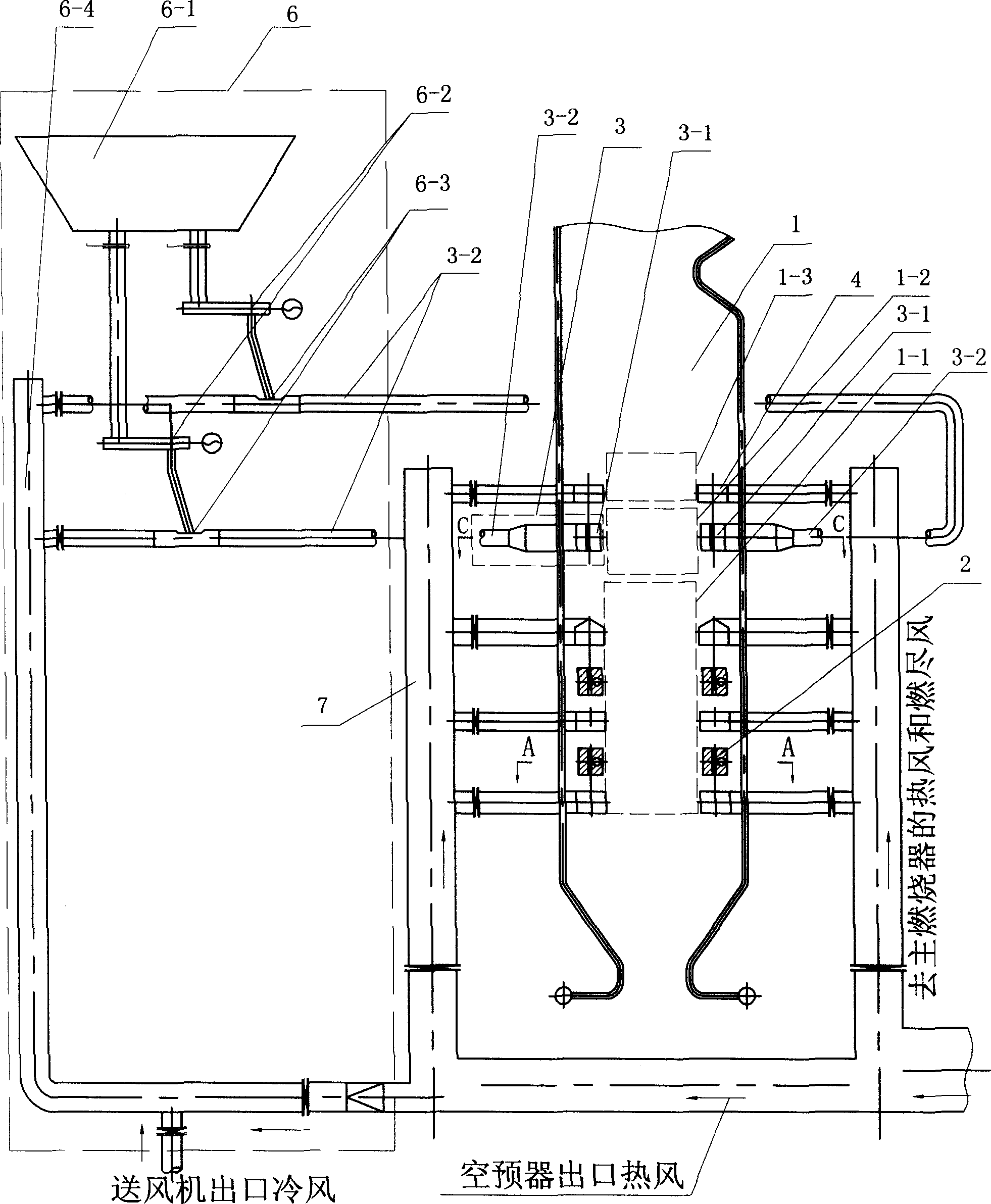

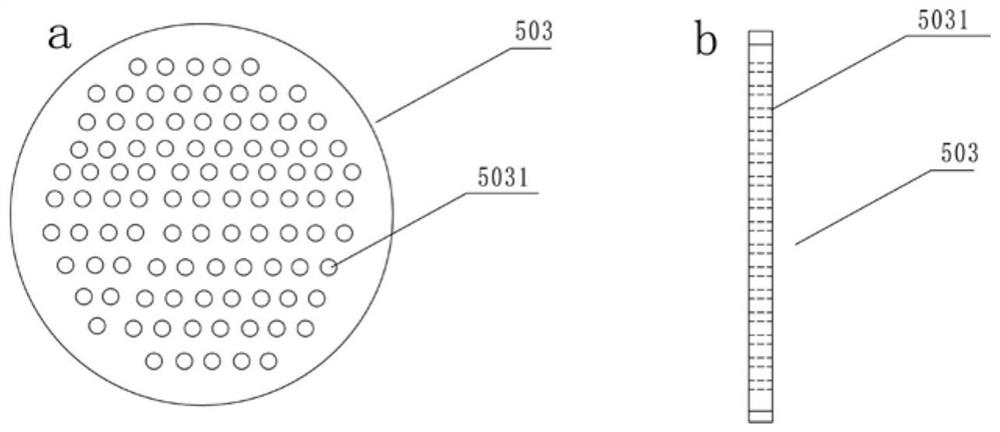

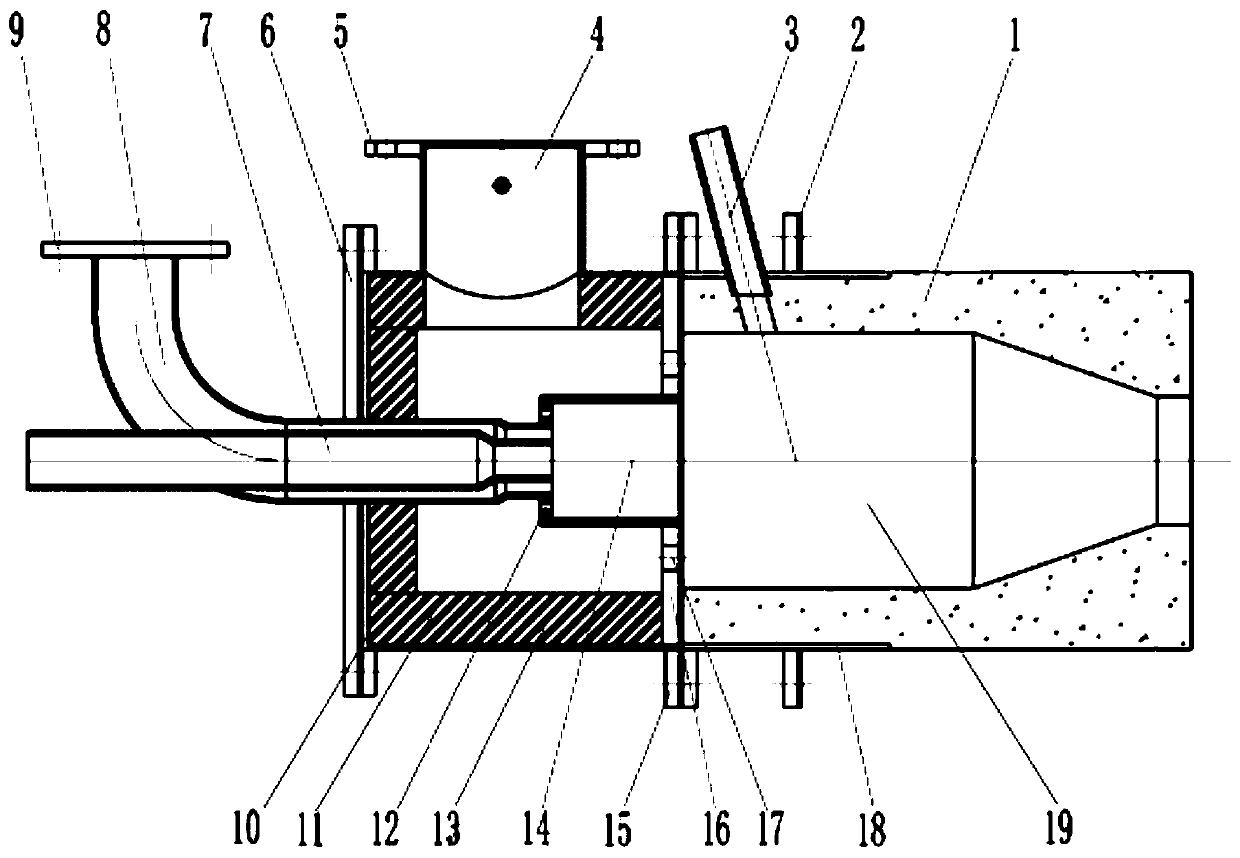

Multi-burner pulverized coal combustion device

InactiveCN103196137AGuaranteed to burnGuaranteed burnout ratePulverulent fuel combustion burnersCold airCombustor

The invention discloses a pulverized coal combustion device which is capable of combusting coal with poorer quality and aims at being used for an industrial boiler. The combustion device comprises an inner barrel and an outer barrel; and a pulverized coal start-up burner, a central burner, an annular burner, a sandwich secondary air port, a cyclone secondary air port and a direct secondary air port are arranged on the combustion device. When the start-up burner is in a stable burning state, the central burner and the annular burner can be guaranteed to stably and fully burn pulverized coal with different quality; and the burning temperature is controlled by cold air volume, so that a large amount of NOx pollutants can be prevented from being generated.

Owner:刘柏谦

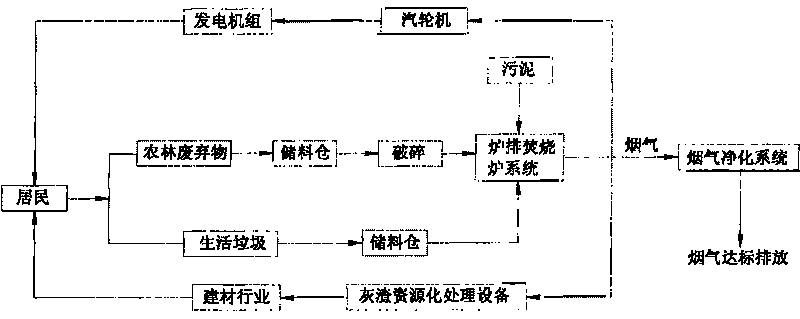

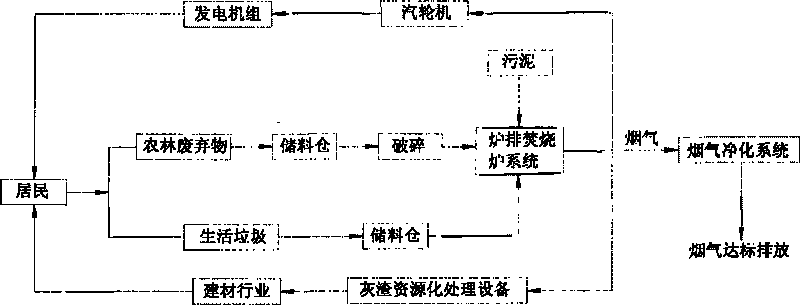

Method for mixed burning of agriculture and forestry waste, sludge and household garbage by using grate furnace

The invention relates to the technical field of energy environmental engineering and provides a method for mixed burning of agriculture and forestry waste, sludge and household garbage by using a grate furnace. The method comprises burning the agriculture and forestry waste, sludge and household garbage in a grate garbage burning furnace, igniting by using agriculture and forestry waste, and adding household garbage and sludge in the furnace to realize mixed burning when the temperature of the furnace rises to 850 DEG C, wherein the mass percent of the agriculture and forestry in the mixed fuel is within 40 percent, the mass percent of sludge in the mixed fuel is within 30 percent, the burning temperature of the grate burning furnace is controlled at 850 to 1000 DEG C, and the smoke gas generated by burning stayed in the furnace is controlled above two seconds. The invention is low in the cost, improves the burning efficiency of the garbage burning furnace, solves the problem of pollution caused by the sludge, ensures that the agriculture and forestry waste can be recycled, reduces discharge of pollutants, particularly heavy metal and dioxin and reduces the consumption of fossil energy.

Owner:SOUTHEAST UNIV

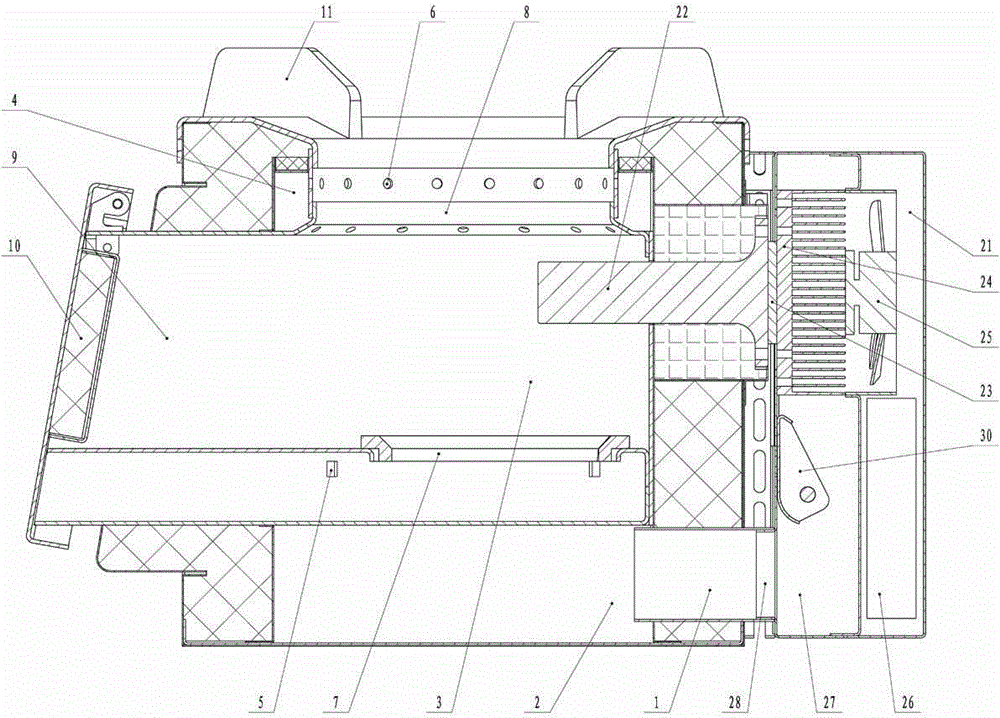

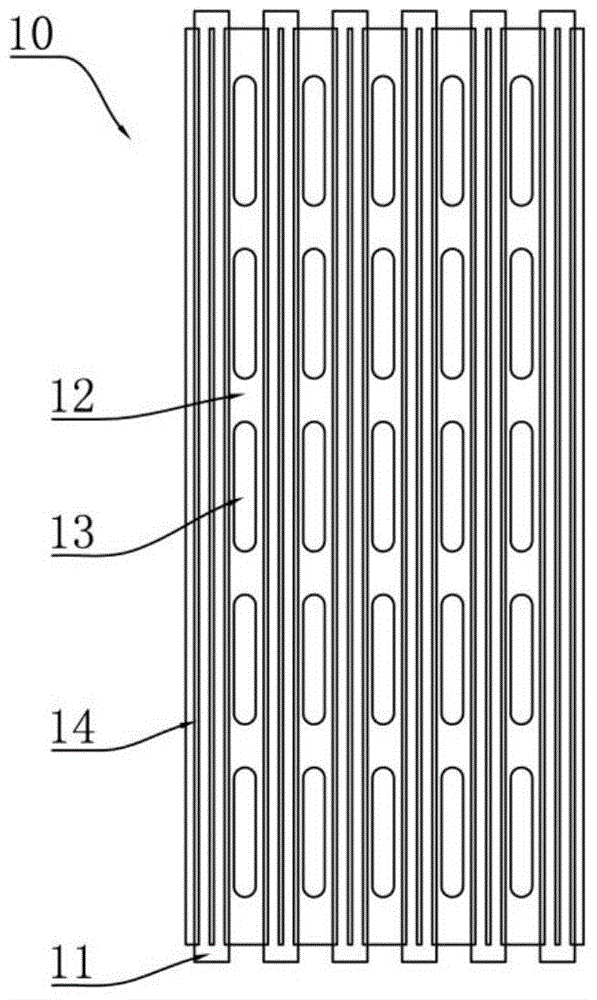

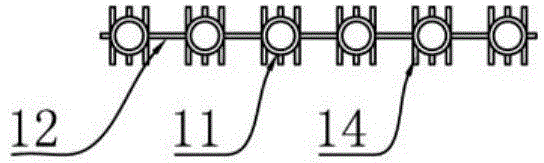

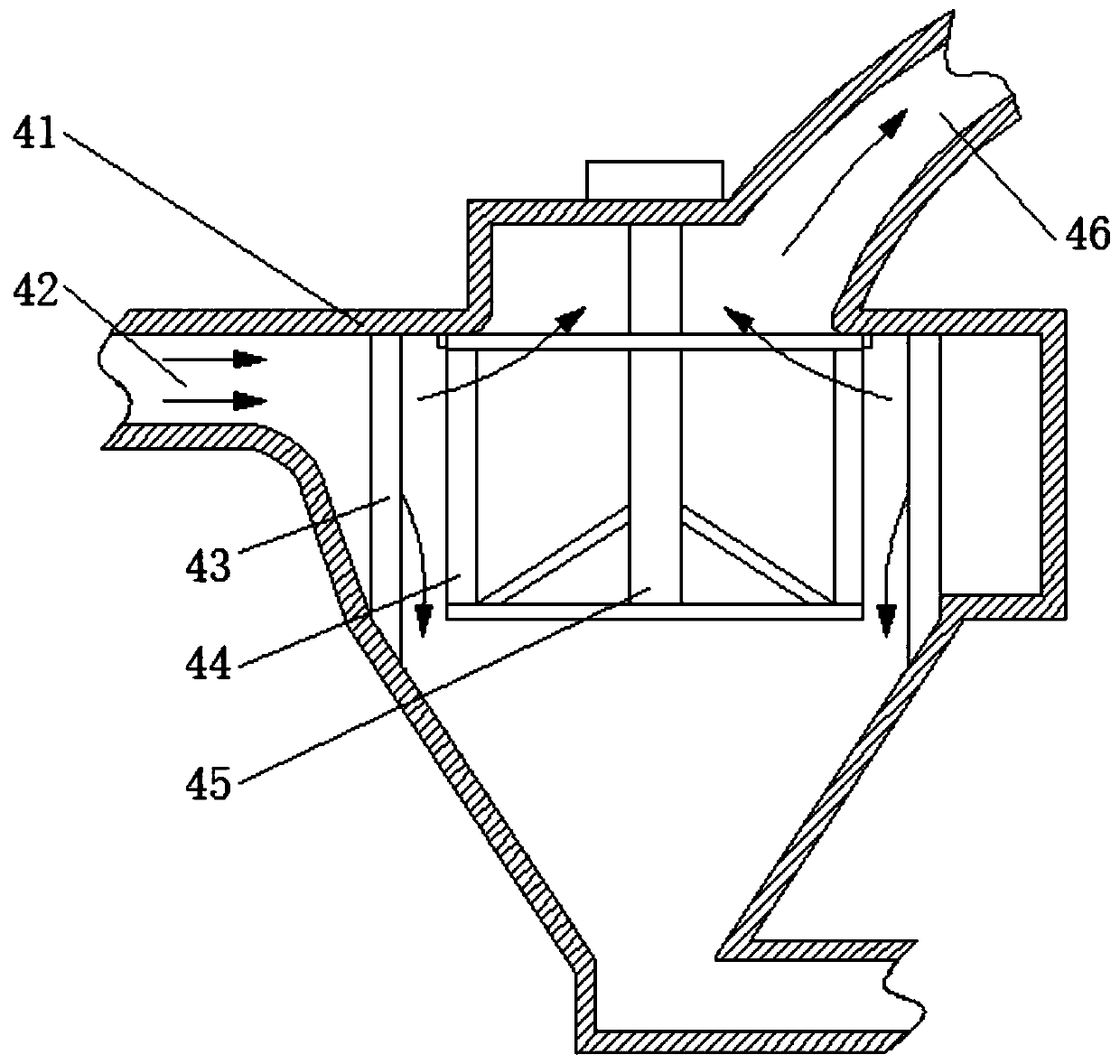

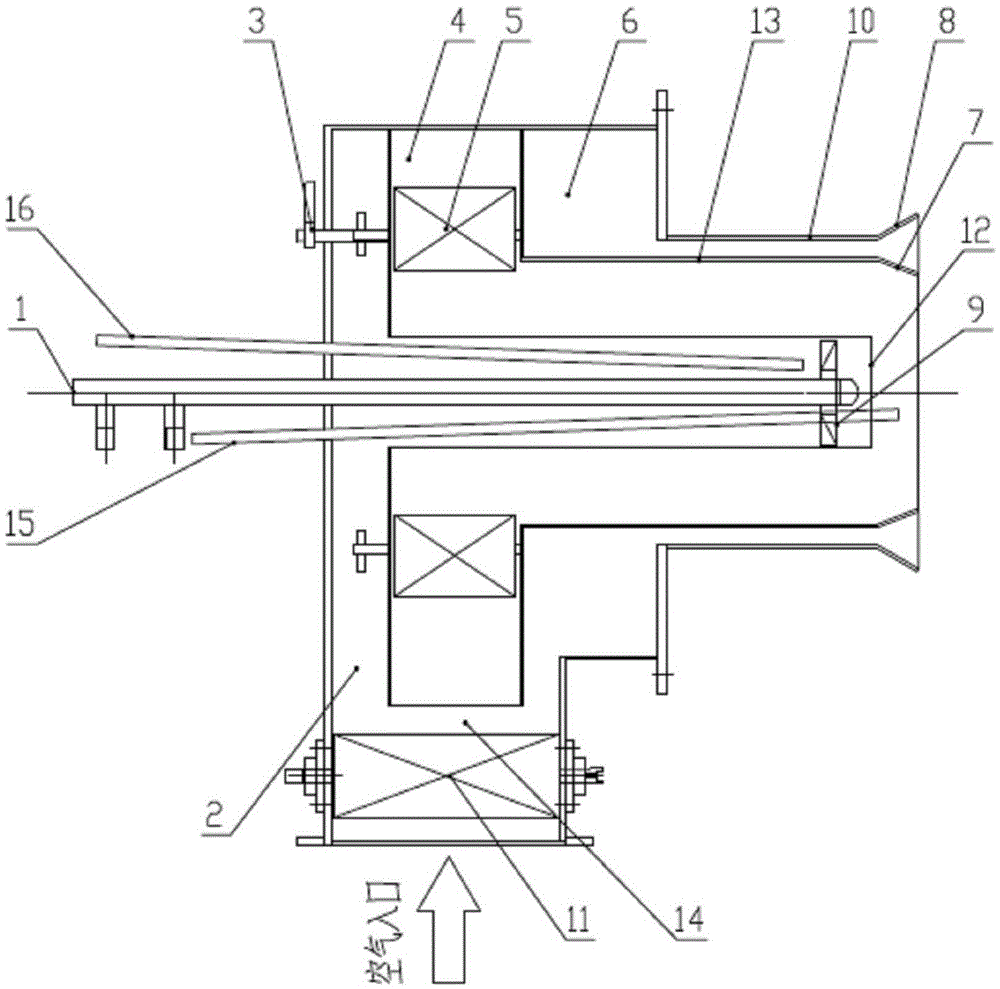

Biomass and powder coal mixed combustion and biomass recombusting and denitrating combustion apparatus

InactiveCN1673619AEmission reductionHigh volatile contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorRoom temperature

The present invention is one burning apparatus for the composite burning of biomass and coal powder and re-burning and denitrifying of biomass. The burning apparatus includes hearth, main coal powder burning area inside the hearth, main nozzles and biomass nozzles installed on the four corner of the hearth. The present invention has the following advantages: lower NOx exhaust rate, burning out of biomass fuel, large scale utilization of biomass, reduced room temperature CO2, and lowered SOx exhaust and simple apparatus structure.

Owner:HARBIN INST OF TECH

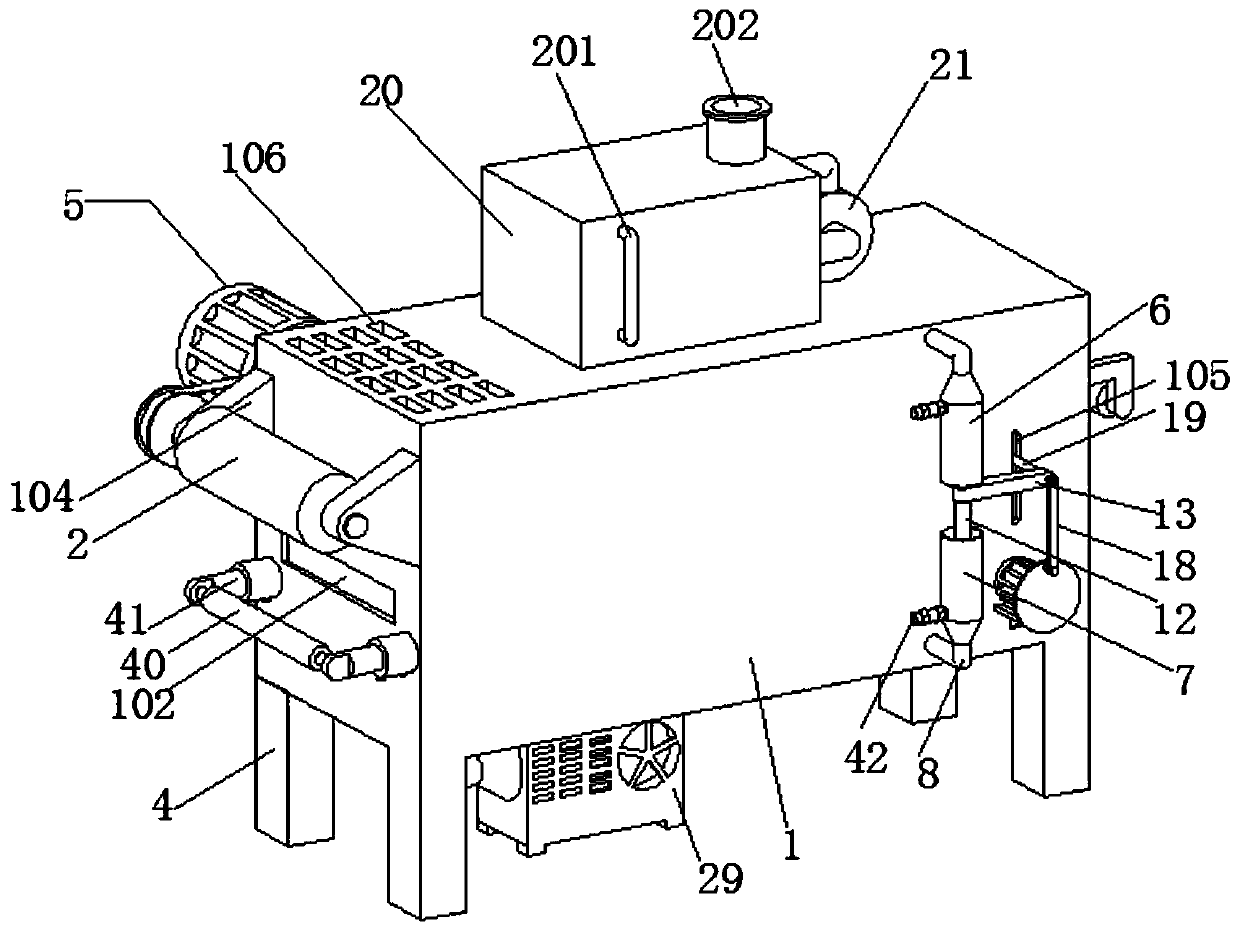

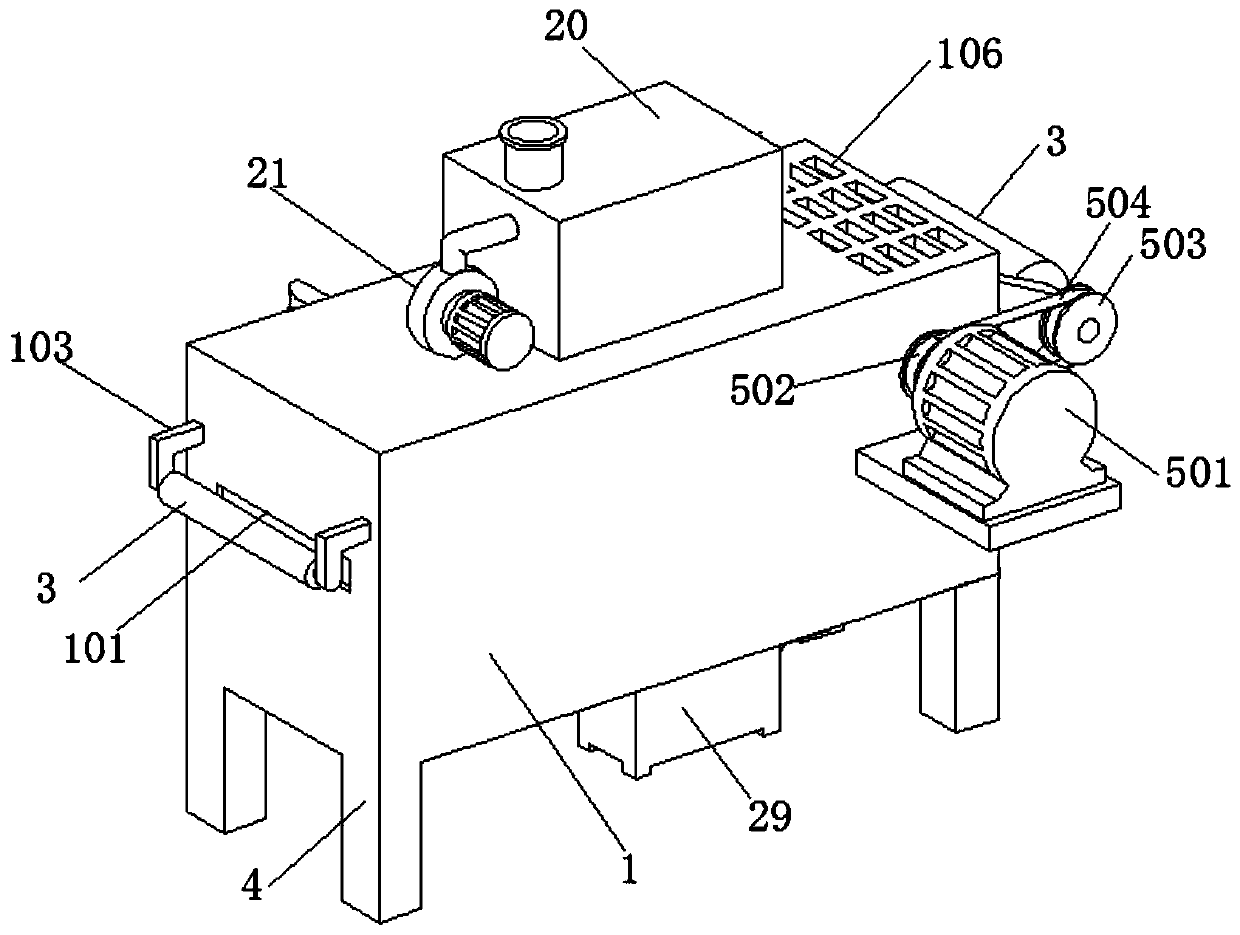

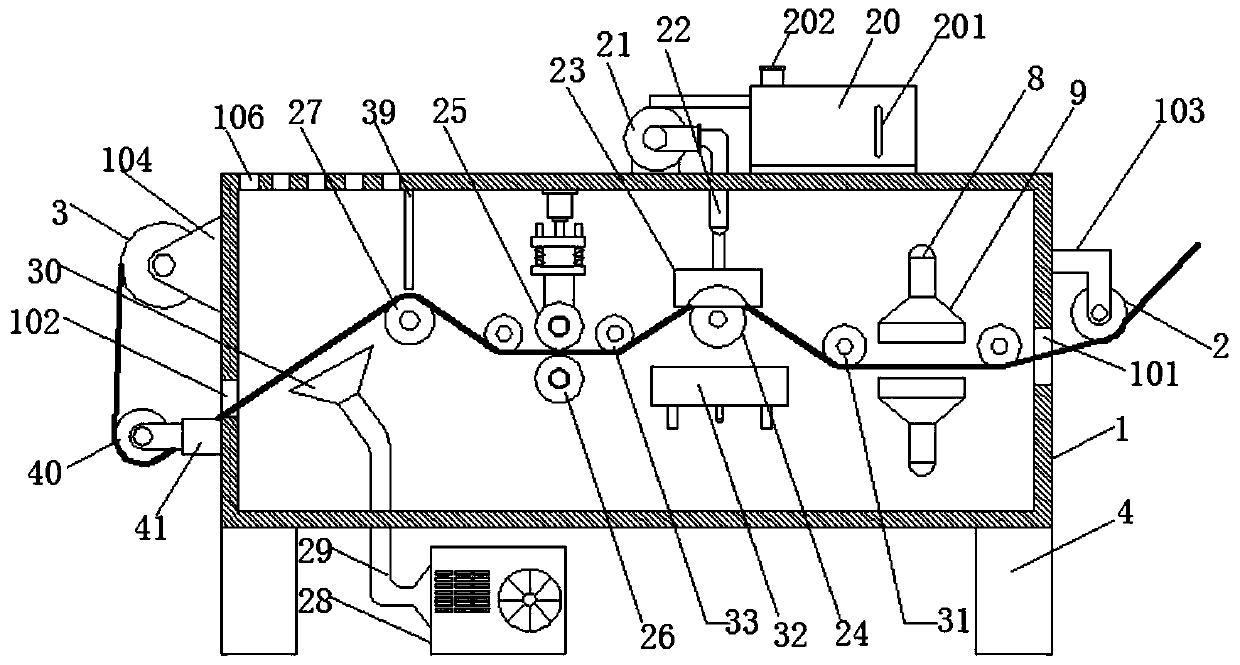

Spinning machine for textile fabric producing and processing and technology of spinning machine

ActiveCN111501169AImprove surface qualityNo wrinklesMechanical cleaningPressure cleaningSpinningDust control

The invention relates to the technical field of textile fabric processing equipment, and particularly discloses a spinning machine for textile fabric producing and processing and a technology of the spinning machine. A machine case, a winding roller and a guiding-in roller are included. Stand bars are arranged at the four corner positions of the lower surface of the machine case. A fabric inlet isformed in the right side face of the machine case. A fabric outlet is formed in the left side face of the machine case. The right side face of the part, located above the fabric inlet, of the machinecase is provided with a first rotation support, and the guiding-in roller is rotationally arranged on the first rotation support. Wind power combined electrostatic precipitation is conducted on the spun formed fabric firstly, then, anti-static liquid is sprayed to the fabric, the fabric obtained after anti-static liquid spraying is subjected to ironing treatment, finally, after an air heater is used for drying the fabric at the front treatment end, rolling is conducted, accordingly, static electricity does not exist on the surface of the prepared textile fabric, meanwhile, the dust on the surface of the textile fabric is effectively removed, wrinkles do not exist on the surface of the ironed textile fabric, the fabric surface quality is greatly improved, and the product market competitiveness is improved.

Owner:浙江兰溪银丰纺织有限公司

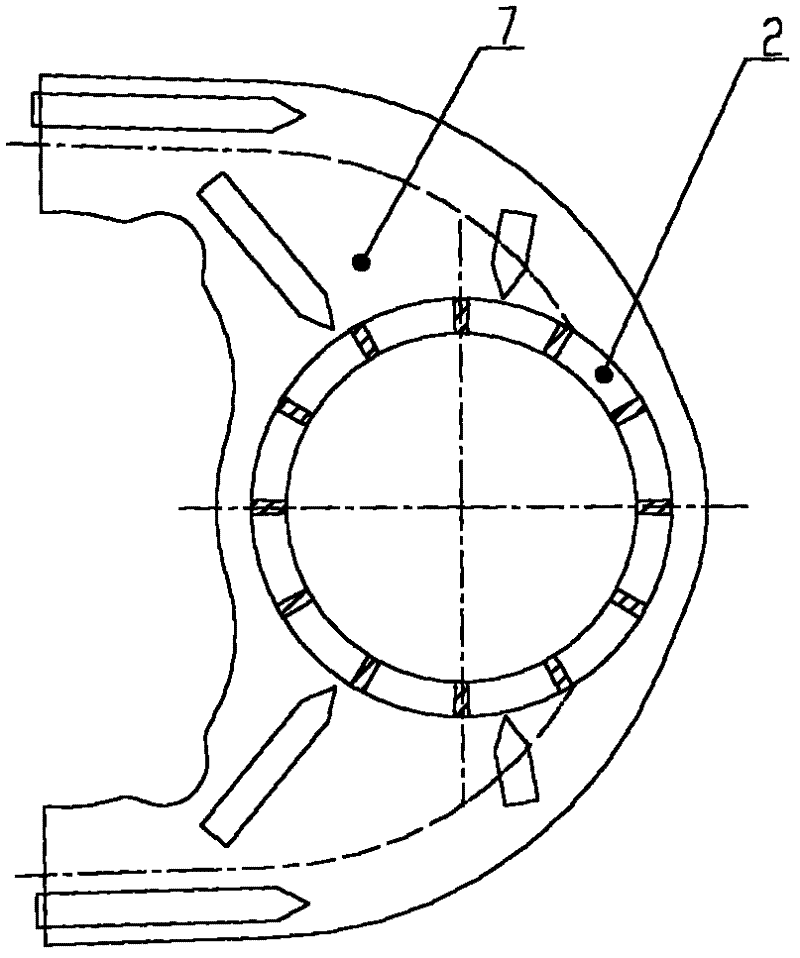

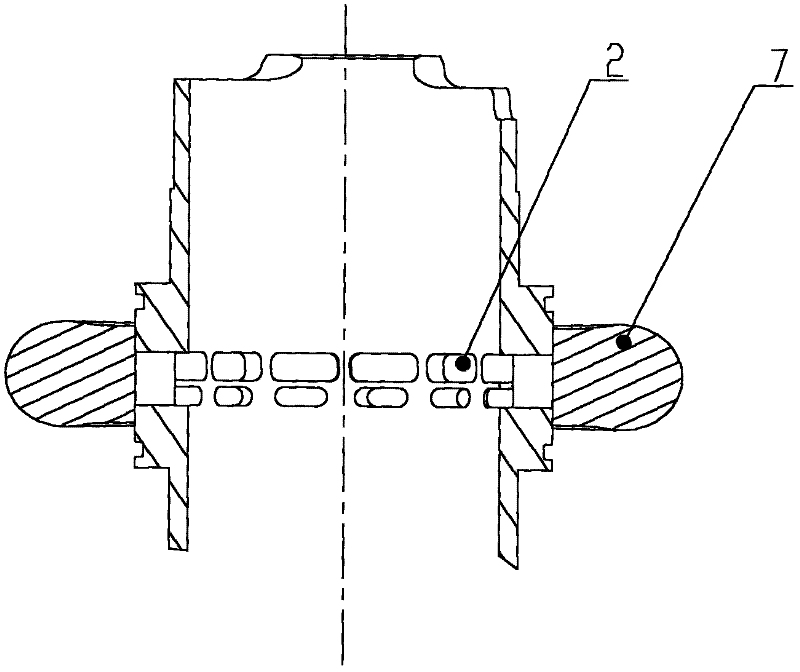

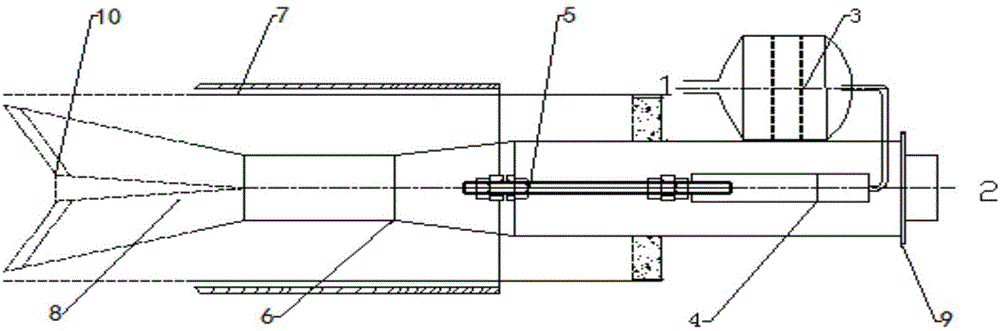

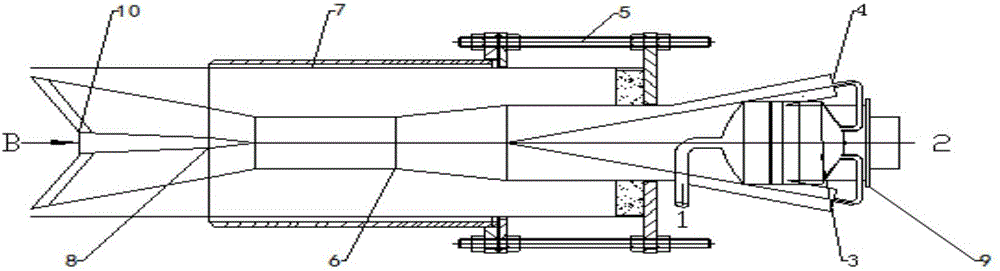

Air inlet device with two air inlet channels for two-stroke engine

InactiveCN102230421AIncrease air intakeGuaranteed to burnExhaust apparatusCombustion-air/fuel-air treatmentInlet channelShrinkage rate

The invention relates to a air inlet device with two air inlet channels for a two-stroke engine, which comprises an air inlet piston (1), a cylinder sleeve (3) and an exhaust piston (6), wherein the air inlet piston (1) and the exhaust piston (6) are arranged in the cylinder sleeve (3); an annular air inlet (2) and an annular exhaust opening (5) are circumferentially arranged on the excircle of the cylinder sleeve (3); double exhaust channels (7) are arranged on the annular exhaust opening (5); an oil sprayer installation opening (4) is arranged on the cylinder sleeve (3); the air channel cross-sectional area shrinkage rate of the double exhaust channels (7) is 10-12mm<2> / mm; and the fresh air is charged from both ends of double air inlet channels (7). The invention has the advantages of improving air inlet amount, reducing the pressure loss, preventing the problem of airflow congestion caused by overlarge initial airflow speed and ensuring the formation of isobaric airflow in the air channel.

Owner:CHINA NORTH IND GRP NO 70 RES INST

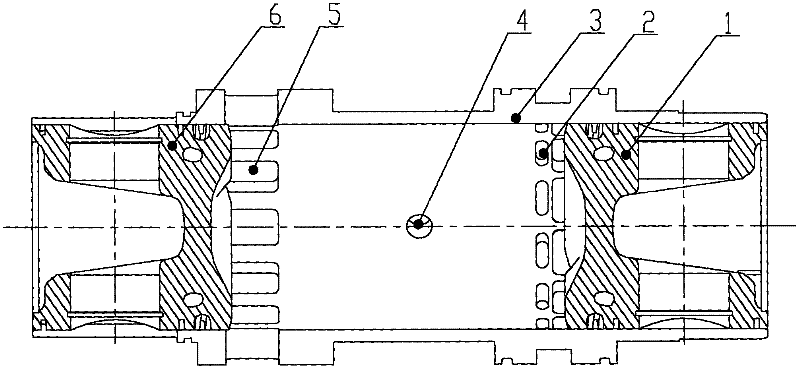

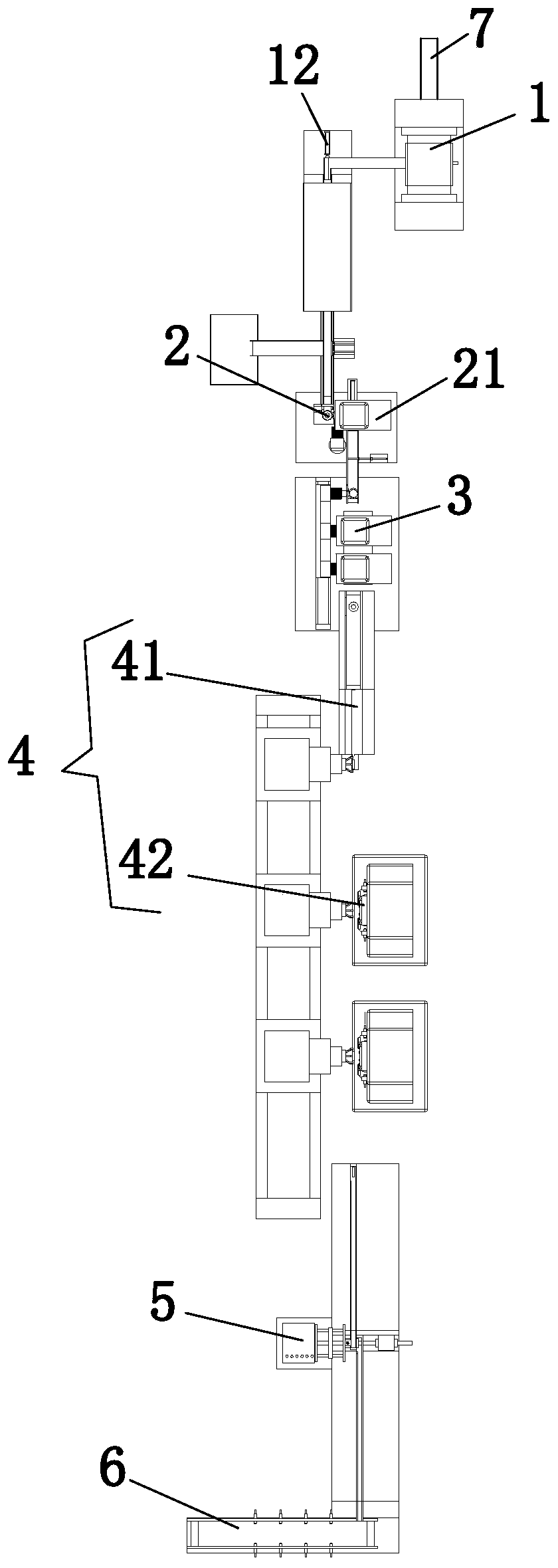

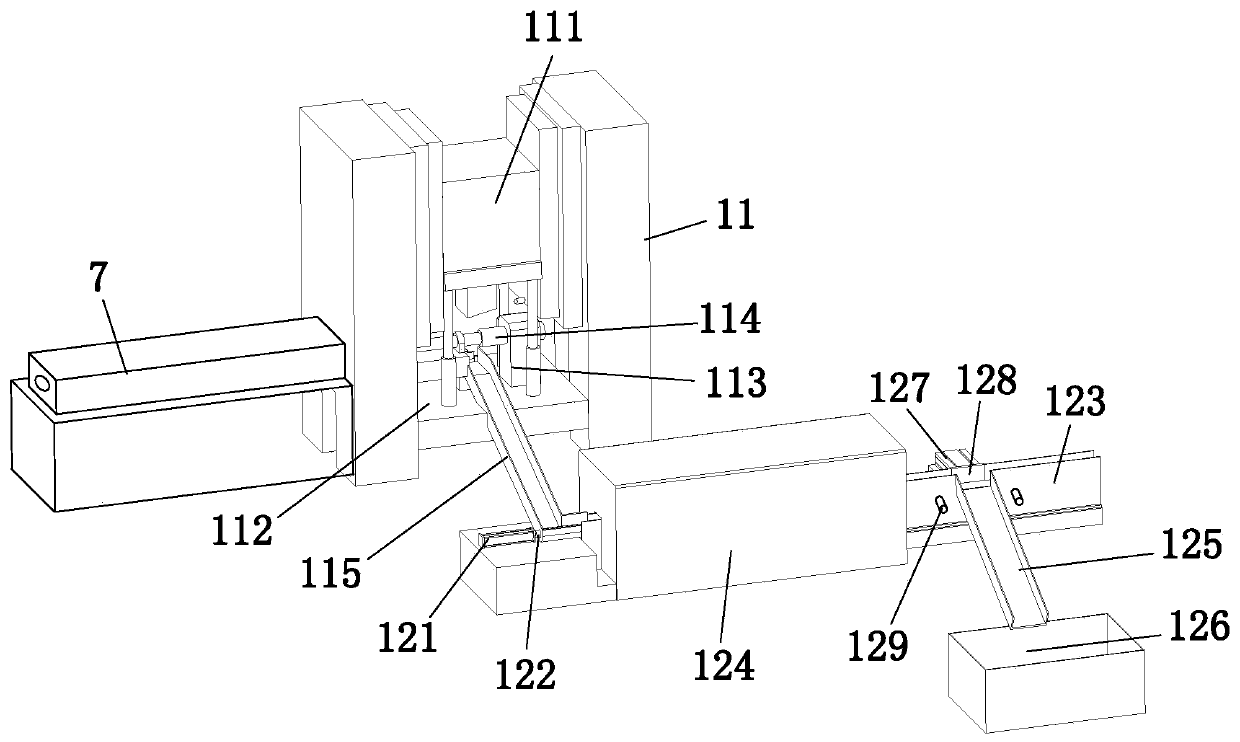

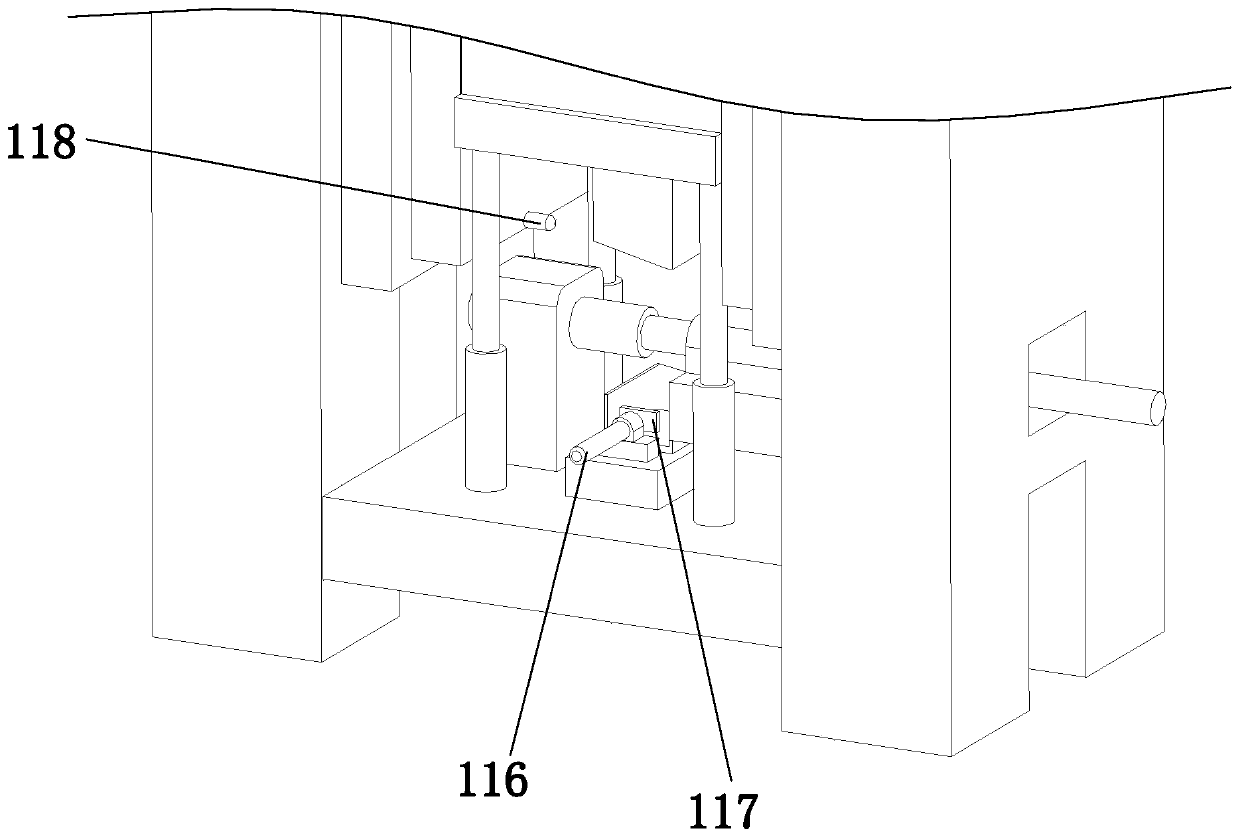

Bearing intelligent precision forging automatic production line

InactiveCN111069517AThere is no poor quality inside and outsideLittle difference in internal and external qualityShaping toolsPerforating toolsProduction linePunching

The invention relates to the technical field of bearing production equipment, in particular to a bearing intelligent precision forging automatic production line which comprises a feeding mechanism, anupsetting mechanism, a punching flattening mechanism, a continuous reaming mechanism, a finishing diameter mechanism and a discharging mechanism, wherein the feeding mechanism comprises a feeding component and a pushing component; the upsetting mechanism comprises an overturning component and an upsetting component; the overturning component is arranged at the tail end of the pushing component; the punching flattening mechanism is arranged by the side of the upsetting component; the continuous reaming mechanism comprises a conveying component and a continuous reaming component; the conveyingcomponent is arranged by the side of the punching flattening mechanism; the continuous reaming component is arranged at the tail end of the conveying component; the finishing diameter mechanism is arranged at the tail end of the continuous reaming component; and the discharging mechanism is arranged at the tail end of the finishing diameter mechanism. The bearing intelligent precision forging automatic production line can realize automatic processing of bearing precision forging, lowers the labor intensity, shortens the blank transferring distance, reduces the temperature differences of different processing parts of the blank, and improves the production efficiency and the bearing precision.

Owner:浙江赛赛轴承有限公司

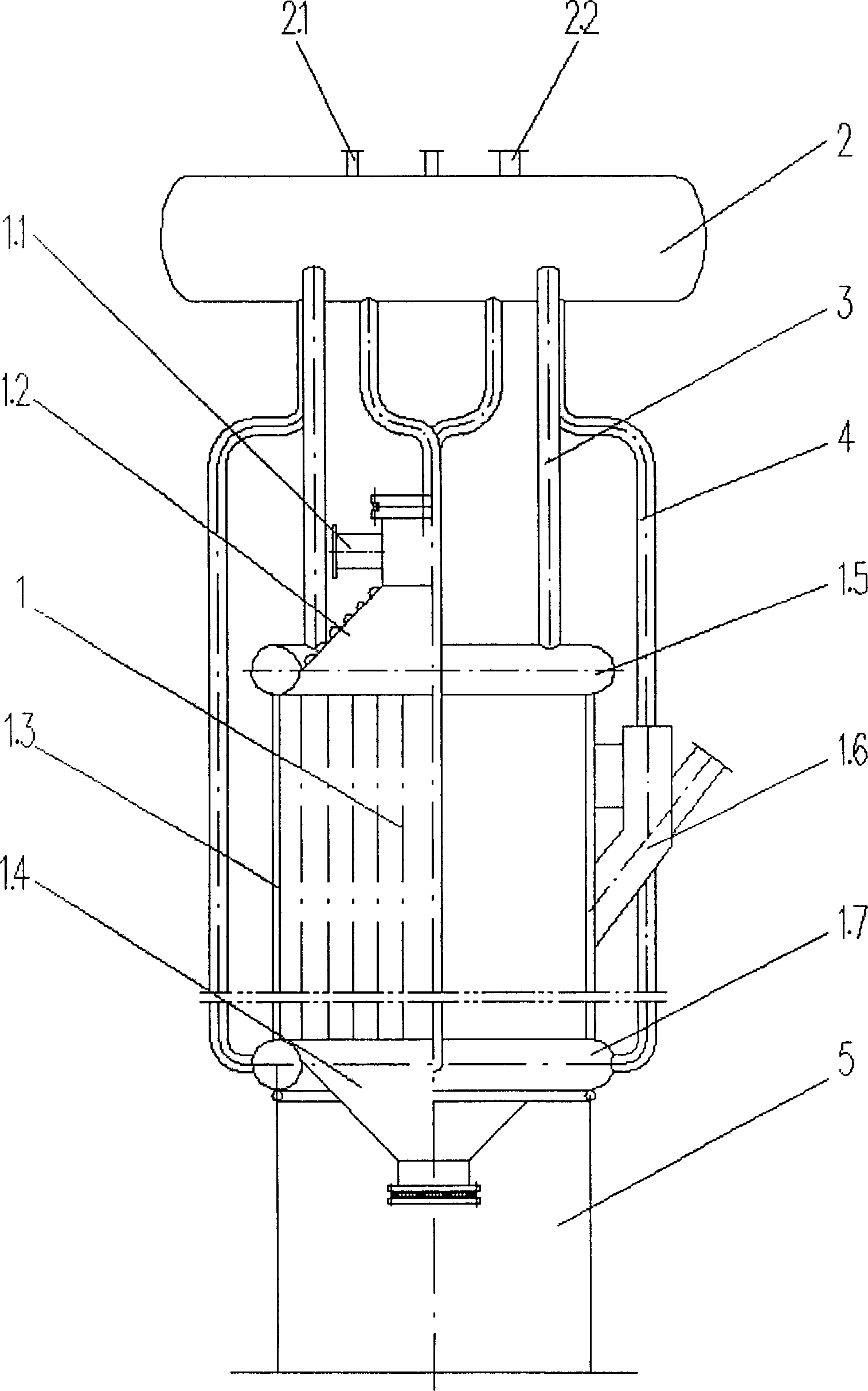

Energy saving type phosphorus reaction tower for producing high pure phosphoric acid

InactiveCN1857996ASimple structureRealize waste heat recoveryPhosphorus oxyacidsMouth piecePhosphoric acid

The present invention discloses a kind of energy saving phosphorus reaction tower for producing high purity phosphoric acid. The vertical sealed tower has ring film type water cooling wall formed with stainless steel pipes and finned sheets through welding, upper header tank and upper conic end with fume outlet connected to the upper end of the ring film type water cooling wall, lower header tank and lower conic end connected to the lower end of the ring film type water cooling wall, inclined phosphorus spraying gun mouth piece in the lower part, apron type pedestal connected to the lower header tank, steam collector connected between the steam-water separator and the upper header tank, down take connected between the steam-water separator and the lower header tank, and the steam-water separator with steam outlet pipe and cold water inlet pipe. The present invention realizes the afterheat recovery of phosphoric acid producing process, and has high heat efficiency and phosphoric acid as high as 99 %.

Owner:ZHEJIANG UNIV

Fuel gas water heater

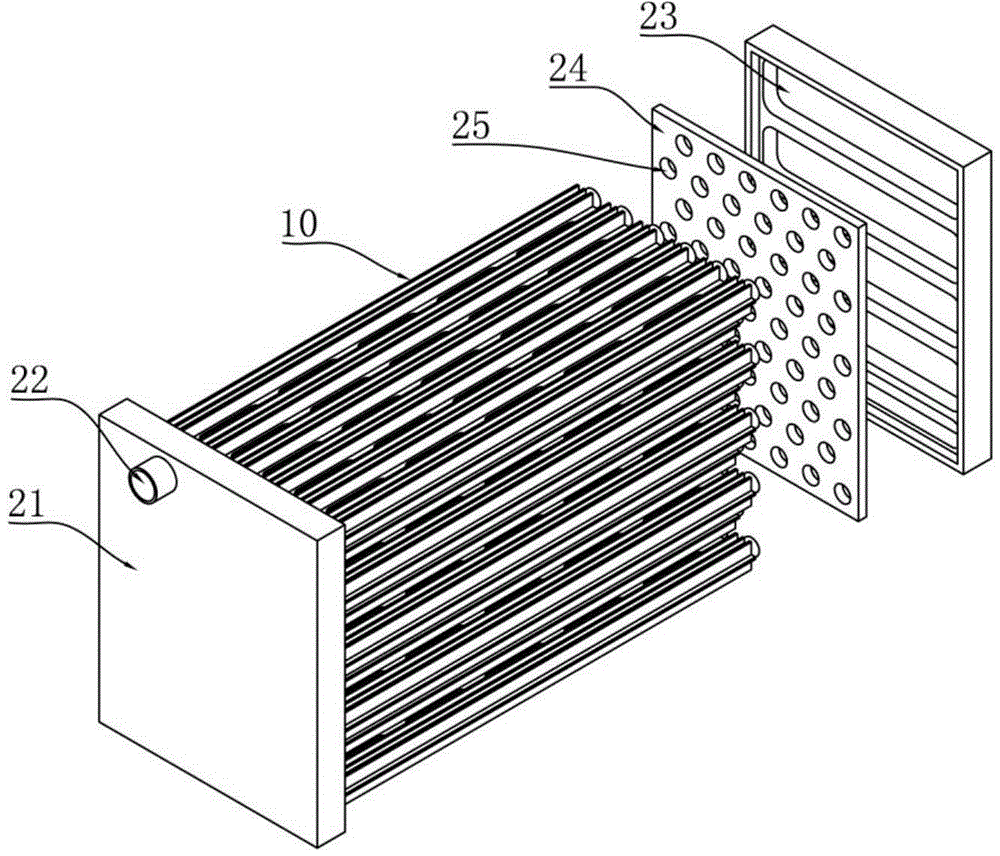

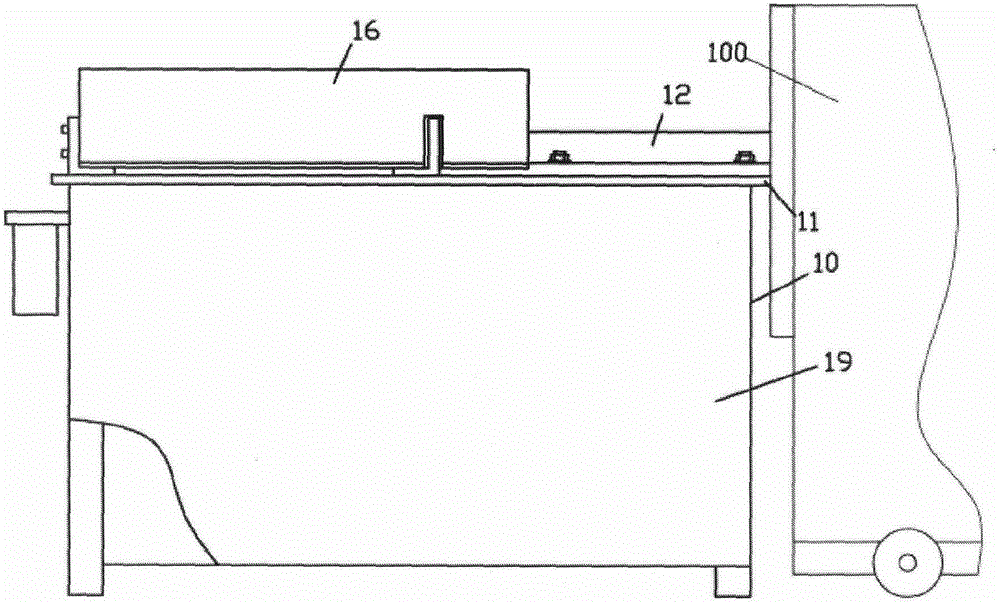

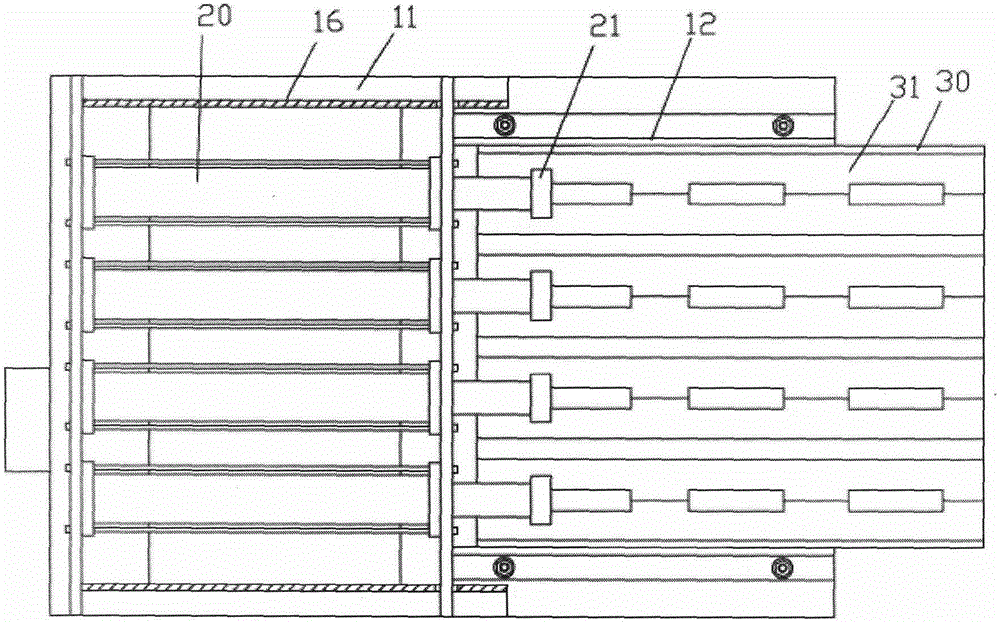

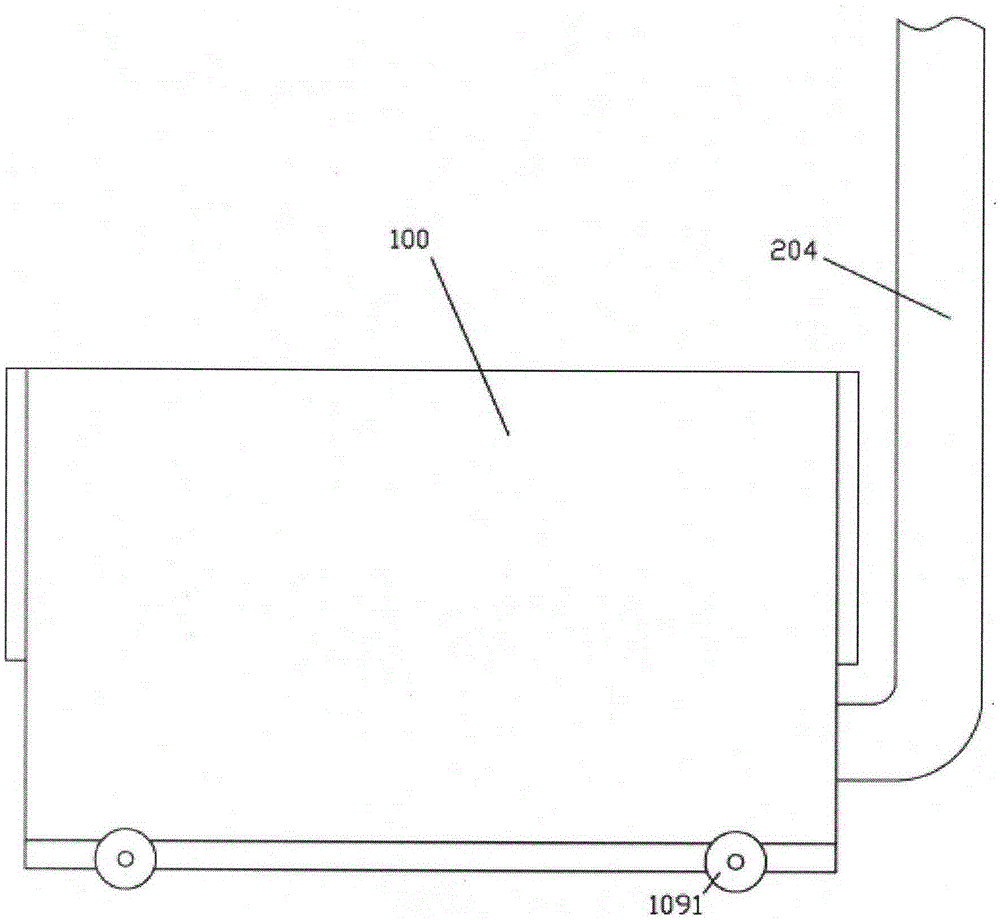

InactiveCN103557586AIncrease the heat exchange areaImprove heat exchange efficiencyWater heatersHeat lossesEngineering

The invention discloses a fuel gas water heater. The fuel gas water heater comprises a heat exchanger. The heat exchanger is formed by a plurality of heat exchange sheets arranged in parallel and an end cover. The water heater comprises a water heater casing, a heat exchange body, a fire disc, an ignitor, a cold water pipe and a hot water pipe, wherein the heat exchanger is mounted in a condenser jacket. Compared with the prior art, the fuel gas water heater is higher in heat exchange efficiency, the energy utilization rate of the water heater is high, and the heat loss is less.

Owner:李林

Environment-friendly biomass particle forging furnace

The invention discloses an environment-friendly biomass particle forging furnace. The environment-friendly biomass particle forging furnace comprises an automatic feeding device, a forging furnace cavity shell, a combustion furnace body and an exhaust smoke filtering device. The automatic feeding device is arranged in front of the forging furnace cavity shell. The combustion furnace body is arranged on the side edge of the forging furnace cavity shell. The exhaust smoke filtering device is arranged behind the forging furnace cavity shell. An exhaust pipe of the exhaust smoke filtering device is fixed to the forging furnace cavity shell and is communicated with an exhaust through hole in the forging furnace cavity shell. The environment-friendly biomass particle forging furnace can carry out automatic feeding, ash formed by waste generated by forge pieces can be left in an ash collecting through groove, and the ash is removed in the non-shutdown state. Meanwhile, ash and waste generated by fuel can be prevented from blocking a circulation hole, and the combusting and heating effects are guaranteed. Particle scrap filtering is carried out on the combusted smoke firstly, then the combusted smoke enters a water tank to be filtered again, accordingly, not too many scraps or particles are accumulated in the water tank, the service life is prolonged, and frequent water changing or cleaning is not needed.

Owner:HANGZHOU YINGFA FURNACE TECH CO LTD

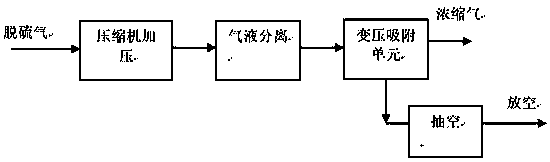

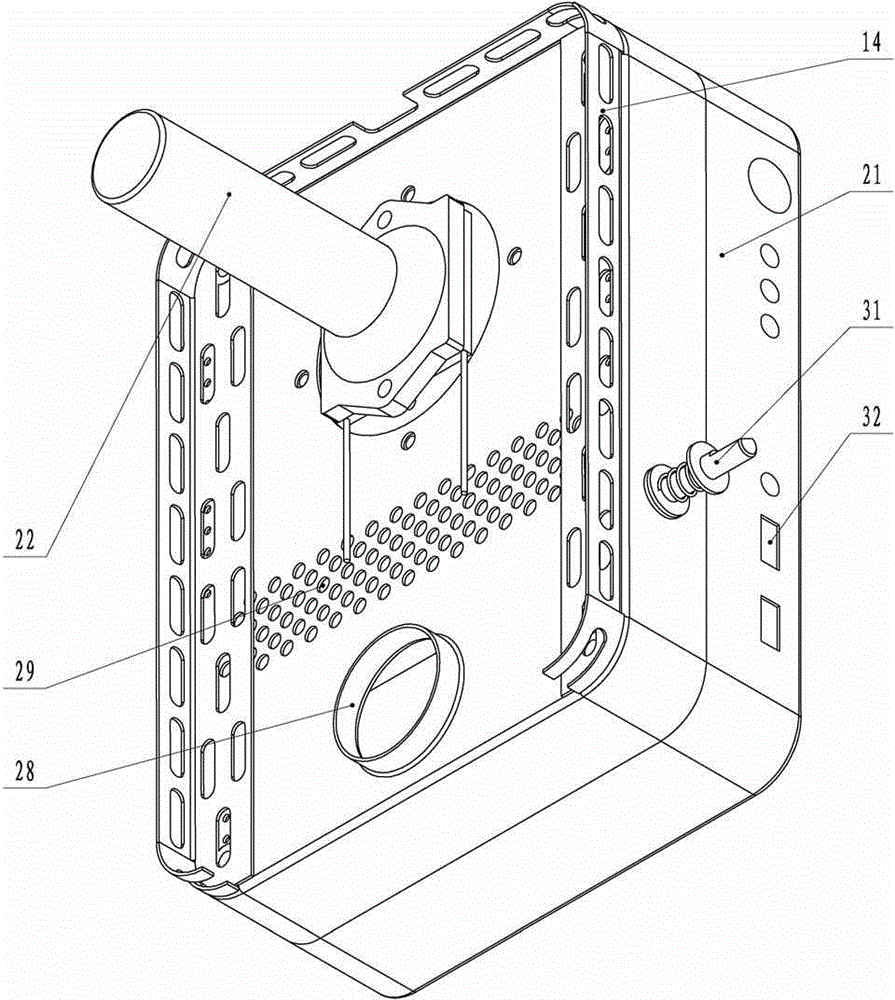

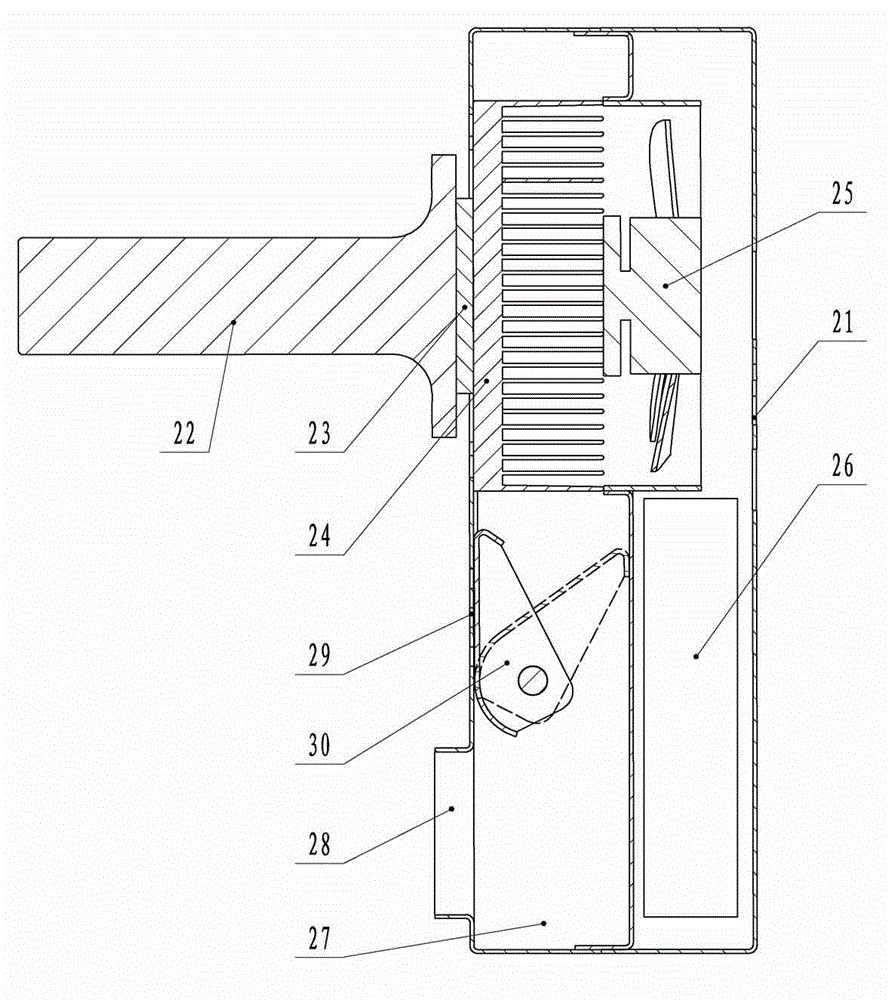

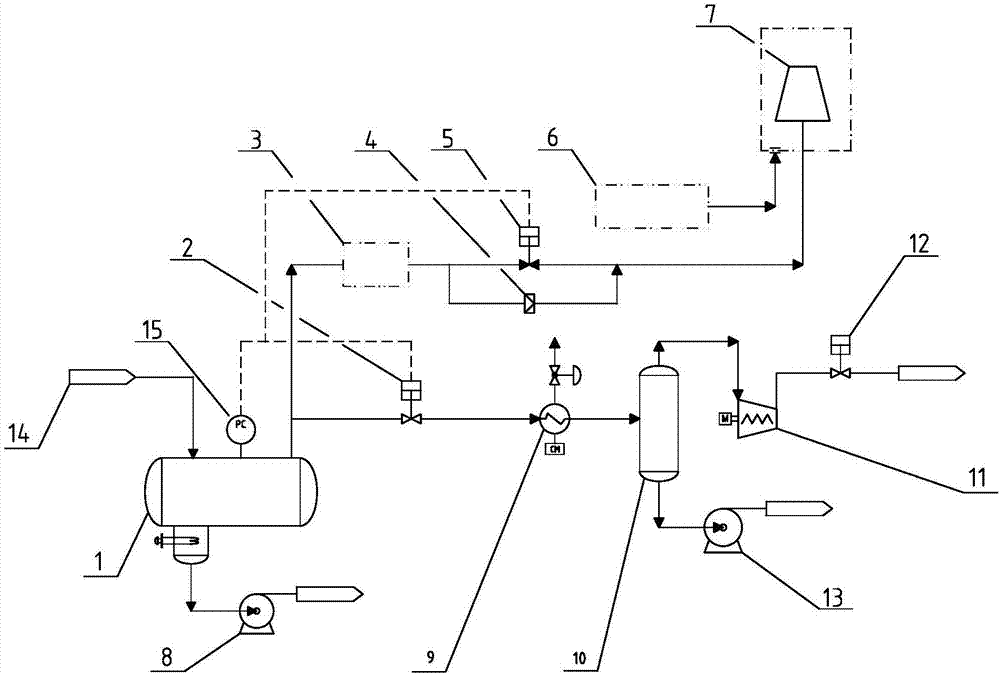

FPSO torch gas recycling system

InactiveCN107218609AEnergy savingReduce pollutionDispersed particle separationGaseous fuelsSTI OutpatientProcess engineering

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

Waste liquid incineration boiler of recycling smoke adherence protection

The invention relates to the technical field of waste liquid treatment, and specifically to a saliferous organic waste liquid incineration boiler of recycling smoke adherence protection. The boiler comprises a lower heat-insulating hearth, a radiation cooling chamber, a horizontal flue and a tail flue which are connected in turn, and a soot blower which is installed above the radiation cooling chamber, the horizontal flue and the tail flue; the tail flue is provided with a I-level economizer, a II-level economizer and the like. The key point of the saliferous organic waste liquid incineration boiler is as follows: the partial smoke at the outlet of the II-level economizer is recycled, and enters the lower heat-insulating hearth and the radiation cooling chamber as the adherence protection smoke; and the connecting position between the lower heat-insulating hearth and the radiation cooling chamber is a V-shaped included angle, the side wall of the V-shaped included angle is a water cooled wall, a fire-proof material is paved on the water cooled wall, and the bottom of the V-shaped included angle is a liquid-state discharging device. The incineration boiler is capable of solving the problems that the boiler wall is corroded, the slag is not smoothly discharged, and the discharge value of NOx is higher, and has the advantages of simple structure, convenient use, high processing efficiency, energy conservation, water-saving and the like.

Owner:北京华电光大装备技术有限公司

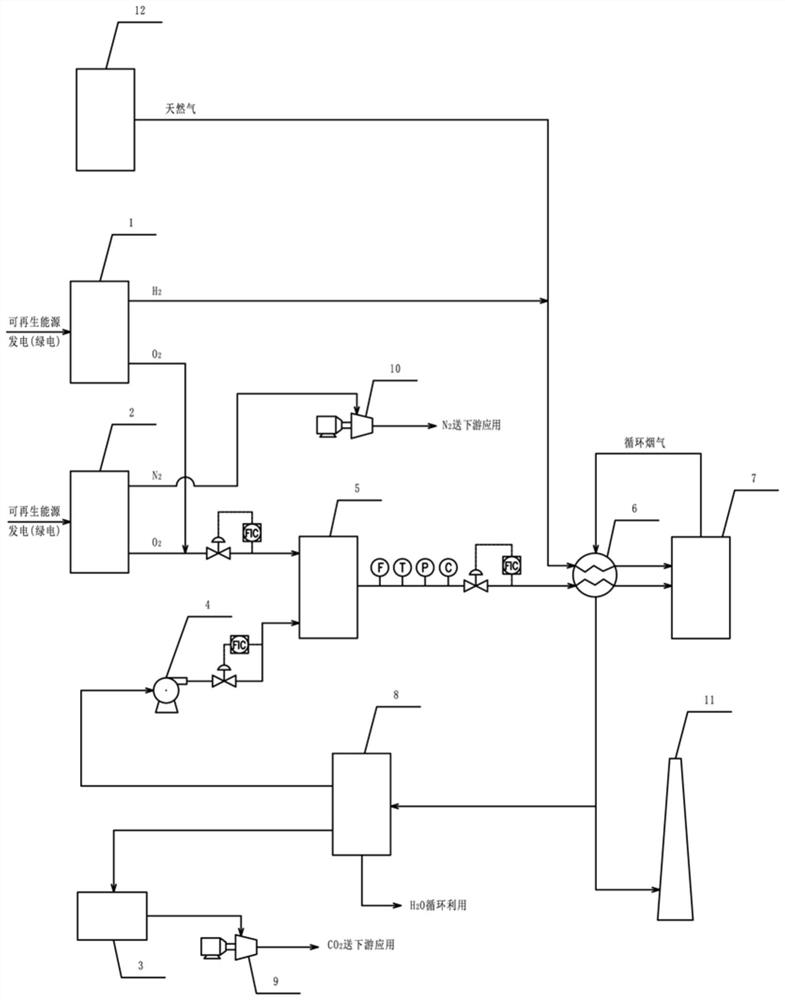

Nitrogen-insulating combustion and CO2 capture and utilization process for gas-fired boiler

The invention discloses a gas-fired boiler nitrogen-insulating combustion and CO2 capture and utilization process. A system required by the process comprises a natural gas supply device, a water electrolysis hydrogen production device, an oxygen preparation device, a nitrogen compressor, a carbon-based nitrogen-insulating gas mixer, a gas heat exchanger, a gas-fired boiler, a chimney, a flue gas dehydration device, an air blower, a CO2 recovery device and a CO2 compressor. The method has excellent performance in the aspects of yield increase, energy conservation and emission reduction, the unit consumption of per ton of steam and natural gas can be reduced by 10% or above, the yield can be improved by 10% or above, the flue gas emission is reduced, and ultralow emission of NOx is achieved.

Owner:SHANGHAI YUANHAN ENERGY&CHEM TECH CO LTD +1

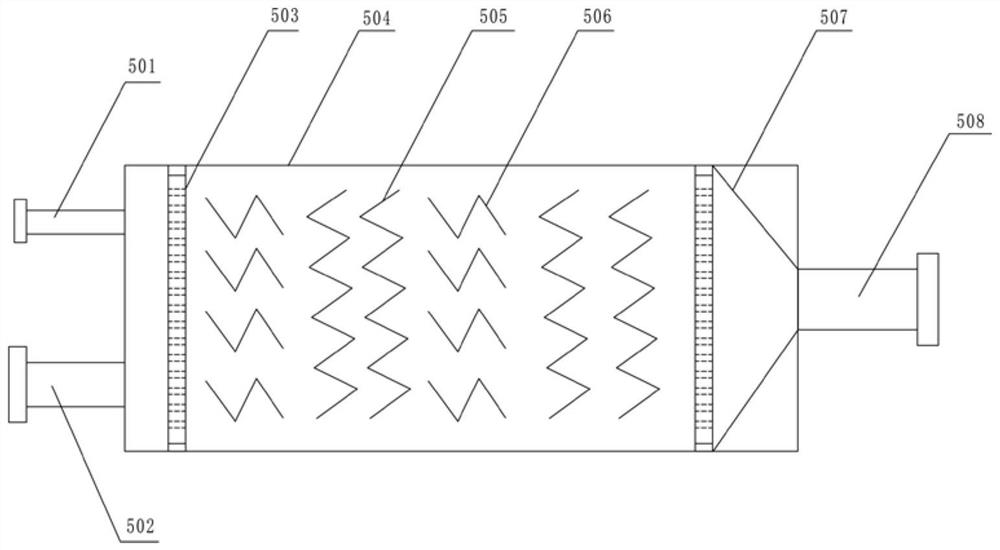

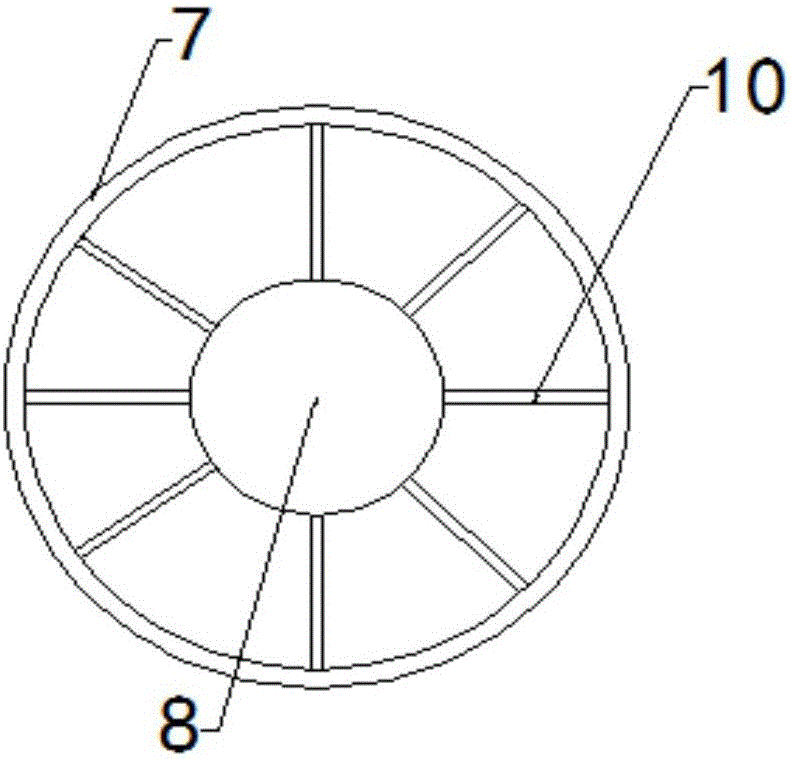

Saturated steam catalytic burner used for cement decomposition furnace

ActiveCN105953224ALow running costFuel NOx suppressionFuel feeding arrangementsSpecial fuel supply arrangementsDecompositionCoal

The invention discloses a saturated steam catalytic burner used for a cement decomposition furnace. The burner comprises an inner sleeve, a saturated steam channel, a catalyst tank, a conical chamfer and cyclone wind wings; the catalyst tank is connected with the saturated steam channel which is connected with the inner sleeve; and the outlet end of the inner sleeve is provided with the conical chamfer and the cyclone wind wings; saturated steam enters the saturated steam channel through the catalyst tank; coal air enters the inner sleeve from the inlet end of the inner sleeve, after the coal air is mixed with the saturated steam coming from the saturated steam channel at the variable-diameter position of the inner sleeve, the diffusion degree of coal powder is increased through the conical chamfer; meanwhile, by means of the cyclone wind wings, the coal powder and the saturated steam rotationally enter the decomposition furnace; and a backflow area is formed at the end portion of a coal pipe, and the purpose of generating CO and H2 is achieved. The saturated steam catalytic burner reduces the generation amount of fuel type nitrogen oxides, reduction components generated after the saturated steam is added can reduce more generated NOx, and the sewage charge and the running cost of a whole cement factory are reduced.

Owner:上海三融环保工程有限公司

Fly ash fluidized bed combustion decarburizing device

PendingCN110762517AHigh carbon contentCarbon content increased and decreasedFluidized bed combustionGas current separationHearthAir blower

The invention relates to the technical field of fly ash decarburization and discloses a fly ash fluidized bed combustion decarburizing device comprising a fly ash material bin, an air blower, an electric heating device, an air powder concentrator, a spiral feeding machine, a hearth, an ash cooler, a cyclone separator, a material return valve, an air heat exchanger, a dust remover, an induced draftfan and a chimney. According to the differences in the aspects of specific gravity and particle size between carbon not burned out and burned-out carbon in the fly ash, the fly ash is carried by hotair to enter an air powder concentrator to be screened, the large-particle and high-carbon-content fly ash falls into the bottom of the air powder concentrator to undergo a next procedure, so that only a part of fly ash needs to be re-combusted, and the work efficiency of reducing the carbon content of the fly ash is improved; and meanwhile, the carbon content in the fly ash combusted in the hearth is increased, the fly ash in the hearth can be stably combusted to emit a large amount of heat, and the utilization ratio of the fly ash is improved.

Owner:JIANGSU XINFANGYUAN ELECTRIC EQUIP MFG

Large-speed-difference flue gas circulation and ultralow nitrogen oxide high-speed burner and control method thereof

PendingCN111457377AReduce NOX emissionsReduce gas calorific valueIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyNitrogen oxidesCombustion chamber

The invention relates to a large-speed-difference flue gas circulation and ultralow nitrogen oxide high-speed burner and a control method thereof. The burner is provided with a burner brick, an air, fuel gas and circulating flue gas inlet tube, a burner housing and a pre-combustion chamber, wherein the inner cavity of the burner brick is a combustion chamber; a fuel gas inlet end of the pre-combustion chamber is provided with a primary air inlet channel; the outlet of the pre-combustion chamber is provided with an air distributing disc; and a secondary air inlet channel is arranged on the airdistributing disc. While the burner works, fuel gas and flue gas is pre-mixed and combusted in the pre-combustion chamber. Through a two-stage air distribution way, a gas mixture sprayed out by the pre-combustion chamber and flow speed of combustion-supporting air sprayed out through the secondary air inlet channel define large speed difference, so that an air flow reflow region is made in the outlet area of the pre-combustion chamber; and the airflow reflow region guarantees stable fuel gas and complete combustion in a furnace kiln. According to the control method, circulating flue gas is notinput into the burner while the furnace temperature is lower than a temperature of 900 DEG C, circulating flue gas is input into the burner to participate in combustion while the furnace temperatureis higher than the temperature of 900 DEG C, the circulating flue gas reduces a fuel gas heat value and a high temperature point of combustion flames, and ultralow NOX emission is realized.

Owner:WUHAN UNIV OF SCI & TECH

Air preheater arrangement structure of boiler

InactiveCN102221218AGuaranteed to burnReduce cokingCombustion processIndirect carbon-dioxide mitigationFlueThermal efficiency

The invention provides an air preheater arrangement structure of a boiler, which can satisfy the requirements on drying process when a powder processing system grinds brown coal, and simultaneously can ensure normal combustion and less coking in a combustion zone, thereby further solving the contradiction between the boiler drying process and the thermal efficiency of the boiler. The air preheater arrangement structure comprises an air preheater, a flue and a hot primary air flue, and is characterized in that the air preheater comprises a tubular air preheater and a rotary air preheater, the tubular air preheater is arranged above the rotary air preheater, the flue penetrates through the tubular air preheater and then is connected with a smoke inlet of the rotary air preheater, an inlet of the rotary air preheater is communicated with cold air, an air outlet of the rotary air preheater is connected with an air inlet of the tubular air preheater by the hot primary air flue, a secondary air outlet is arranged in the middle of the hot primary air flue and is communicated with the combustion zone, and a primary air outlet of the tubular air preheater is communicated with a dying zone of the powder processing system for grounding the brown coal.

Owner:WUXI HUAGUANG BOILER

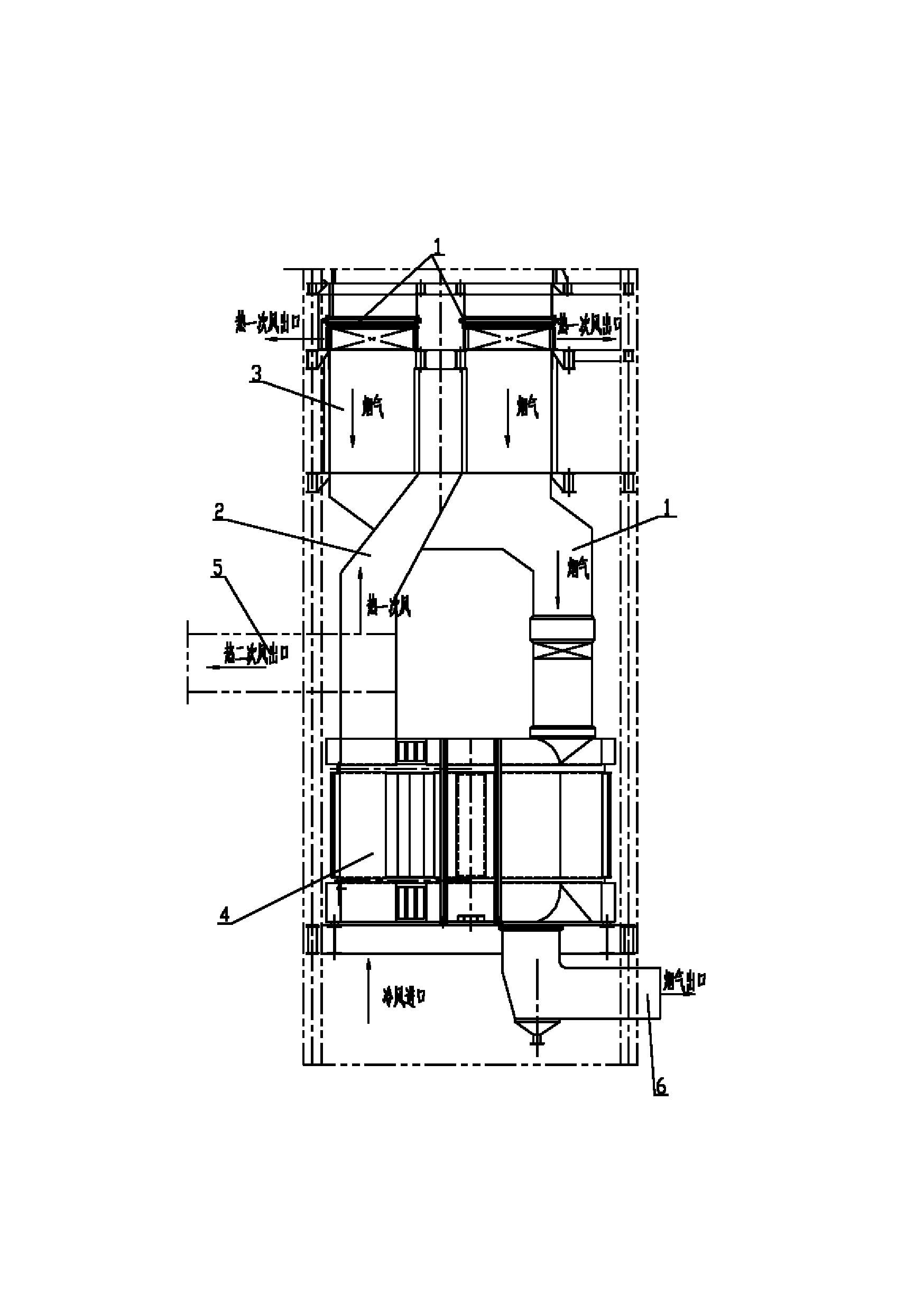

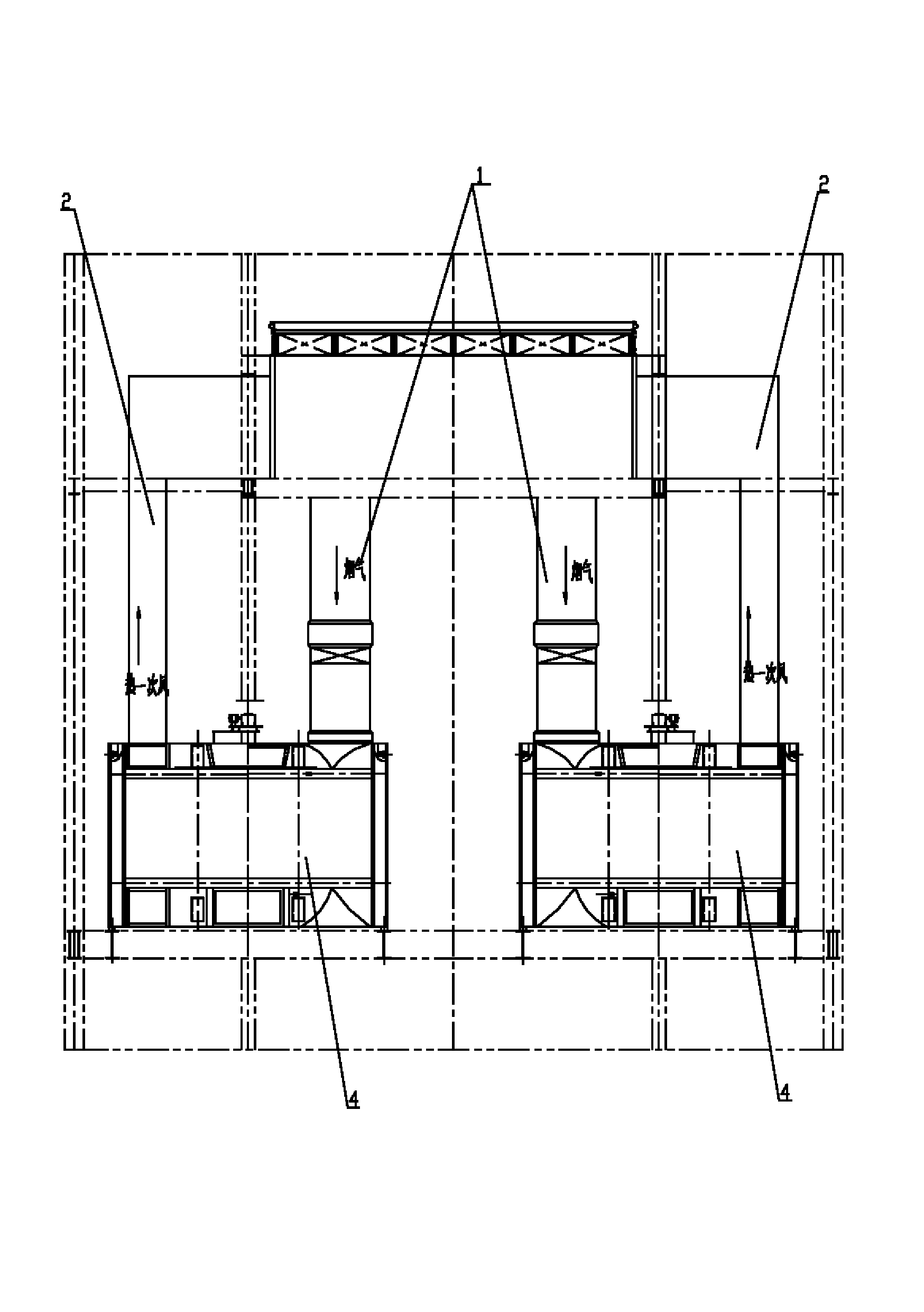

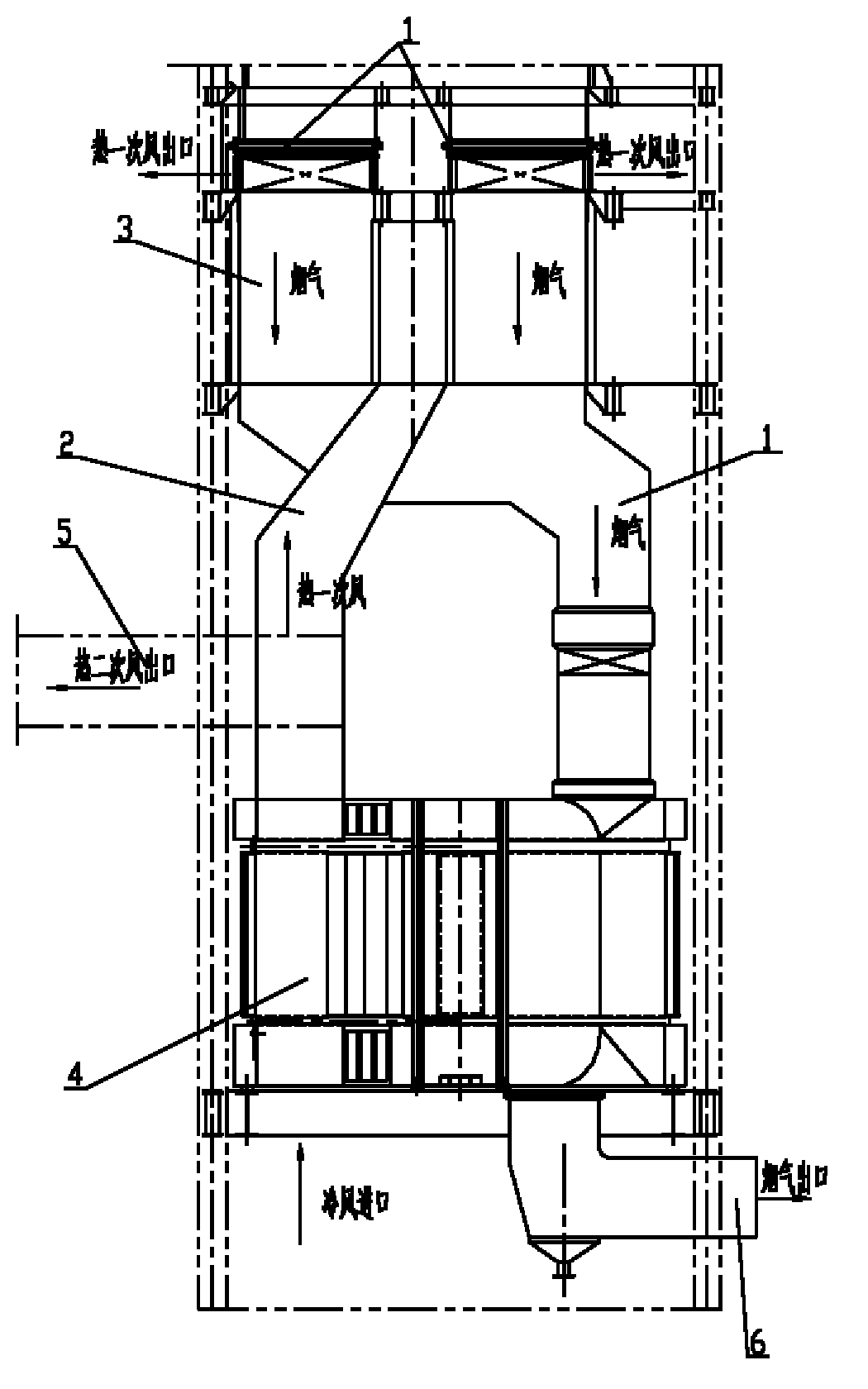

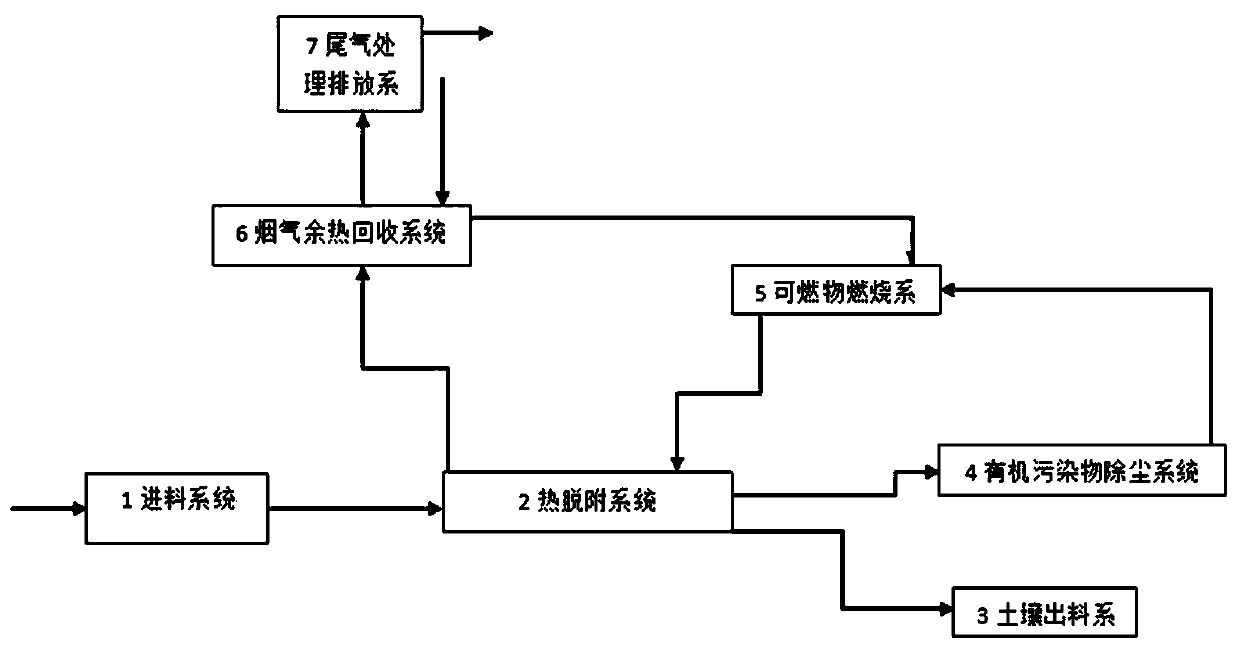

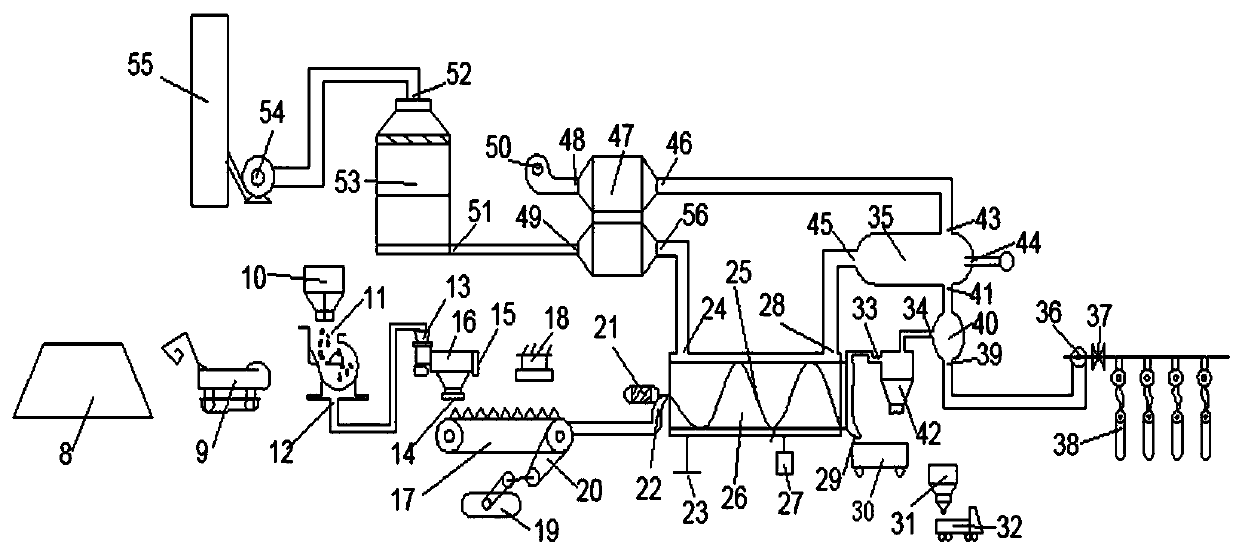

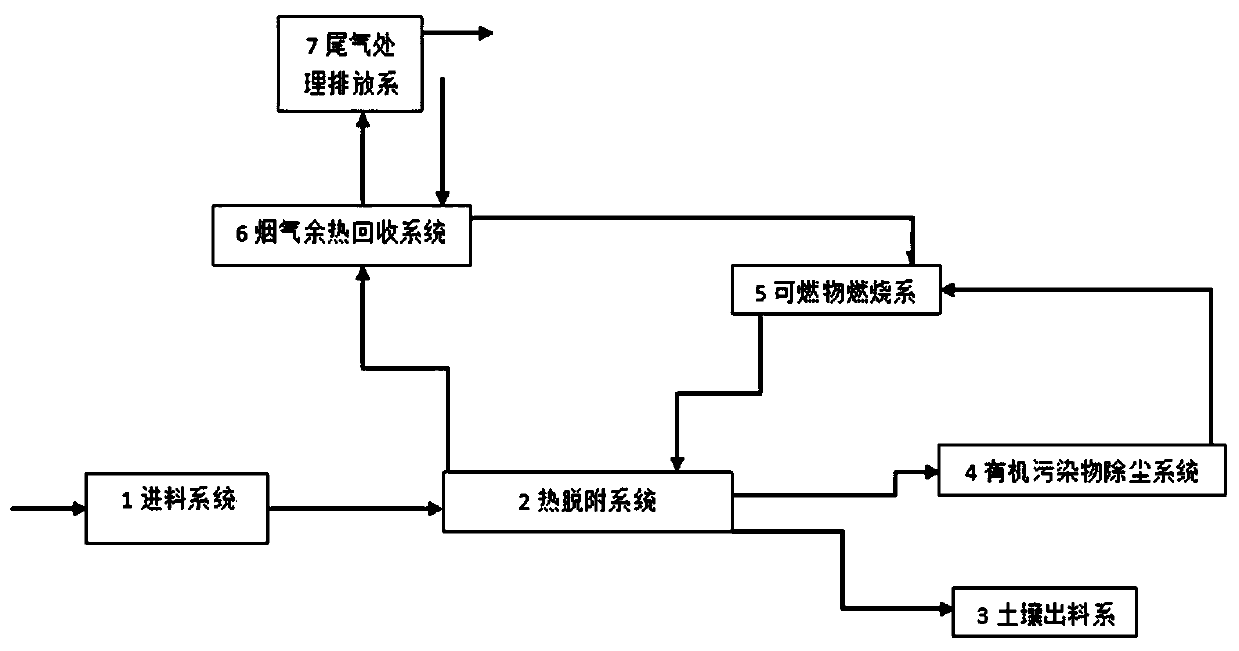

Thermal remediation system for organic matter contaminated soil through double-phase transformation heat treatment

InactiveCN111014268AAvoid generatingReduce the burden onContaminated soil reclamationIncinerator apparatusCrusherThermal desorption

The invention relates to a thermal remediation system for organic matter contaminated soil through double-phase transformation heat treatment. The system comprises a feeding system, a thermal desorption system, an organic pollutant dust removal system, a combustible combustion system, a flue gas waste heat recovery system and a tail gas treatment emission system, wherein the feeding system consists of a hammer crusher communicated with an organic contaminated soil inlet, a screening machine communicated with an outlet of the hammer crusher, a conveying belt communicated with an outlet of the screening machine, and an iron remover above an outlet of the conveying belt; a soil feeding port of the thermal desorption system is connected with an outlet of a belt conveyor, a lower end outlet ofthe tail of the thermal desorption system is communicated with a steel type conveying belt, and an upper end outlet of the tail of the thermal desorption system is communicated with the organic pollutant dust removal system. Energy consumption and tail gas treatment costs are reduced, organic pollutant heat and flue gas waste heat can be recycled, fuel is saved, energy consumption is reduced, thetreatment efficiency is high, tail gas is discharged after being treated, and environmental protection is facilitated.

Owner:TIANJIN UNIV

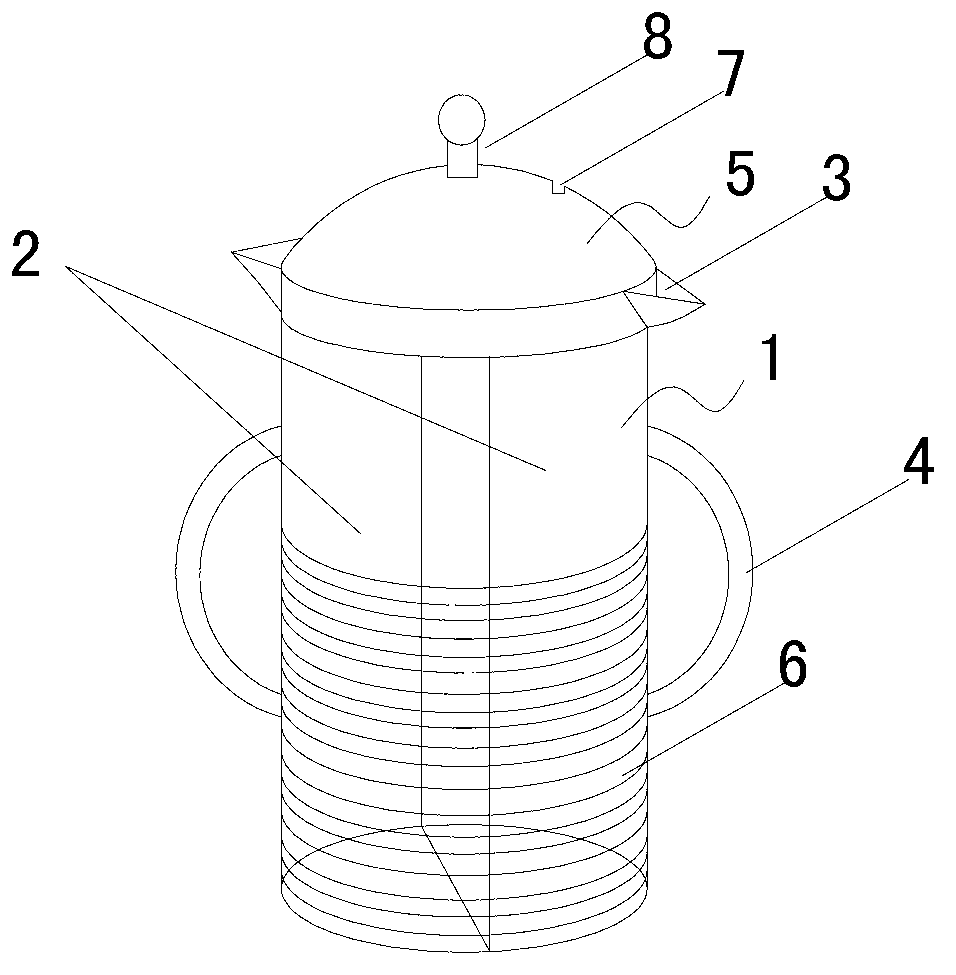

Medical inspection beaker

InactiveCN103341373AMeet the needs of simultaneous heatingNo splashingLaboratory glasswaresFiberMechanical engineering

The invention discloses a medical inspection beaker which comprises a beaker body, wherein the beaker body is internally divided into a plurality of liquid containing chambers evenly in the vertical direction; liquid outlets in one-to-one correspondence to the liquid containing chambers are evenly distributed in the edge at the top end of the beaker body along the circumferential direction; at least one handle is arranged on the outer side wall of the beaker body; a lid is arranged at an opening of the beaker body; the lid is provided with drainage holes which have the quantity same as that of the liquid outlets and correspond to the liquid outlets in position; and the beaker body is wound with a heatproof fiber layer. By designing the plurality of liquid containing chambers, simultaneous heating for various liquids can be achieved, flexibility of use is improved and the medical inspection beaker is very safe to use.

Owner:贵州森威商贸有限公司

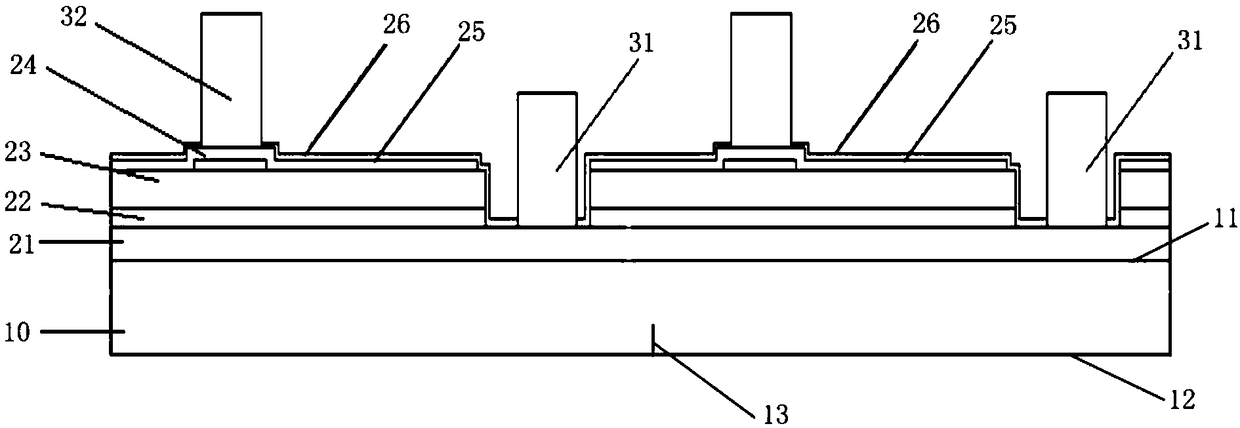

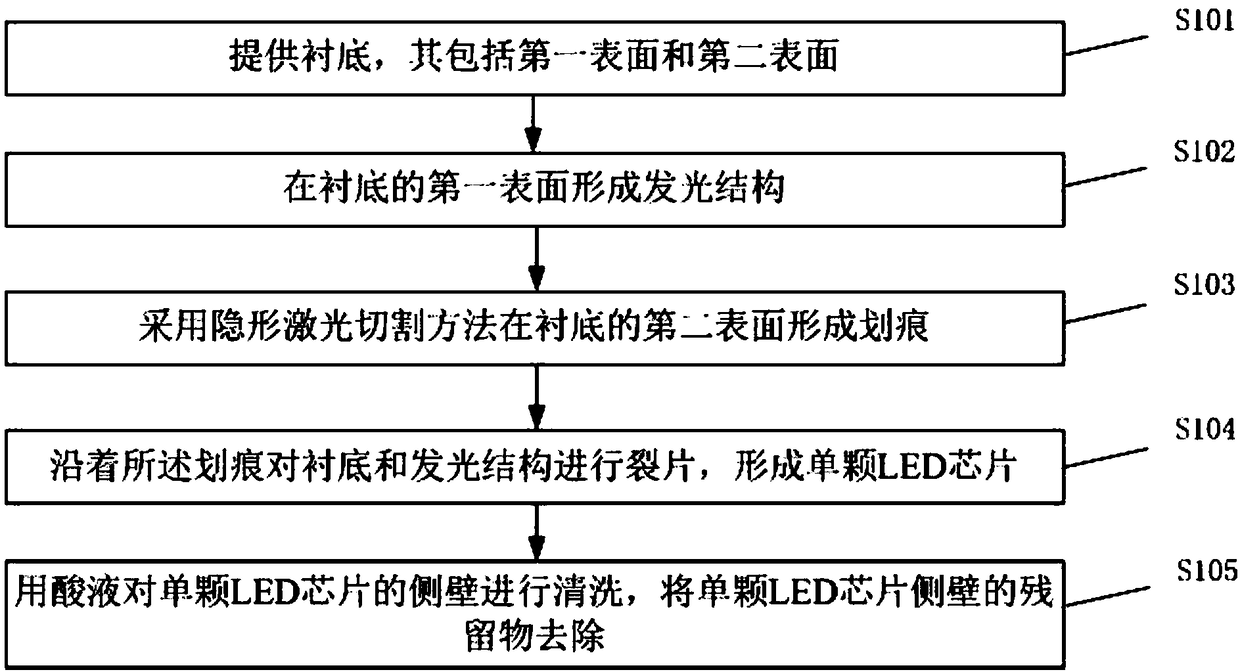

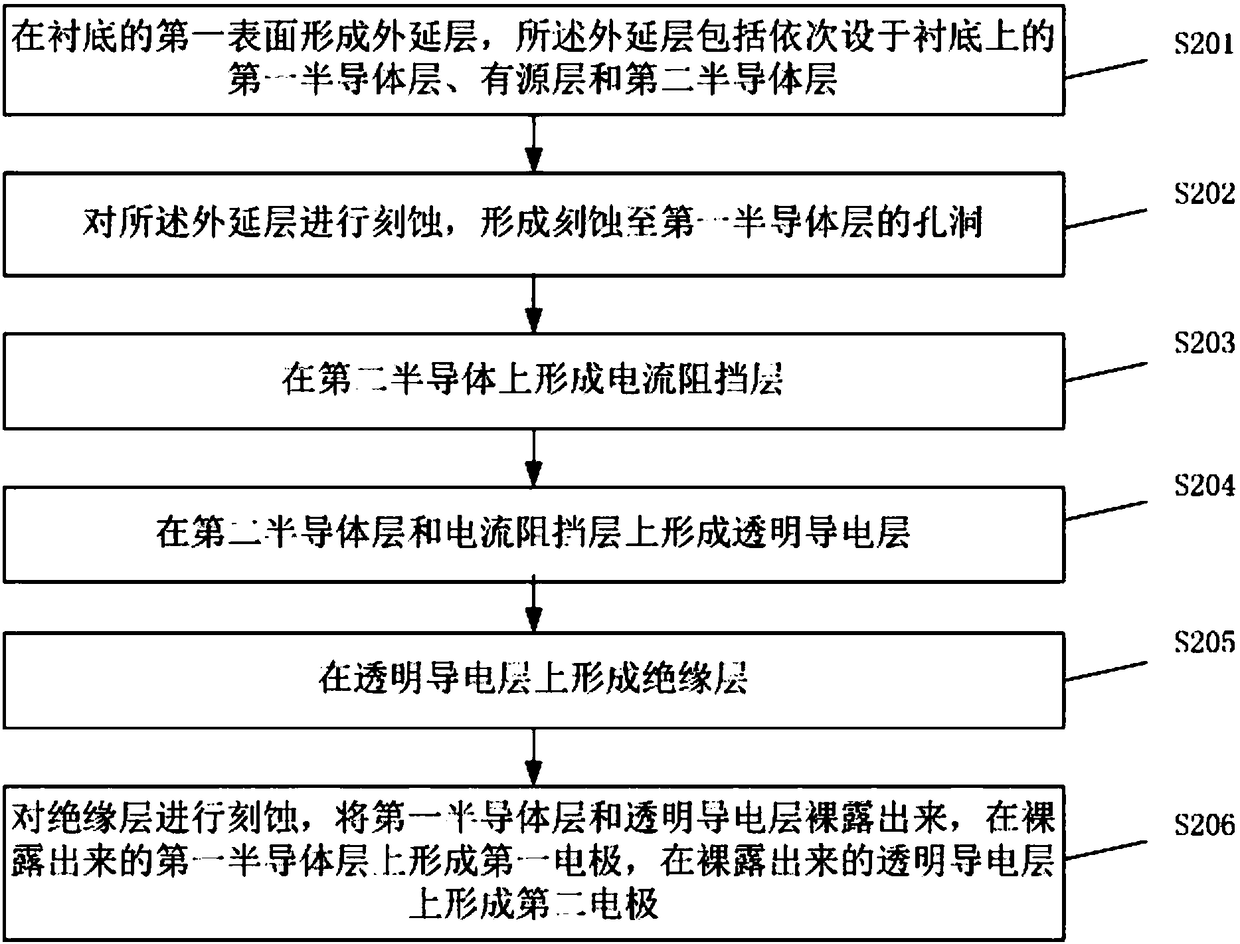

Hidden cutting LED chip and manufacturing method thereof

PendingCN108538783AImprove yieldSolve the leakSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLaser cutting

The present invention discloses a hidden cutting LED chip and a manufacturing method thereof. The manufacturing method comprises the steps of: providing a substrate consisting of a first surface and asecond surface; forming a luminescence structure at the first surface of the substrate; employing a hidden laser cutting method to form scratches at the second surface of the substrate; performing splitting of the substrate and the luminescence structure along the scratches to form a single LED chip; and performing cleaning of the side walls of the single LED chip by employing acid liquor, and removing the residue at the side walls of the single LED chip. The hidden cutting LED chip and the manufacturing method thereof effectively solve the electric leakage problem of a LED chip without cutting channels, improve the chip yield and are convenient for large-scale mass production.

Owner:FOSHAN NATIONSTAR SEMICON

Crude oil swirling low-nitrogen burner of steam-injection boiler

InactiveCN105526585AGuaranteed to burnRealize ignition and stable combustionBurnersNitrogen oxidesLow nitrogen

The invention discloses a swirling crude oil burner, utilizing burning crude oil, of a steam-injection boiler. Such a crude oil swirling low-nitrogen burner comprises, in an air flow direction, an air inlet, a control damper, a central air chamber, a secondary air chamber, a peripheral air chamber, a secondary air nozzle and a peripheral air nozzle in order. Central air orderly flows through the central air chamber, a central air duct and a flame stabilizer. Secondary air orderly flows through the secondary air chamber, a secondary air swirling plate, a secondary air duct and the secondary air nozzle. Peripheral air orderly flows through the peripheral air chamber, a peripheral air duct and the peripheral air nozzle. An oil gun, a flame detector and the flame stabilizer all are arranged in the central air duct. The burner provided by the present invention organizes air for combustion via reasonable staging to realize staged combustion of the crude oil, and therefore, the generation of nitrogen oxides may be effectively reduced and nitrogen emissions may be reduced; in addition, the burner has the advantages of simple system, easy maintenance, low maintenance cost and long service life.

Owner:南京创能电力科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com